Method for preparing bovine skin gelatin by enzyme treatment

An enzyme treatment, cowhide technology, which is applied in the preparation methods of peptides, chemical instruments and methods, animal/human proteins, etc., can solve the problems of low gelatin yield, etc., and achieve the effect of cleaning and environmental protection in the production process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

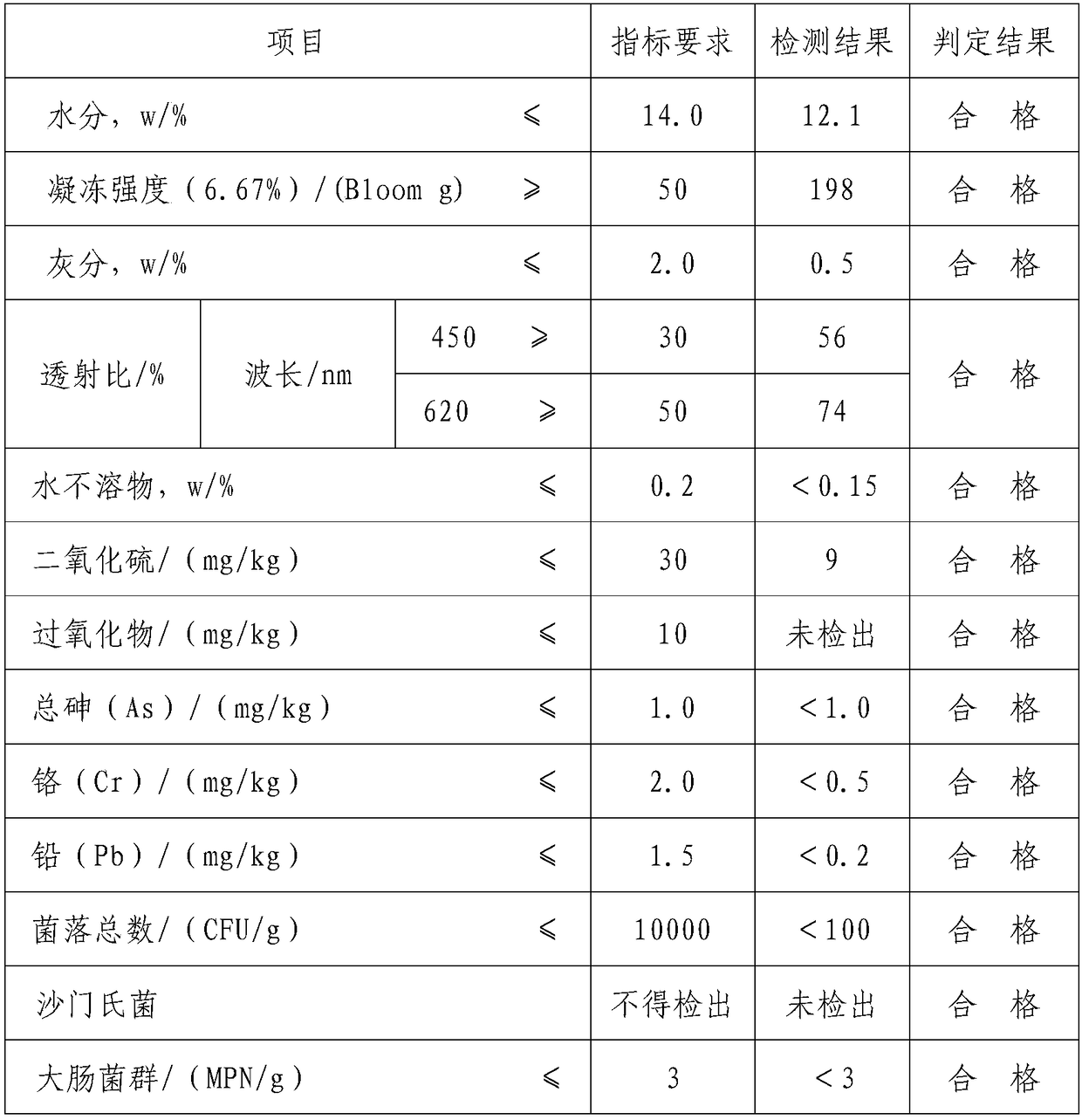

Image

Examples

Embodiment 1

[0054] The method for preparing cowhide gelatin by enzyme treatment comprises the following process steps:

[0055] A. Raw material pretreatment

[0056] Take the cowhide corner waste, cut into strips, add water to wash and remove impurities;

[0057] B. Enzyme hydrolysis reaction

[0058] Add distilled water to the cleaned leather prepared in step A, and bathe in water for 2 hours at a temperature of 50°C; add a compound enzyme composed of alkaline protease and alkaline lipase to the treated leather, wherein alkaline protease The amount of enzyme added is 500U per gram of raw hide, the amount of alkaline lipase added is 10U per gram of raw hide, and the enzymolysis reaction is carried out at pH = 8-10 and the temperature is 35 ° C for 10 hours;

[0059] C. Enzyme inactivation

[0060] After the enzymolysis reaction, discharge the enzymolysis solution, add water and stir for 5 minutes, remove the cleaning water, add distilled water again, and bathe in water for 10 minutes a...

Embodiment 2

[0068] The difference between this embodiment and embodiment 1 is:

[0069] B. Enzyme hydrolysis reaction

[0070] Add distilled water to the cleaned leather prepared in step A, and bathe in water for 10 minutes at a temperature of 80°C; add a compound enzyme consisting of alkaline protease and alkaline lipase to the treated leather, wherein alkaline protease The amount of enzyme added is 2000U per gram of raw hide, the amount of alkaline lipase added is 200U per gram of raw hide, and the enzymolysis reaction is carried out at pH = 8-10 and the temperature is 45°C for 6 hours;

[0071] C. Enzyme inactivation

[0072] After the enzymatic hydrolysis reaction, discharge the enzymatic hydrolysis solution, add water to stir and wash for 15 minutes, remove the washing water, add distilled water again, and bathe in water for 3 minutes at a temperature of 90°C;

[0073] D. Extraction

[0074] Place the material prepared in step C in a water bath at 60°C for 8 hours;

[0075] All t...

Embodiment 3

[0077] The difference between this embodiment and embodiment 1 is:

[0078] B. Enzyme hydrolysis reaction

[0079] Add distilled water to the cleaned leather prepared in step A, and bathe in water for 1 hour at a temperature of 70°C; add a compound enzyme consisting of alkaline protease and alkaline lipase to the treated leather, wherein alkaline protease The amount of enzyme added is 1500U per gram of raw hide, the amount of alkaline lipase added is 100U per gram of raw hide, and the enzymolysis reaction is carried out at pH = 8-10 and the temperature is 40°C for 8 hours;

[0080] C. Enzyme inactivation

[0081] After the enzymolysis reaction, discharge the enzymolysis solution, add water and stir to wash for 10 minutes, remove the cleaning water, add distilled water again, and bathe in water at 80°C for 7 minutes;

[0082] D. Extraction

[0083] The material prepared in step C was placed in a 70°C water bath for 6 hours;

[0084] All the other contents are the same as in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com