Aluminum extrusion die and surface strengthening and toughening treatment process

A processing technology, aluminum extrusion technology, applied in the direction of metal material coating technology, coating, solid diffusion coating, etc., can solve the problem of insufficient thickness of diffusion layer and solid solution strengthening, steep gradient distribution of hardness of co-infiltration layer, and vein-like shape. Crystal microstructure defects and other problems, to achieve the effect of delaying the peeling time of the infiltration layer, gentle hardness gradient, thickness and strength improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

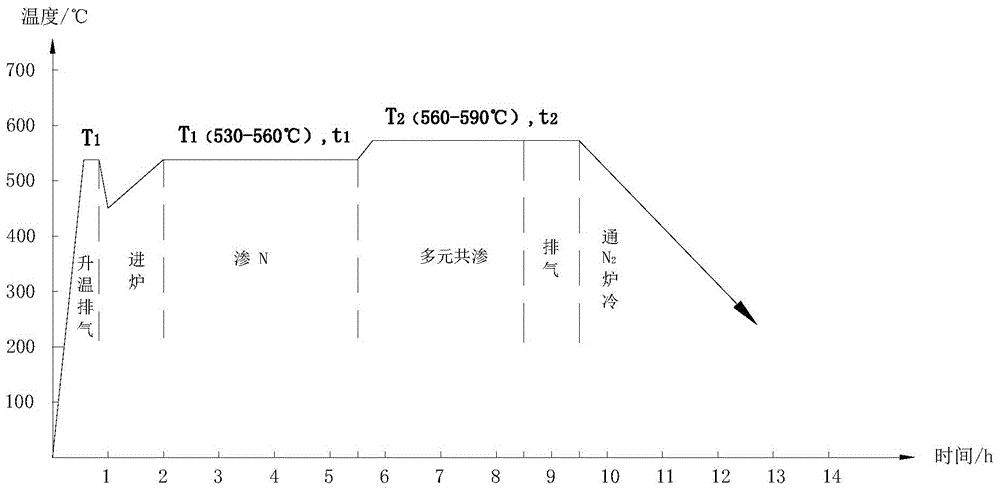

[0041] Hot extrusion die H with aluminum profile 13 Steel (4Cr 5 MoSiV 1 ) as an example, please refer to figure 1 As shown, the surface strengthening and toughening treatment process of the aluminum extrusion die in this embodiment is as follows:

[0042] (1) After cleaning and drying the aluminum extrusion mold to be treated, place it in the special frame for mold co-infiltration heat treatment at intervals, and place a specified amount of metal surface cleaning activator (by NH 4 Cl and quartz sand are uniformly mixed according to the volume ratio of 0.8 to 1.3:6), so that the surface of the mold working belt can remove 4Cr during the subsequent heating process. 5 MoSiV 1 Passivation Film Cr on Steel Extrusion Die Surface 2 o 3 , Clean and activate the surface of the mold to facilitate the absorption and infiltration of N, S, O atoms by its surface.

[0043] (2) Heat up to the first stage process temperature T in the pit heat treatment furnace 1 (530~560°C), hoist t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com