Seaweed flavor powder

A technology of flavor and seaweed, applied in the field of food and food flavors, can solve the problems of reduced concentration of flavor components, long heating time of materials, destruction of flavor components, etc., and achieves the effects of improved water solubility, good dispersibility, and reduced heating time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0022] Example 1 (kelp flavor powder)

[0023] 1. Preparation of kelp extract

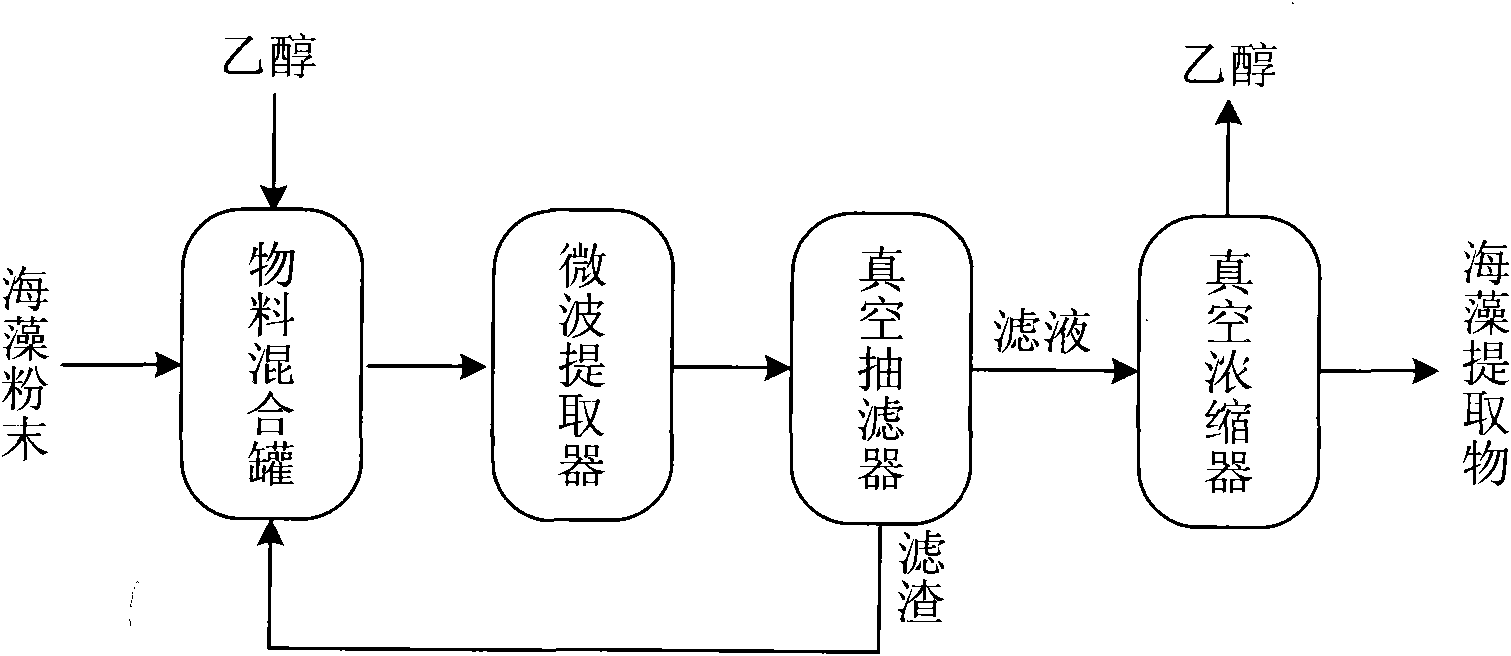

[0024] First dry the clean kelp in an oven at 60°C, then crush it through a 40-mesh sieve to obtain kelp powder for later use; then refer to the attached figure 1 To extract, the specific extraction process is as follows:

[0025] The kelp powder is transferred to the material mixing tank, and the concentration of adding 4 times (w: v) is 85% ethanol to mix and then send into the microwave extractor. The ratio of the flow rate is 55, continuous microwave extraction at a temperature of 30°C; the microwave extract flows into a vacuum filter for filtration, the filtrate is sent to a vacuum concentrator, and the filter residue is returned to the microwave extractor for another extraction under the same conditions. The filtrate after the secondary extract is filtered by the vacuum filter is also sent to the vacuum concentrator; after the 2 filtrates are combined in the vacuum concentrator, they are co...

example 2

[0034] Example 2 (seaweed flavor powder)

[0035] 1. Preparation of laver extract

[0036] First dry the clean laver in an oven at 40°C, then crush it through a 20-mesh sieve to obtain laver powder for later use; then refer to the attached figure 1 To extract, the specific extraction process is as follows:

[0037] Transfer the seaweed powder to the material mixing tank, add 7 times (w: v) concentration of ethanol and mix it into the microwave extractor, control the microwave power to 2400W, and the material flow rate to be 53L / h, that is, the microwave power and material The ratio of the flow rate is 45, continuous microwave extraction at a temperature of 40°C; the microwave extract flows into the vacuum filter for filtration, the filtrate is sent to the vacuum concentrator, and the filter residue is returned to the microwave extractor for extraction twice under the same conditions. The filtrate after the secondary and tertiary extracts are filtered by the vacuum filter is ...

example 3

[0046] Example 3 (Kombu flavor powder)

[0047] 1. Preparation of kelp extract

[0048] First dry the clean kelp in an oven at 80°C, then crush it through a 60-mesh sieve to obtain kelp powder for later use; then refer to the attached figure 1 To extract, the specific extraction process is as follows:

[0049] Kelp powder is transferred to the material mixing tank, and the concentration of adding 3 times (w:v) is 95% ethanol to mix and send into the microwave extractor. The ratio of the flow rate is 16, continuous microwave extraction at a temperature of 50°C; the microwave extract flows into the vacuum filter for filtration, the filtrate is sent to the vacuum concentrator, and the filter residue is returned to the microwave extractor to be extracted again under the same conditions. The filtrate after the secondary extract is filtered by the vacuum filter is also sent to the vacuum concentrator; after the 2 filtrates are combined in the vacuum concentrator, they are concentr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com