Electric pressure cooker brewing machine and beverage brewing method through same

A pressure cooker and brewing machine technology, applied in beverage preparation devices, household appliances, applications, etc., can solve the problems of complex structure, low safety, and inconvenient operation of coffee pots, and achieve simple and reasonable structure, strong versatility, and low occupation small space effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

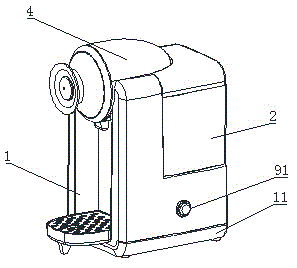

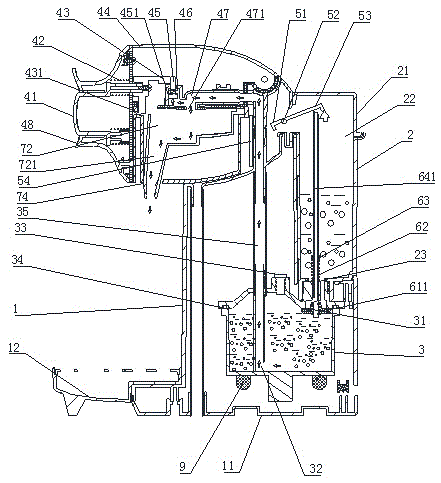

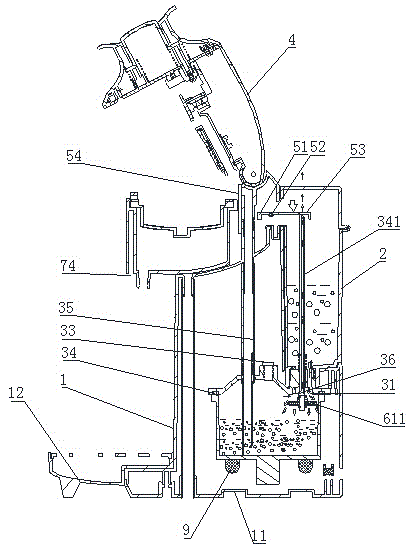

[0061] Such as Figure 1 to Figure 5 As shown, the electric heating pressure cooker brewing machine of the present invention includes a main body 1, a heating mechanism arranged on the main body 1, a water tank 2 for storing water and a brewing mechanism for brewing beverages, the water tank 2 is fixed or The activity is set on body 1.

[0062] The heating mechanism includes an electric pressure cooker 3 arranged on the main body 1, at least a part of which is located below the water tank 2, and a heater 9 for supplying heat to the electric pressure cooker 3. The main body 1 is provided with a device for controlling the operation of the heater 9 Power switch 91. The electric heating pressure cooker 3 is provided with a first water inlet 31 communicating with the water tank 2, a first water outlet 32 communicating with the brewing mechanism and an exhaust opening communicating with the atmosphere. The first water outlet 31 is arranged on the electric heating pressure cooker....

Embodiment 2

[0081] Such as Figure 6a ~ Figure 6b As shown, the electric heating pressure cooker described in this embodiment, except that the water inlet switch 6 is different from Embodiment 1, other structures and working principles are the same as Embodiment 1. The water inlet switch 6 is a float valve, and the float valve includes a The float 65 in the pressure cooker and the second connecting rod 642 connected with the float 65, the upper surface of the float 65 is provided with a second seal 612, and the gravity of the float 65 is less than the buoyancy of water to it; The rod 642 extends into the water tank through the first water inlet 31 of the electric pressure cooker 3 and the second water outlet 22 of the water tank 2; the second connecting rod 642 is hollow, and an exhaust hole is arranged inside it 36, the buoy 65 includes a sealed cavity (such as Figure 6b shown), or the lower opening forms a relatively sealed cavity with the water surface (such as Figure 6a shown); th...

Embodiment 3

[0083] Such as Figure 7 As shown, except for the water inlet switch 6 and the control mechanism of the electric heating pressure cooker brewing machine described in this embodiment, other structures and working principles are the same as those in Embodiment 1. The water inlet switch in this embodiment is a solenoid valve, so The magnetic valve includes a third sealing member 613, a first magnet 661 arranged on the third sealing member 613, a first magnet 661 arranged on the first water inlet 31 of the electric heating pressure cooker 3 or the second water outlet 23 of the water tank 2 and the second water outlet 23. A second magnet 662 with the same magnetism as the magnet 661, a third connecting rod 643 is also arranged on the third sealing member 613, the maximum repulsive force between the first magnet 661 and the second magnet 662 is the same as that of the third sealing member The sum of gravity and the gravity of the third connecting rod is less than the buoyancy force ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com