Non-oxidizing normalizing process of steel pipe and device

A non-oxidizing, steel pipe technology, used in manufacturing tools, heat treatment equipment, furnaces, etc., can solve the problems of inability to obtain F+P structure, difficult to rapidly cool steel pipes, etc., to improve the timely delivery rate, improve efficiency, and reduce costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

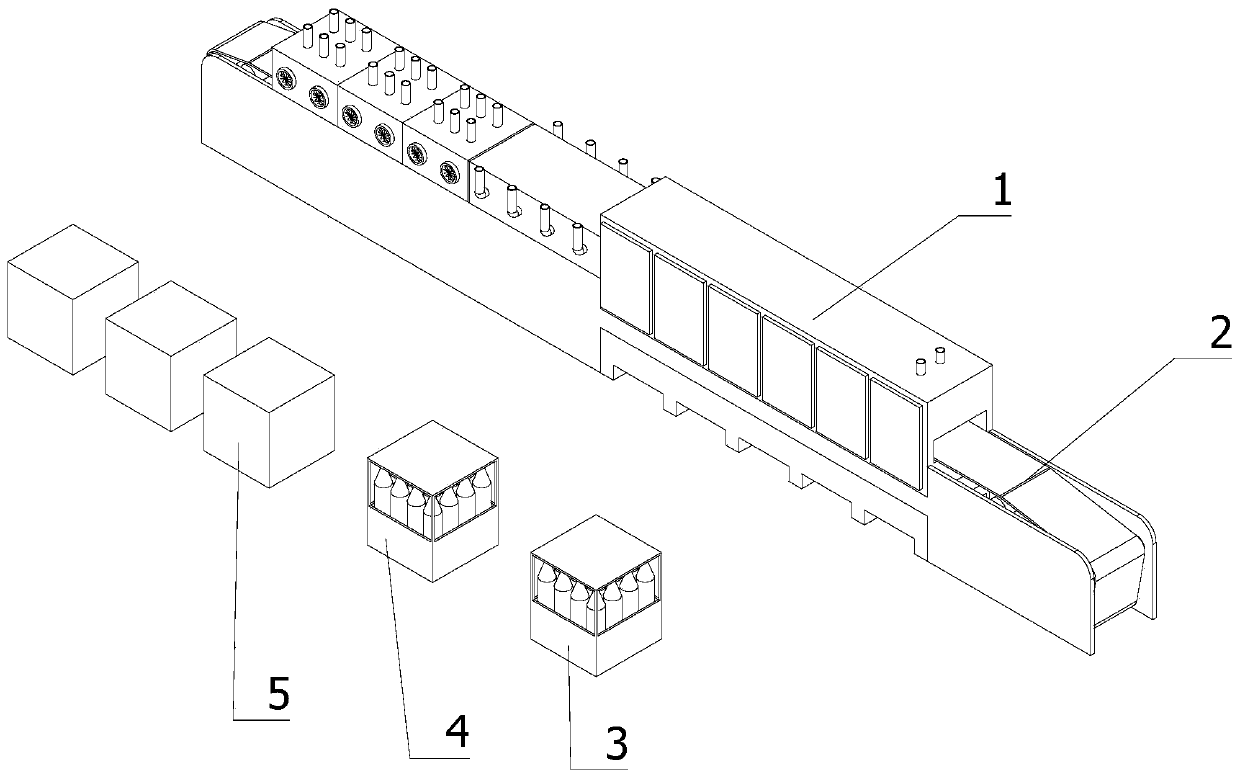

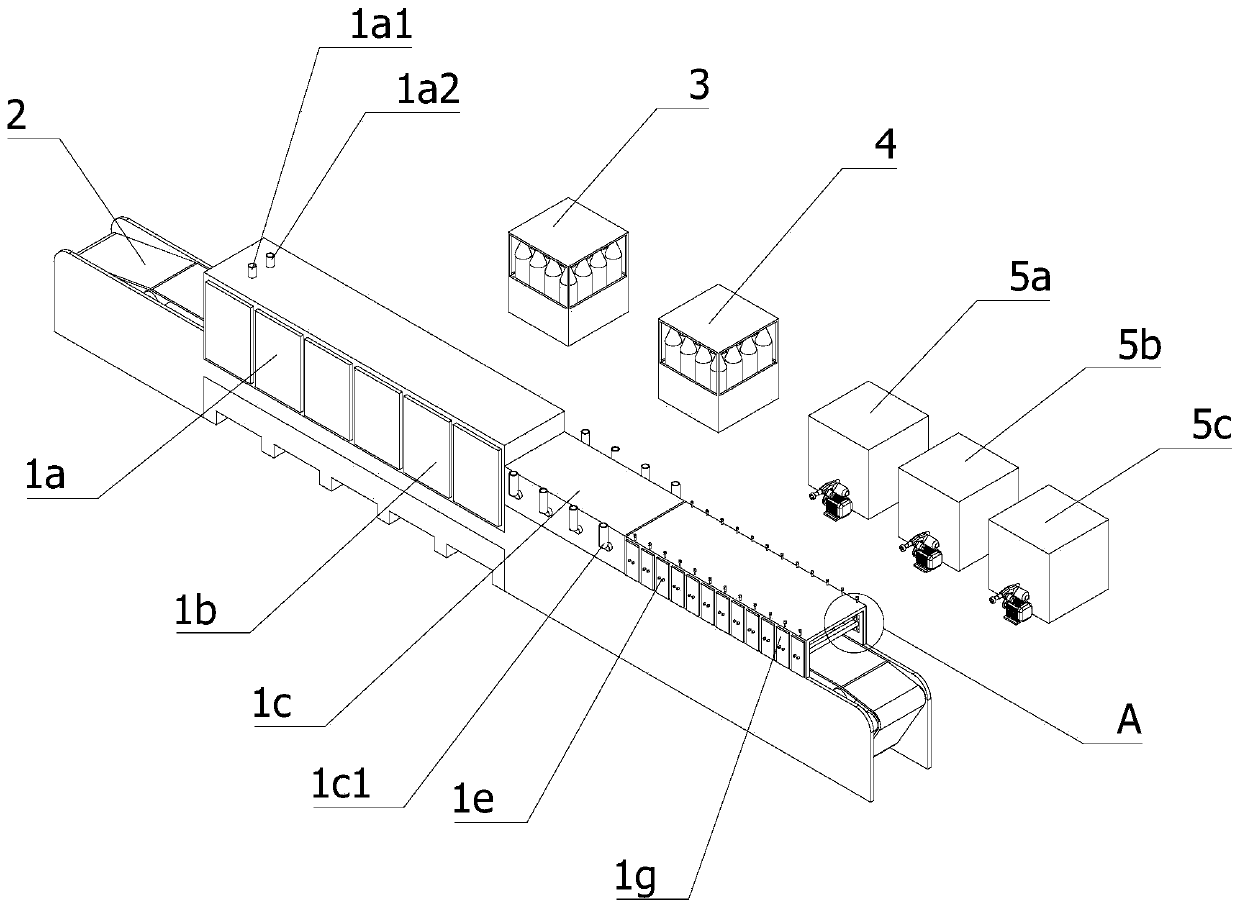

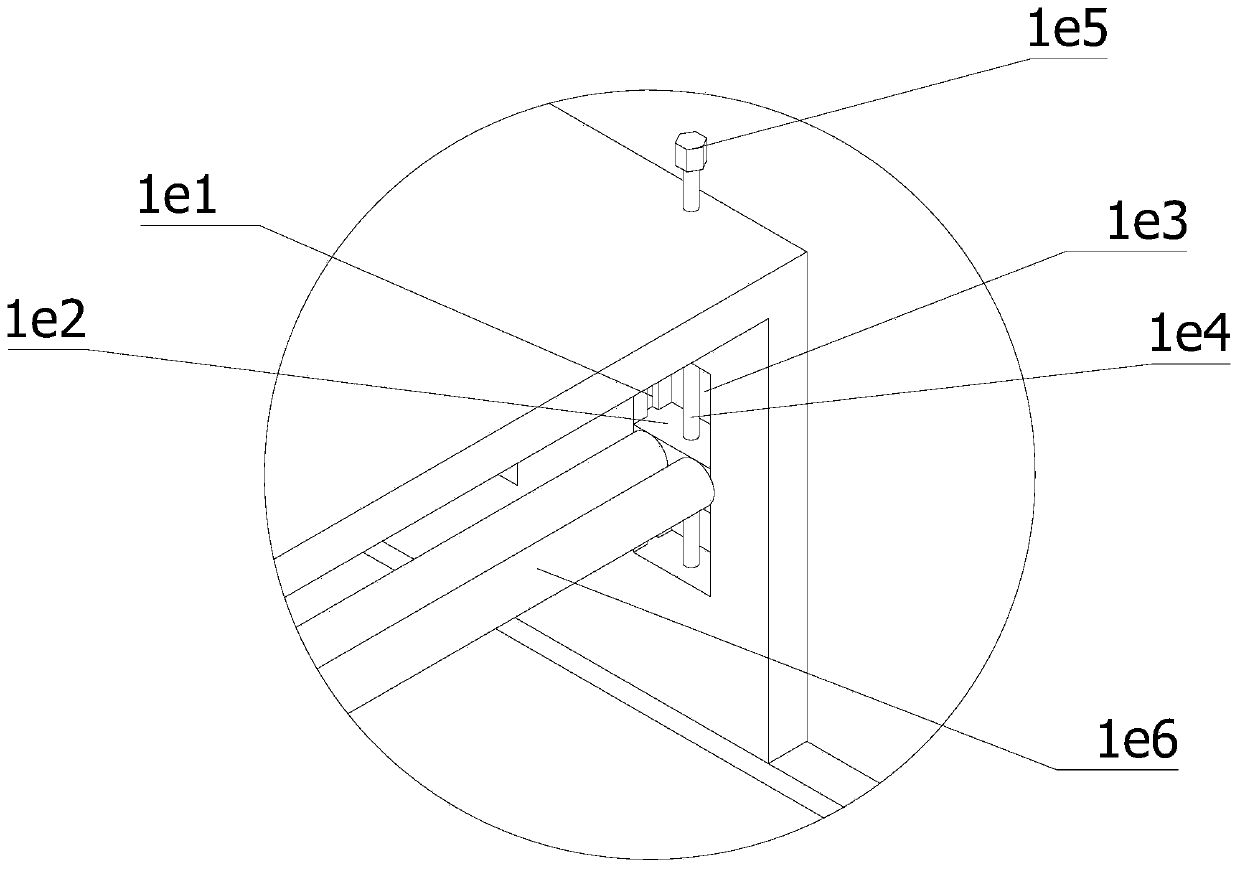

[0040] refer to Figure 1 to Figure 7 A steel pipe non-oxidation normalizing device shown includes a furnace 1, a transmission mechanism 2, a nitrogen station 3, a hydrogen station 4 and a water tank 5;

[0041] The transmission mechanism 2 runs through the interior of the furnace 1, and the furnace 1 is sequentially provided with a heating zone 1a, a heat preservation zone 1b, an air cooling zone 1c and a water cooling zone from the entrance to the exit. The water cooling area is connected;

[0042] The nitrogen station 3 is connected to the heating zone 1a, the heat preservation zone 1b and the air cooling zone 1c through the pipeline, the hydrogen station 4 is connected to the heating zone 1a and the heat preservation zone 1b through the pipeline, and the water tank 5 is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com