A kind of three-dimensional porous boron carbon nitrogen material and its preparation method and application

A three-dimensional porous, boron-carbon-nitrogen technology, applied in the field of nanomaterial preparation and photocatalysis, to achieve the effects of mild and controllable conditions, low price and stable catalyst

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

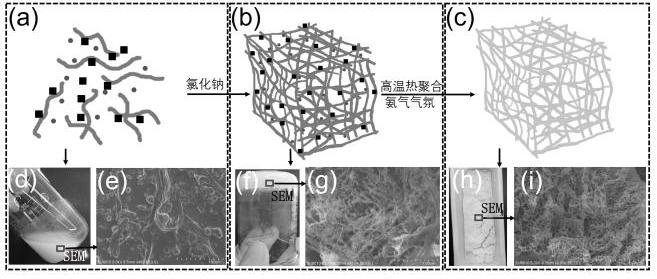

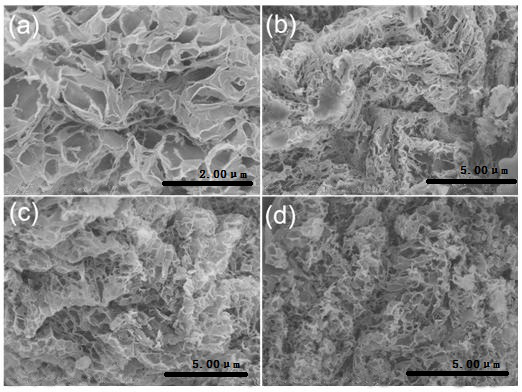

Embodiment 1

[0024] Take 0.5 g of boric acid, 1 g of urea and 2.5 g of starch in a 25 mL beaker, add 5 mL of pure water and 2.5 g of sodium chloride, and dissolve them by ultrasonic waves, and then stand at room temperature and pressure for 3 h to obtain a three-dimensional Porous hydrogel precursor, take out the precursor, place it in a corundum ark, and put it into a horizontal high-temperature tube furnace. After heating up to 1000 ℃ and heat treatment for 5 h, the three-dimensional porous boron carbon nitrogen material can be obtained.

Embodiment 2

[0026] Take 1 g of boric acid, 2 g of urea and 5 g of starch in a 25 mL beaker, add 10 mL of pure water and 5 g of sodium chloride, and dissolve them by ultrasonic waves, and then stand at room temperature and pressure for 4 h to obtain a three-dimensional The porous hydrogel precursor was taken out, placed in a corundum ark, and placed in a horizontal high-temperature tube furnace, under an ammonia atmosphere (flow rate of 200 mL / min), at a heating rate of 5 ℃ / min After heating up to 1250 ℃ and heat treatment for 5 h, the three-dimensional porous boron carbon nitrogen material can be obtained.

Embodiment 3

[0028] Take 1 g of boric acid, 2 g of urea and 5 g of starch in a 25 mL beaker, add 10 mL of pure water and 3 g of sodium chloride, and dissolve them by ultrasonic waves, and then stand at room temperature and pressure for 2 h to obtain a three-dimensional The porous hydrogel precursor was taken out, placed in a corundum ark, and placed in a horizontal high-temperature tube furnace, under an ammonia atmosphere (flow rate: 300 mL / min), at a heating rate of 5 °C / min After heating up to 1100 ℃ and heat treatment for 8 h, the three-dimensional porous boron carbon nitrogen material can be obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com