Device and method for online treatment of antifouling and moisture-penetrable fabric

A fabric and moisture-permeable technology is applied in the field of devices for on-line treatment of antifouling and moisture-permeable fabrics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

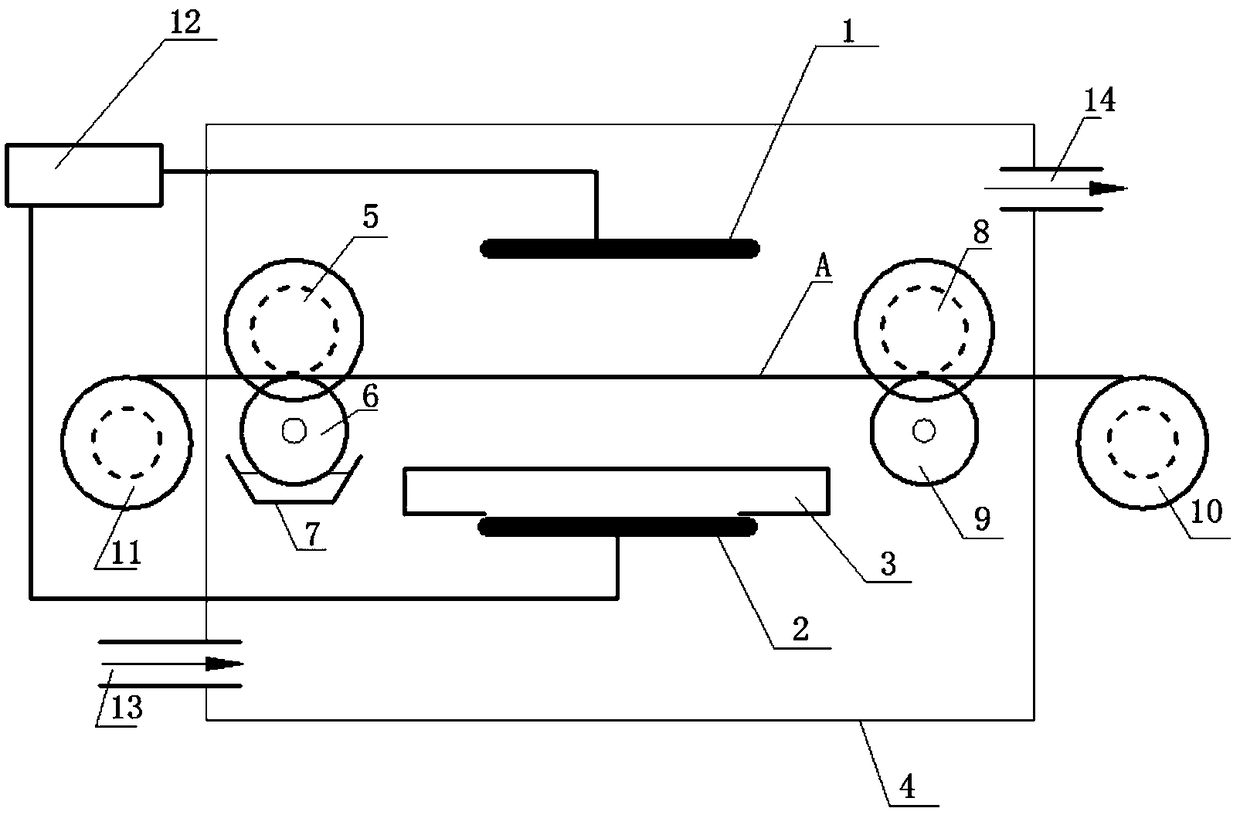

[0024] Example 1: A device for on-line processing of anti-fouling and moisture-permeable fabrics

[0025] The device for on-line treatment of anti-fouling and moisture-permeable fabrics, including upper electrode 1, lower electrode 2, medium 3, treatment chamber 4, film-coated roller 5, coating roller 6, liquid storage tank 7, film-coated winding roller 8, Support roller 9, winding roller 10, unwinding roller 11, power supply 12, air intake hole 13, exhaust hole 14; upper electrode 1 and lower electrode 2 are relatively arranged in the described processing chamber 4, and are connected with the power supply 12 through a circuit Connected; the lower electrode 2 is provided with a dielectric 3, and the coating roller 5, the coating roller 6, the coating winding roller 8, and the support roller 9 are respectively arranged on both sides of the upper electrode 1 and the lower electrode 2; The liquid storage tank 7; the left and right sides of the processing chamber 4 are respectivel...

Embodiment 2

[0029] Example 2: A method for on-line treatment of anti-fouling and moisture-permeable fabrics

[0030] A method for on-line treatment of anti-fouling and moisture-permeable fabrics, mainly comprising the following steps:

[0031] (1) The film roll is installed on the coating roller 5, and the coating solution is added to the liquid storage tank 7;

[0032] (2) Fabric A is set to be wound to winding roll 10 by unwinding roll 11 through coating roll 5 and coating roll 6, and coating winding roll 8 and support roll 9;

[0033] (3) Set the unwinding and winding speed to 5cm / min, and the pressure between the coating roll and the coating roll and the coating winding roll and the support roll is 100N;

[0034] (4) Pass an inert gas into the treatment chamber, turn on the power supply, turn the gas into plasma, and perform coating grafting treatment on the fabric.

[0035] Among them, the discharge frequency of the plasma is set: 10kHz-100kHz; the voltage: 1-10kV; the distance bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com