Method for preparing activated carbon by physical activation of excess sludge

A technology for preparing activated carbon and excess sludge, applied in chemical instruments and methods, inorganic chemistry, carbon compounds, etc., can solve problems such as the shutdown of sewage treatment plants, and achieve the effect of efficient utilization and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

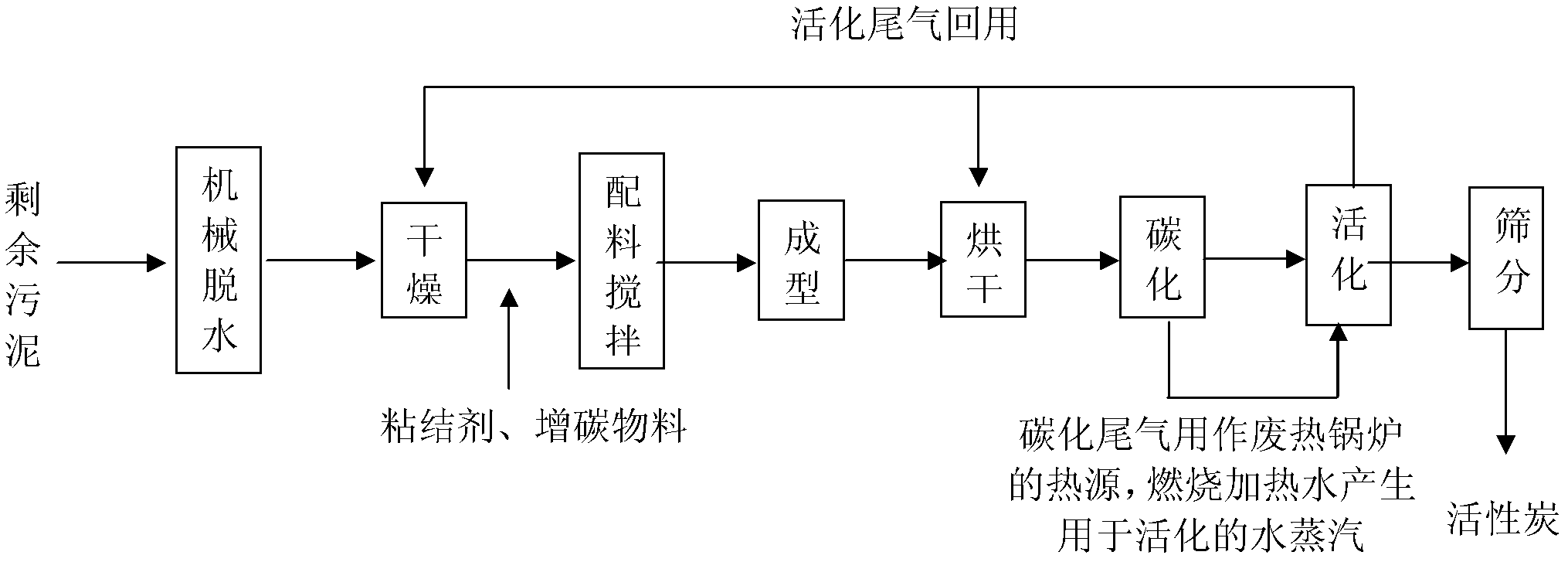

[0023] Such as figure 1 As shown, after mechanical dehydration, the residual sludge of a petrochemical company with a mass moisture content of 75% was taken, and the exhaust gas from the activation furnace was dried at 110°C until the mass moisture content was 25%, and then 5% (mass percent) of coal powder and 5% (mass percent) of coal tar, after stirring and mixing, they are extruded under a pressure of 50 MPa; the molding materials are dried at 110°C for 6 hours with exhaust gas from an activation furnace, and the dried materials are transported to carbonization The furnace is carbonized at 350°C for 2 hours, and the carbonized material is transported to the activation furnace where water vapor is fed (the tail gas in the carbonization furnace is sent to the waste heat boiler for combustion through the induced draft fan, and the heat generated is heated by water) for activation at 700°C for 3 hours, and the output of the activation furnace is screened Activated carbon is obt...

Embodiment 2

[0025] Such as figure 1 As shown, after mechanical dehydration, the residual sludge of a sewage treatment plant in a pharmaceutical and chemical plant with a mass moisture content of 85% was taken. After belt filter press, the moisture content was 85%, and the exhaust gas from the activation furnace was dried at 120°C to the mass moisture content 40%, then add coal powder and 1% (mass percentage) coal tar that account for 10% (mass percentage) of the absolute dry sludge, after stirring and mixing, under 150MPa pressure, extrusion molding; The exhaust gas from the activation furnace is dried at 120°C for 2 hours, the dried material is transported to the carbonization furnace for carbonization at 500°C for 0.5 hours, and the carbonized material is transported to the steam (the exhaust gas in the carbonization furnace is sent to the waste heat boiler for combustion through the induced draft fan, and the heat generated heats the water produced) in the activation furnace at 850°C f...

Embodiment 3

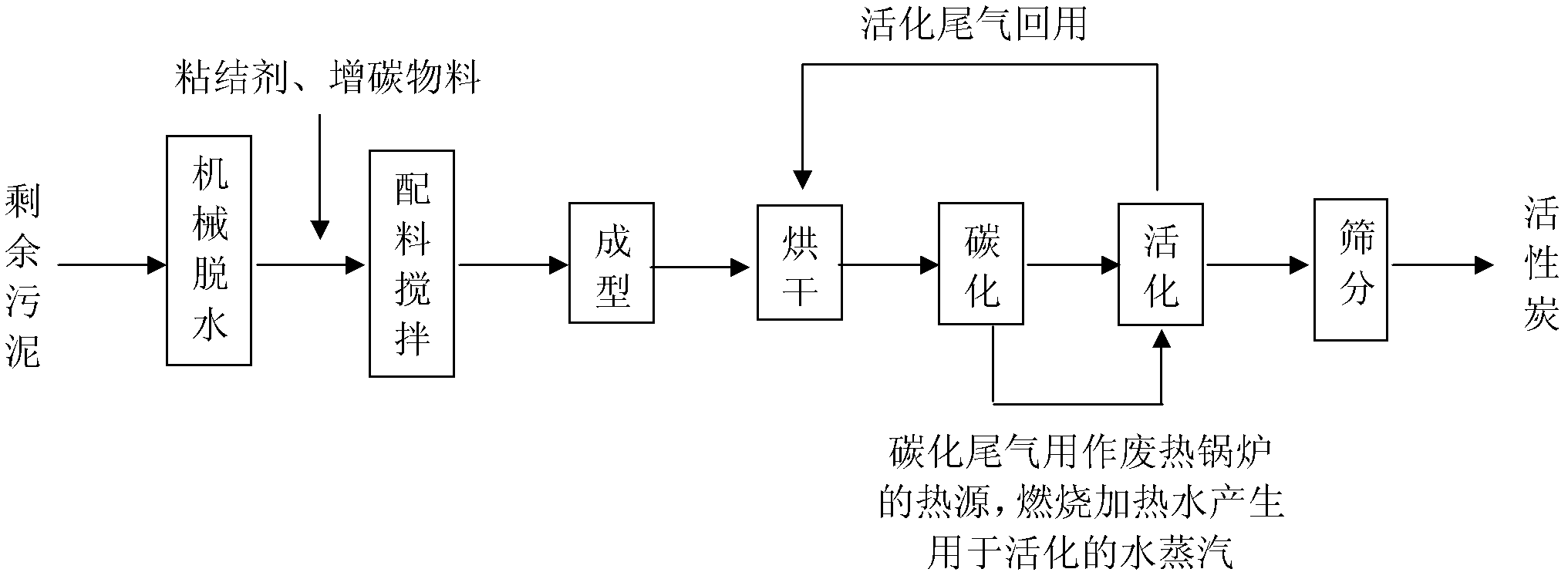

[0027] Such as figure 2 As shown, after mechanical dehydration, take the residual sludge of a domestic sewage treatment plant with a mass moisture content of 85%, add 4% (mass percentage) of sawdust and 3% (mass percentage) of coal tar, and stir, After mixing, extrude under the pressure of 100MPa; use the exhaust gas from the activation furnace to dry at 110°C for 4 hours, and transport the dried material to the carbonization furnace for carbonization at 500°C for 0.5 hours. The exhaust gas is sent to the waste heat boiler for combustion through the induced draft fan, and the heat generated is generated by heating water) The activation furnace is activated at 950°C for 1 hour, and the output of the activation furnace is screened to obtain activated carbon. After testing, its specific surface area: 336m 2 / g, iodine value: 422mg / g, strength 91%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com