Wound protective film spray and preparation method thereof

A technology for protective film and wound surface, applied in the field of wound protective film spray and preparation thereof, can solve the problems of inability to effectively isolate bacteria, insufficient film-forming strength, and difficulty in spraying, and achieve moderate viscosity, short film-forming time, Avoid excessive wasteful effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

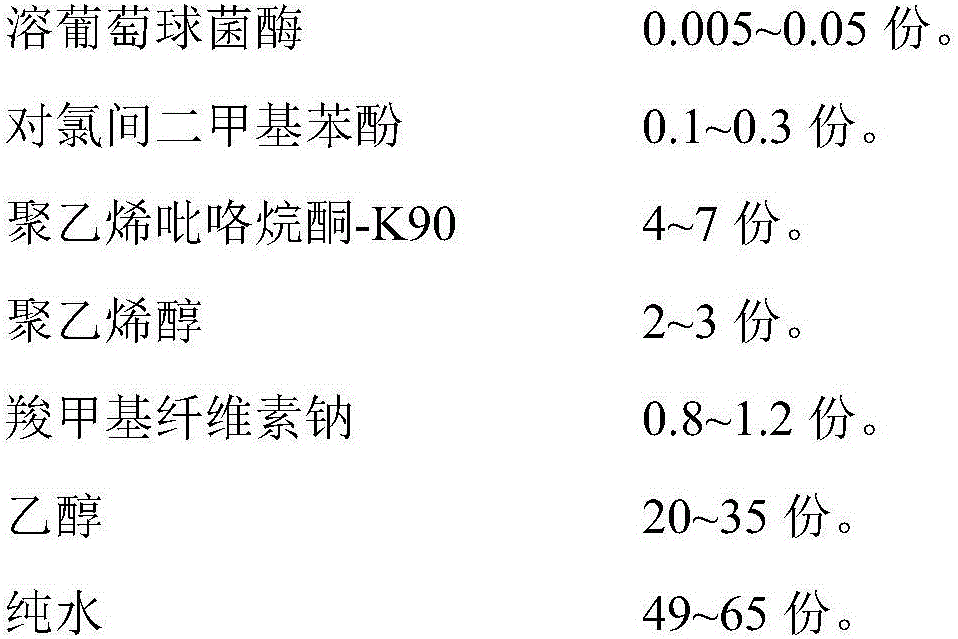

[0030] Wound protective film spray 1 comprises the following components by mass:

[0031]

[0032] Test results:

[0033] The film-forming time of Wound Protective Film Spray 1, that is, the time when the solution no longer flows on the skin, is 7 seconds. The tensile strength of the protective film 1 formed by Wound Protective Film Spray 1 on the skin is 0.15Mpa, and the elongation at break is 7 seconds. The rate is 141%.

Embodiment 2

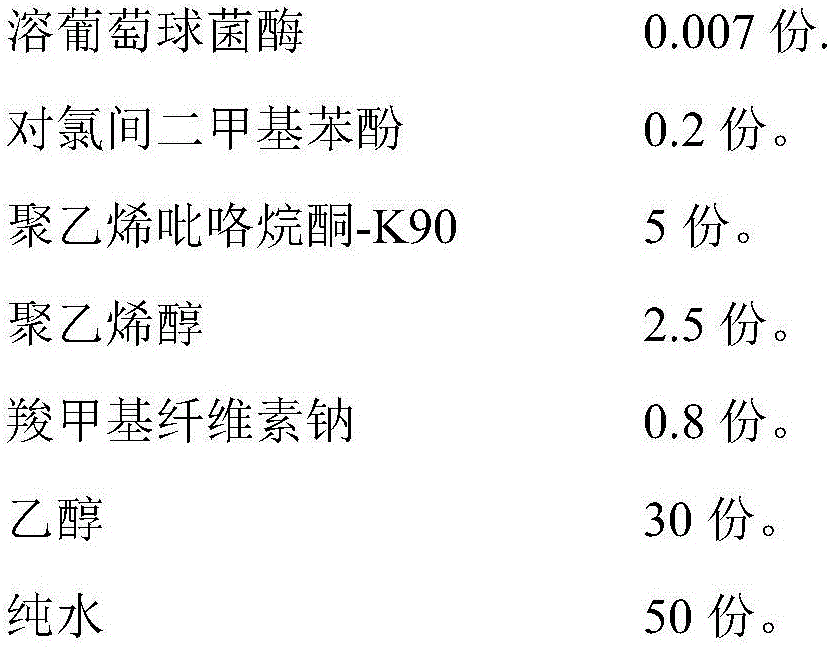

[0035] Wound protective film spray 2 comprises the following components by mass:

[0036]

[0037] Test results:

[0038] The film-forming time of the wound protection film spray 2 is 9 seconds when the solution no longer flows on the skin. The tensile strength of the protective film 2 formed by the wound protection film spray 2 on the skin is 0.09Mpa, and the elongation at break is 0.09Mpa. The rate is 130%.

Embodiment 3

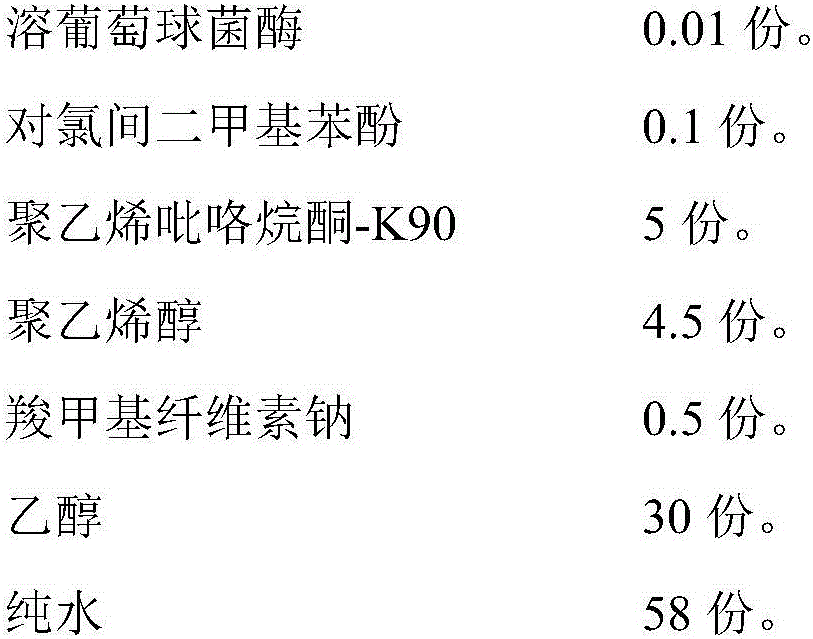

[0040] Wound protective film spray 3 comprises the following components by mass:

[0041]

[0042] Test results:

[0043] The film-forming time of the wound protection film spray 3, that is, the time when the solution no longer flows on the skin, is 8 seconds. The tensile strength of the protective film 3 formed by the wound protection film spray 3 on the skin is 0.12Mpa, and the elongation at break is 0.12Mpa. The rate is 142%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com