Road base reinforcing high-polymer loading and grouting method

A technology of road base layer and high polymer, which is applied in the field of rapid maintenance of high polymer grouting, which can solve the problems of poor durability and achieve good durability, cost saving and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

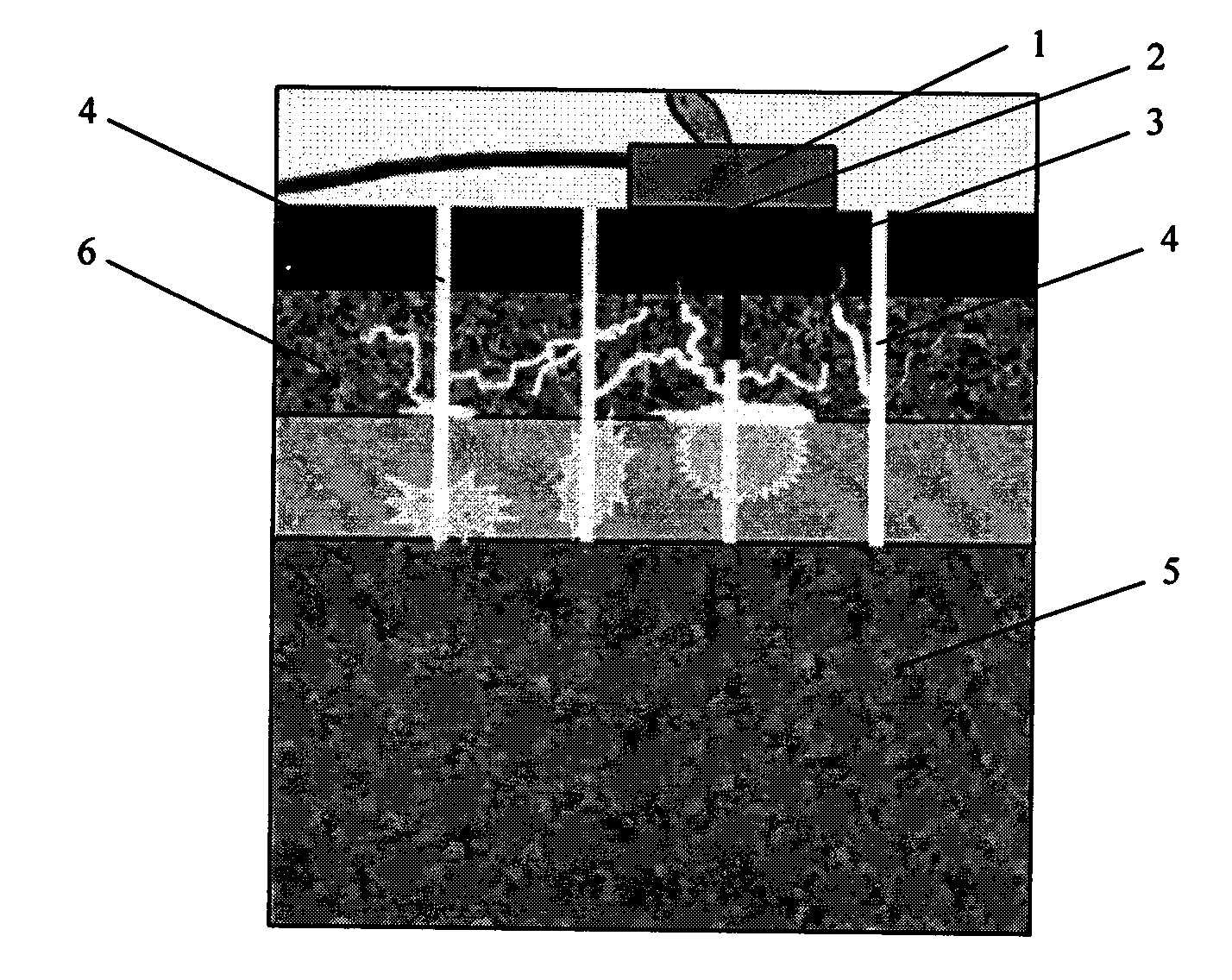

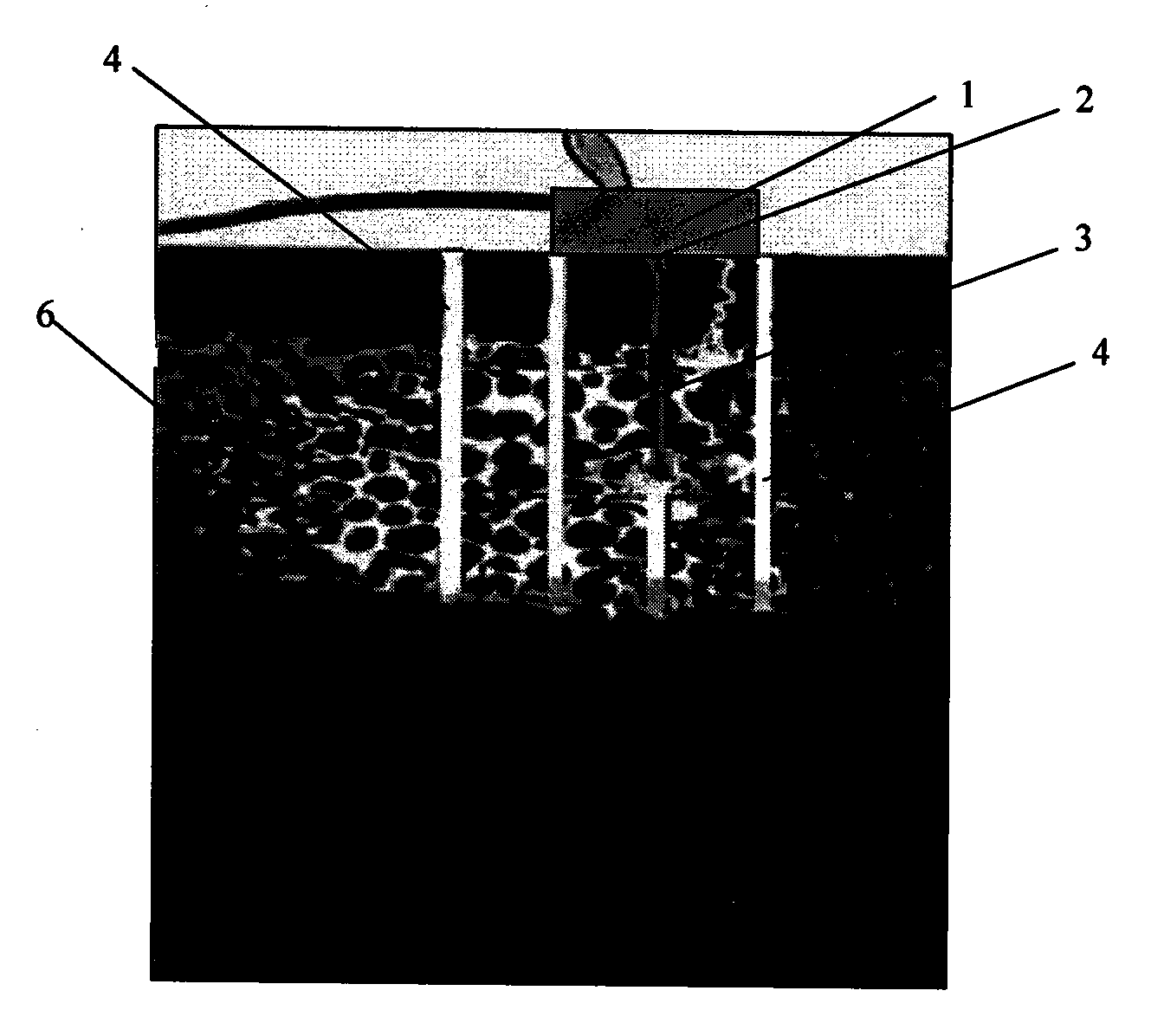

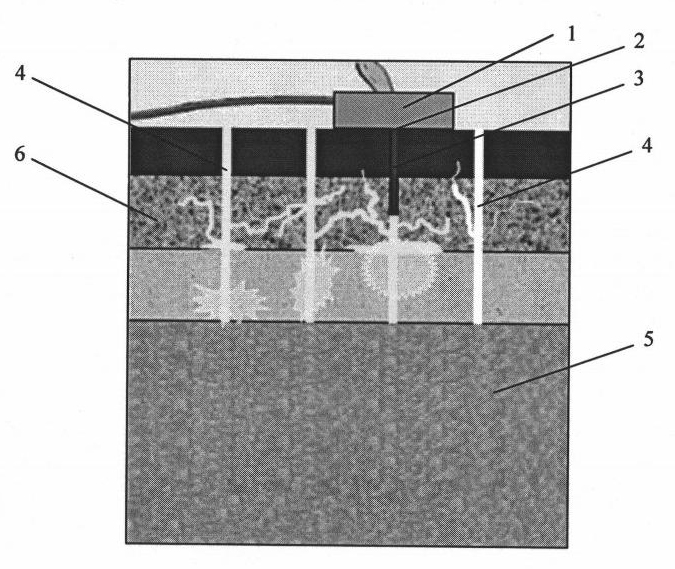

[0026] Embodiment: The polymer loaded grouting method for road base reinforcement of the present invention, for the loose semi-rigid pavement and flexible base pavement, the loading device 1 applies additional load to the road surface to prevent the expansion force of the high polymer material after the reaction Jack up the road surface; inject high polymer material into the base layer, the volume of the material will expand rapidly after the reaction, and the loose base layer will be consolidated, so as to achieve the purpose of strengthening the base layer.

[0027] The specific implementation steps are:

[0028] (1) Use non-destructive testing techniques such as falling weight deflection meter (FWD) and ground penetrating radar (GPR) to test and evaluate the performance of the pavement; according to the test and evaluation results, analyze the condition of the pavement base layer, and determine the road sections that need to be reinforced;

[0029] (2) For the road section ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com