Patents

Literature

30results about How to "Improve delivery" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

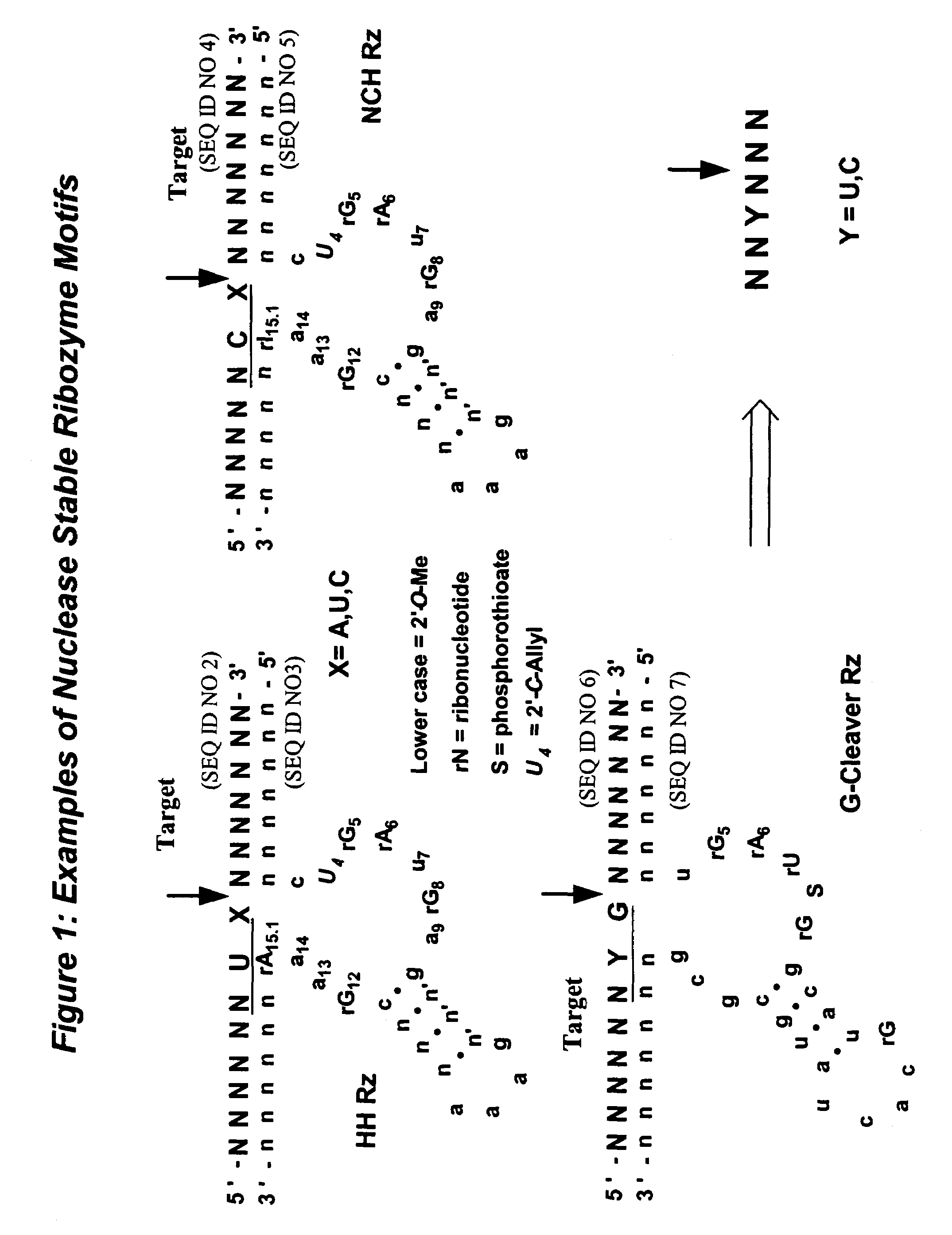

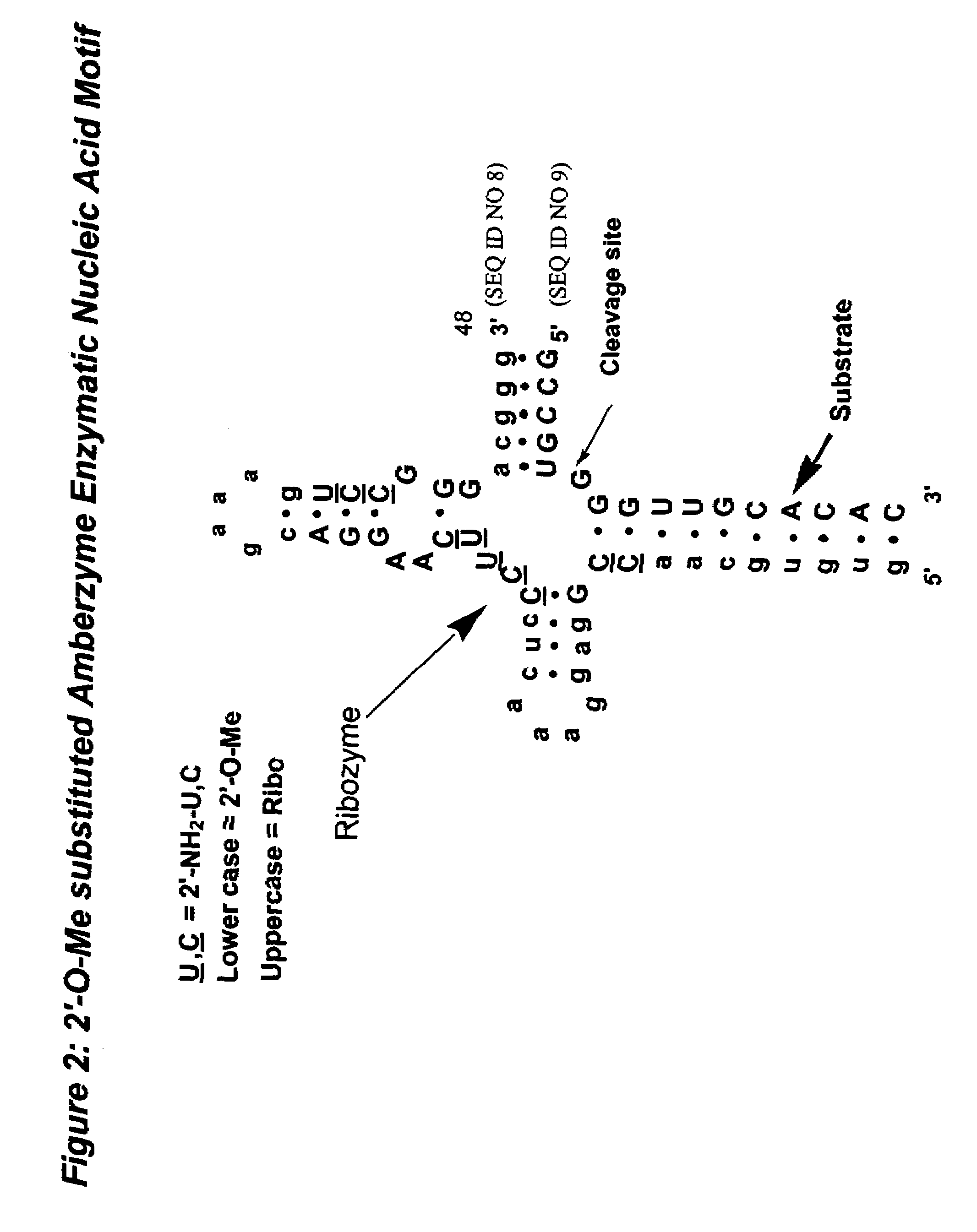

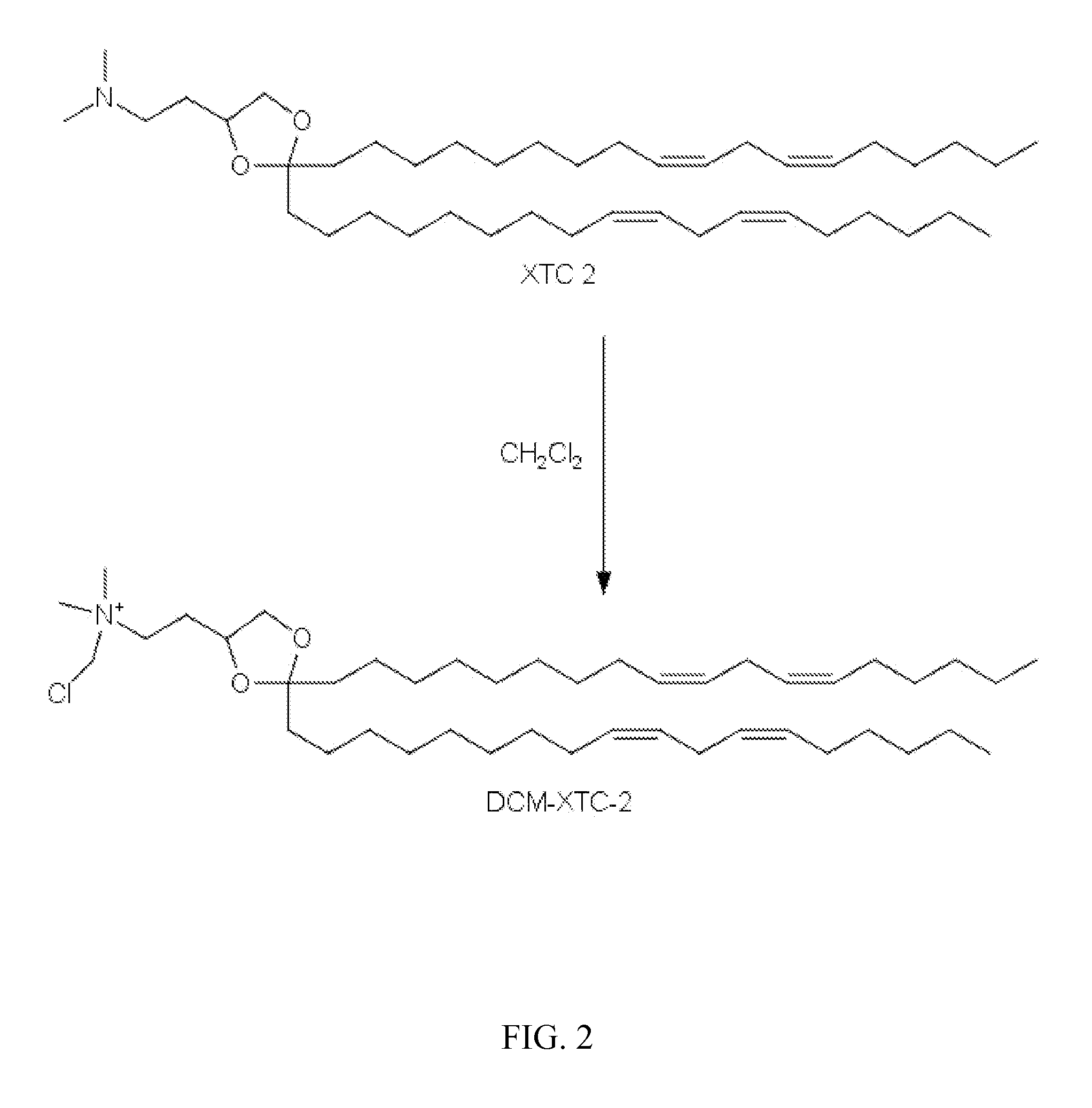

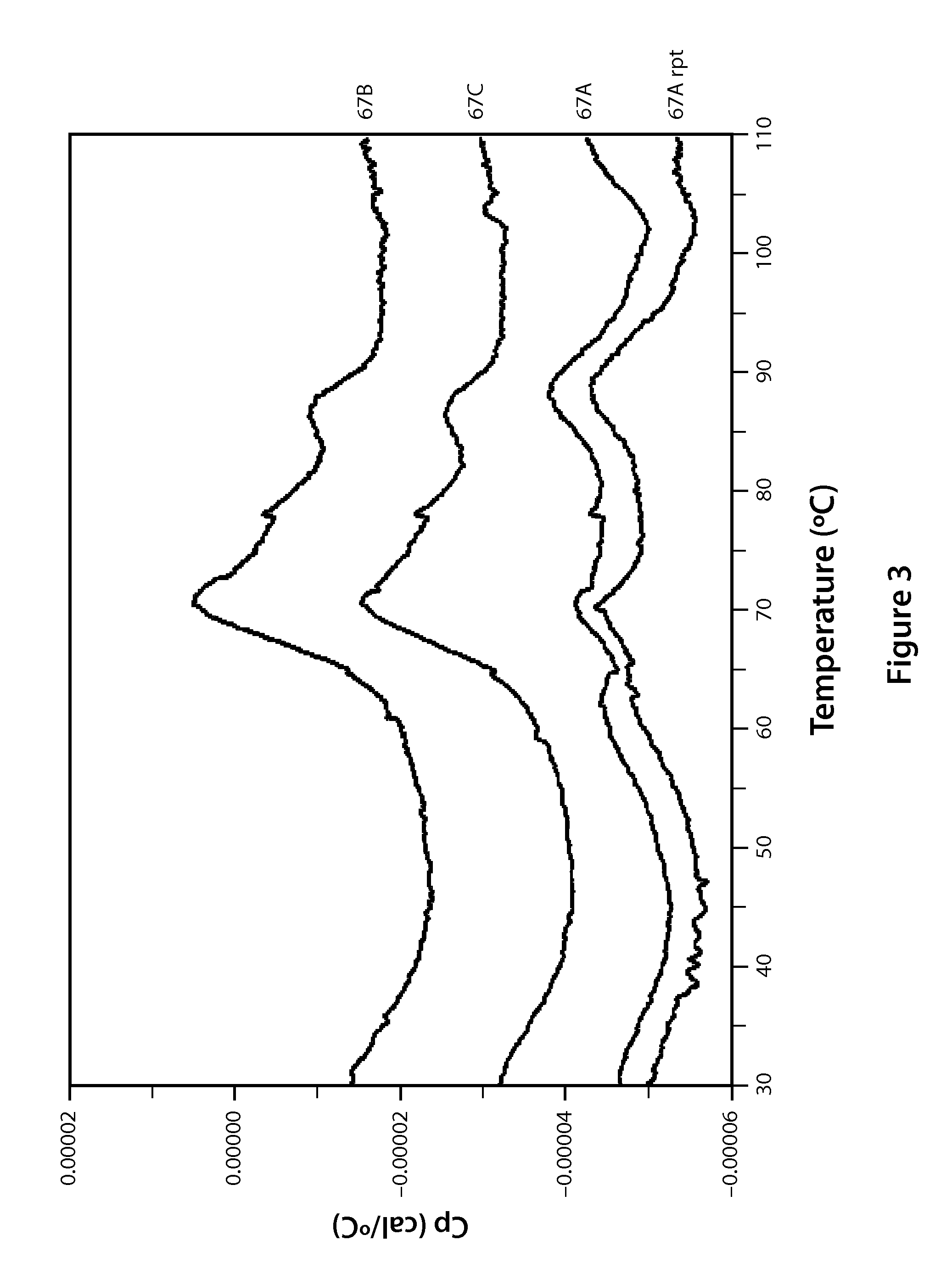

Polycationic compositions for cellular delivery of polynucleotides

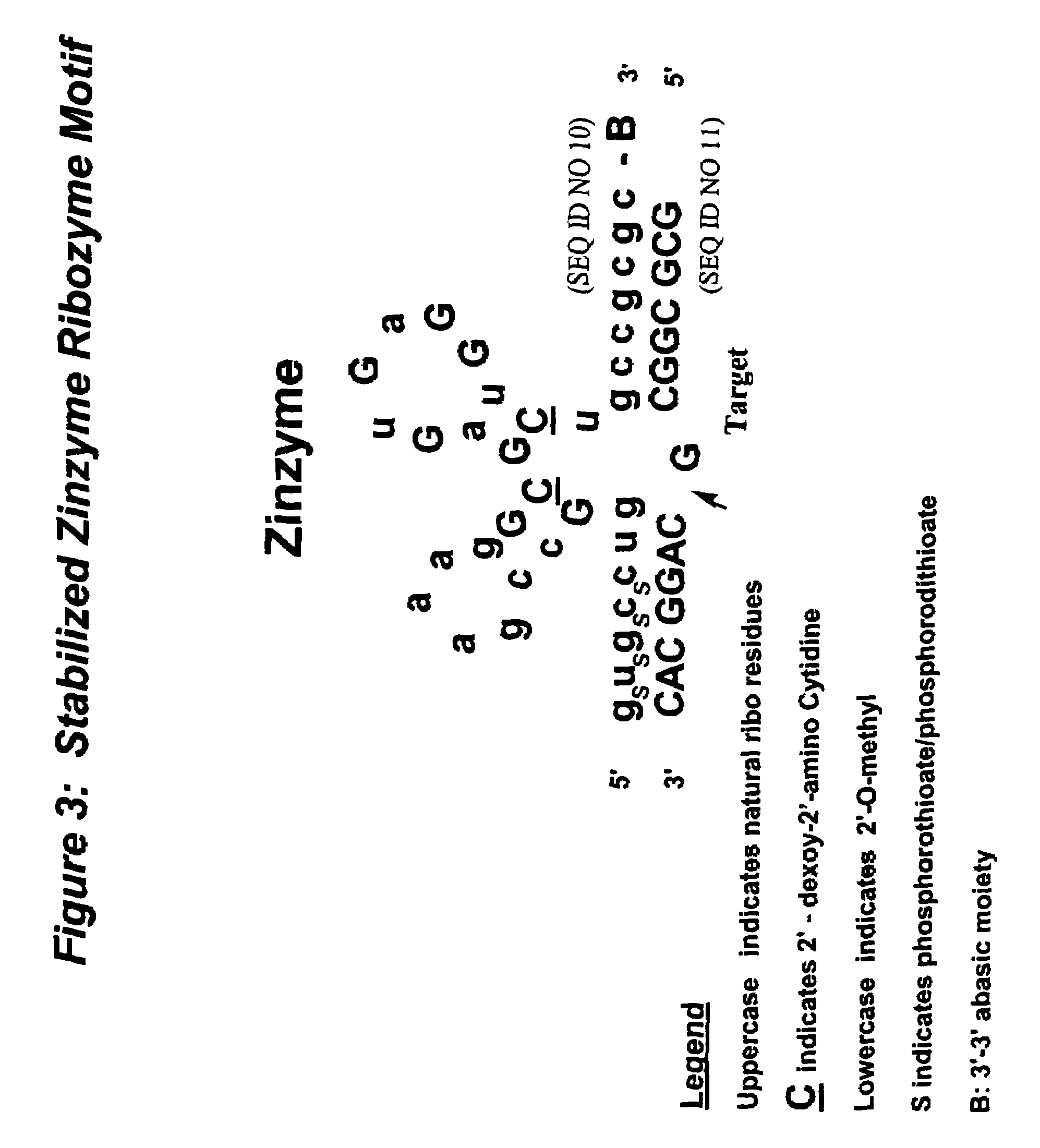

InactiveUS20050222064A1Facilitate deliveryImprove deliveryCompounds screening/testingBiocideAntibodyRibozyme

The present invention relates to delivery of biologically active molecules to cells. Specifically, the invention relates to polycationic compositions, polymers and methods for delivering nucleic acids, polynucleotides, and oligonucleotides such RNA, DNA and analogs thereof, including short interfering RNA (siRNA), ribozymes, and antisense, or peptides, polypeptides, proteins, antibodies, hormones and small molecules, to cells by facilitating transport across cellular membranes epithelial tissues and endothelial tissues. The compositions and methods of the invention are useful in therapeutic, research, and diagnostic applications that rely upon the efficient transfer of biologically active molecules into cells, tissues, and organs.

Owner:SIRNA THERAPEUTICS INC

Conjugates and compositions for cellular delivery

This invention features conjugates, degradable linkers, compositions, methods of synthesis, and applications thereof, including galactosamine and N-acetyl galactosamine derived conjugates of biologically active compounds, including antibodies, antivirals, chemotherapeutics, peptides, proteins, hormones, nucleosides, nucleotides, non-nucleosides, and nucleic acids including enzymatic nucleic acids, DNAzymes, allozymes, antisense, dsRNA, siNA, siRNA, triplex oligonucleotides, 2,5-A chimeras, decoys and aptamers.

Owner:SIRNA THERAPEUTICS INC

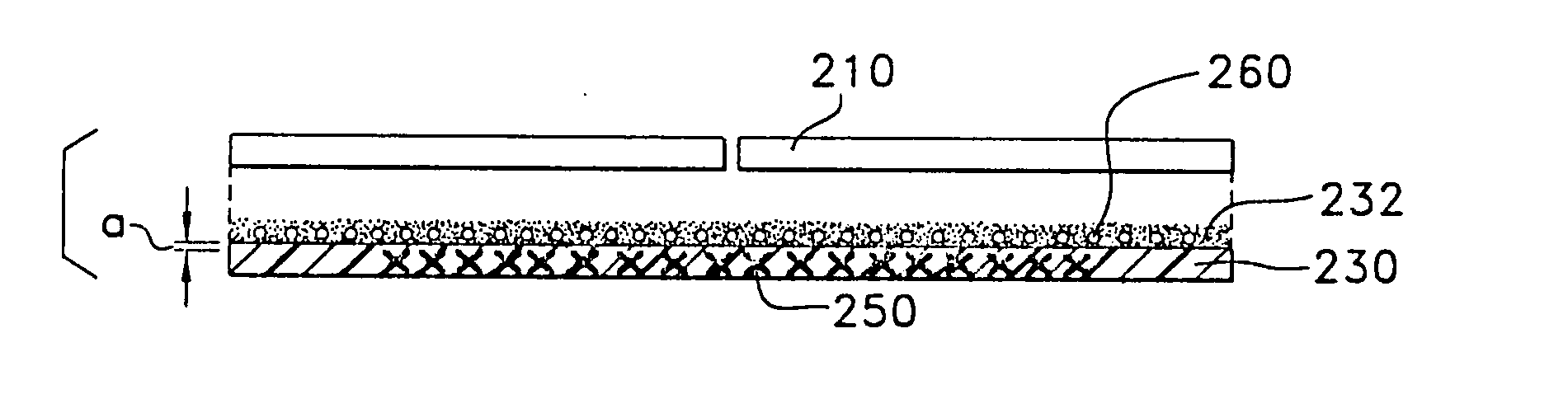

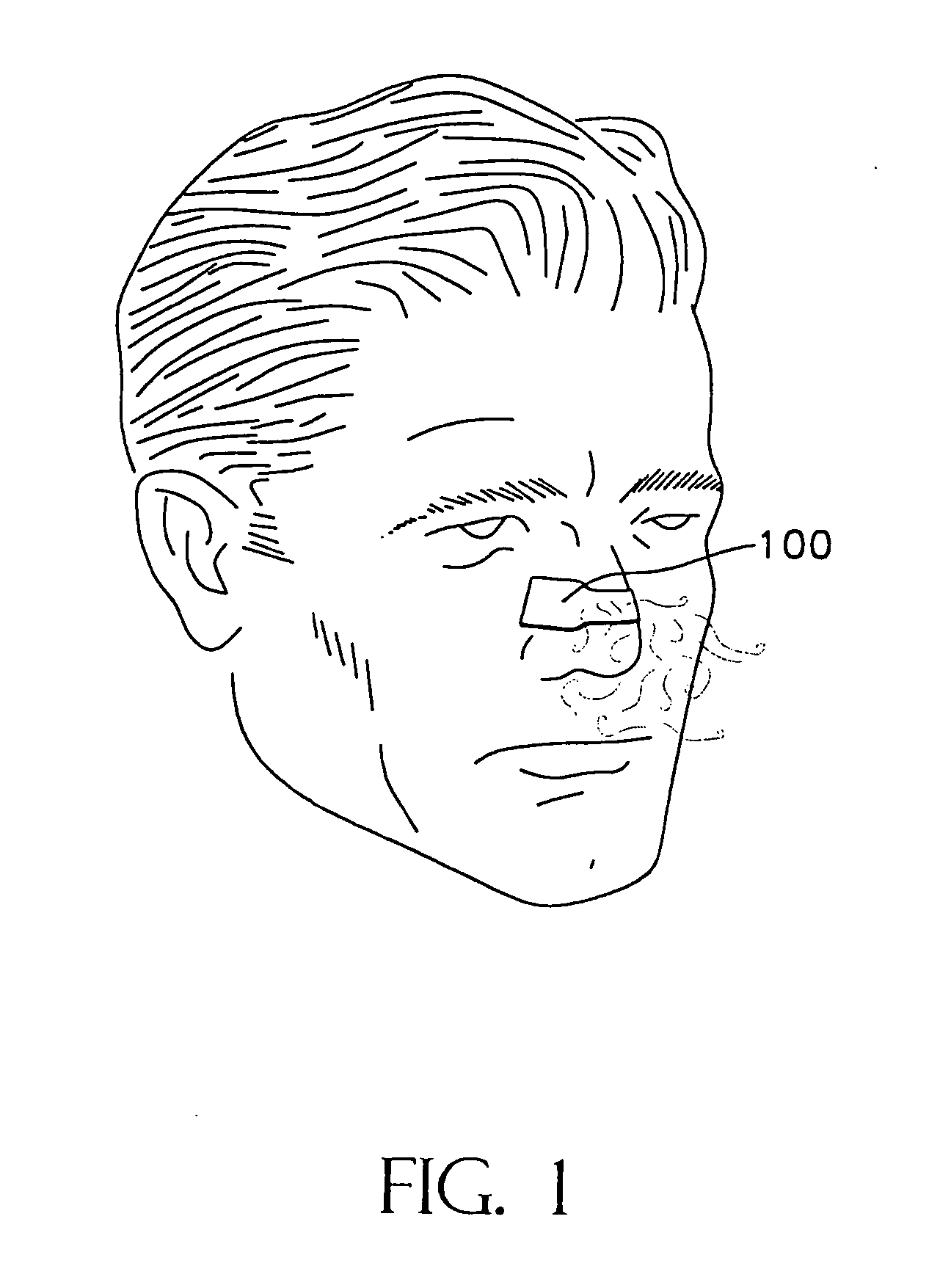

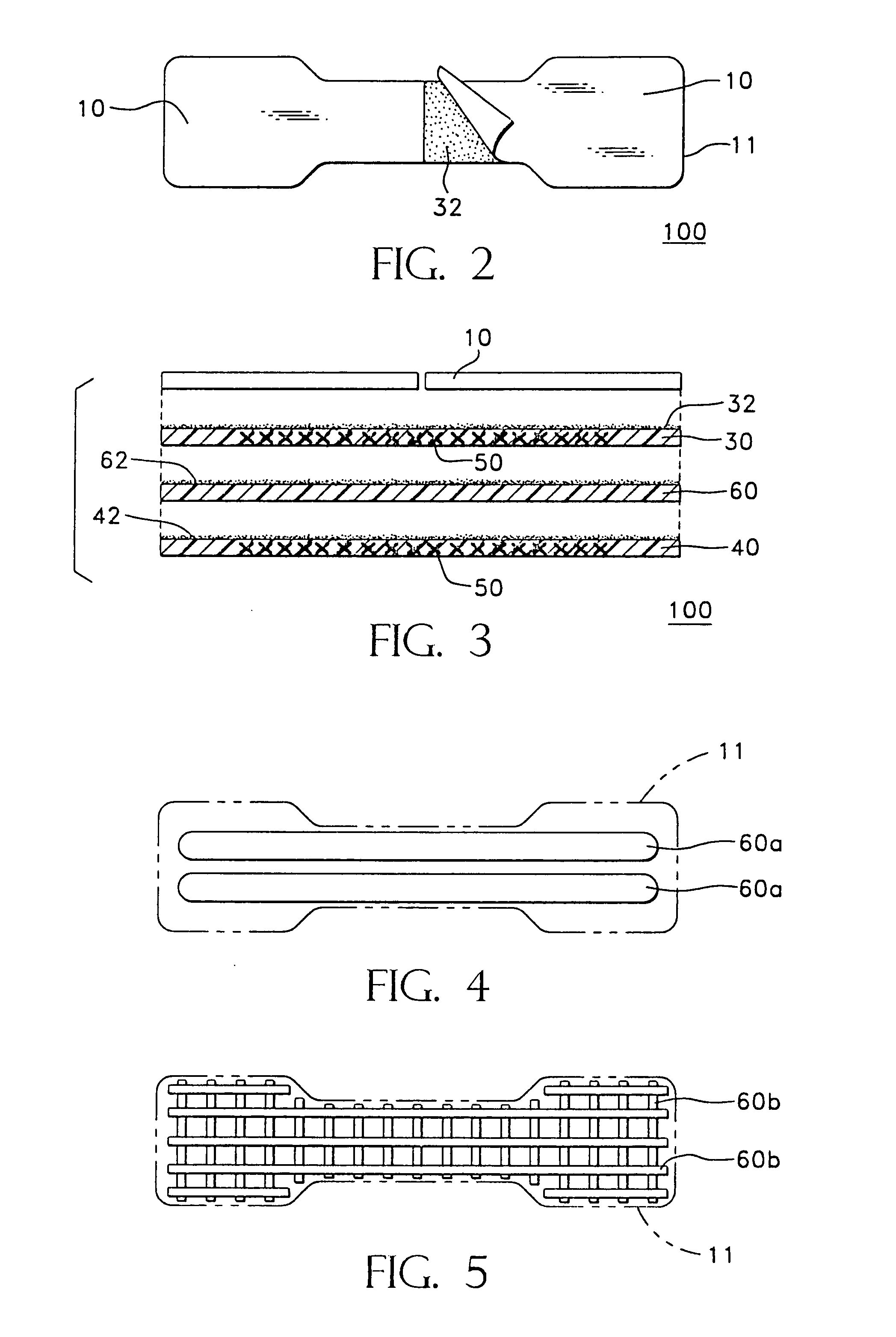

Adhesively applied external nasal strips and dilators containing medications and fragrances

InactiveUS20050066965A1Improve deliveryExtending olfactory effectivenessRespiratorsBreathing filtersPressure sensitiveDrug

Nasal dilators and strips, methods of their manufacture, and methods for improving the breathing of individuals are provided. The strips and dilators include an elongated substrate, with or without a dilating component or portion, having top and bottom surfaces and a pressure-sensitive adhesive disposed on the bottom surface. The dilator is designed to provide a gentle expanding force to the nasal wall tissue when the dilator is adhesively attached to the nose. This invention further includes a cosmetic fragrance, an aromatic medication and / or transdermal medication disposed on the strips or dilators. In order to improve the shelf-life and in-use olfactory effectiveness of such products, fragrance delivery mechanisms are used. Separation of volatile oils and adhesives are also provided to minimize adhesive residue.

Owner:WINTER BREATH

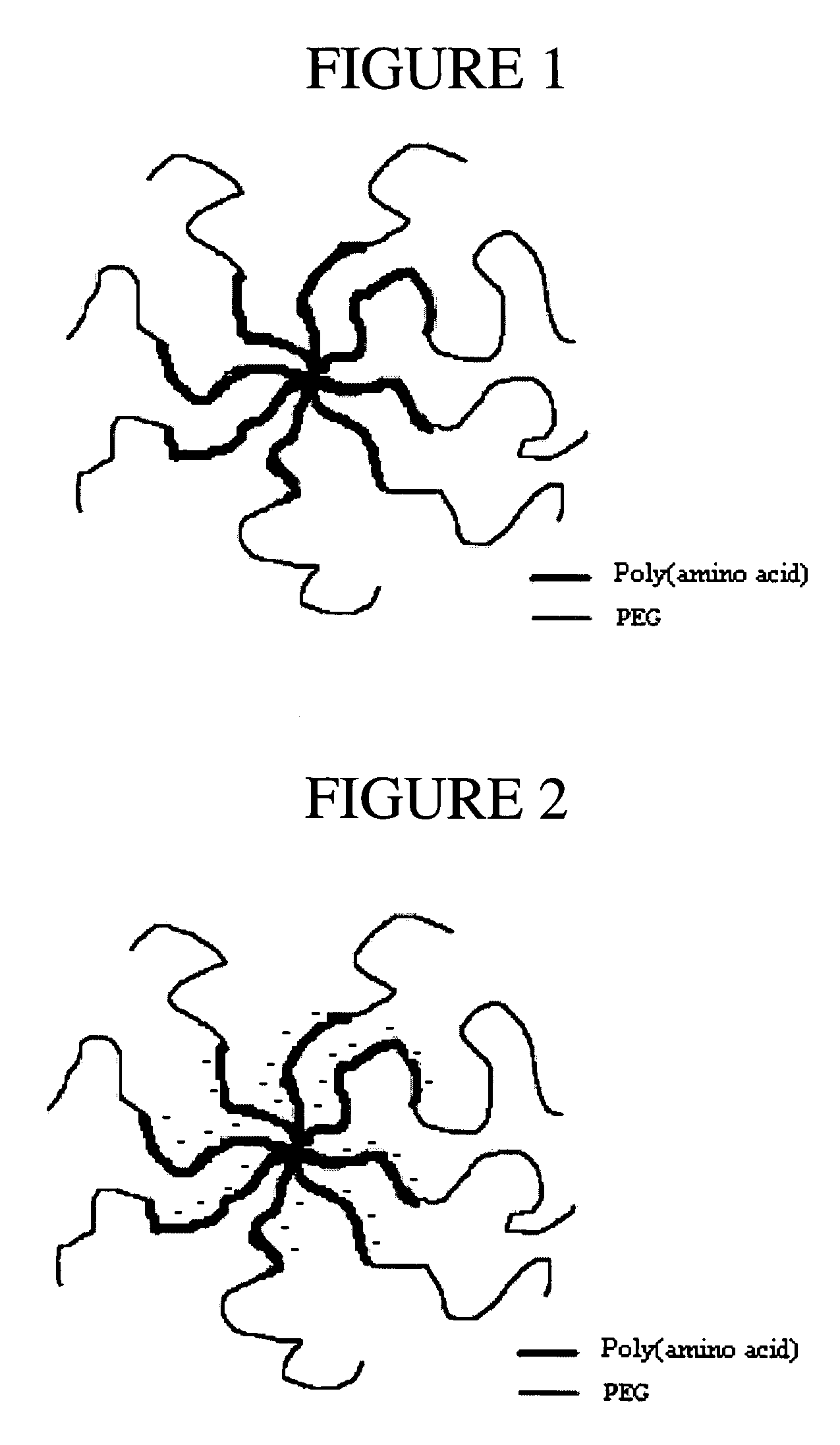

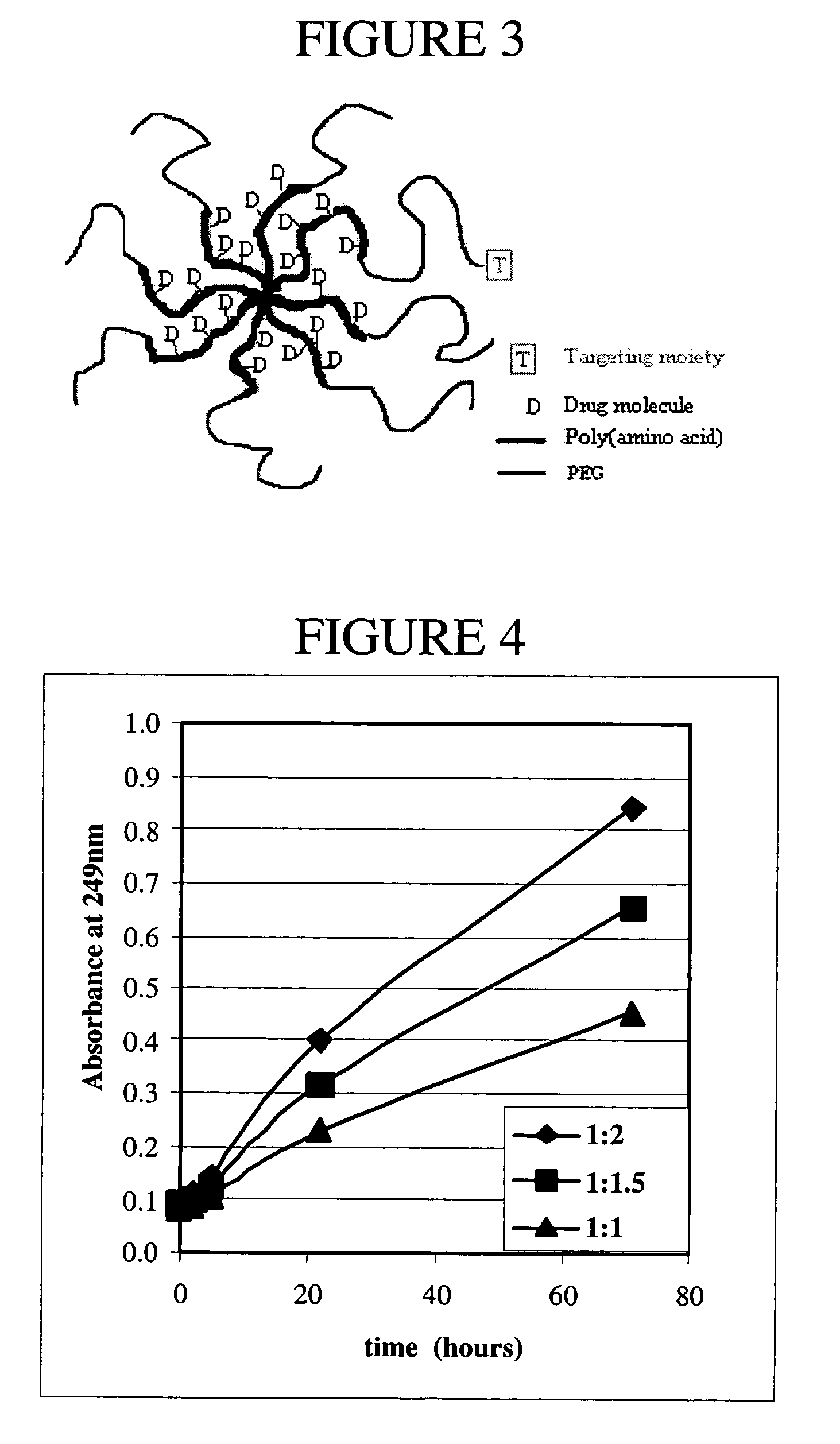

Multi-arm polypeptide-poly (ethylene glycol) block copolymers as drug delivery vehicles

ActiveUS7316811B2Improve deliveryReduce deliveryPharmaceutical non-active ingredientsSynthetic polymeric active ingredientsDrugDrug delivery

The invention provides a multi-arm block copolymer for use in delivering a variety of bioactive agents. The copolymer of the invention contains a central core from which extend multiple (3 or more) copolymer arms. Each copolymer arm possesses an inner polypeptide segment and an outer hydrophilic polymer segment. Thus, the overall structure of the copolymer comprises an inner core region that includes the central core and the inner polypeptide segment, while the outer core region is hydrophilic in nature. The multi-arm copolymer of the invention is particularly useful for delivery of biologically active agents that can be entrapped within the inner core region.

Owner:NEKTAR THERAPEUTICS INC

Targeted conjugates and particles and formulations thereof

InactiveUS20170151339A1Improve deliveryReduce deliveryPowder deliveryOrganic active ingredientsActive agentPharmaceutical formulation

Particles, including nanoparticles and microparticles, and pharmaceutical formulations thereof, comprising conjugates of an active agent such as a therapeutic, prophylactic, or diagnostic agent attached to a targeting moiety via a linker have been designed which can provide improved temporospatial delivery of the active agent and / or improved biodistribution. Methods of making the conjugates, the particles, and the formulations thereof are provided. Methods of administering the formulations to a subject in need thereof are provided, for example, to treat or prevent cancer or infectious diseases.

Owner:TVA (ABC) LLC

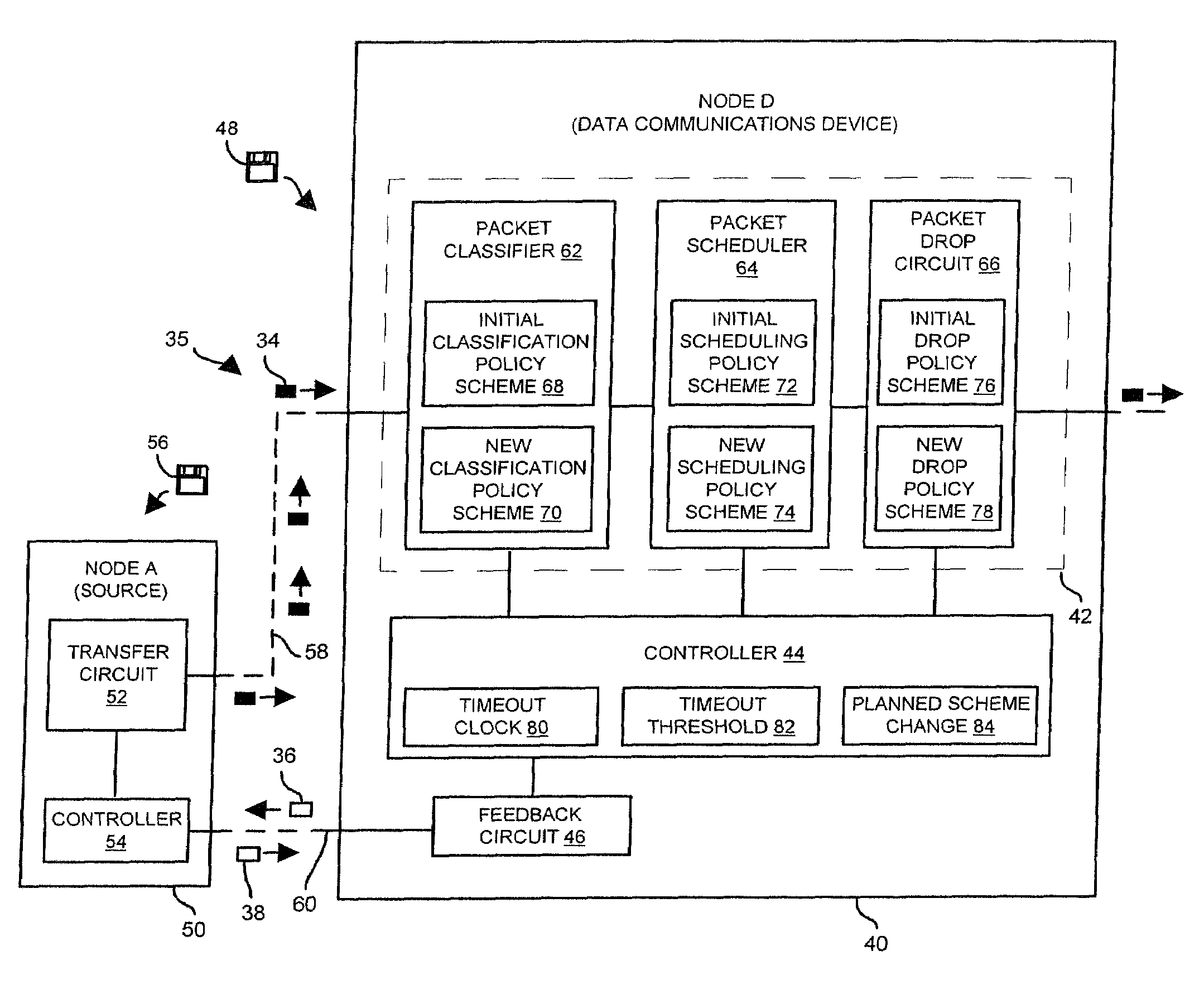

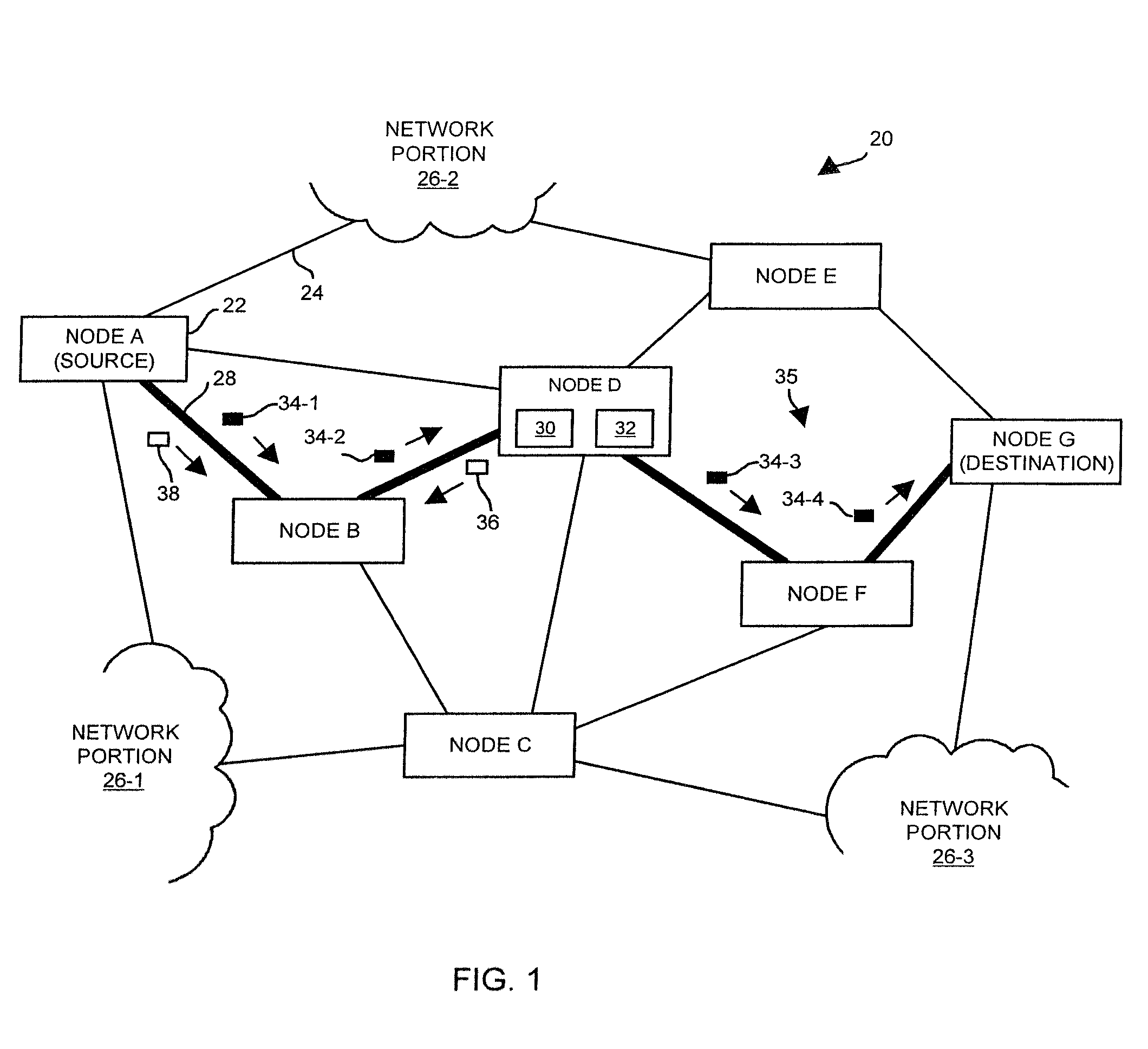

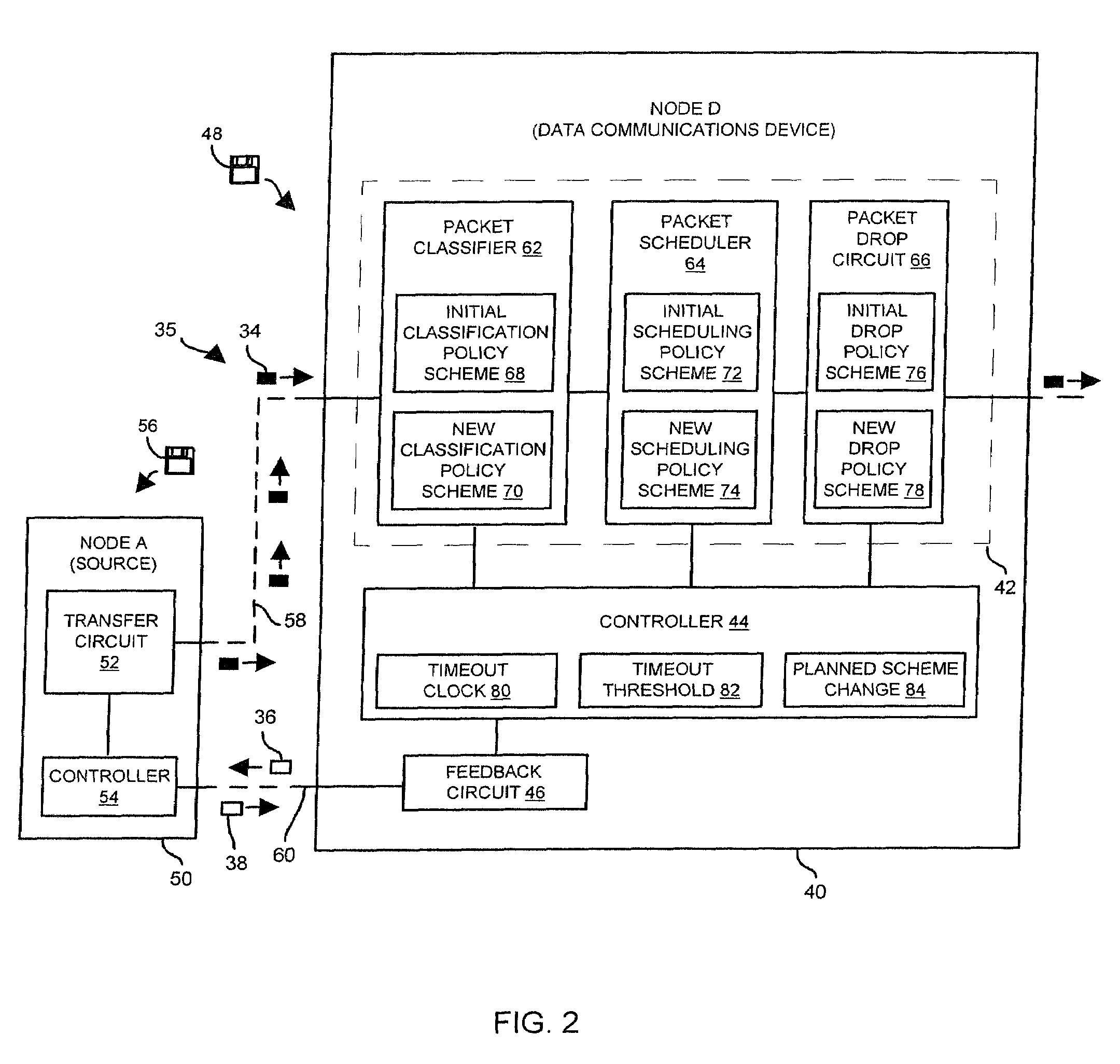

Methods and apparatus for managing a flow of packets using change and reply signals

InactiveUS7477601B1Improve deliveryReduce congestionError preventionTransmission systemsReal-time computingControl data

Techniques are provided for controlling a flow of packets in a data communications device. A first technique involves transferring packets of a particular packet flow based on an initial policy scheme, and planning a scheme change to change the initial policy scheme to a new policy scheme based on conditions within the data communications device existing while transferring the packets of the particular flow based on the initial policy scheme. The first technique further involves providing a change signal to the source of a particular packet flow (e.g., a sending host). The change signal indicates that the data communications device has planned the scheme change. Additionally, the first technique involves processing the scheme change based on either a reply signal from the source or an absence of a reply signal from the source.Another technique involves outputting packets of a particular packet flow to a data communications device that transfers the packets of the particular packet flow based on an initial policy scheme. Additionally, the technique involves receiving, in response to the outputted packets of the particular packet flow, a change signal from the data communications device. The change signal indicates that the data communications device has planned a scheme change to change the initial policy scheme to a new policy scheme. Furthermore, the technique involves providing, to the data communications device, a reply signal that provides direction for processing the scheme change.

Owner:CISCO TECH INC

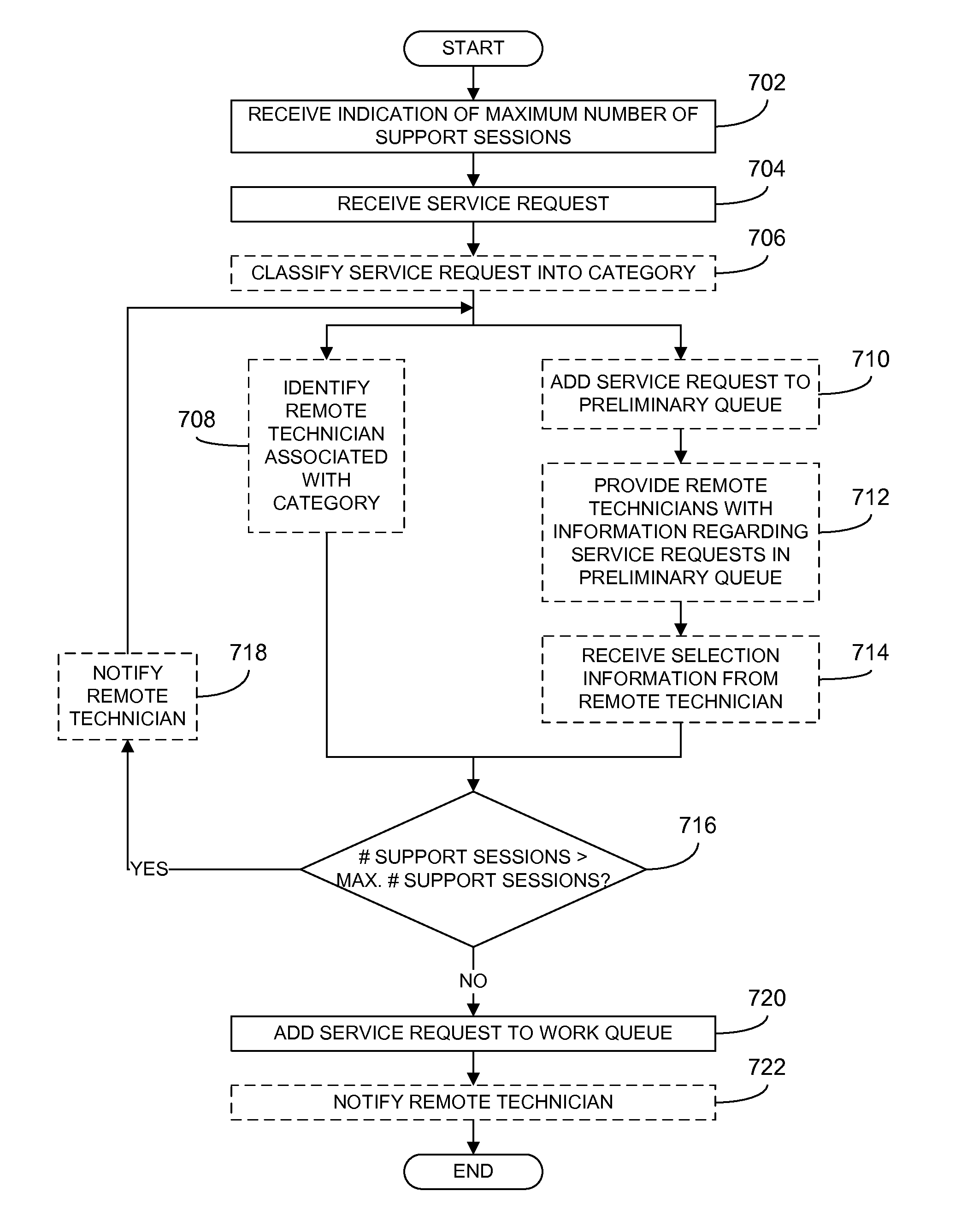

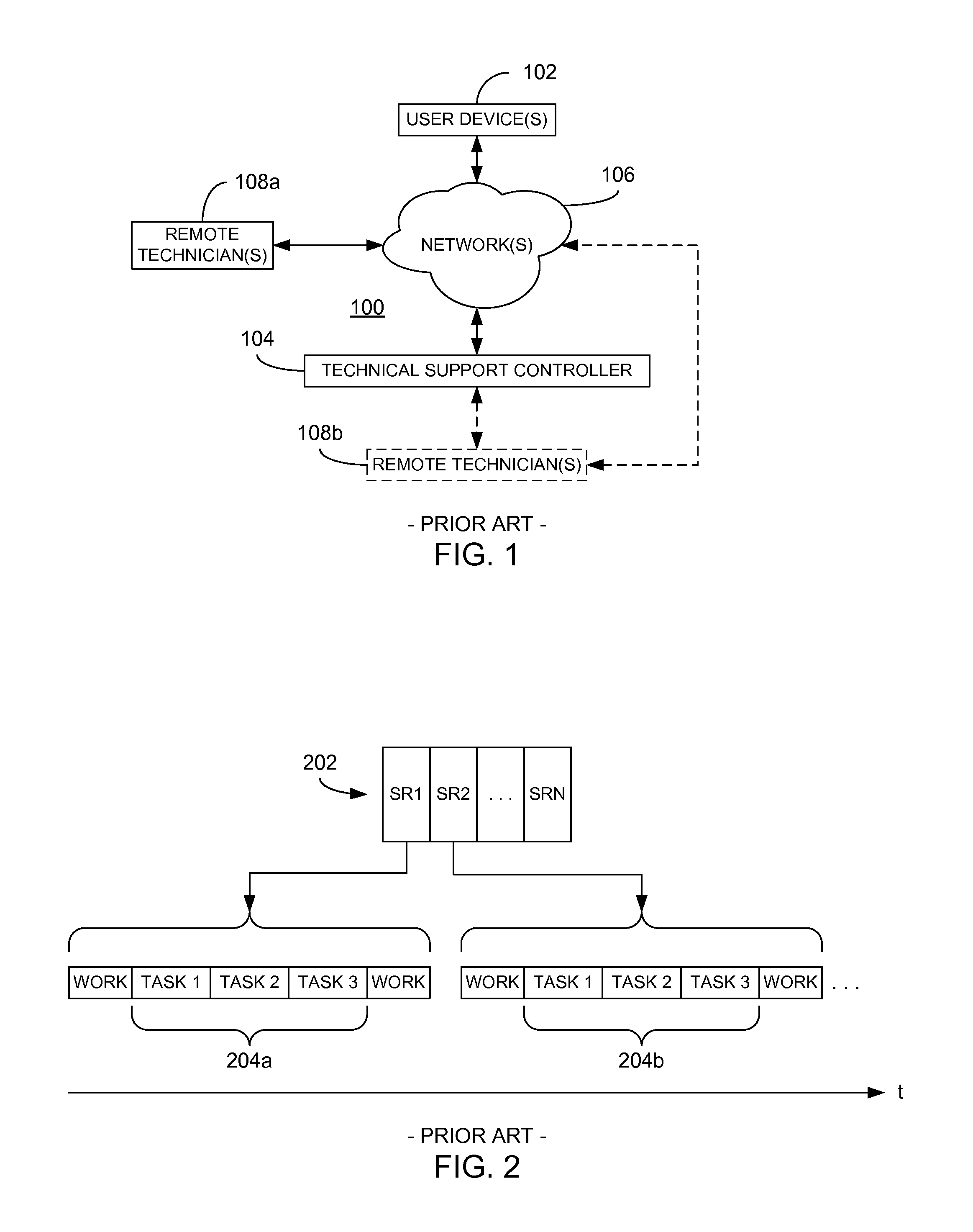

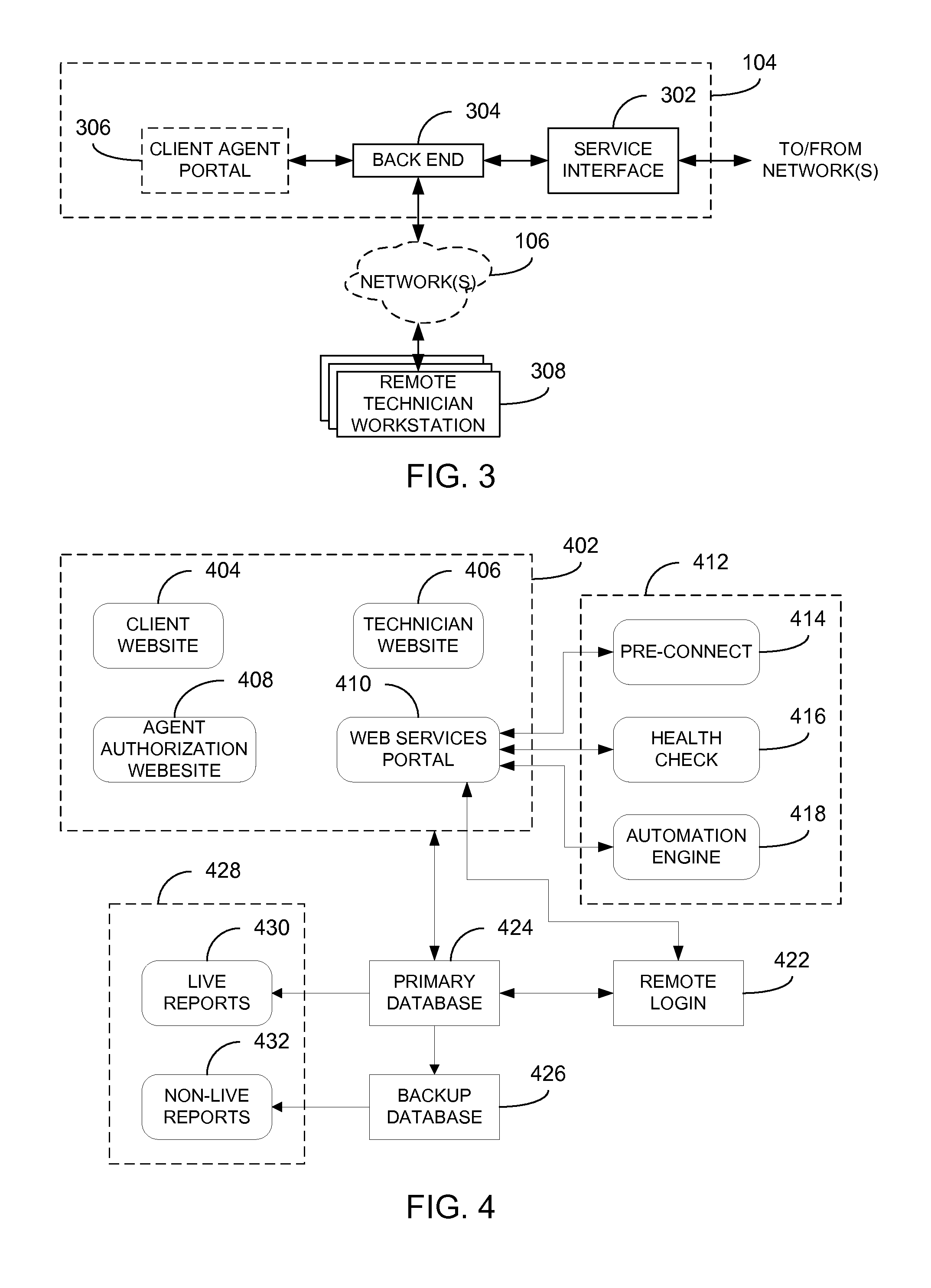

Multiple simultaneous session support by a remote technician

ActiveUS20110202380A1Improve deliveryImprove efficiencyMultiple digital computer combinationsManual exchangesTechnical supportDistributed computing

In a remote technical support system, a technical support controller receives an indication of a maximum number of support sessions to be serviced by a remote technician. Thereafter, the technical support controller receives a service request for a user device. The technical support controller determines if handling of the service request by the remote technician would cause the number of support sessions currently being handled by the remote technician to exceed the previously-indicated maximum number of support sessions. If not, the service request is added to a work queue for the remote technician. Each service request may be classified into categories such that only remote technicians associated with a given category can handle service requests for that category. Furthermore, the process of selecting a remote technician to handle a given service request can be completely automated or based on individual remote technicians selecting service requests from a preliminary queue.

Owner:ACCENTURE GLOBAL SERVICES LTD

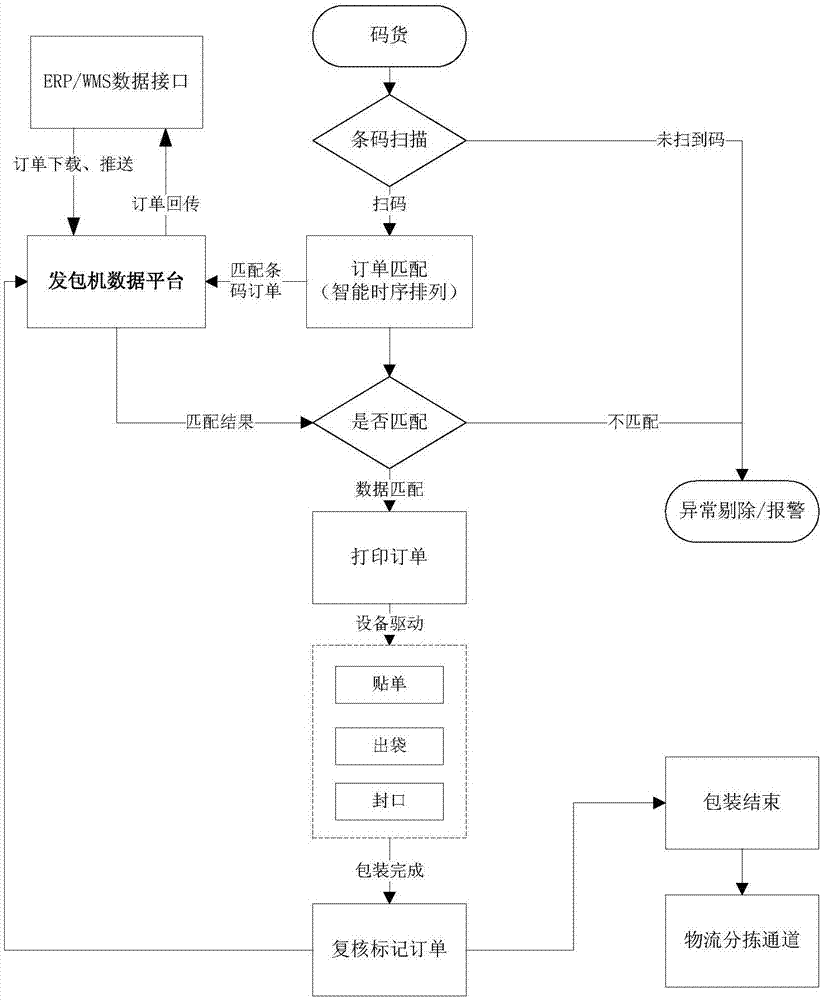

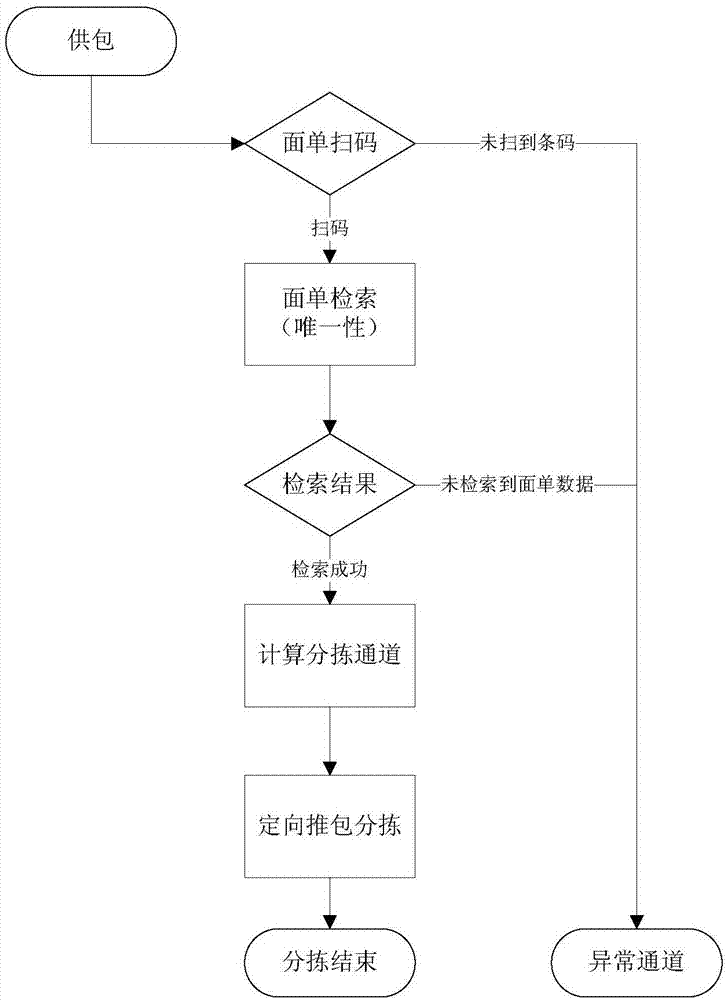

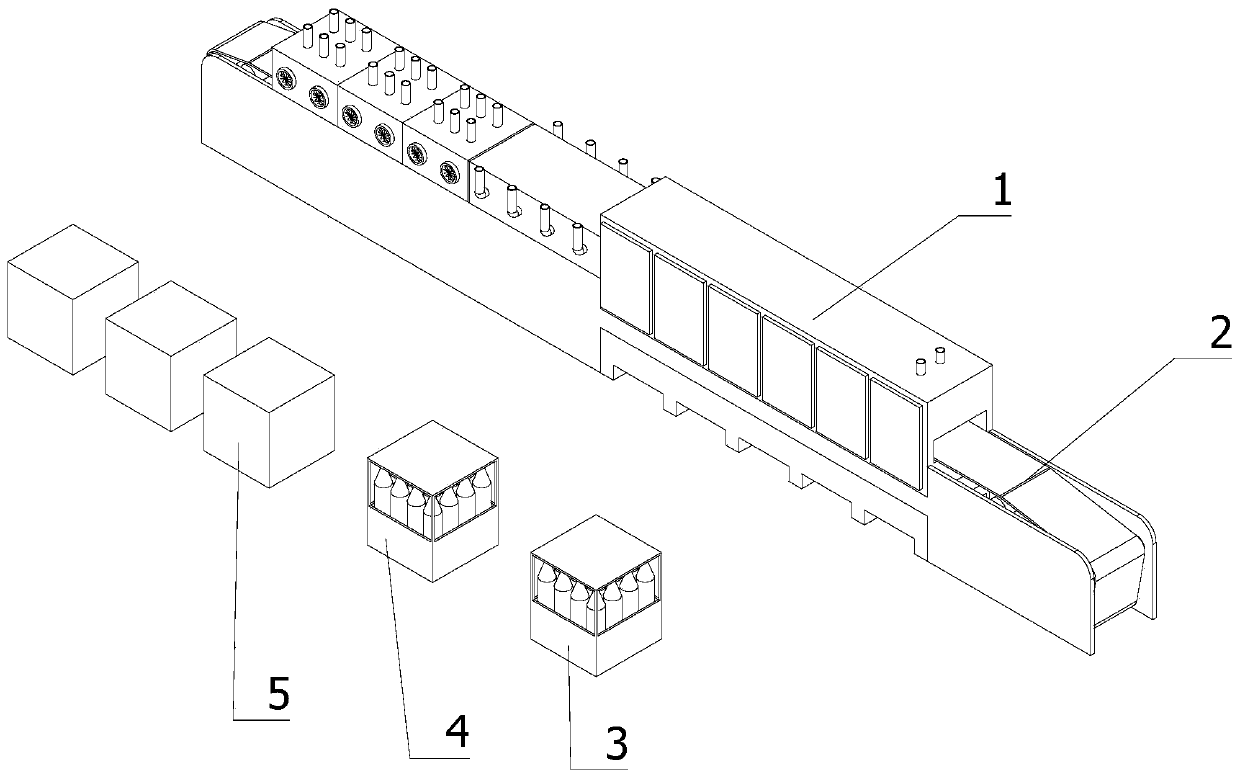

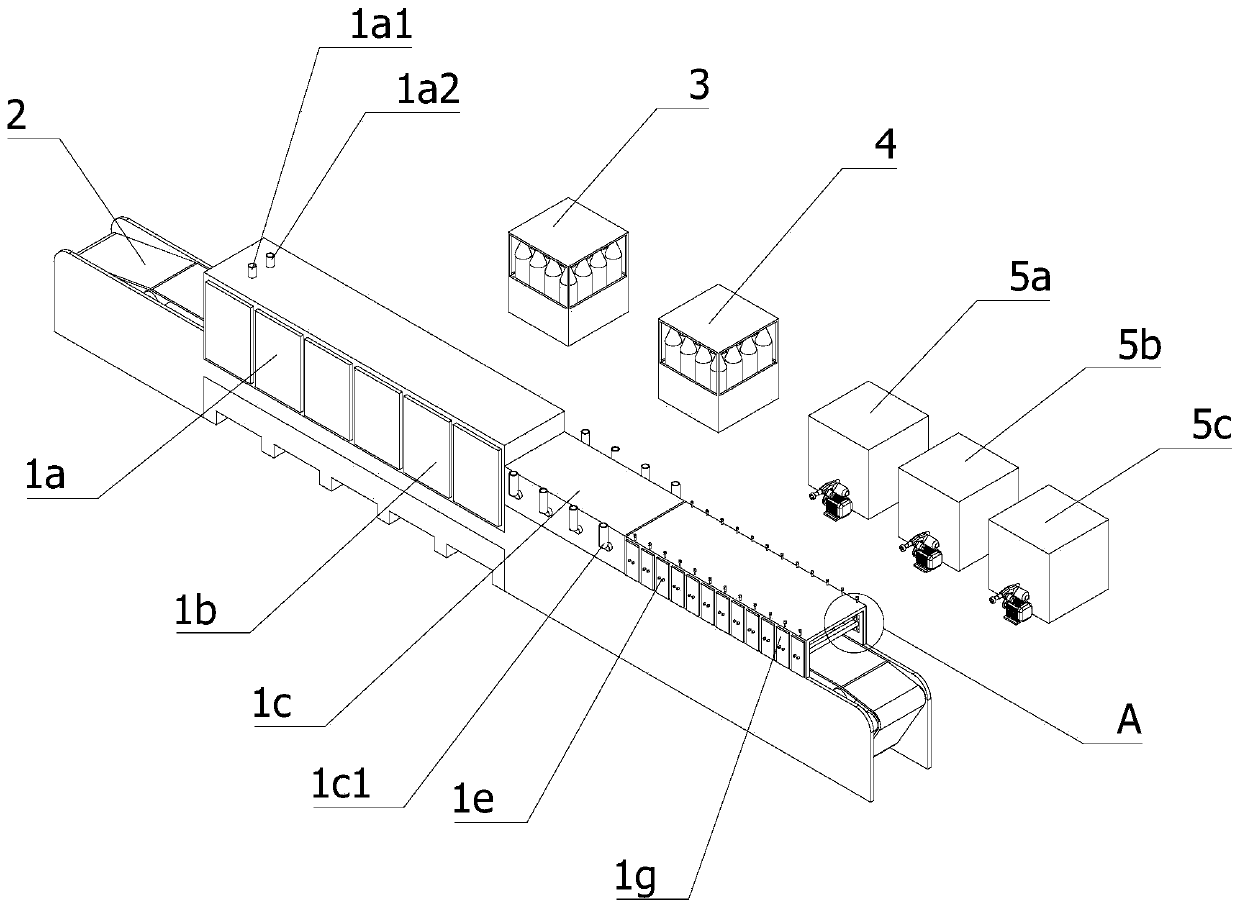

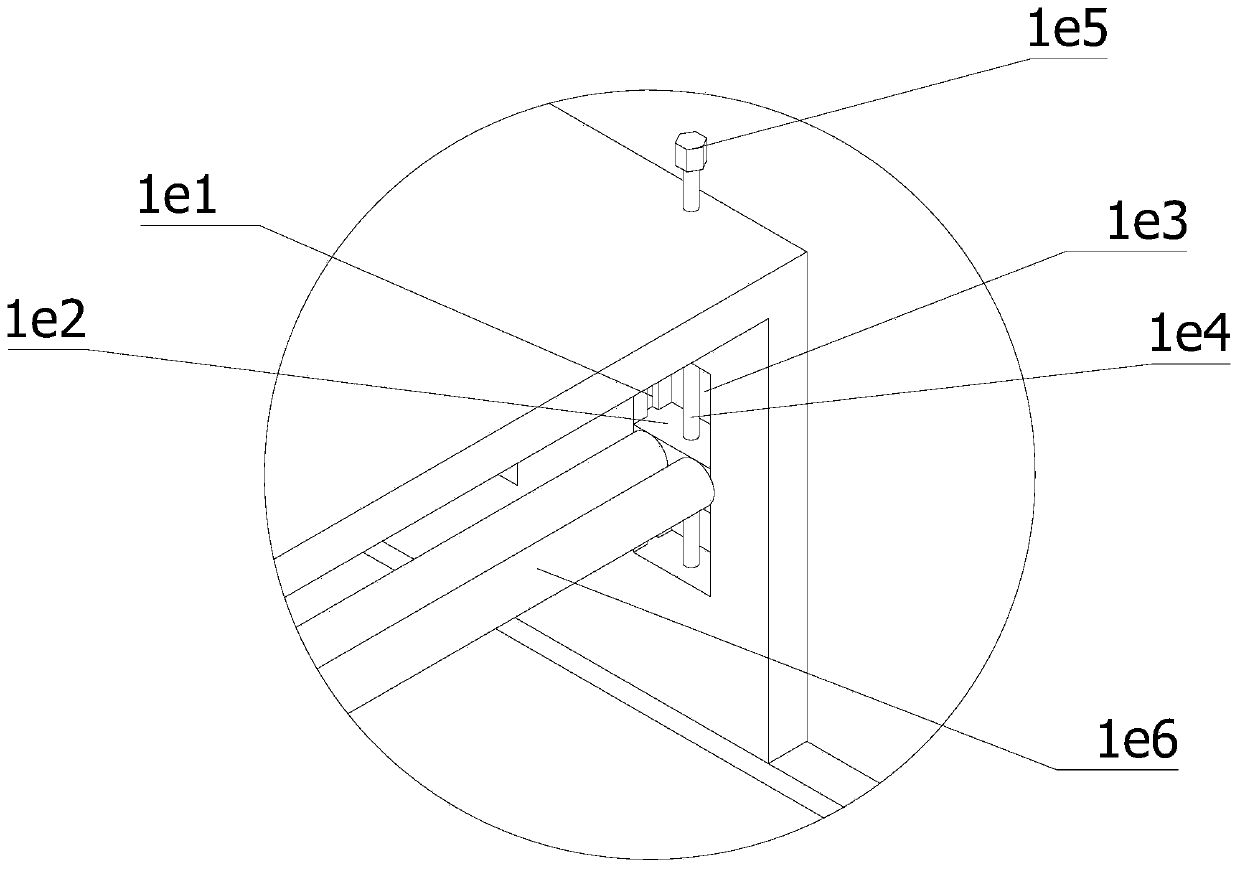

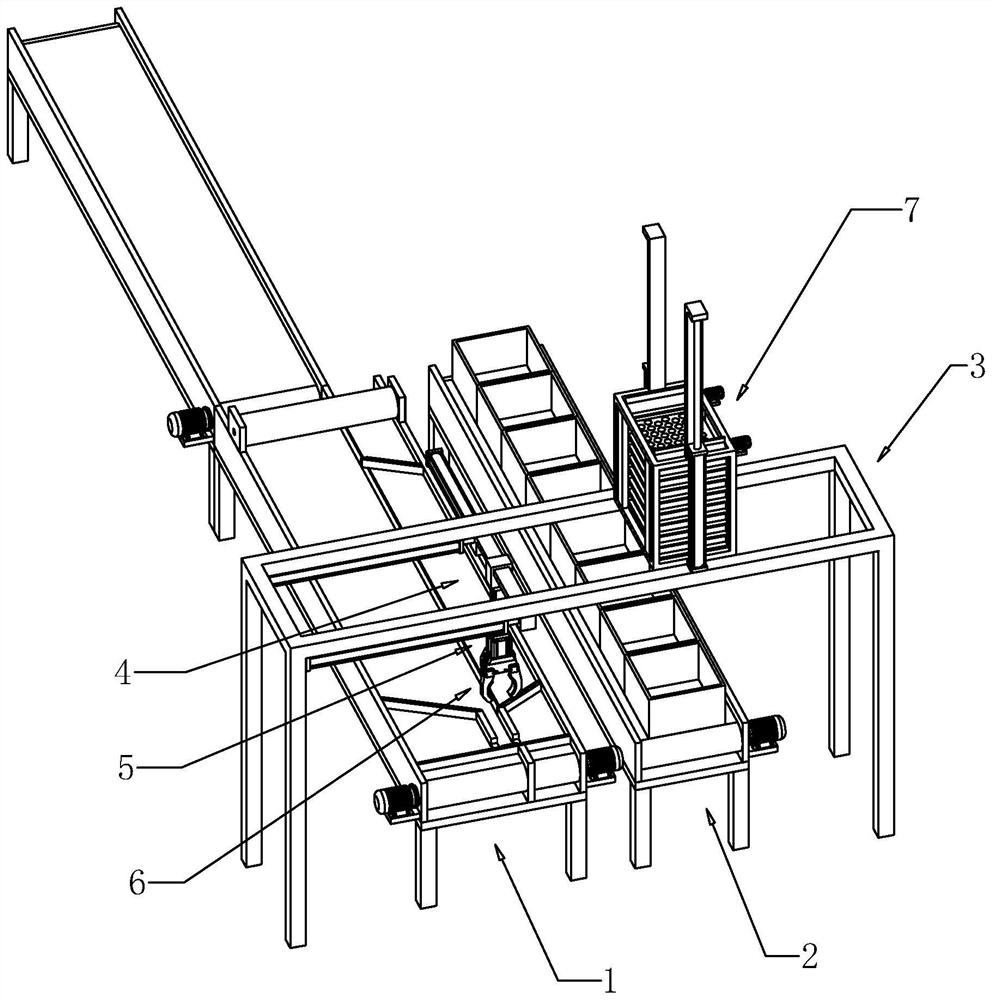

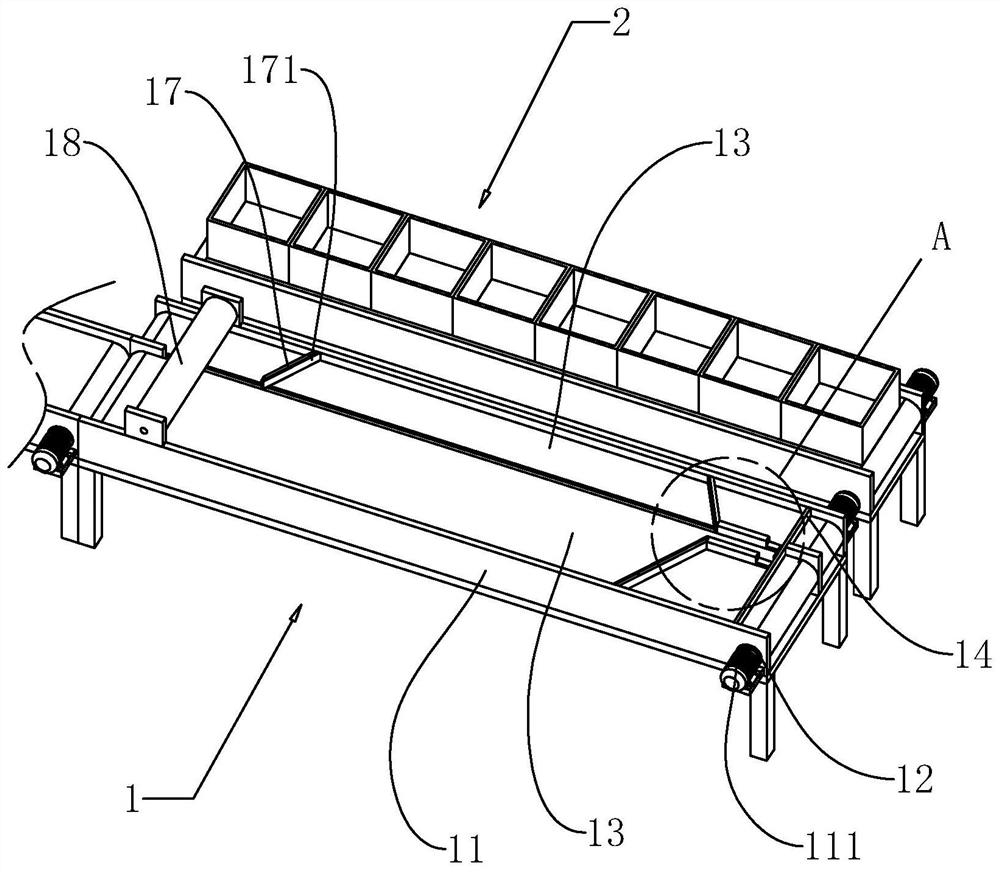

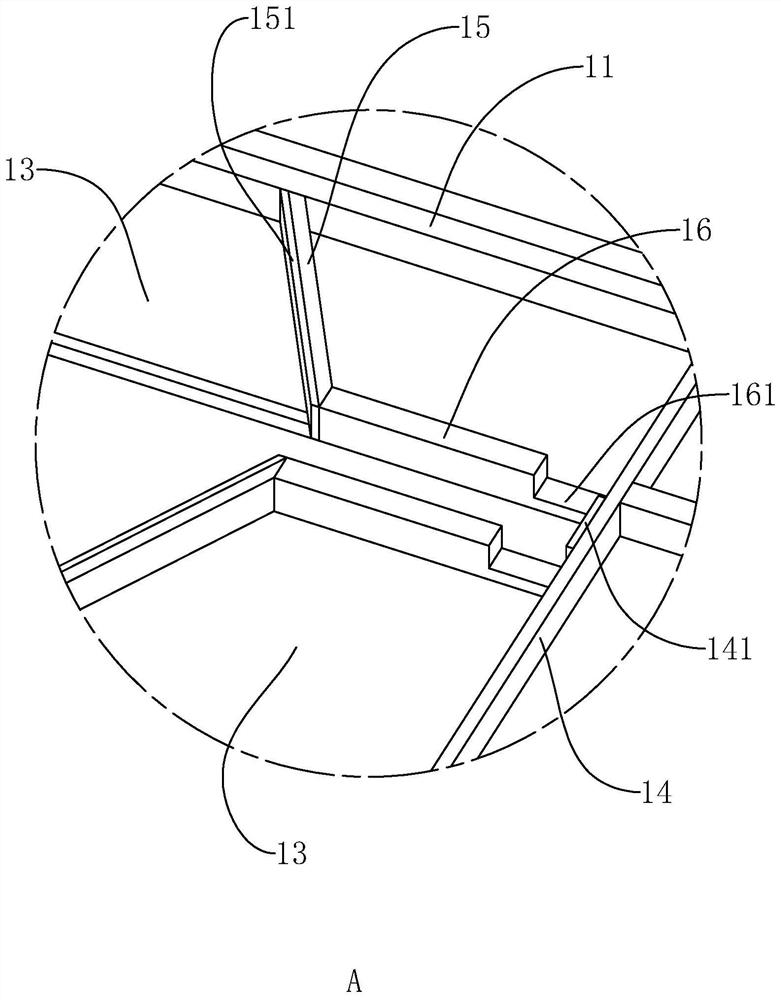

Electronic commerce delivered package rechecking and sorting method

InactiveCN107442436ALower Proficiency RequirementsReduce workflowCo-operative working arrangementsBuying/selling/leasing transactionsData matchingLogistics management

The invention discloses an electronic commerce delivered package rechecking and sorting method. The electronic commerce delivered package rechecking and sorting method comprises the following steps that (1) commodities are sorted by a sorting staff and put into a packing machine; (2) commodity barcodes are scanned by the packing machine; (3) the barcodes scanned by the packing machine are automatically matched with commodity orders, and matched barcode order results are output; (4) the matched barcode orders are matched with order data of a data platform of a delivered-package packing machine, the matched results are output by the data platform of the delivered-package packing machine; (5) data matching is conducted on the matched results output by the data platform of the delivered-package packing machine and the matched barcode order results; (6) the data is matched, and a surface list is printed; (7) the packing machine drives equipment to conduct list posting, bag discharging and sealing; (8) packing is completed, the order is rechecked and marked, and the data is transmitted to the data platform of the delivered-package packing machine; and (9) packing is finished, and logistics sorting is conducted. According to the electronic commerce delivered package rechecking and sorting method, delivery efficiency is improved, and promotion in the respects of delivery, service and customer experience is brought for the electronic commerce enterprise.

Owner:JIANGSU BAILIAN SOFTWARE CO LTD

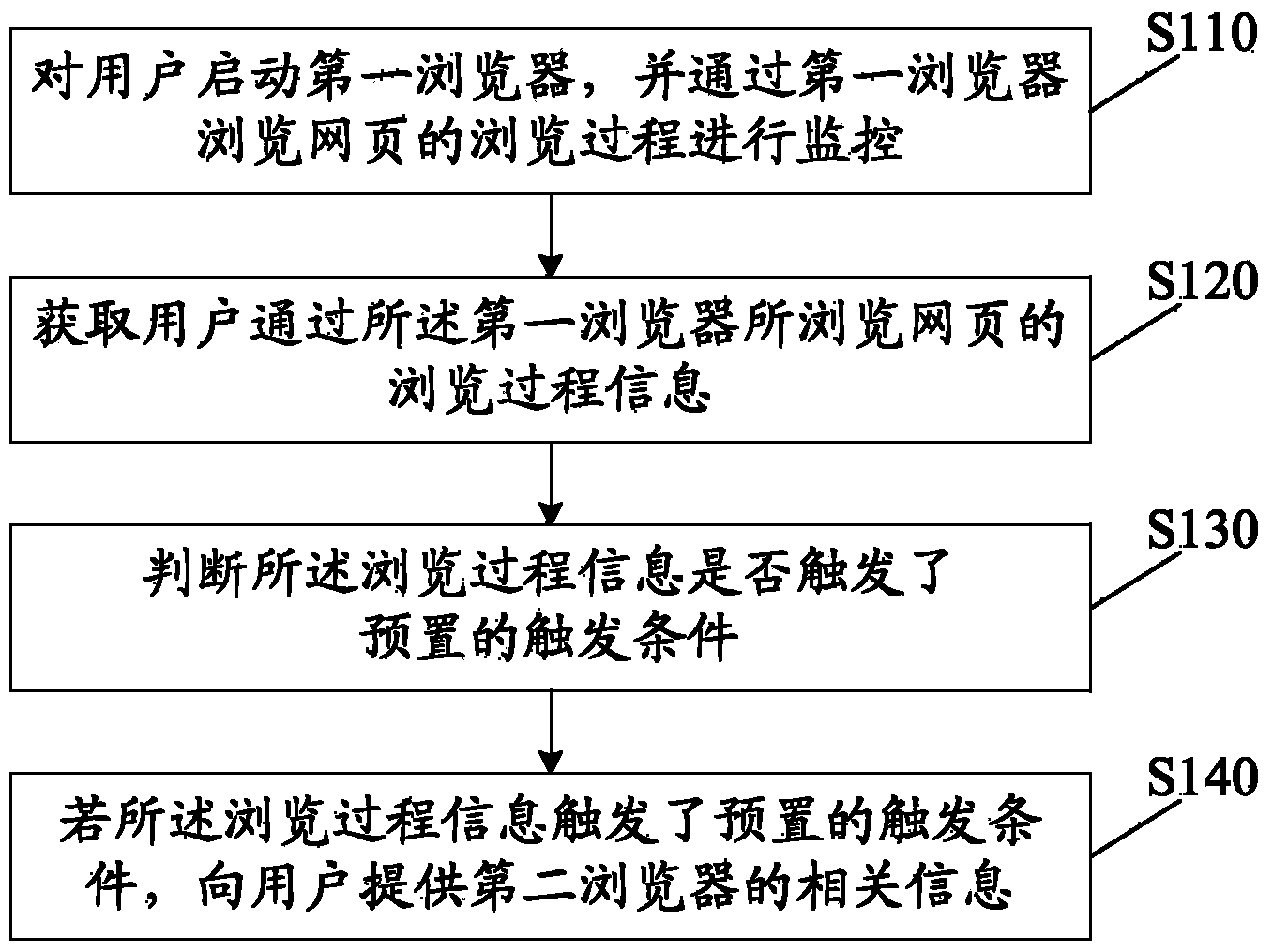

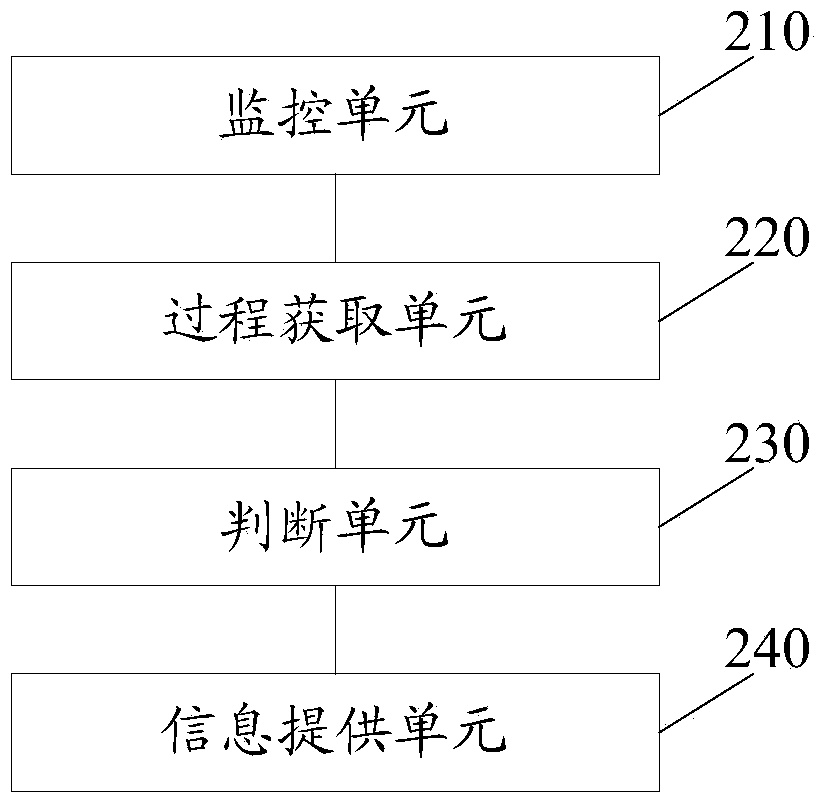

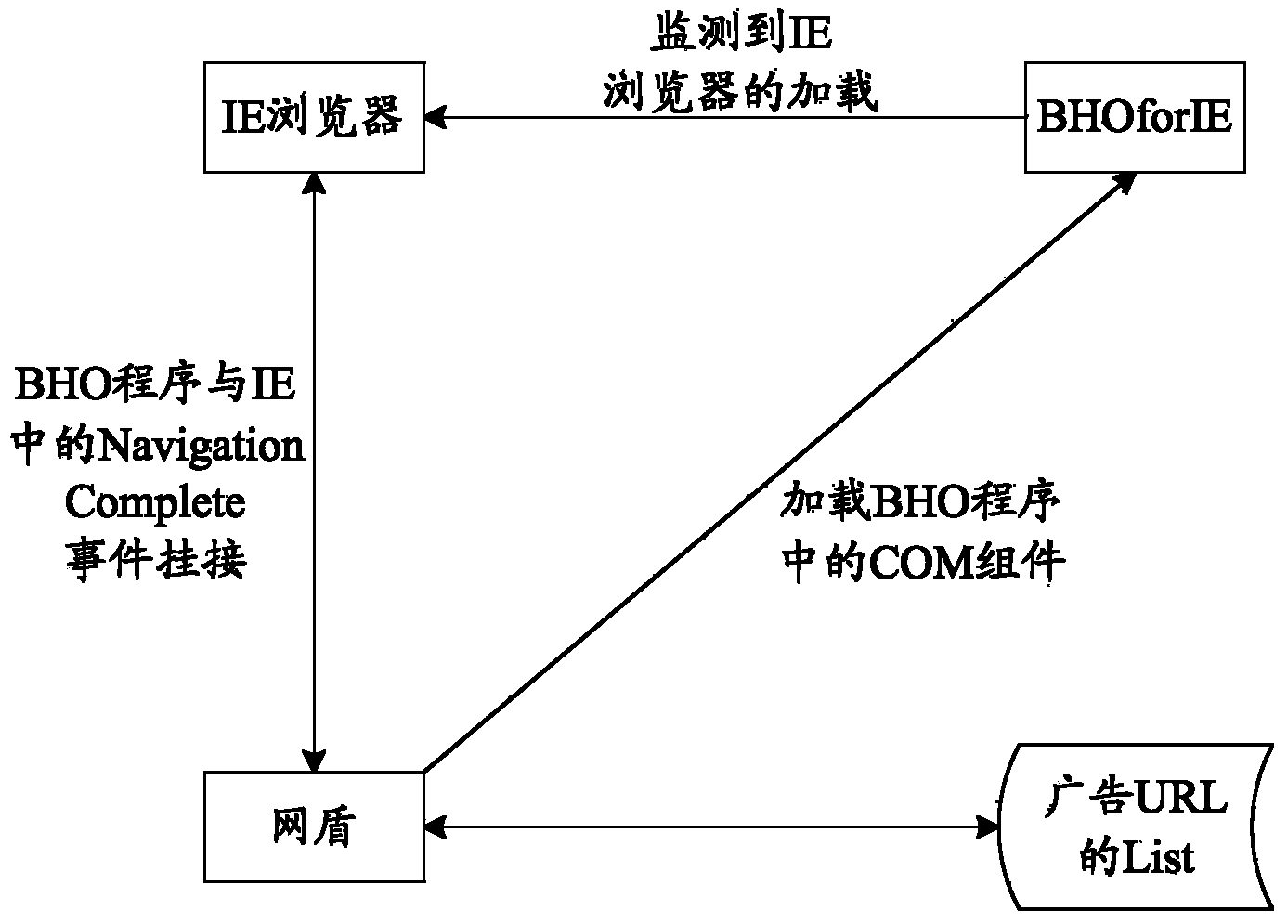

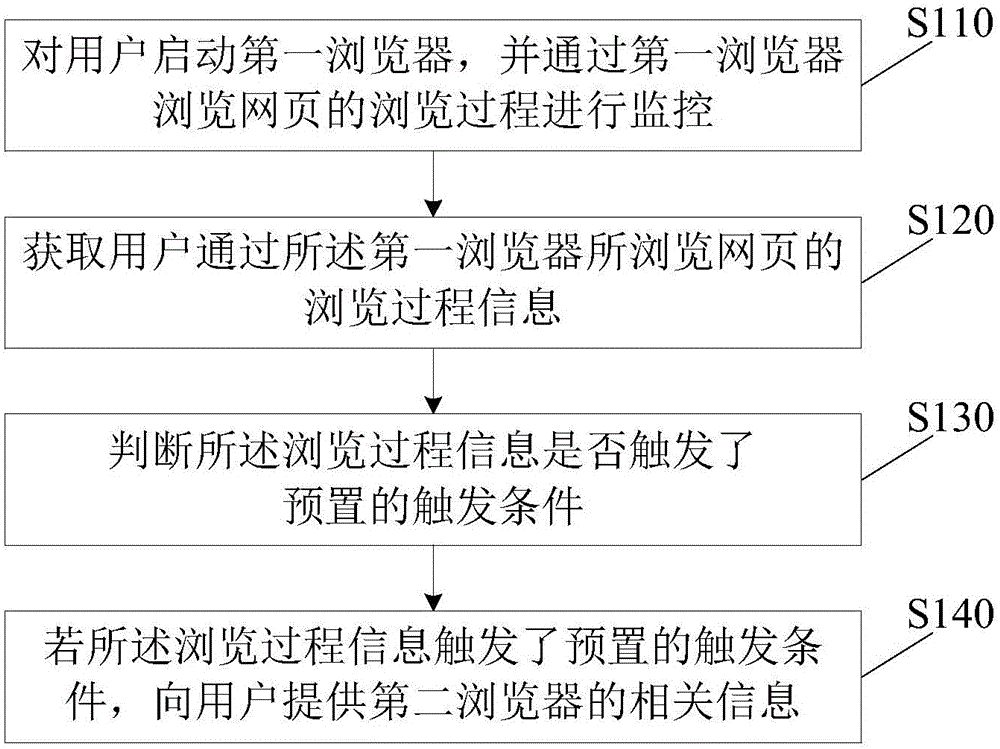

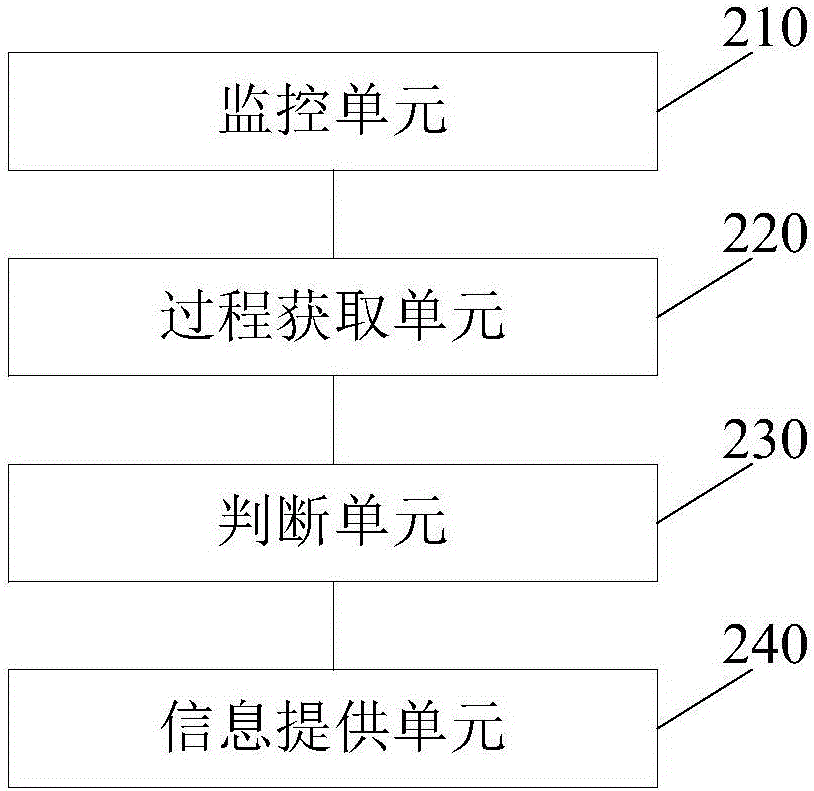

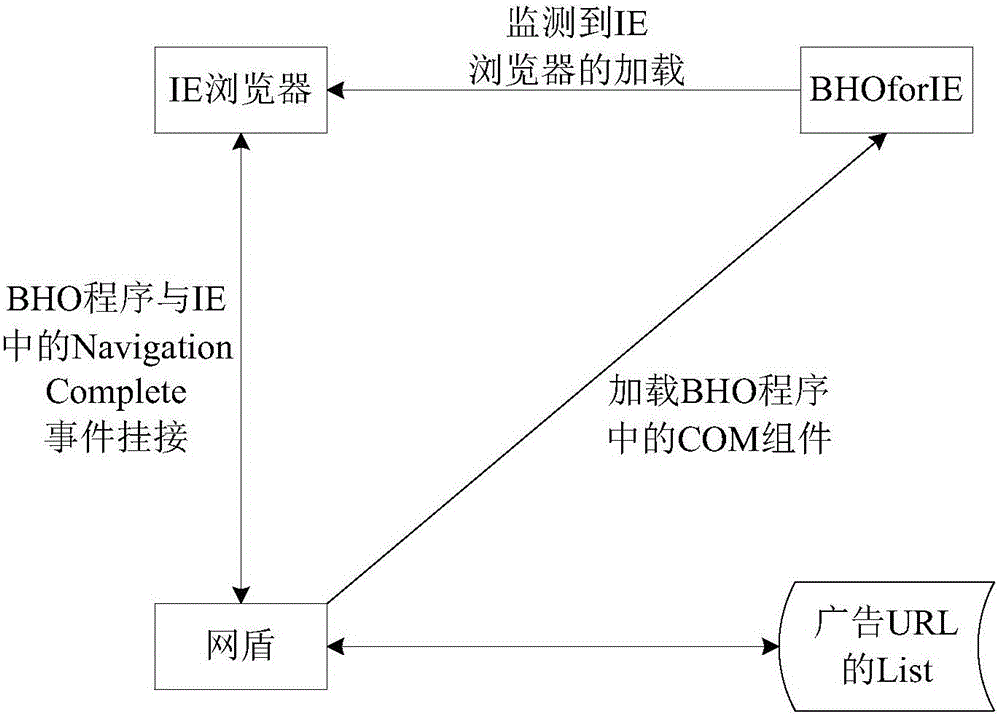

Method and device for providing browsers

ActiveCN103514021AConvenient browser delivery methodImprove deliveryHardware monitoringProgram loading/initiatingWeb pageProcess information

The invention discloses a method and device for providing browsers. The method for providing the browsers includes the first step of starting the first browser for a user, and monitoring the browsing process for browsing webpages through the first browser, the second step of obtaining browsing process information of the user for browsing the webpages through the first browser, and the third step of judging whether the browsing process information triggers preset triggering conditions or not, and providing relevant information of the second browser for the user if the browsing process information triggers the preset triggering conditions. Through the method, the relevant information of the second browser can be provided for the user according to the defects existing in the browsing process when the user uses the first browser. The user can install the second browser according to the relevant information of the second browser, and therefore the more convenient browser providing method is provided.

Owner:BEIJING QIHOO TECH CO LTD

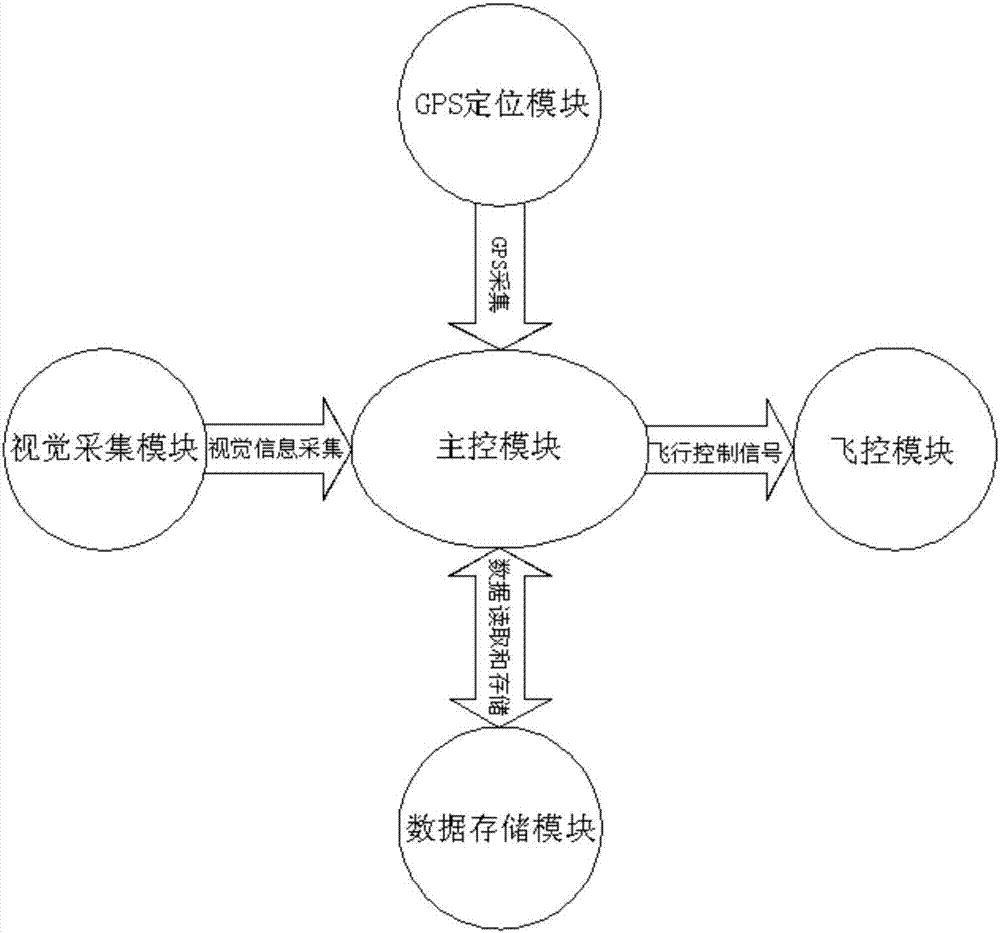

System and method for flight route planning of logistics UAV (unmanned aerial vehicle) on basis of grid map

ActiveCN107992083AImprove deliveryImprove efficiencyPosition/course control in three dimensionsLogistics managementUncrewed vehicle

The invention discloses a system and a method for flight route planning of a logistics UAV (unmanned aerial vehicle) on the basis of a grid map. A data storage module is used for storing existing gridmap data; a master control module is used for acquiring location information of a departure point and a destination of the UAV, reading the grid map data in the data storage module, performing UAV flight route planning according to the location information of the departure point and the destination and the grid map data, and sending planned flight route information to a flight control module; a GPS (global positioning system) module is used for realizing accurate positioning of the UAV; the flight control module adopts GPS for controlling the UAV to fly along the planned flight route for logistics distribution or transceiving. According to the system and the method, the flight route of the logistics UAV is rapidly planned according to the existing grid map data, and the logistics UAV canarrive in any place along the planned flight route for logistics distribution or transceiving.

Owner:POWERVISION TECH

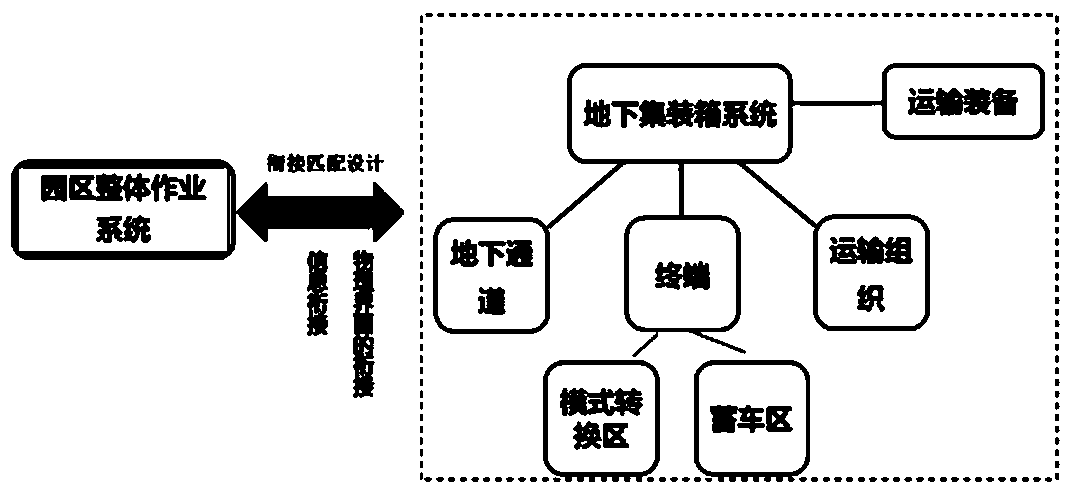

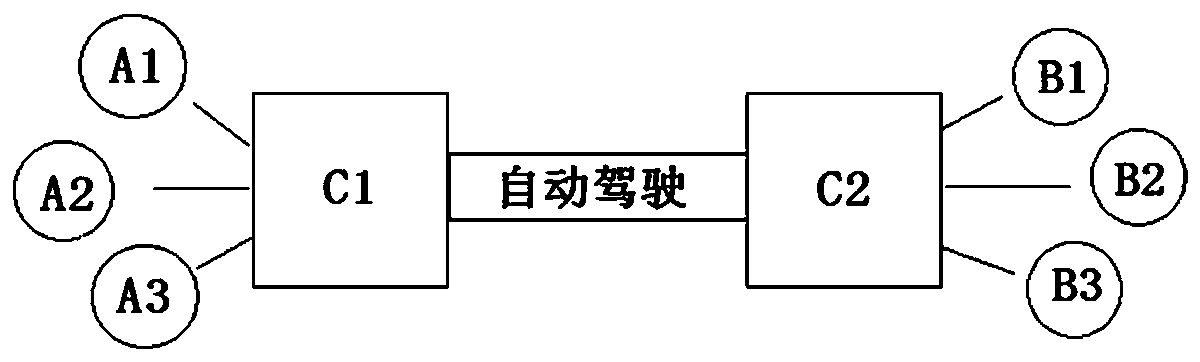

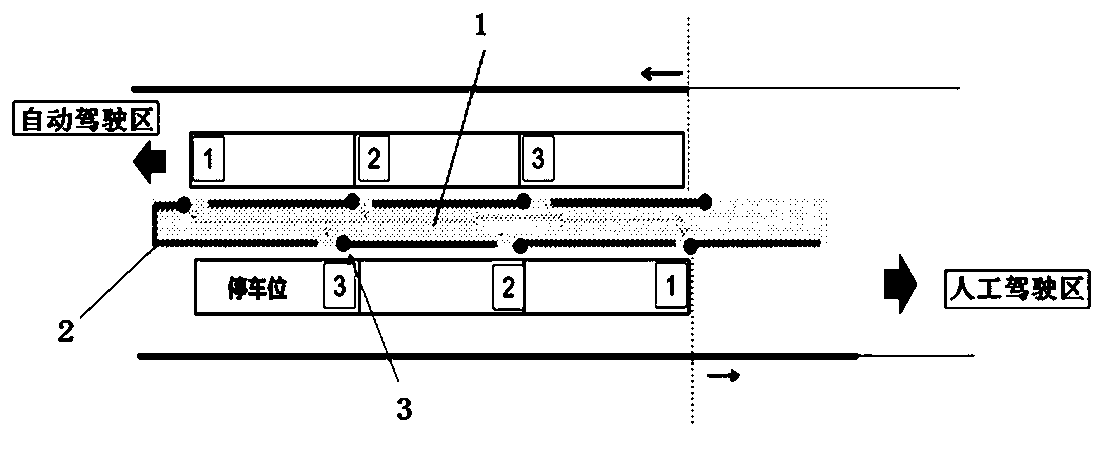

Underground passage for unmanned automatic freight transportation and system thereof

The invention discloses an underground passage for unmanned automatic freight transportation. An automatic driving area is formed in the underground passage. A mode conversion area is arranged at theend of the underground passage and is used for separating an artificial driving area from the automatic driving area. The mode conversion area includes a pedestrian zone and lanes arranged at both sides of the pedestrian zone; isolation facilities are arranged between the pedestrian zone and the lanes at the two sides; and isolation facilities are also arranged between the pedestrian zone and theautomatic driving area. A staff passage is set between the pedestrian zone and the artificial driving area. A plurality of parking spaces are arranged at the lanes at two sides of the pedestrian zone;and shielding doors matching the parking spaces are arranged in the isolation facilities between the pedestrian zone and the lanes at the two sides. According to the invention, the dual-mode transportation system combining automatic driving with manual driving is put forward; switching between the automatic driving and manual driving is realized by setting the mode switching area; and the high-efficiency transportation of automatic driving is realized by using the underground dedicated passage.

Owner:SHANGHAI MUNICIPAL ENG DESIGN INST GRP

Non-oxidizing normalizing process of steel pipe and device

InactiveCN109929972AIdeal hardnessIdeal thicknessFurnace typesHeat treatment furnacesRoom temperatureNitrogen

The invention relates to a non-oxidizing normalizing process of a steel pipe. The non-oxidizing normalizing process of the steel pipe is characterized by comprising the following steps of S1, pretreatment which comprises the following sub-steps of S11, preheating and heating; and S12, heat preserving, specifically, a conveying mechanism continues to convey the steel pipe forwards to a heat preserving area, the heat preserving temperature is 850-900 DEG C, and the heat preserving time is 6-8 min; S2, air cooling, specifically, nitrogen is fed into an air cooling area through a nitrogen station,the nitrogen is used as media, and used for fast cooling the steel pipe, and the steel pipe is cooled to 350-400 DEG C within the time of 1.5-2 min; S3, water cooling, specifically, a water cooling area is divided into three segments, the temperature rebounding of the steel pipe is 150-200 DEG C in the first segment of the water cooling area, that is, the temperature of the steel pipe is made tobe 500-600 DEG ; and in the first segment of the water cooling area and the second segment of the water cooling area, the steel pipe is gradually cooled to be 200 DEG C or below; and S4, discharging out of a furnace, air cooling is performed till a room temperature is achieved. The invention further discloses a device used for the non-oxidizing normalizing process of the steel pipe. Due to the non-oxidizing normalizing process of the steel pipe, the cooling speed is effectively controlled, the ideal hardness, organization and surface quality are achieved, cost is lowered, and the on-time delivery rate is increased.

Owner:ZHEJIANG MINGHE STEEL PIPE CO LTD

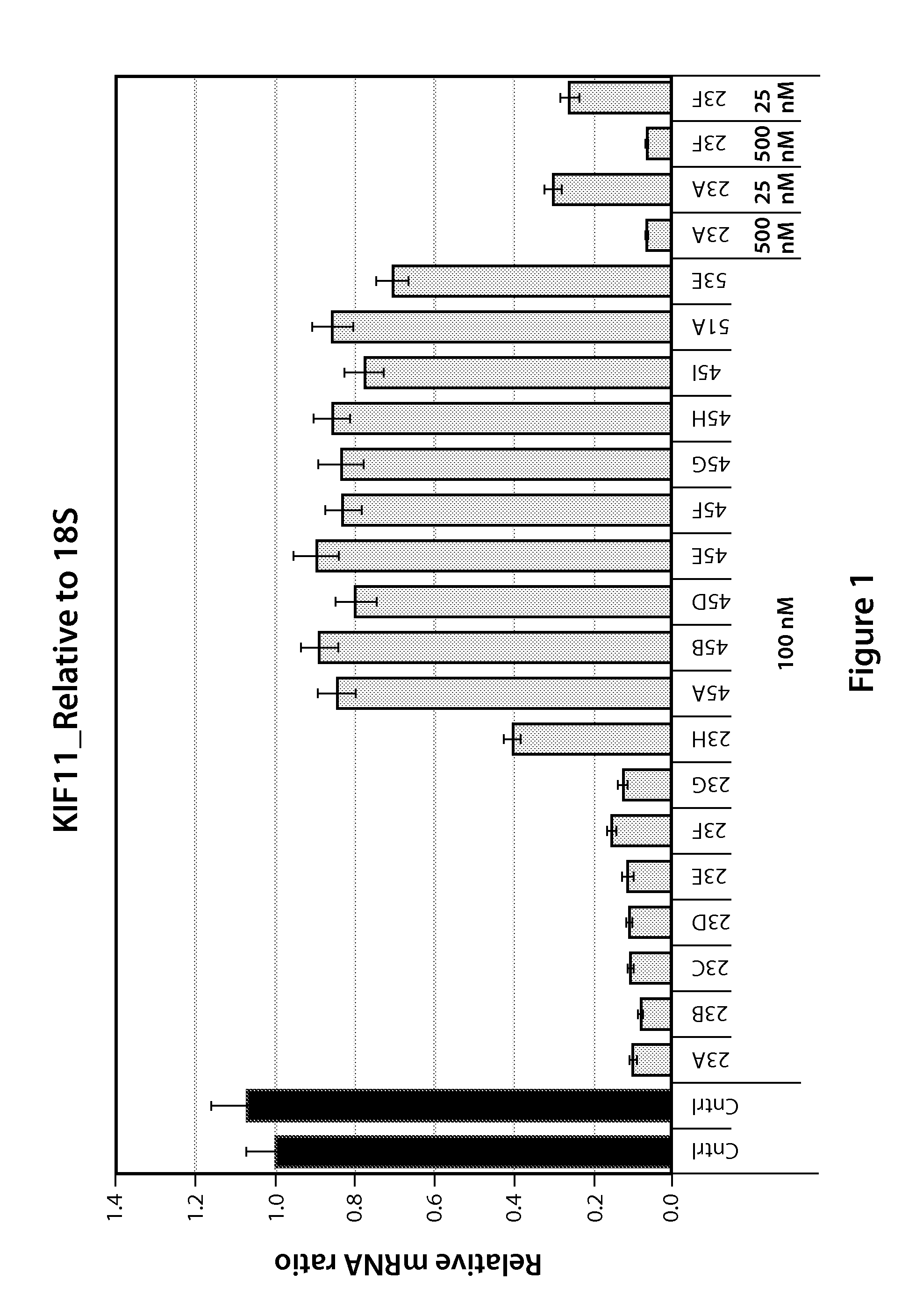

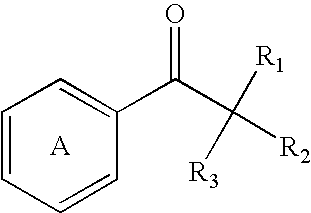

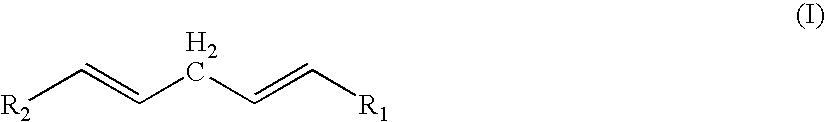

Compounds and Compositions for Nucleic Acid Formulation and Delivery

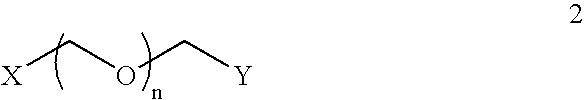

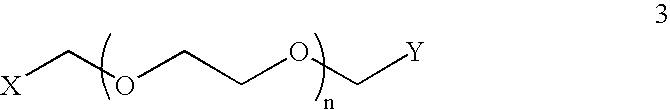

InactiveUS20130072543A1Improve deliveryMore efficaciousOrganic active ingredientsNanotechMedicinal chemistryPEGylation

The invention relates to compositions containing compounds of formula I:and pharmaceutically acceptable salts thereof, wherein R, R1, R2, R3, and n are defined in the detailed description and claims. In addition, the present invention relates to novel formulations containing compounds of formula I for improved delivery of nucleic acids such as siRNA to the cytoplasm of target cells. In particular embodiments these formulations comprise compounds of formula I, phospholipids, cholesterol, and pegylated lipids. The present invention also relates to methods of manufacturing and using such compounds and compositions.

Owner:ARROWHEAD RES CORP

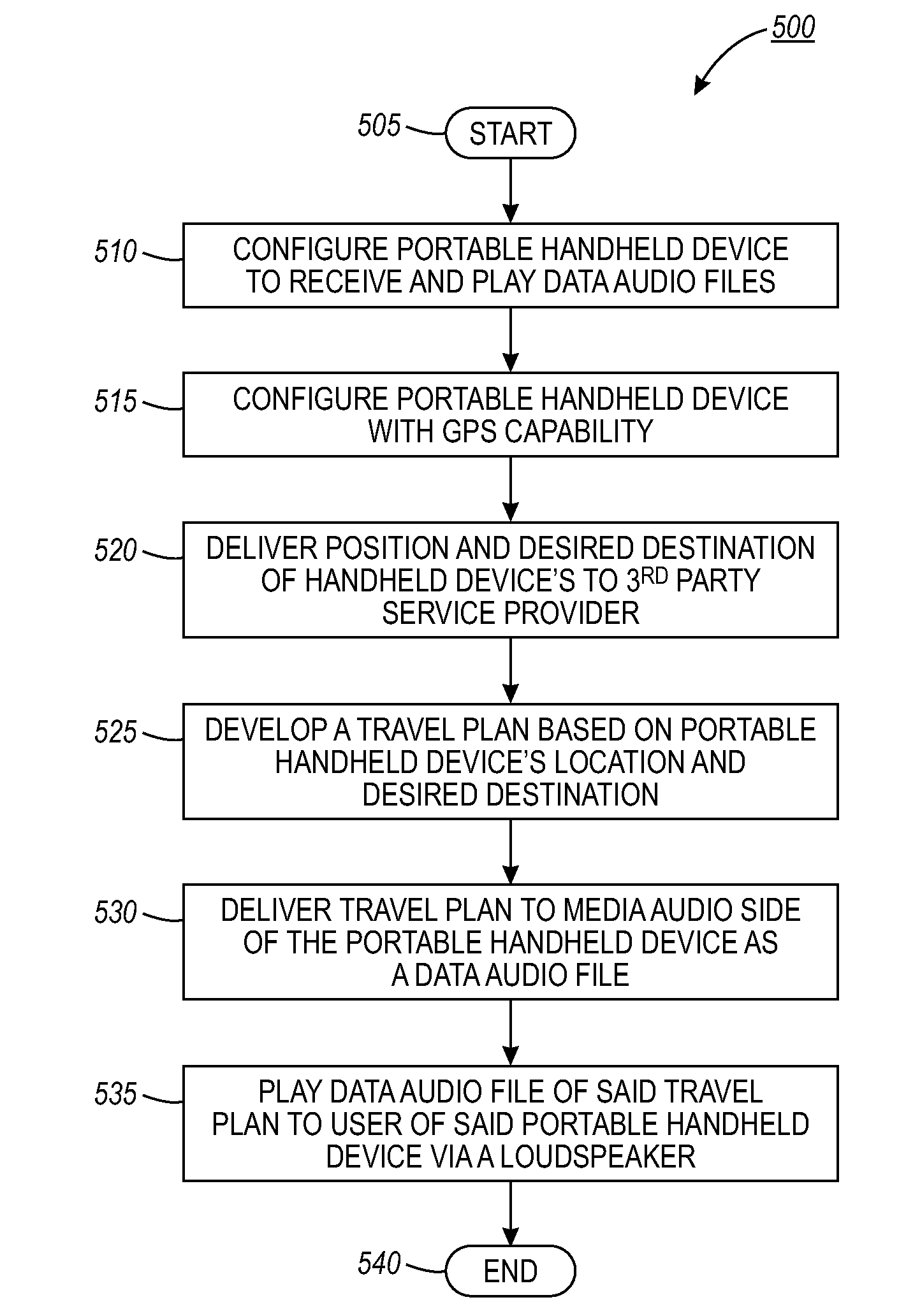

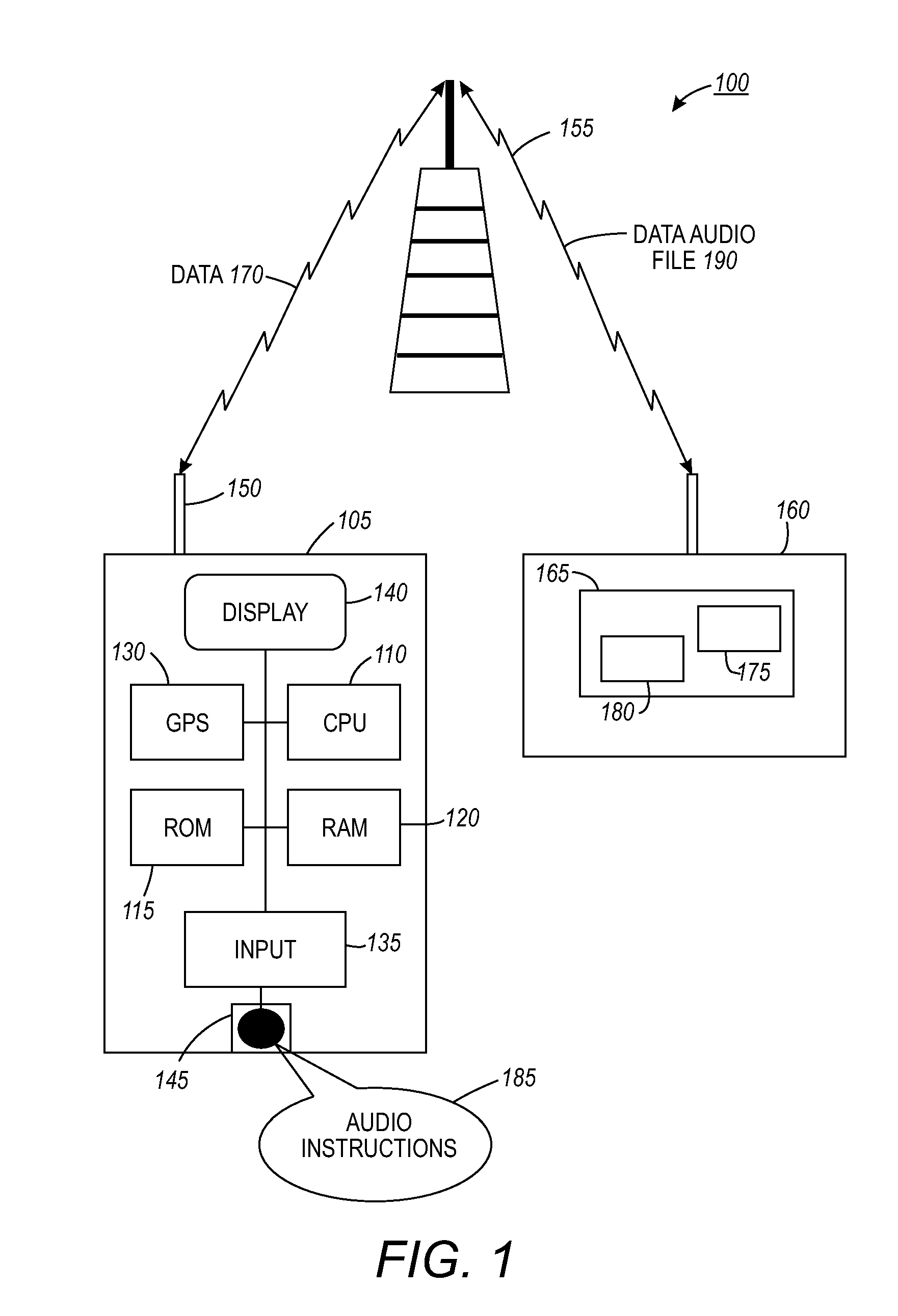

Navigational GPS voice directions via wirelessly delivered data audio files

InactiveUS20110153194A1Improve deliveryReduce deliveryInstruments for road network navigationNavigational calculation instrumentsService providerProgram planning

A method and system for delivering audio directions to a portable handheld wireless communications device. A portable handheld device can be configured to receive and play data audio files, such as, for example, MP3 audio files. Thereafter, a processor or third party service provider can generate a set of travel plans based on the location of the portable handheld device and the desired destination. The travel plan(s) can be delivered to the portable handheld device as a data audio file, which can then be played through the portable handheld device, thereby providing audio instructions that are related to the set of travel plans.

Owner:XEROX CORP

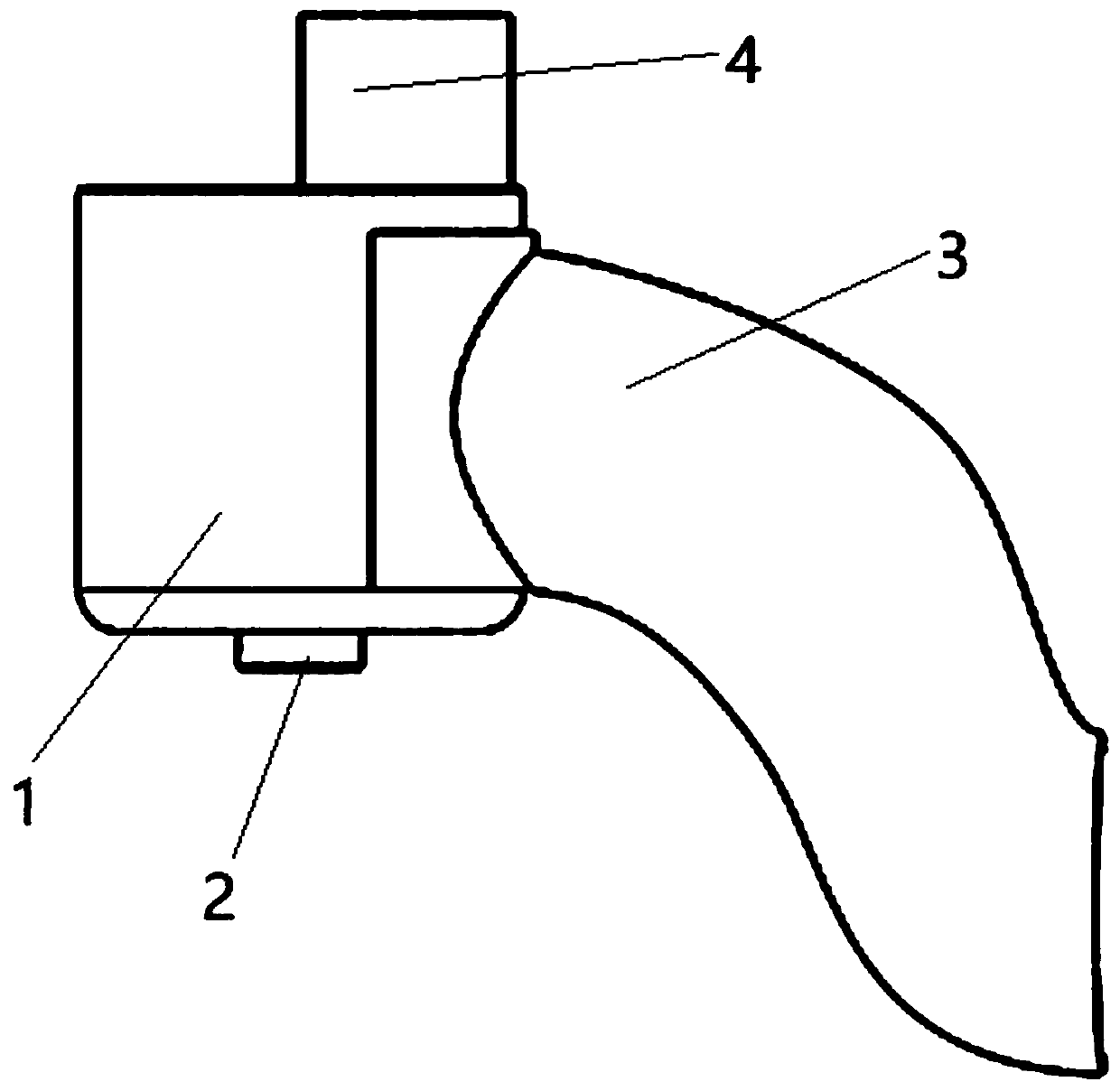

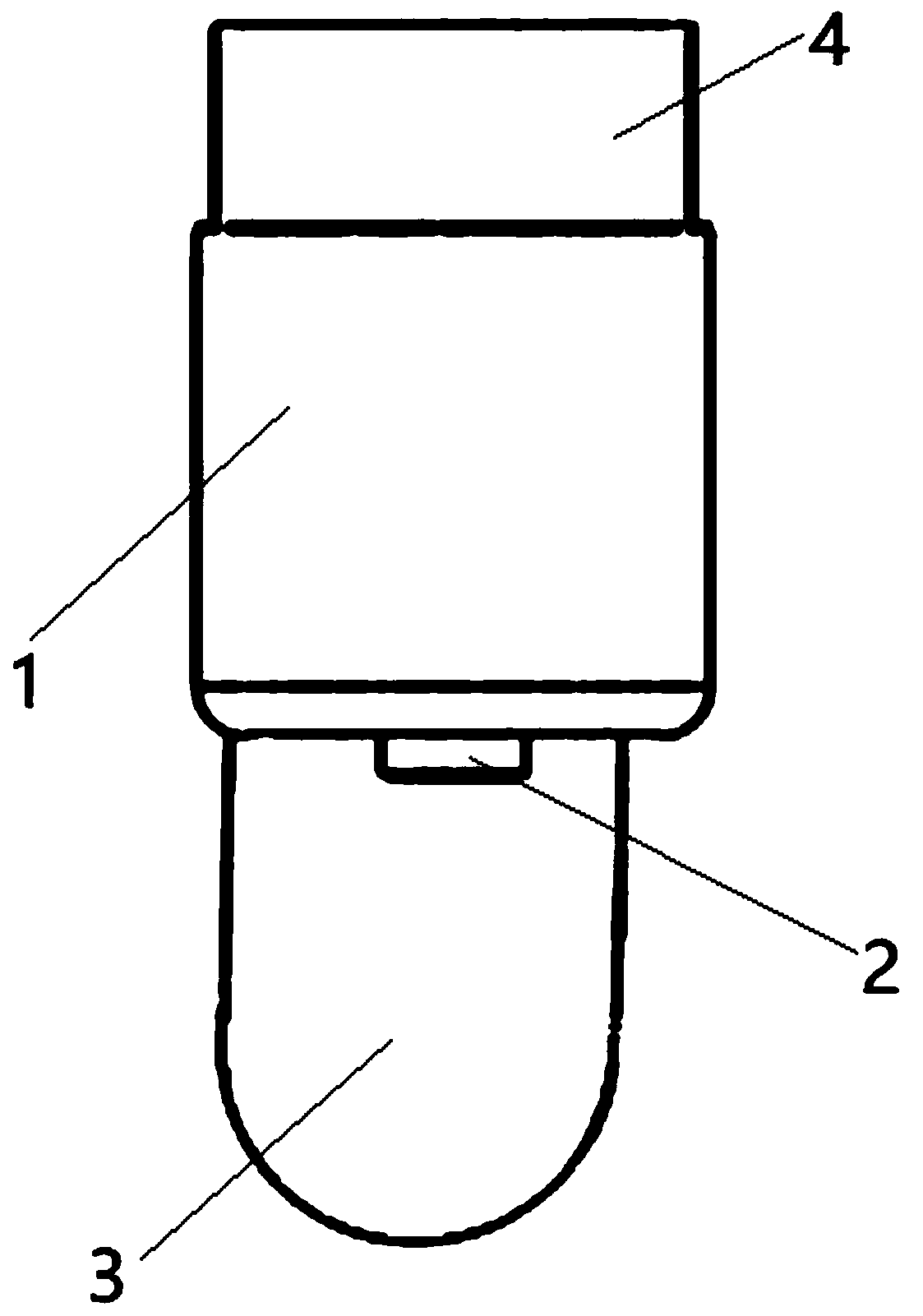

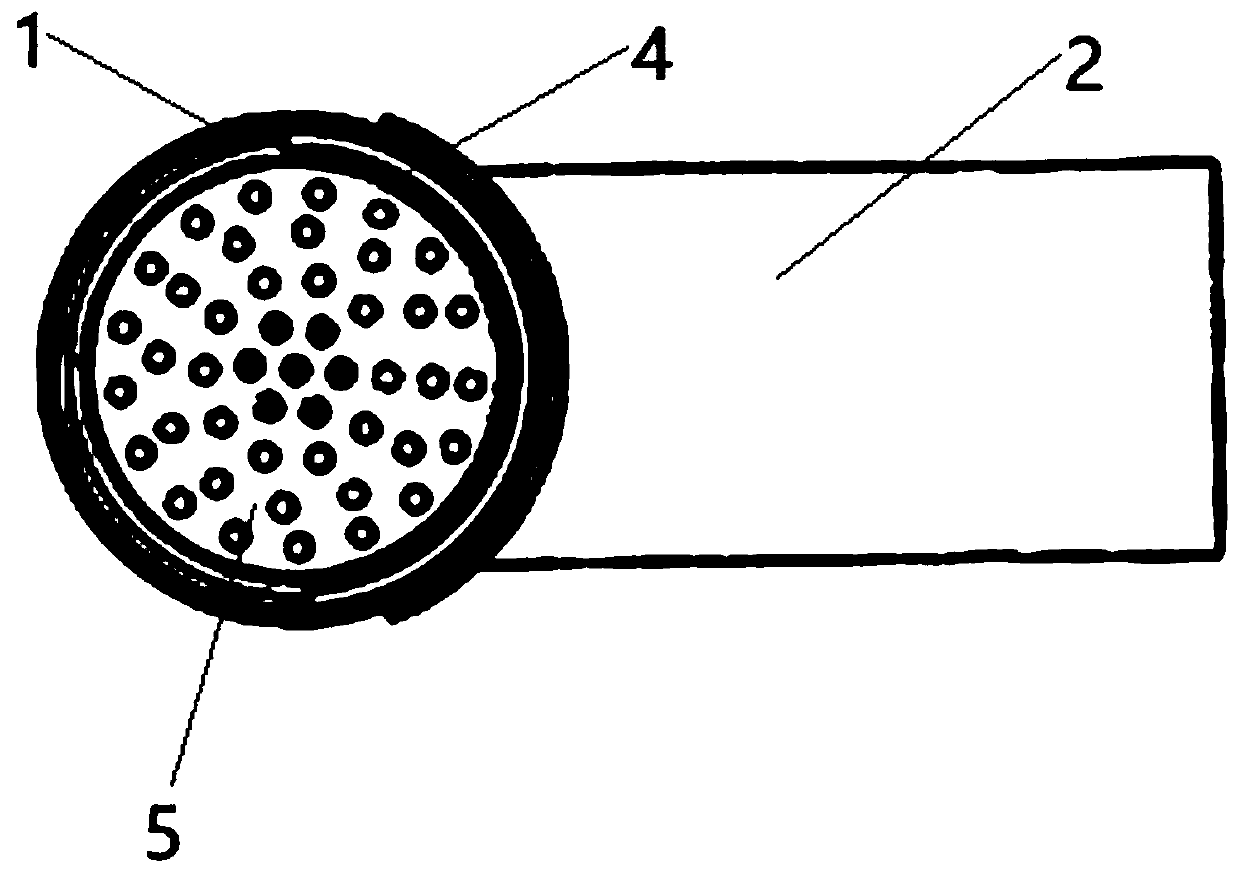

Household food waste treatment device

PendingCN110847302AReduce construction costsLow input costDomestic plumbingRefuse collectionWastewater

The invention relates to a household food waste treatment device. The household food waste treatment device comprises a water basin funnel (1). The bottom of the water basin funnel (1) is provided with a waste water channel (2) communicating with the inner cavity of the water basin funnel (1), and the side part of the water basin funnel (1) is provided with a waste channel (3) communicating with the inner cavity of the water basin funnel (1). A valve structure (4) is arranged between the inner cavity of the water basin funnel (1) and an inlet of the waste channel (3). A filtering structure (5)is arranged in the inner cavity of the water basin funnel (1). The filtering structure (5) is used for separation between waste water and waste in the household food waste. The valve structure (4) isused for controlling whether the inner cavity of the water basin funnel (1) communicate with the inlet of the waste channel (3) or not, so that whether the separated waste is discharged out from thewaste channel (3) or not is controlled. The household food waste treatment device allows kitchen garbage and waste water to be poured into the water basin together and rapidly separates out the kitchen garbage for centralized treatment, and therefore the household food waste treatment device achieves rapid putting, collecting and pouring of the kitchen garbage, saves the waste collecting time costfor people and improves life quality.

Owner:龚程思

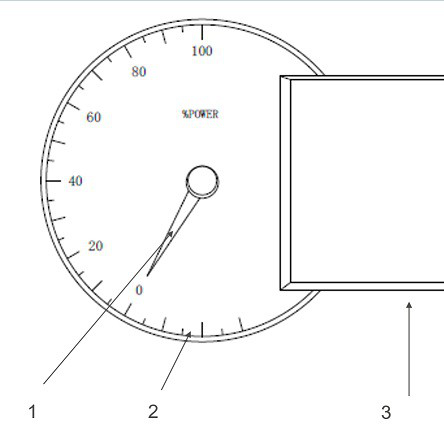

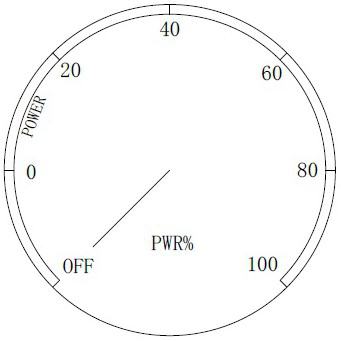

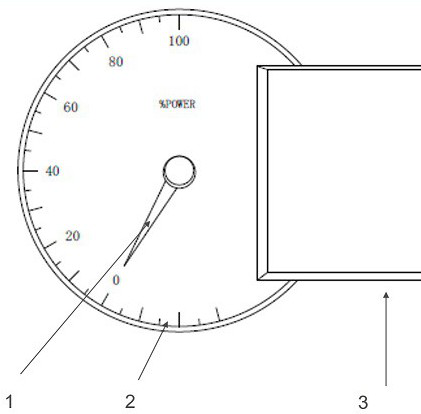

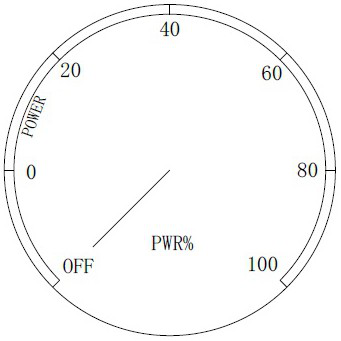

Function display method and system based on electric vehicle power meter

ActiveCN112319222AImprove recognitionStrong replaceability2D-image generationVehicular energy storageElectric machineryElectric vehicle

The invention discloses a function display method and system based on an electric vehicle power meter, and relates to the technical field of driving information display. The method adopts a display mode of numerical indication and a percentage model, a main interface module comprises a central information display area, an output power meter and a speedometer, interface display elements are symmetrical, and the recognition degree is high; the main interface is high in information replaceability and suitable for sharing a platform with a fuel vehicle, the platform borrowing degree is high, energy recovery is reflected through a green model and fonts, an energy flow interface does not need to be repeatedly displayed any more, the main interface is low in use rate, the energy flow interface isomitted, the information providing mode can be optimized, the interaction level of user experience (UE) is reduced, the power meter and the motor power percentage display mode are visual and novel, and based on output power and power percentage signals, the signals can be displayed in the main display interface in an energy quantification mode, and convenience is provided for data checking in theproduction and after-sales process.

Owner:YANFENG VISTEON ELECTRONICS TECH NANJING

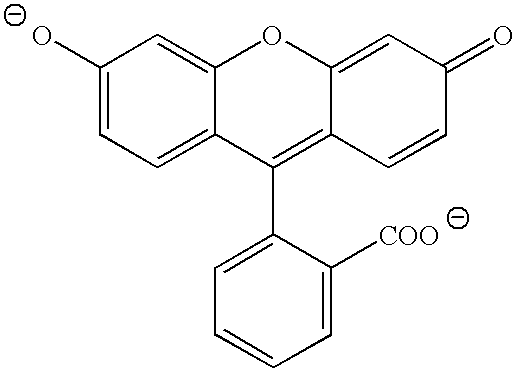

Perfumes

InactiveUS20100234259A1Improve deliveryDetergent perfumesSoap detergent compositionsChemistryDouble bond

The invention provides a laundry cleaning and / or care composition comprising, separately, a photo-bleach which is not a pro-fragrance (and which is preferably a singlet oxygen photo-bleach) and a pro-fragrance which is not itself a photo-bleach. The pro-fragrance preferably comprises at least one, non-aromatic, C—C double-bond, more preferably at least two C—C double-bonds, and can be advantageously be a commonplace lipid, more preferably a plant-oil. Suitable photo-bleaches comprise water-soluble phthalocyanine compounds. Preferably, the composition further comprises a shading dye to give an overall blue or violet hue to articles laundered, an optional fluorescer and / or a fabric-substantive polymer as a perfume deposition aid. Also disclosed is a method of laundering fabrics using said composition and the use of said composition to perfume fabrics.

Owner:CONOPCO INC D B A UNILEVER

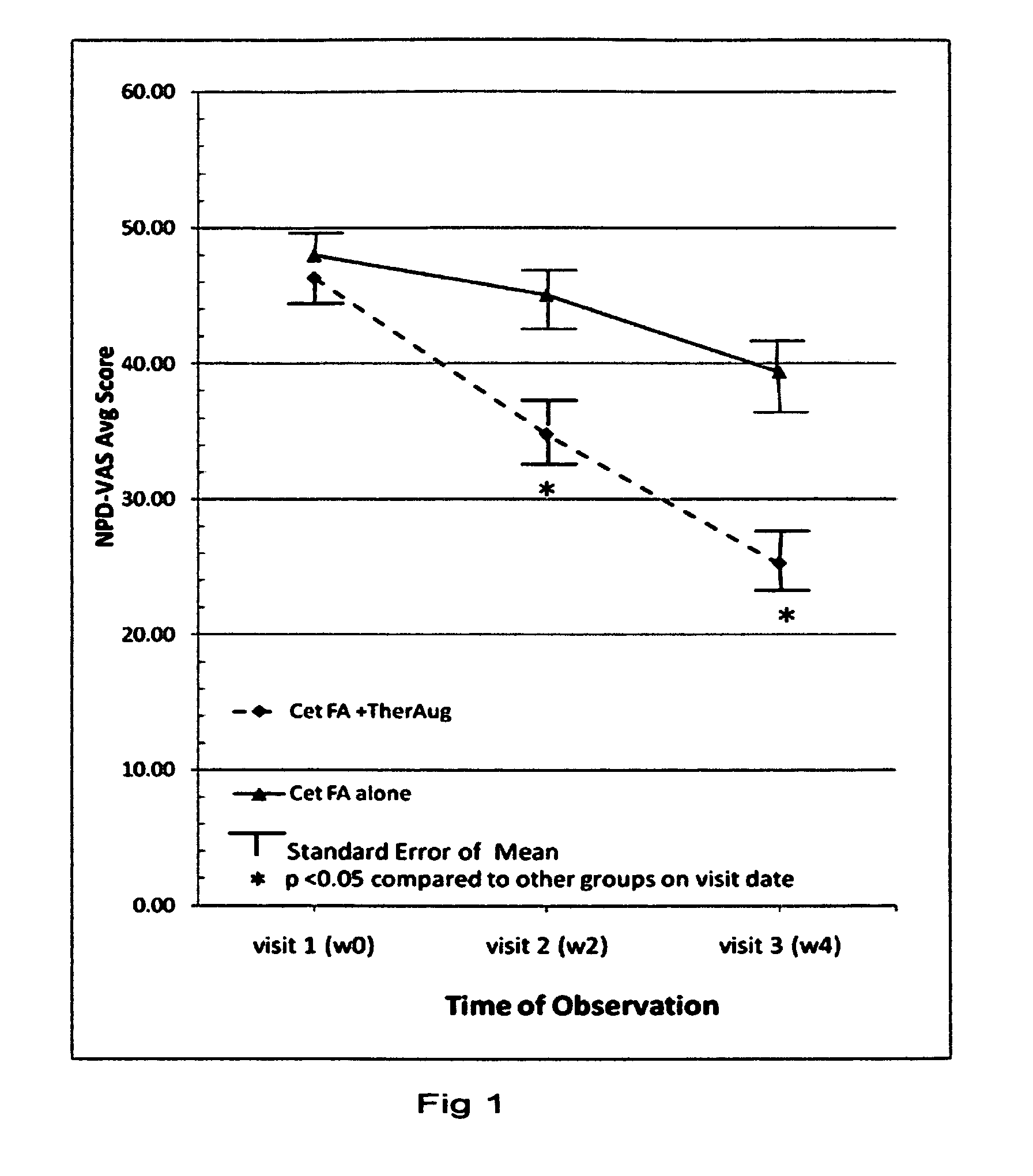

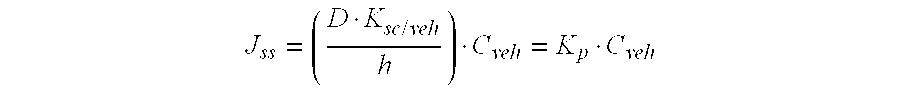

Transdermal Delivery of Medicinal Cetylated Fatty Esters using Phonophoresis or Iontophoresis

The use of phonophoresis or iontophoresis to enhance transdermal delivery of medicinal Cetylated fatty esters when applied in cream or gel compositions is disclosed. These compositions provide hydrophilic salt forms and penetration-enhancing vehicles that work in conjunction with phonophoresis or iontophoresis to increase the efficacy of the medicinal actives.

Owner:BARATHUR RAJ R +1

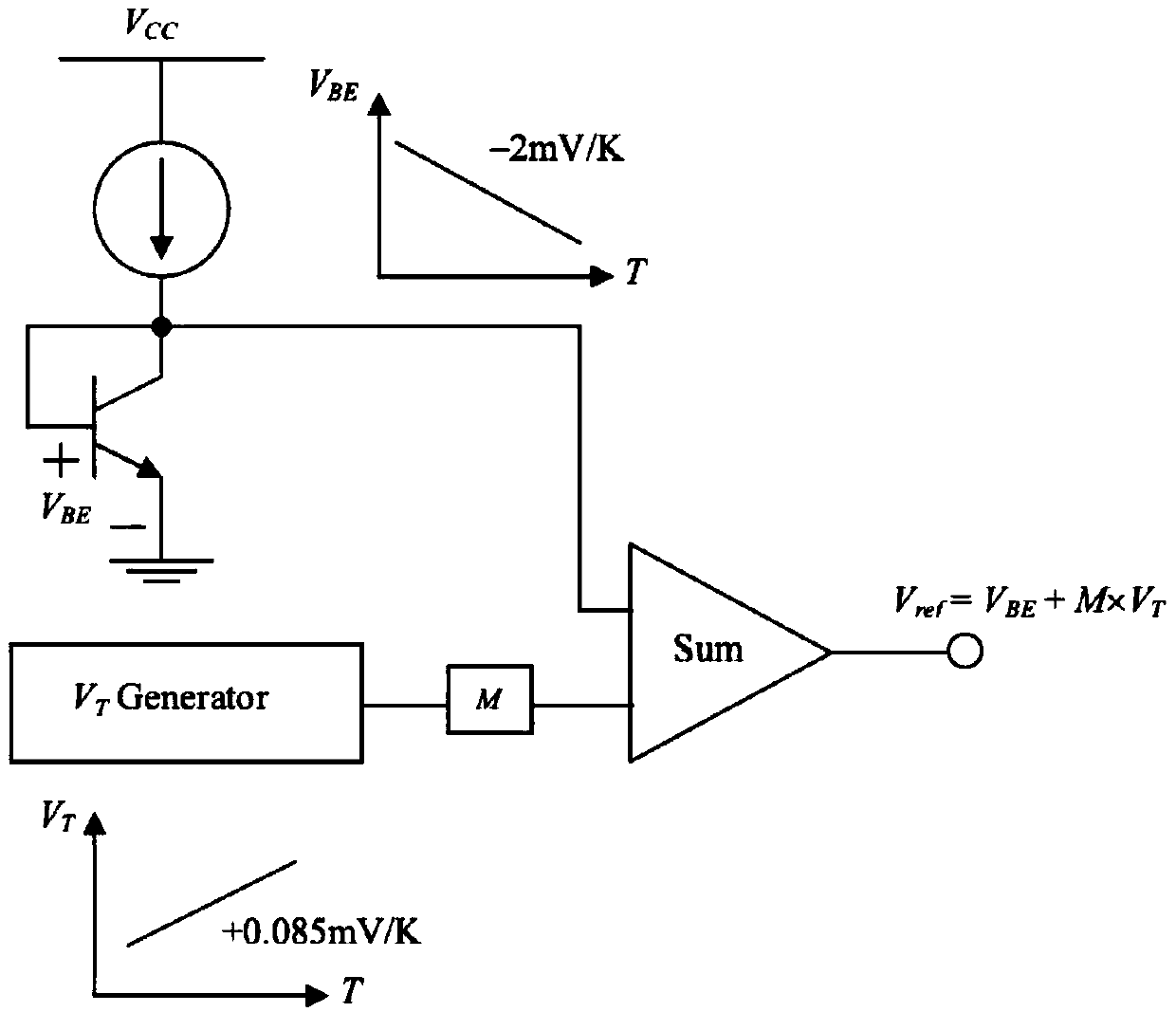

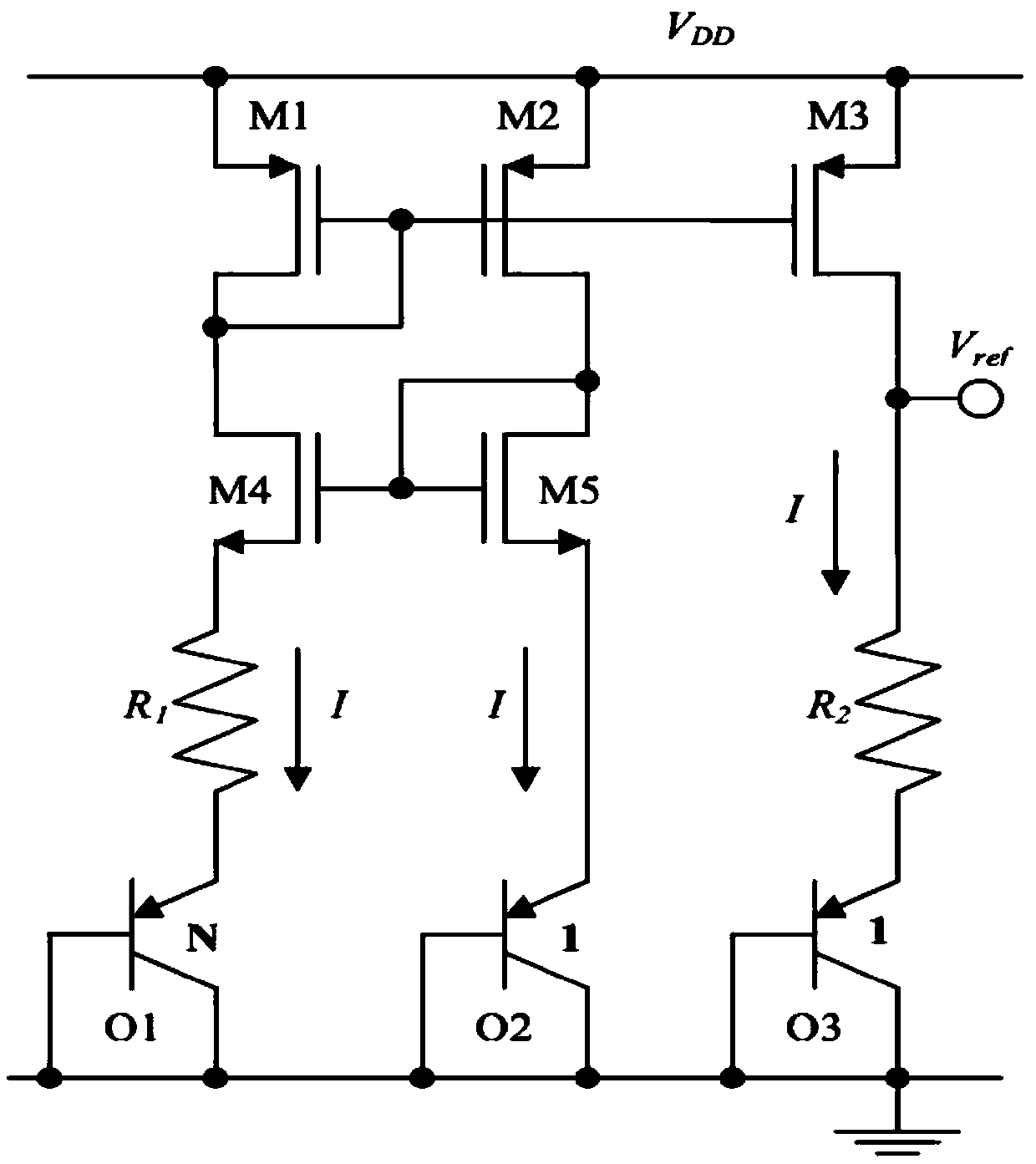

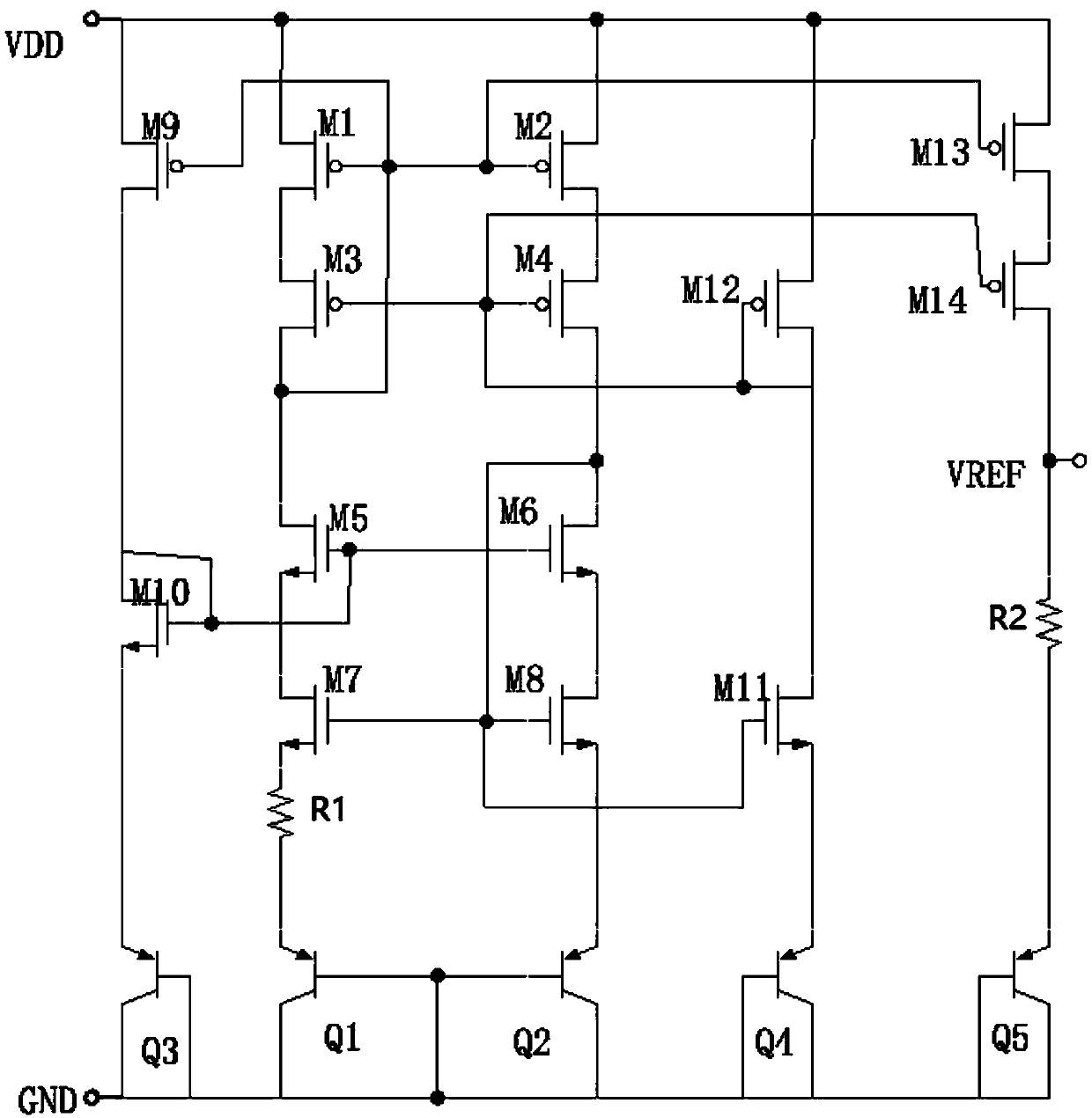

Band-gap reference voltage source capable of improving upper limit of power supply voltage fluctuation

InactiveCN110647206AImprove deliveryIncreased supply voltage rangeElectric variable regulationPhysicsIntegrated circuit

The invention discloses a band-gap reference voltage source capable of improving an upper limit of power supply voltage fluctuation. The band-gap reference voltage source comprises an MOS transistor M1, an MOS transistor M2, an MOS transistor M3, an MOS transistor M4, an MOS transistor M5, an MOS transistor M6, an MOS transistor M7, an MOS transistor M8, an MOS transistor M9, an MOS transistor M10, an MOS transistor M11, an MOS transistor M12, an MOS transistor M13, an MOS transistor M14, a triode Q1, a triode Q2, a triode Q3, a triode Q4, a triode Q5, a resistor R1 and a resistor R2. A three-stage cascode current mirror technology is adopted, and furthermore, a gate bias supply method is improved, so that the power supply voltage range supported by a band-gap reference circuit is expandedto the maximum extent, the service life of the circuit is greatly prolonged, the service environment of the circuit is expanded and the circuit can be flexibly integrated into various integrated circuit chips.

Owner:CHONGQING PAIXINRUWEI TECH CO LTD

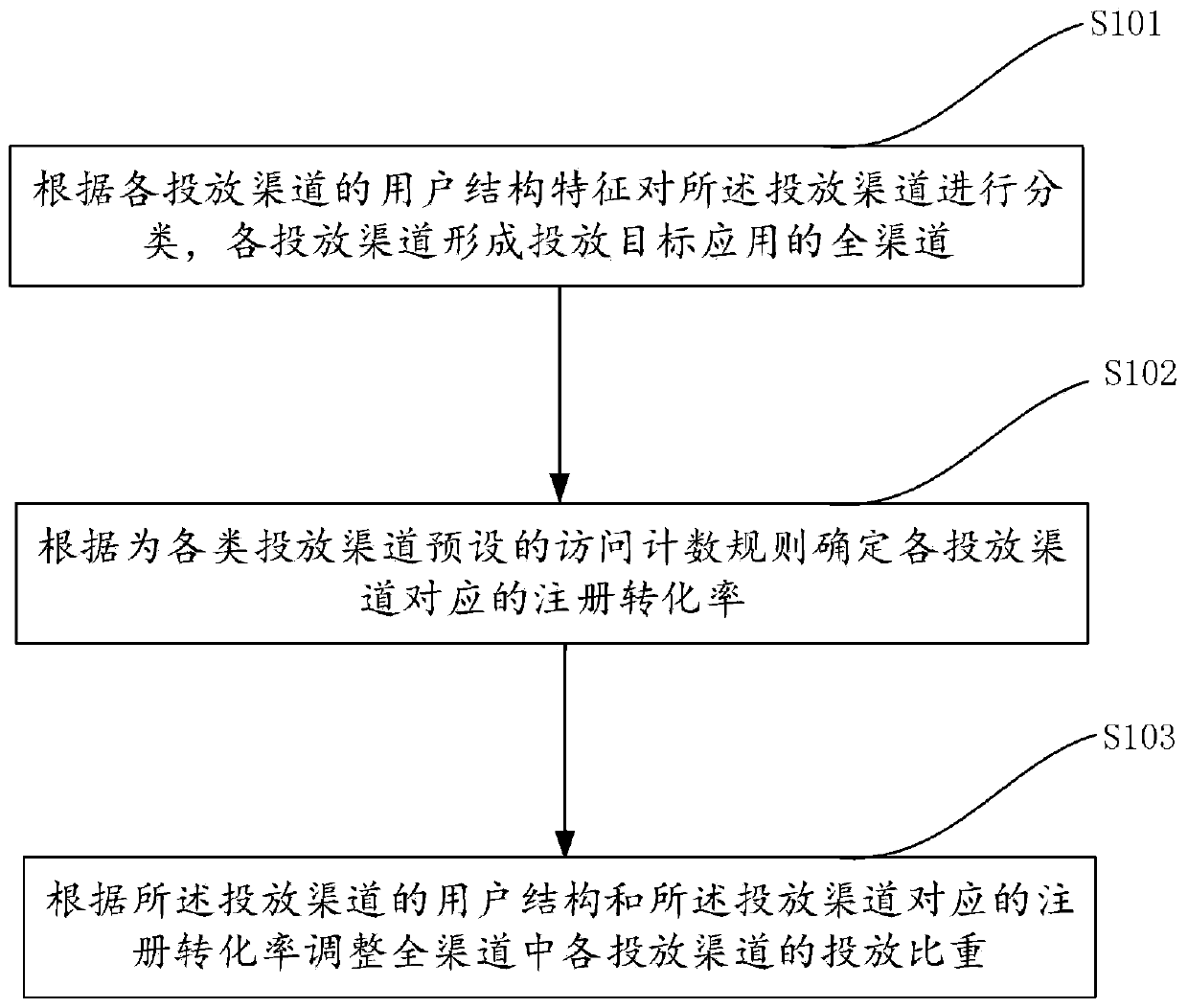

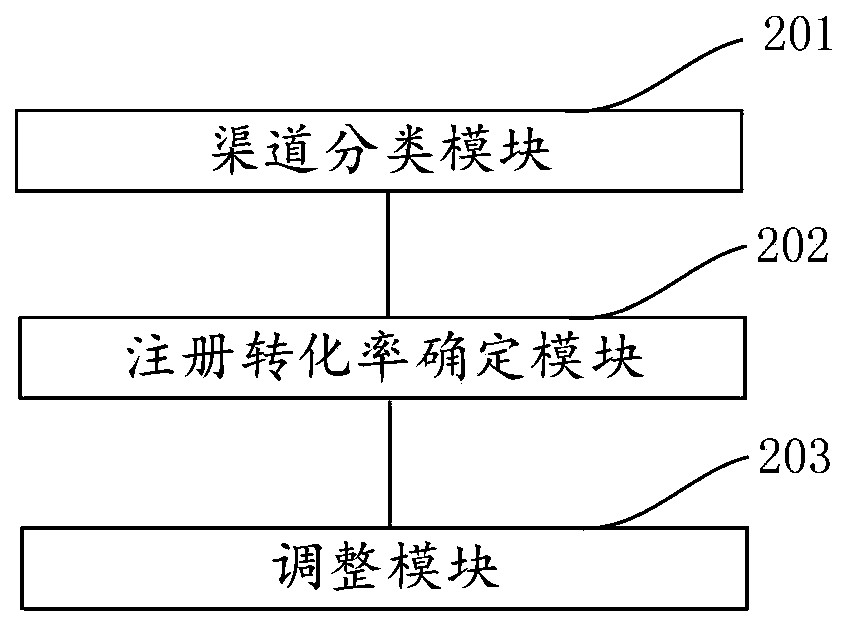

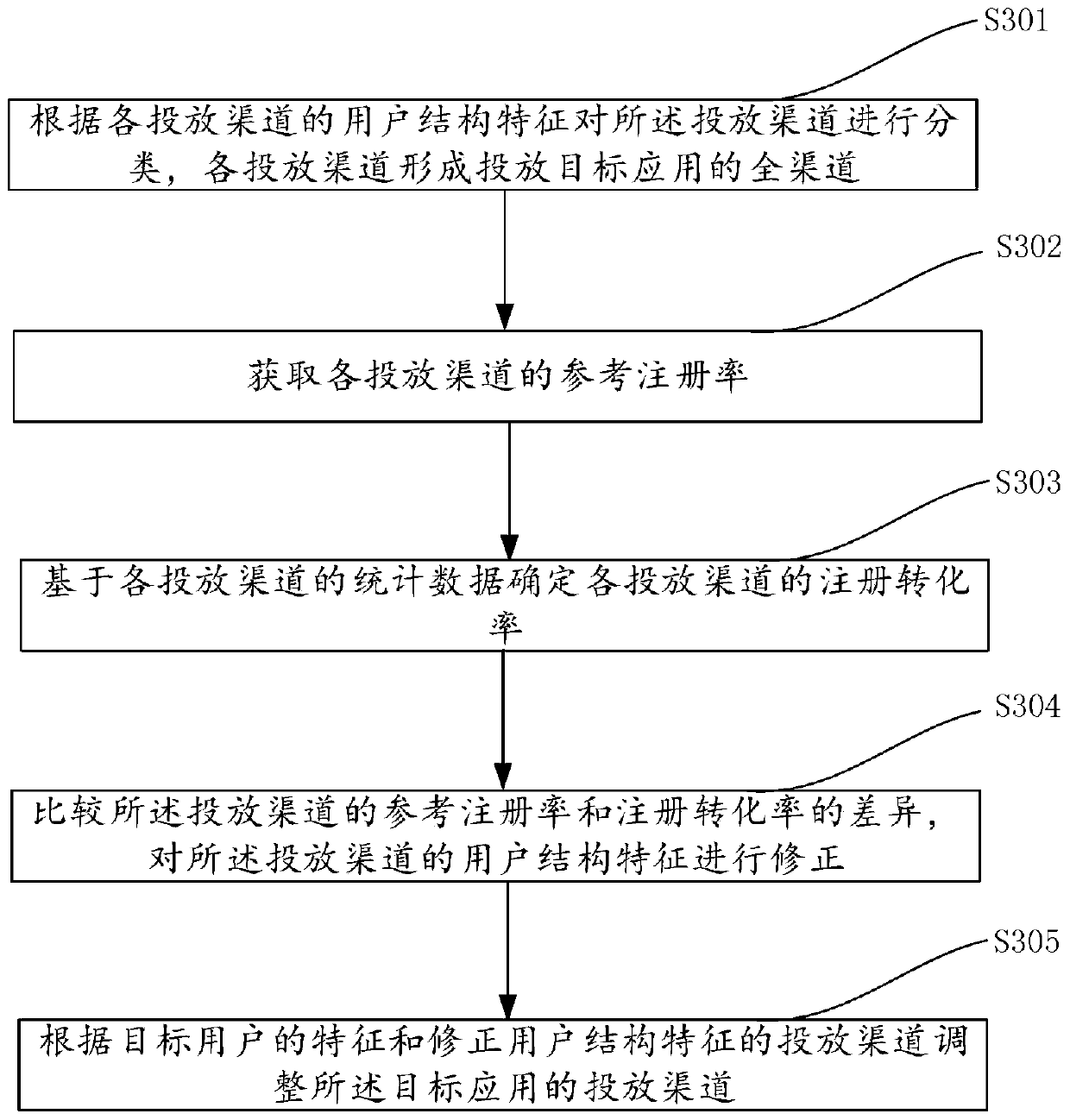

Method and device for controlling delivery channel based on monitoring delivery efficiency and electronic equipment

PendingCN110648181AImprove deliveryImprove the delivery effectAdvertisementsControlled deliveryElectrical and Electronics engineering

The invention provides a method for controlling a delivery channel based on monitoring of delivery efficiency. The registration conversion rate of each delivery channel is monitored; to describe the expectation of the delivery effect of each delivery channel by referring to the registration rate; thus, the registration conversion rate and the reference registration rate are combined; whether eachthrowing channel reaches an expected throwing effect or not can be monitored. The reference registration rates are set for the different delivery channels respectively, so that the delivery efficiencycan be used as a unified standard for evaluating the delivery effect of each delivery channel, the delivery channel of the target application can be controlled according to the delivery efficiency ofeach delivery channel, and the delivery effect is improved.

Owner:上海淇玥信息技术有限公司

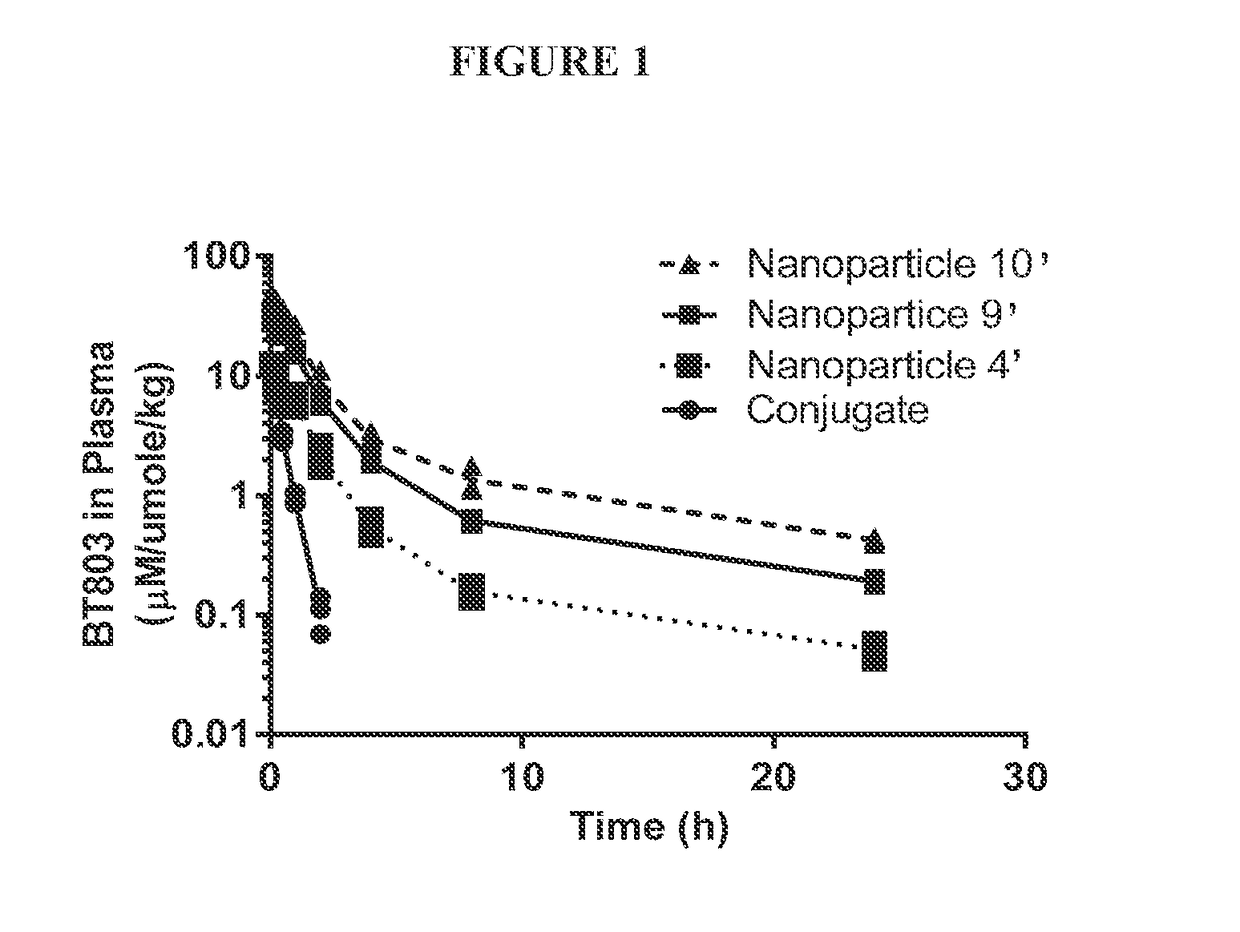

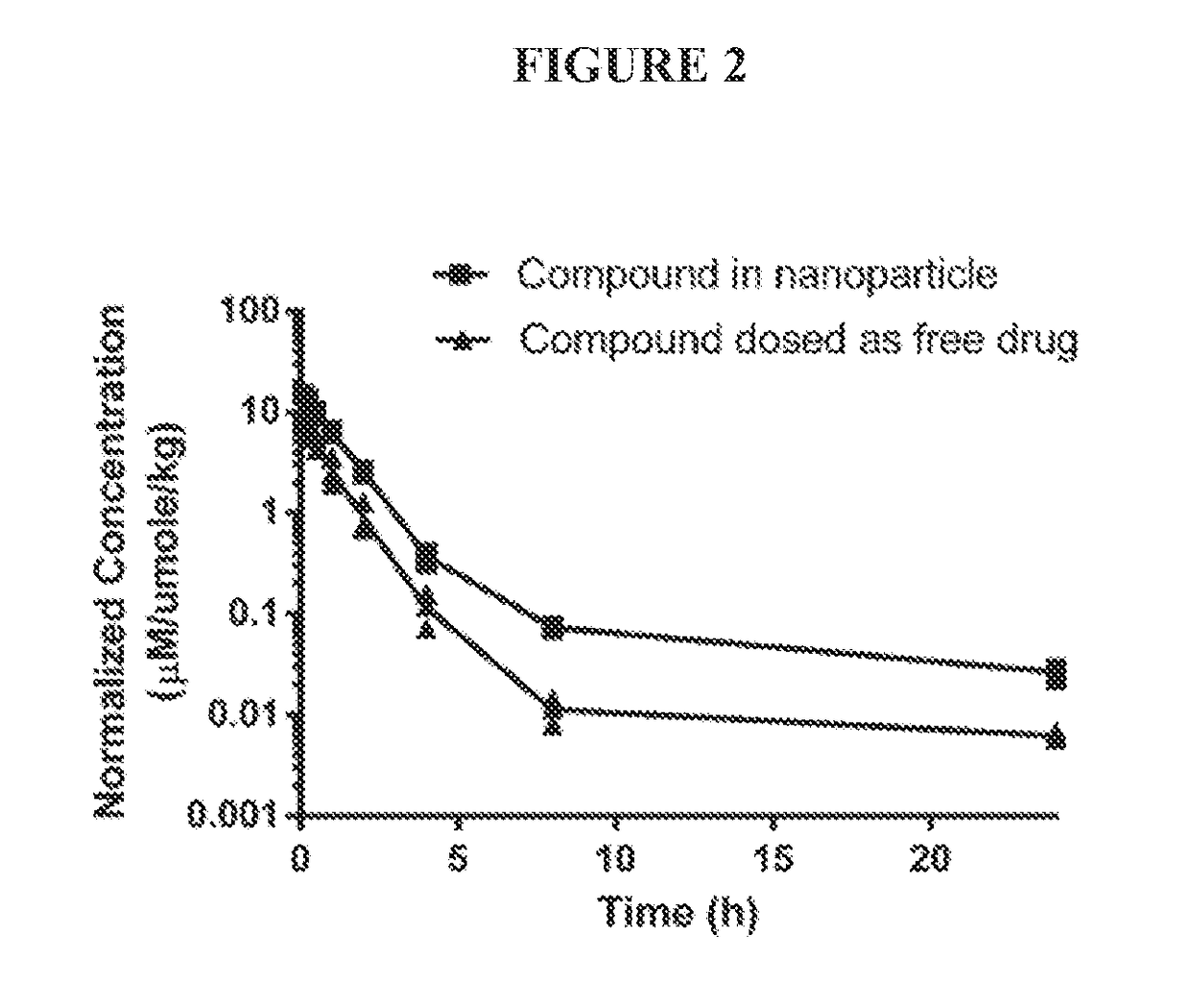

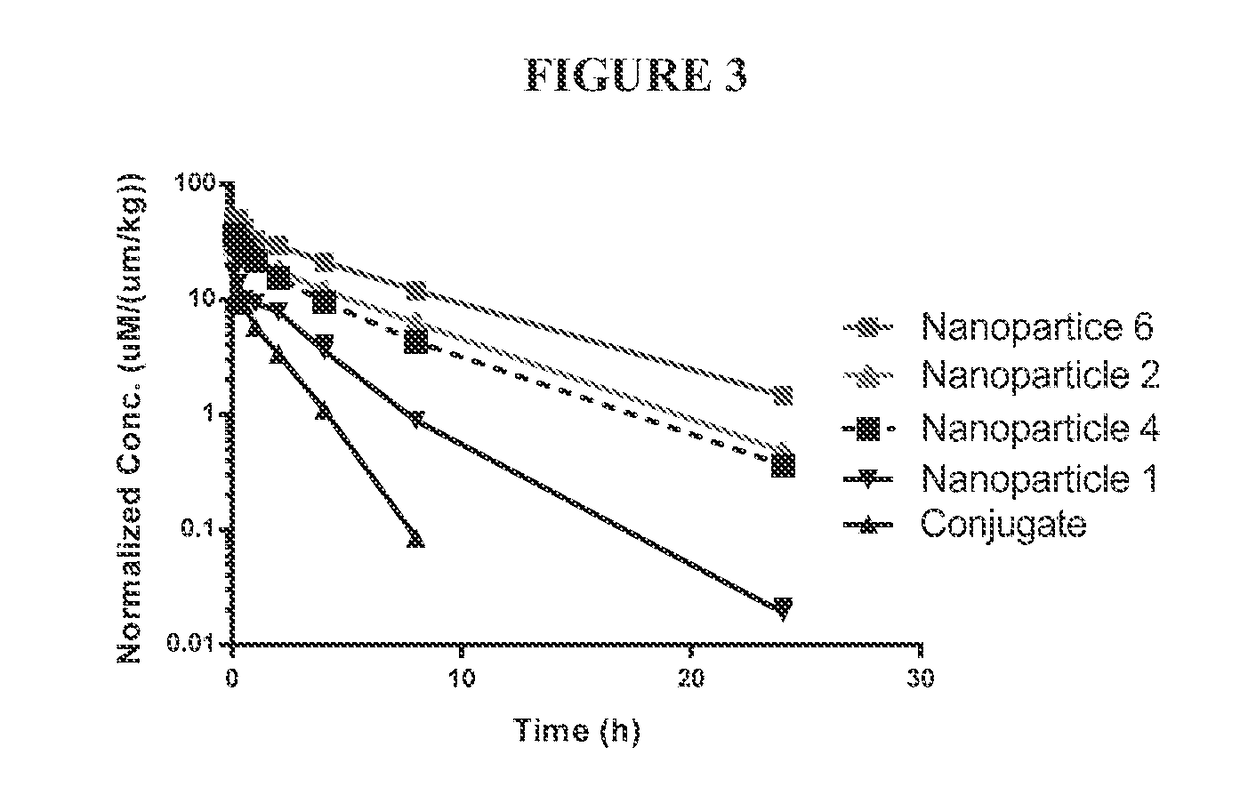

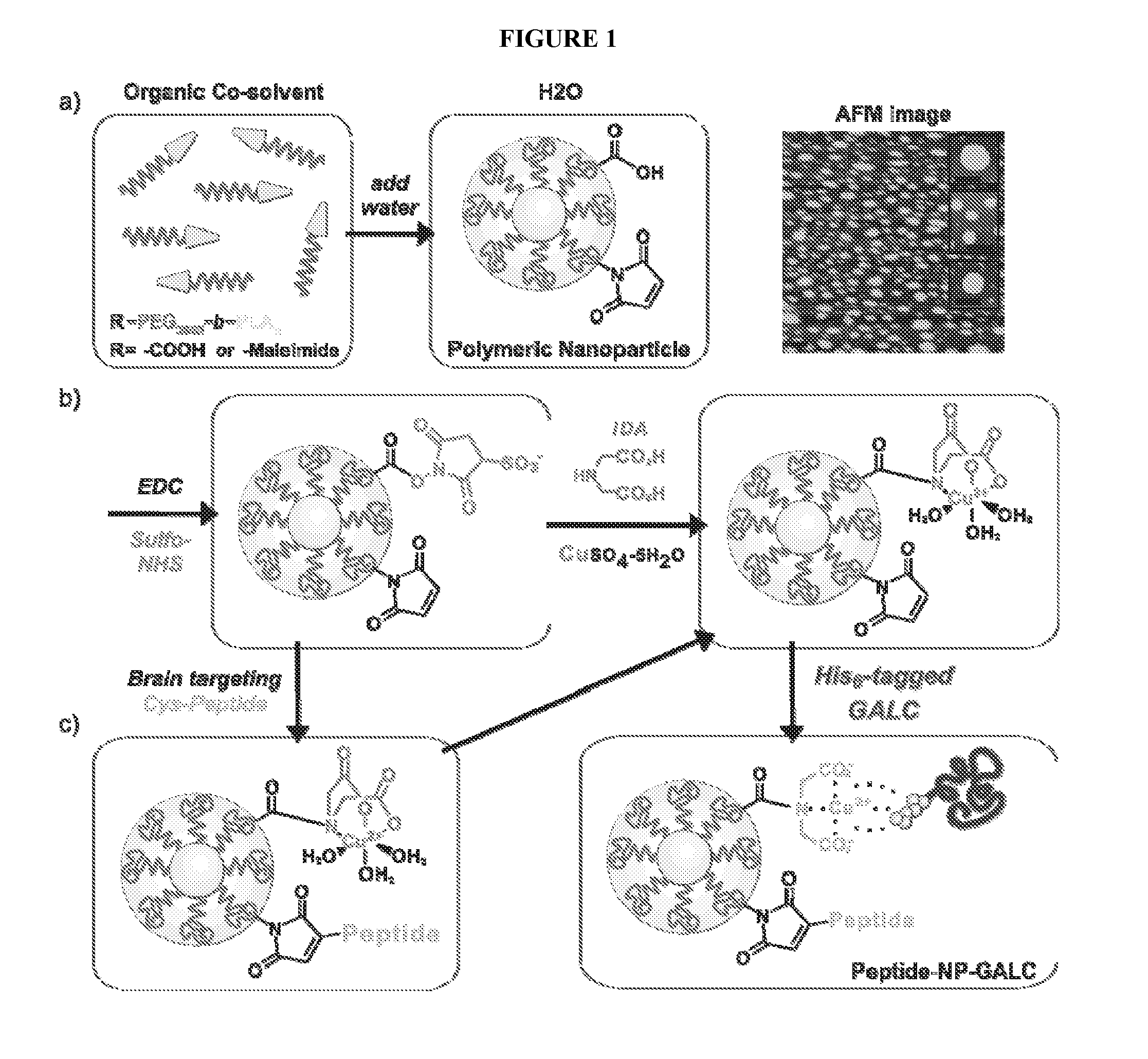

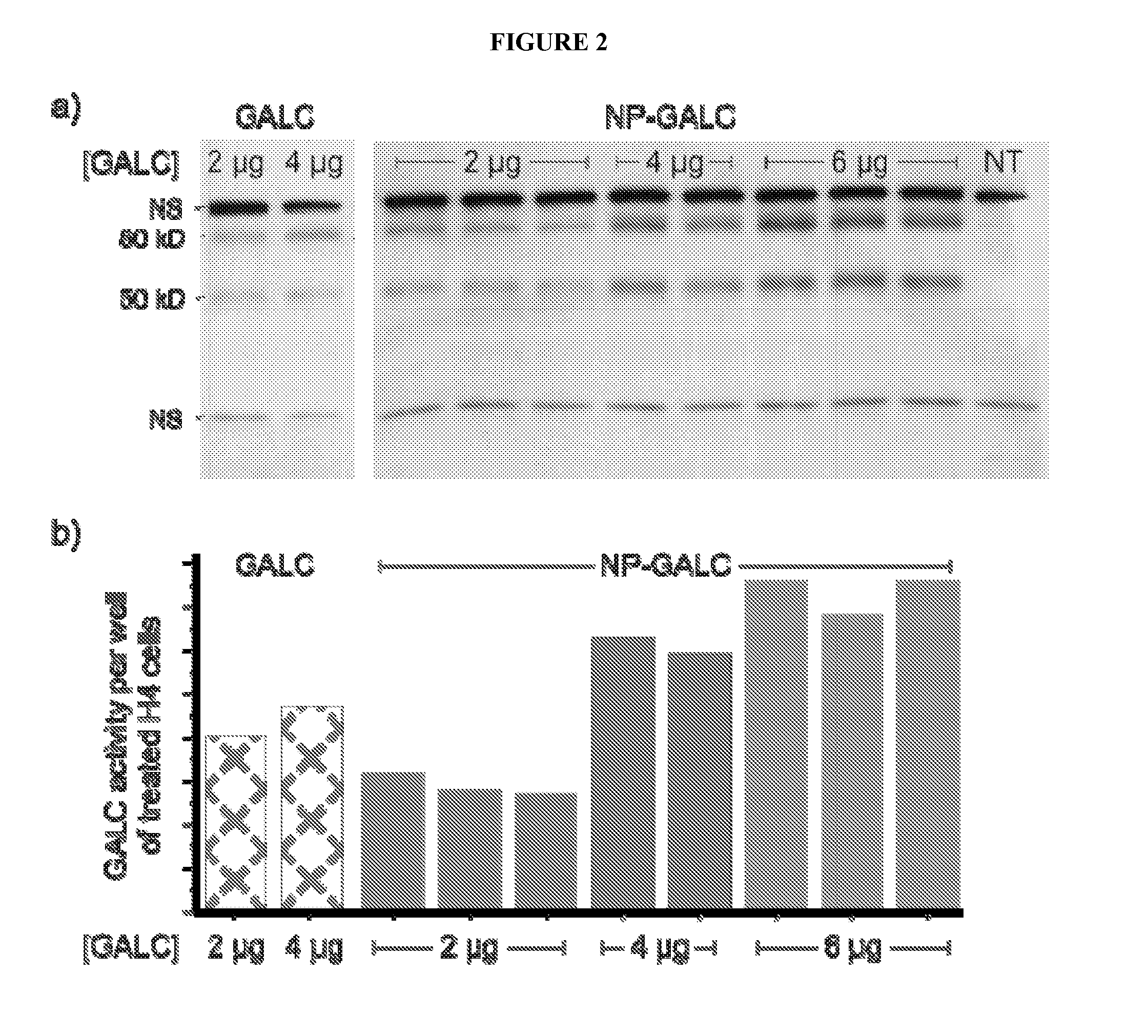

Methods and materials for delivering molecules

ActiveUS20120040432A1Increase half-lifeImprove deliveryPowder deliveryNervous disorderHalf-lifeBioavailability

This document relates to methods and materials involved in delivering molecules to a mammal. For example, methods and materials for using nanoparticles to increase the half-life and the bioavailability of molecules administered to a mammal are provided.

Owner:MAYO FOUND FOR MEDICAL EDUCATION & RES

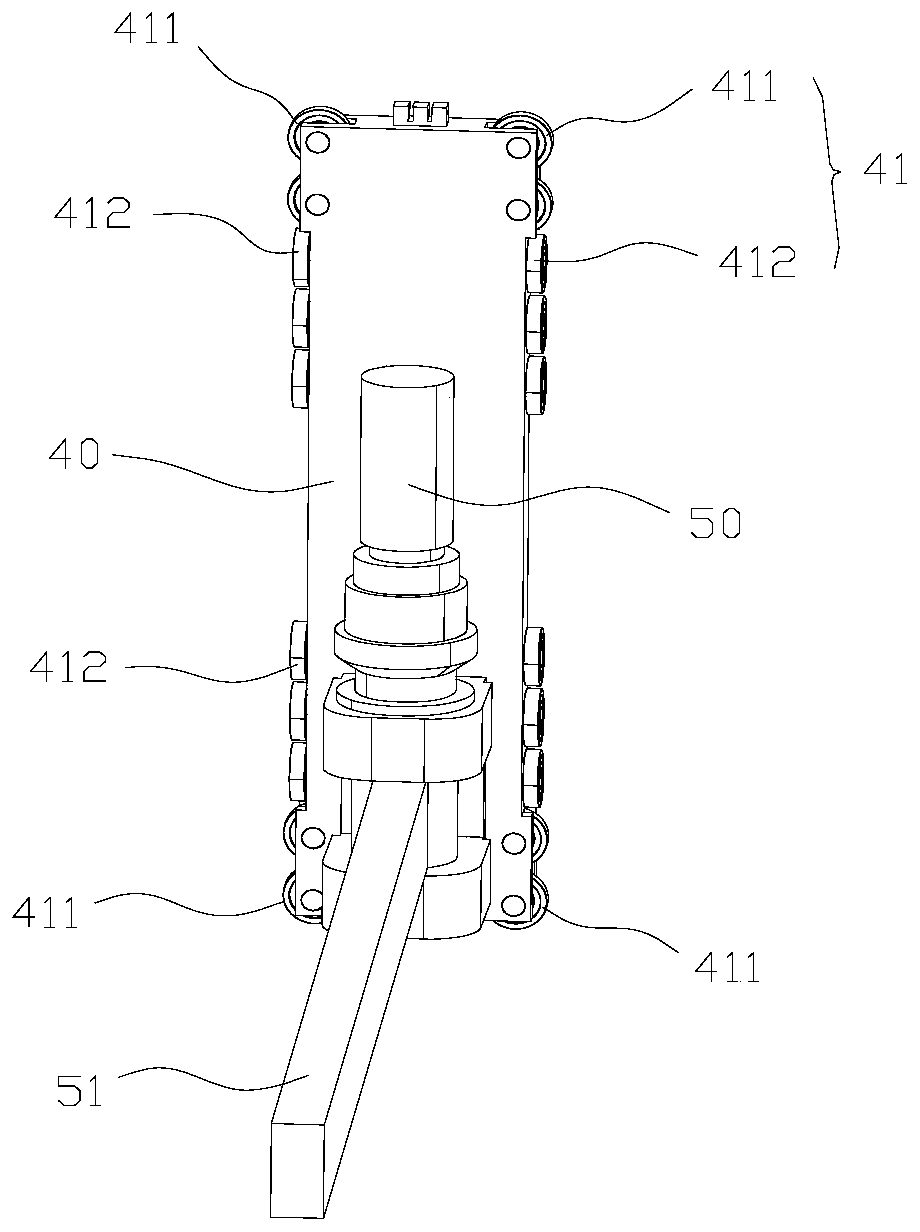

Automatic boxing equipment of apple cleaning line

ActiveCN112977934ARealize automatic packingAchieve freedom of movementClimate change adaptationPackaging fruits/vegetablesRobot handCarton

The invention relates to automatic boxing equipment of an apple cleaning line. The automatic boxing equipment of the apple cleaning line comprises an apple conveying belt and a supporting frame, a mechanical arm is arranged on the supporting frame, a lifting device is arranged on the mechanical arm, a clamping jaw is arranged at the end, close to the apple conveying belt, of the lifting device, the clamping jaw is arranged above the apple conveying belt, and a carton conveying belt is arranged on one side of the apple conveying belt. Cleaned and processed apples are finally conveyed to the apple conveying belt, the apples are conveyed through the apple conveying belt, at the moment, the mechanical arm is started, the mechanical arm moves in the plane, the clamping jaw freely moves in the X-axis direction, the Y-axis direction and the Z-axis direction in cooperation with lifting of the lifting device, and the cleaned and processed apples are clamped through the clamping jaw; and meanwhile, the carton conveying belt conveys apple cartons in a stepping mode, the clamping jaw clamps the apples into the apple cartons, automatic boxing of the apples is achieved, and the automatic boxing equipment of the apple cleaning line has the effect of reducing the labor intensity of operators in the apple boxing stage.

Owner:栖霞市沃尔德果蔬冷藏有限公司

Method and device for providing browser

ActiveCN103514021BImprove deliveryHardware monitoringProgram loading/initiatingRelevant informationWeb page

The present invention discloses a method and device for providing a browser. The method for providing a browser includes: starting a first browser for a user and monitoring the browsing process of web pages through the first browser; and obtaining the user's browsing process through the first browser. The browser browses the browsing process information of the web page; determines whether the browsing process information triggers the preset trigger condition; if the browsing process information triggers the preset trigger condition, provides the user with relevant information of the second browser. Through this method, when the user uses the first browser, relevant information of the second browser can be provided to the user in response to deficiencies in the browsing process. The user can install the second browser based on the relevant information of the second browser, thereby providing a more convenient browser provision method.

Owner:BEIJING QIHOO TECH CO LTD

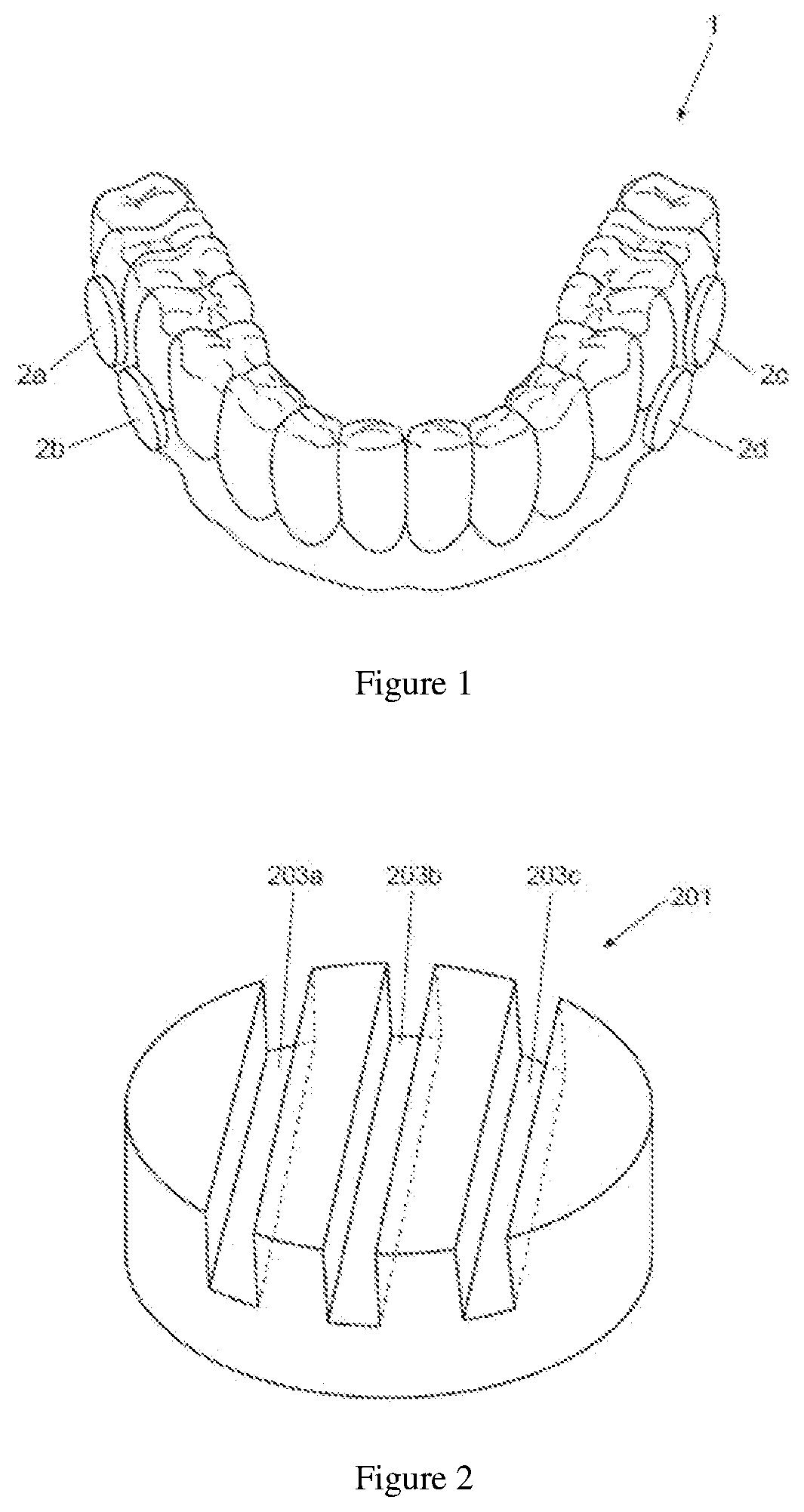

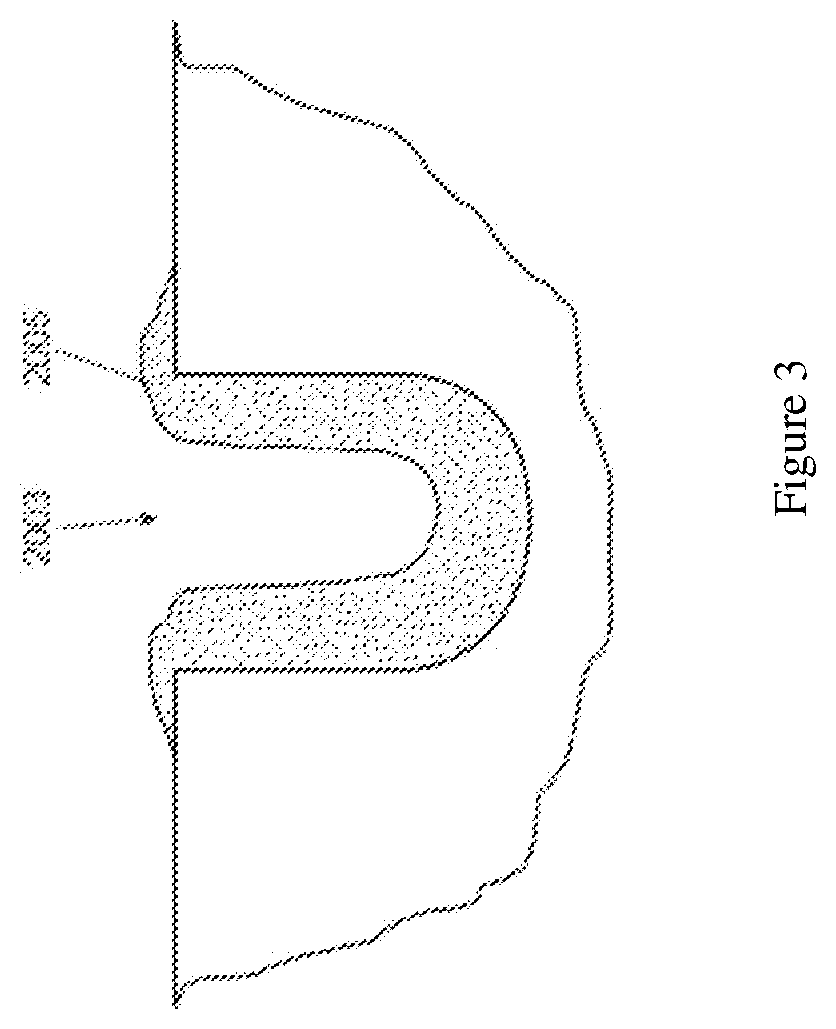

Dentifrice compositions for treatment of dental biofilm

PendingUS20210093527A1Optimize efficacyImprove deliveryCosmetic preparationsToilet preparationsChemistryToothpaste

Dentifrice compositions comprising zinc lactate, glycine, and fluoride ion are provided for treating dental plaque biofilm.

Owner:THE PROCTER & GAMBNE CO

Media advertisement putting system based on vehicle identification and control method thereof

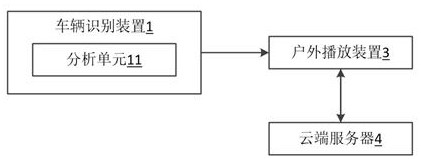

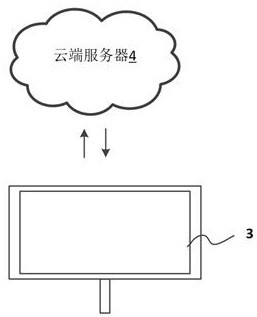

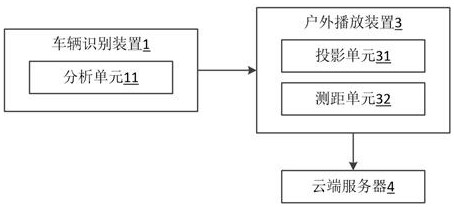

PendingCN111935262AImprove targetingImprove communication effectRoad vehicles traffic controlAdvertisingTelecommunicationsIdentification device

The invention discloses a media advertisement putting system based on vehicle identification and a control method thereof. The media advertisement putting system comprises a vehicle identification device, a putting device, an outdoor playing device and a cloud server, wherein the vehicle identification device is used for identifying the vehicle information; the vehicle identification device is connected with the outdoor playing device; the outdoor playing device is arranged on the roadside and is used for playing specified media information; the outdoor playing device is connected with the cloud server and performs data communication with the cloud server; the cloud server provides media information for the outdoor playing device, wherein the vehicle identification device identifies vehicle information of a vehicle parked in a propagation area of the outdoor playing device, the vehicle identification device further comprises an analysis unit, and the analysis unit matches interest fields of personnel according to the vehicle information; the analysis unit acquires the field of interest of personnel and outputs the field of interest to the outdoor playing device; the outdoor playingdevice plays the media information matched with the field of interest of the personnel to the vehicle.

Owner:杭州云端文化创意有限公司

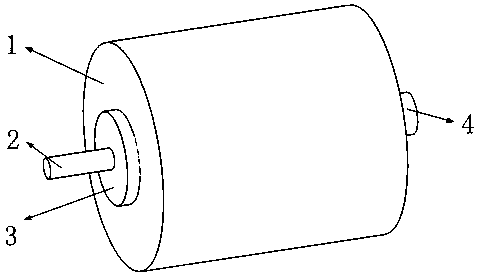

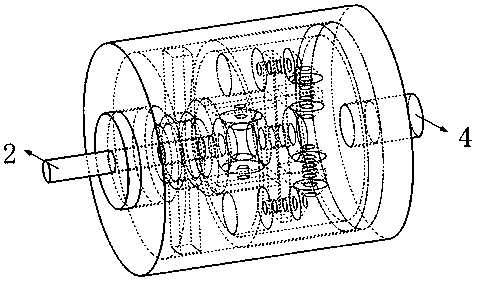

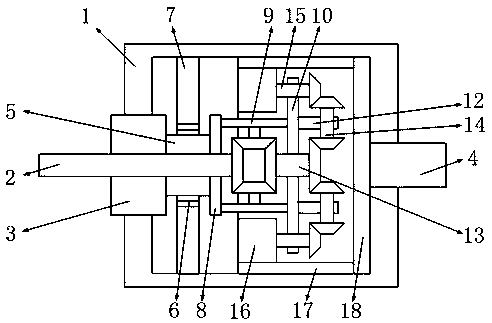

Impact-resistant speed changer based on volute spiral spring

ActiveCN108413018AExtended service lifeImprove deliveryGearingGear vibration/noise dampingClutchVariator

The invention belongs to the technical field of speed changers and particularly relates to an impact-resistant speed changer based on a volute spiral spring. The impact-resistant speed changer comprises a first shell body, an input shaft, a connection mechanism, an output shaft, a one-way clutch ring, a first shaft, a gear ring, the volute spiral spring and the like. By using the volute spiral spring in the connection mechanism to realize variable speed drive, the speed changer has the beneficial effects that the effect of variable speed is realized through a simple structure; and meanwhile, due to the fact that the pull force provided by the volute spiral spring is continuous, physical impact damage cannot be generated at the moment of gear shifting and speed changing, and in this way, the service life of the speed changer is greatly prolonged. A gear is made to rotate automatically through meshing of a drive tapered tooth and other tapered teeth, and transfer of large torque is realized; and besides, the gear is made to perform revolution around the gear ring under the gear shifting and speed increasing effect of the connection structure, and transfer of a large rotation speed isrealized under the dual effect of automatic rotation and revolution of the gear. The impact-resistant speed changer is simple in structure and has a good use effect.

Owner:临沂威尔森新型材料有限公司

A function display method and system based on electric vehicle power meter

ActiveCN112319222BHigh borrowingHigh replaceability2D-image generationVehicular energy storageHigh energyElectric machinery

Owner:YANFENG VISTEON ELECTRONICS TECH NANJING

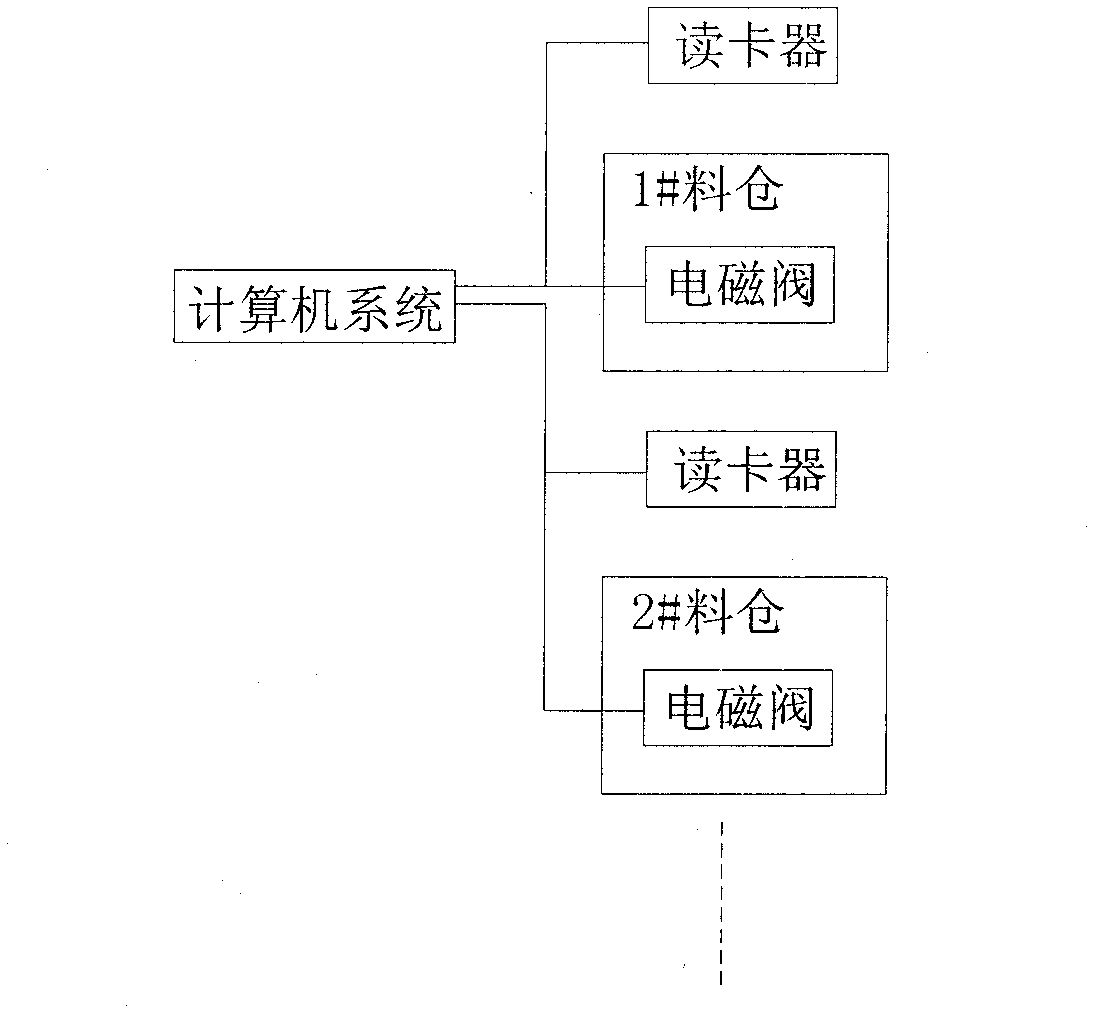

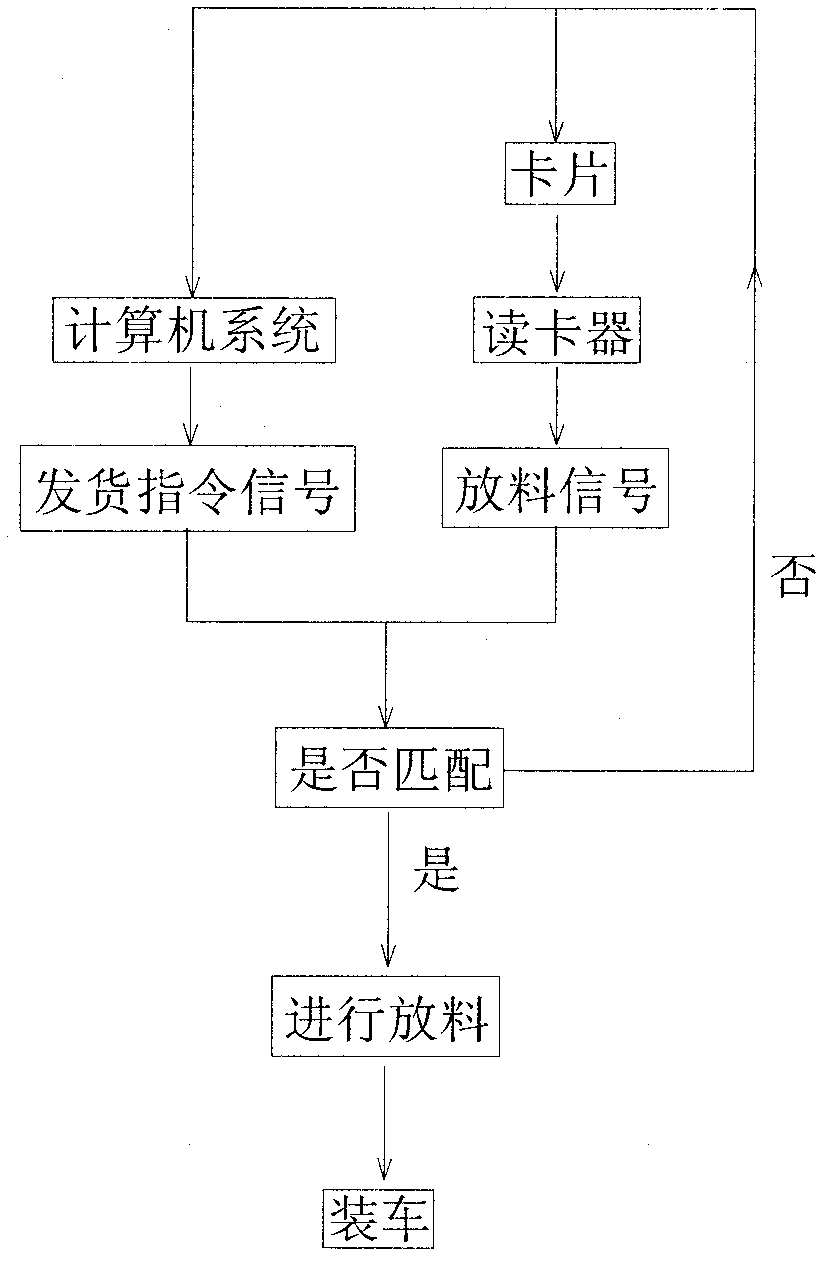

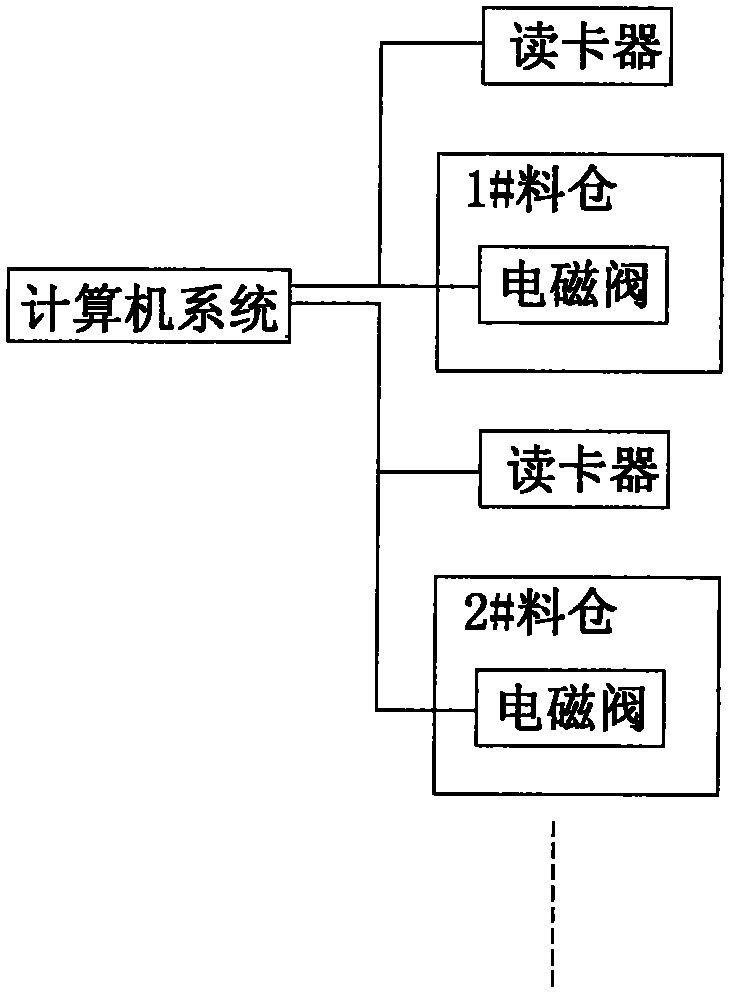

Packaging mistake-proofing device and method

InactiveCN102219113AAccurate operationImprove deliveryControl devices for conveyorsCard readerControl unit

The invention relates to a packaging mistake-proofing device and method. The device comprises more than one group of card reading units, each card reading unit comprises a card reader and a card which is uniquely matched with the card reader; meanwhile, the card reader is respectively connected with a control unit and a discharging actuating device, and the discharging actuating device is arranged on a storage bin which is uniquely matched with the card. The method comprises the following steps of: reading information of the card matched with the card reader corresponding to the designated storage bin by the card reader after the control unit generates a shipping instruction signal for the designated storage bin, outputting a discharging signal, comparing the shipping instruction signal and the discharging signal, if the two signals are matched, carrying out discharging operation by the discharging actuating device, otherwise, not starting the discharging actuating device if the two signals are not matched. By adopting the packaging mistake-proof device and method provided by the invention, faulty operation in a shipping and discharging process of an enterprise for producing black carbon can be effectively prevented, and the shipping and discharging operational efficiency can be improved.

Owner:SUZHOU BAOHUA CARBON BLACK

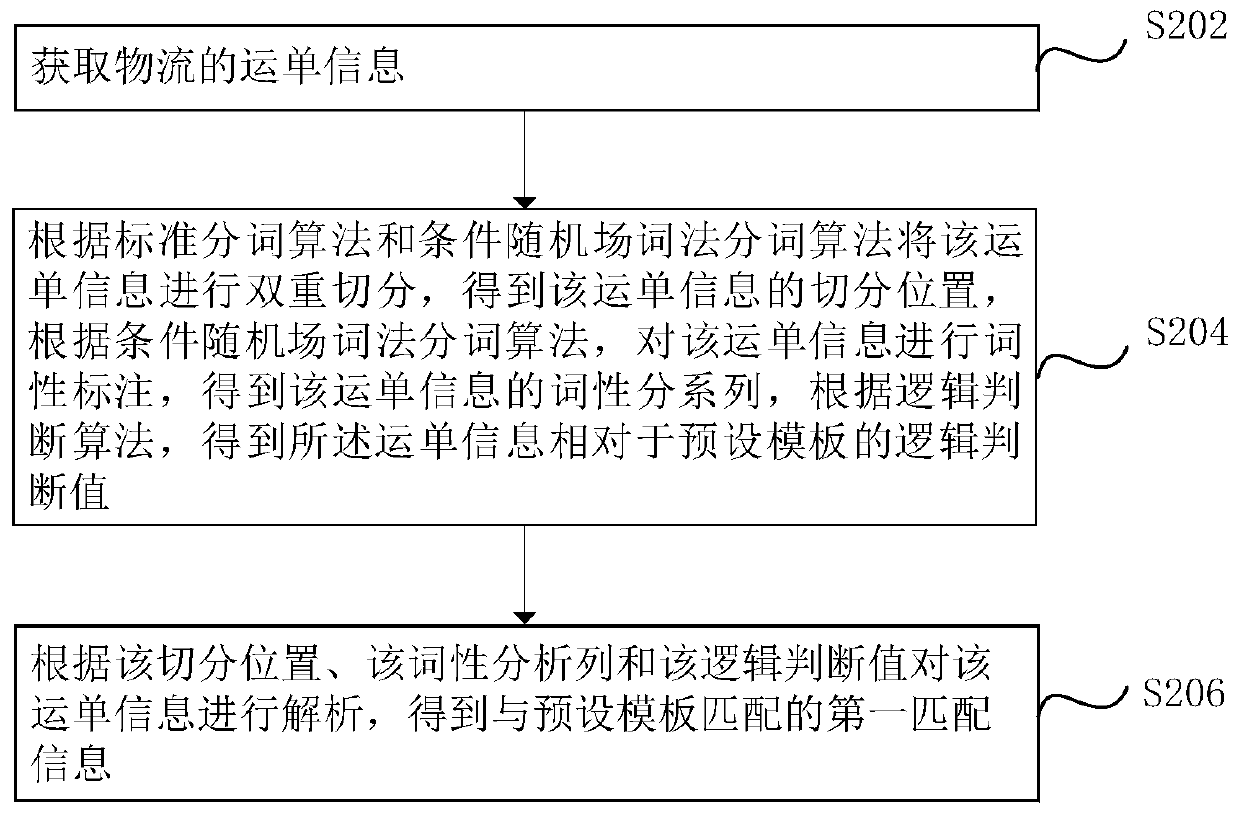

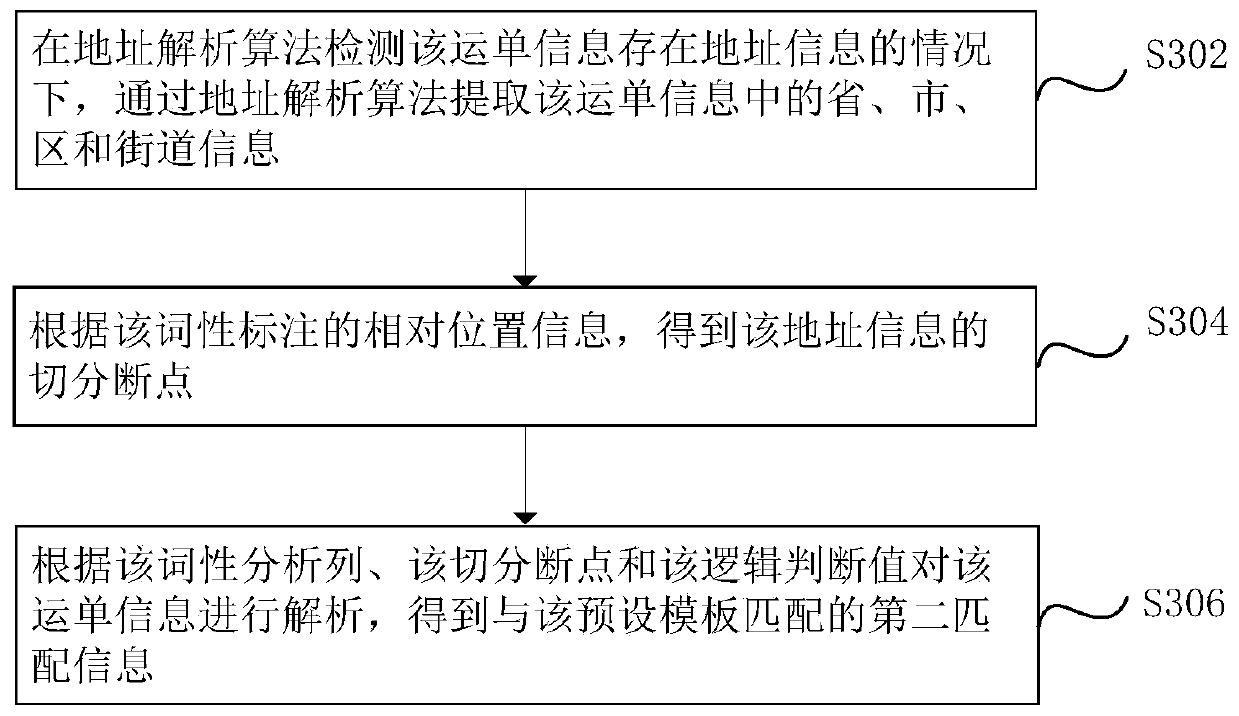

Logistics information identification method and device, computer device and storage medium

PendingCN110826318ASolve the low recognition accuracyEasy to identifyNatural language data processingLogisticsConditional random fieldPart of speech

The invention discloses a logistics information identification method and a device, a computer device and a storage medium. The method comprises the steps of obtaining waybill information of logistics, performing dual segmentation on the waybill information according to a standard word segmentation algorithm and a conditional random field lexical word segmentation algorithm; obtaining a segmentation position of the waybill information; according to a conditional random field lexical word segmentation algorithm, performing part-of-speech tagging on the waybill information; obtaining part-of-speech classification series of the waybill information; according to a logic determination algorithm, obtaining a logic judgment value of the waybill information relative to a preset template; analyzingthe waybill information according to the segmentation position, the part-of-speech analysis column and the logic judgment value; according to the method and the device, the problem of low logistics information identification accuracy is solved, the logistics waybill information identification degree is improved, the cargo distribution and receipt auditing efficiency is improved, and meanwhile, data support can be provided for later logistics service and business development planning.

Owner:ZHEJIANG NUMBER CHAIN TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com