Polyamide 56 fiber as well as preparation method and application thereof

A polyamide and fiber technology, applied in the direction of single-component polyamide rayon, textiles and papermaking, chemical post-treatment of synthetic polymer rayon, etc., can solve the stuffy feeling, blocking the channels between fabrics, and the decline in luck, etc. problems, achieve strong moisture absorption and perspiration, and improve comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

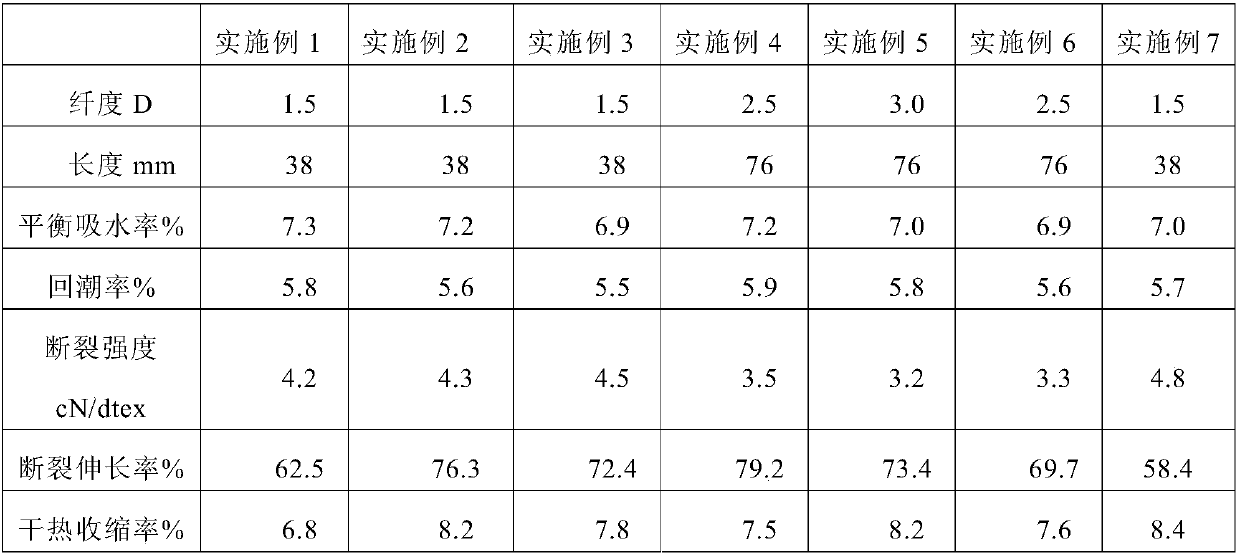

Examples

Embodiment 1

[0084] The preparation method of the polyamide 56 fiber of the present embodiment is as follows:

[0085] 1) After the polyamide 56 melt is sprayed out through the spinneret holes of the spinneret in the spinning box, cooling treatment, oiling treatment and winding treatment are carried out in sequence to obtain the raw silk; the raw silk enters into the feed through the drawing roller machine, put it into the silk barrel;

[0086] Wherein, the temperature of the spinning box is 270°C, the winding speed of the winding treatment is 1000m / min, and when the oiling treatment is carried out with the oiling solution, the mass fraction of the oiling agent is 0.5%;

[0087] The number of holes in the spinneret hole is 800f, the aperture of the spinneret hole is 0.25mm, and the draw ratio of the spinneret of the spinneret plate is 80;

[0088] The cooling treatment is cooling by the surrounding air, and the temperature of the surrounding air is 26°C until the filaments after the windi...

Embodiment 2

[0095] The preparation method of the polyamide 56 fiber of the present embodiment is as follows:

[0096] 1) After the polyamide 56 melt is sprayed out through the spinneret holes of the spinneret in the spinning box, cooling treatment, oiling treatment and winding treatment are carried out in sequence to obtain the raw silk; the raw silk enters into the feed through the drawing roller machine, put it into the silk barrel;

[0097] Wherein, the temperature of the spinning box is 280°C, the winding speed of the winding treatment is 1200m / min, and when the oiling treatment is carried out with the oiling solution, the mass fraction of the oiling agent is 0.3%;

[0098] The number of holes in the spinneret hole is 1000f, the aperture of the spinneret hole is 0.23mm, and the draw ratio of the spinneret of the spinneret plate is 90;

[0099] The cooling treatment is cooling by surrounding air, and the temperature of the surrounding air is 23°C until the filaments after the winding ...

Embodiment 3

[0106] The preparation method of the polyamide 56 fiber of the present embodiment is as follows:

[0107] 1) After the polyamide 56 melt is sprayed out through the spinneret holes of the spinneret in the spinning box, cooling treatment, oiling treatment and winding treatment are carried out in sequence to obtain the raw silk; the raw silk enters into the feed through the drawing roller machine, put it into the silk barrel;

[0108] Wherein, the temperature of the spinning box is 290°C, the winding speed of the winding treatment is 1000m / min, and when the oiling treatment is carried out with the oiling solution, the mass fraction of the oiling agent is 0.5%;

[0109] The number of holes of the spinneret hole is 600f, the aperture of the spinneret hole is 0.3mm, and the draw ratio of the spinneret of the spinneret plate is 70;

[0110] The cooling treatment is cooling by surrounding air, and the temperature of the surrounding air is 28°C until the filaments after the winding pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com