Cyclopropene preservative, and preparation and packaging methods thereof

A technology of propylene and antistaling agents, which is applied in the field of cyclopropene antistaling agents and its preparation, and can solve problems such as content decline and instability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

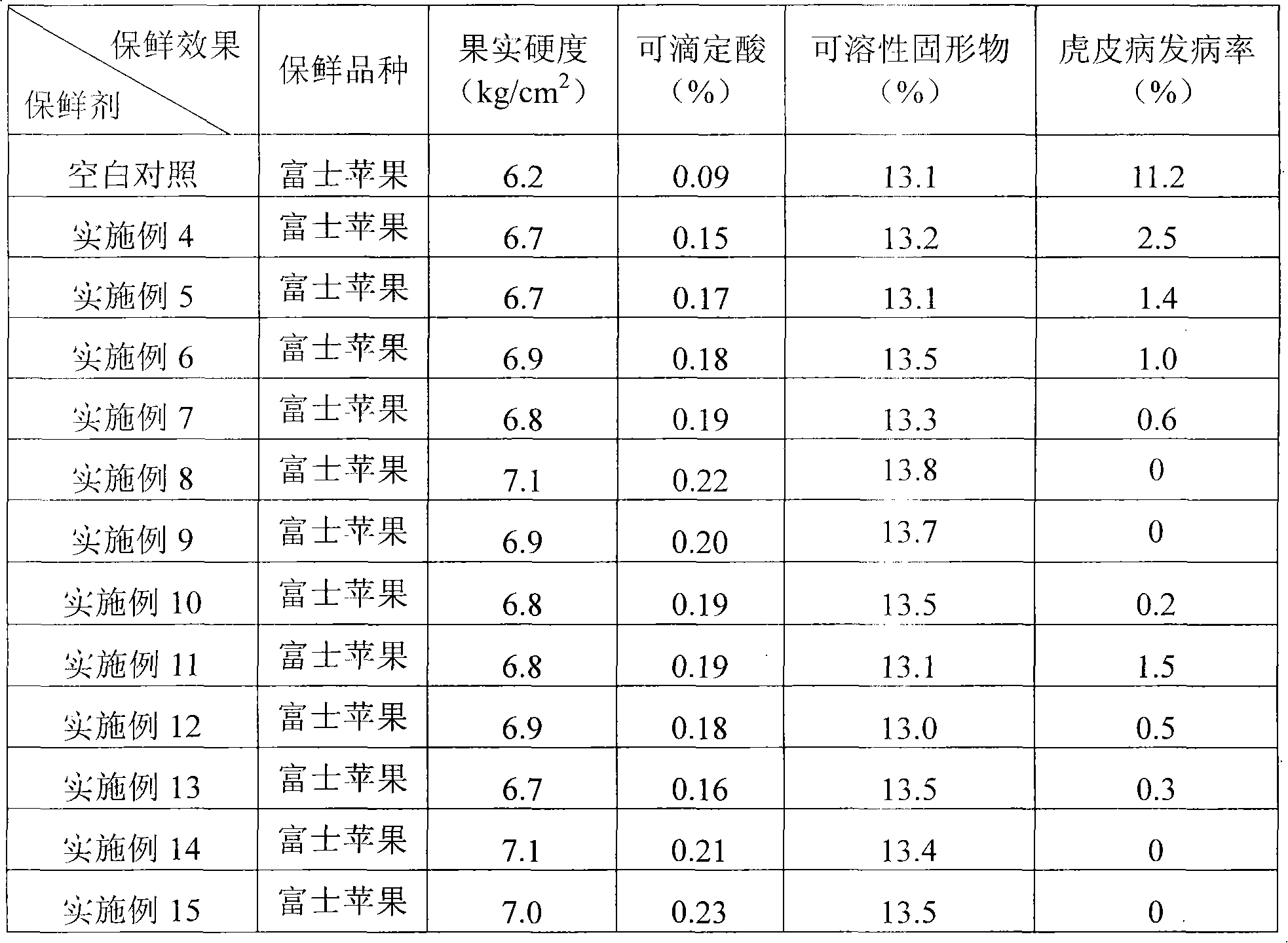

Examples

Embodiment 1

[0068] Embodiment 1: Preparation of cyclopropene inclusion complex powder

[0069] The 1-MCP gas after the synthesis and purification is passed into 10 kilograms of absorption liquids that are composed of 14.5% α-cyclodextrin, 5% white carbon black and 80.5% water, and carry out inclusion absorption at normal temperature, and the stirring speed is 300 revolutions per minute, continue to feed 1-MCP gas for 3 hours, then quickly filter the absorption liquid mixture, add absolute ethanol to wash after the suction filtration, and then suction filter, and finally dry at room temperature to obtain 1.9 kg containing 3.0 % 1-methylcyclopropene inclusion complex powder.

Embodiment 2

[0070] Embodiment 2: Preparation of cyclopropene inclusion complex powder

[0071] The synthesized and purified 1-MCP gas is passed into 10 kg of absorption liquid composed of 1% alkylated α-cyclodextrin, 49% white carbon black, and 50% water, and inclusion absorption is carried out at room temperature. The stirring speed is 300 rpm, and 1-MCP gas is continuously fed for 5 hours, and then the absorption liquid mixture is subjected to rapid suction filtration, and after the suction filtration is completed, absolute ethanol is added for washing, and then suction filtration is performed, and dried in the air at room temperature to obtain 4.95 kg Contains 0.07% 1-methylcyclopropene inclusion complex powder.

Embodiment 3

[0072] Embodiment 3: Preparation of cyclopropene inclusion complex powder

[0073] The 1-MCP gas after the synthesis and purification is passed into 10 kg of absorption liquid composed of 49% esterified α-cyclodextrin, 0.1% white carbon black and 50.9% water, and carries out inclusion absorption at normal temperature, stirring The speed is 300 rpm, and the 1-MCP gas is continuously introduced for 2 hours, and then the absorption liquid mixture is subjected to rapid suction filtration. 3.2% 1-methylcyclopropene inclusion complex powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com