Ceramic-based composite coating and preparation method thereof

A ceramic matrix composite and coating technology, applied in coatings, fireproof coatings, etc., can solve the problems of component failure, affecting the normal use of materials, and falling off.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

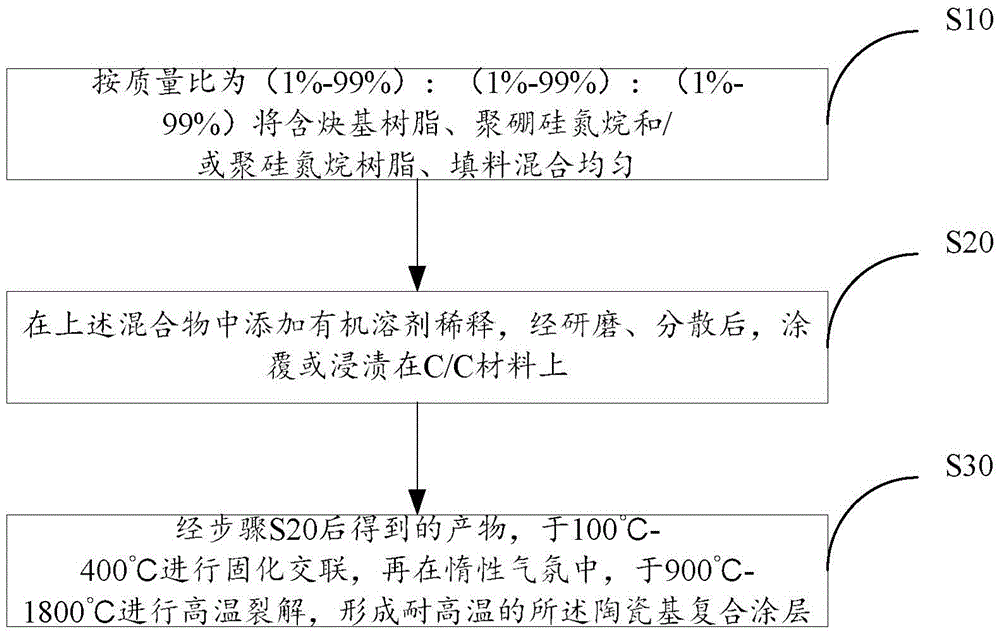

[0043] Such as figure 1 Shown, the preparation method of the ceramic matrix composite coating of one embodiment, comprises the following steps:

[0044] Step S10: by mass ratio (1%-99%): (1%-99%): (1%-99%) containing alkyne group resin, polyborosilazane and / or polysilazane resin, The filler is mixed uniformly, wherein the mass sum of the alkyne-containing resin, the polyborosilazane and / or polysilazane resin, and the filler is 100%;

[0045] Step S20: adding an organic solvent to the above mixture for dilution, and coating or impregnating the carbon fiber after grinding and dispersing;

[0046] Preferably, the solvent is at least one of toluene, xylene, n-hexane, cyclohexane, and n-heptane.

[0047] Step S30: The product obtained after step S20 is cured and cross-linked at 100°C-400°C, and then pyrolyzed at 900°C-1800°C in an inert atmosphere to form the high temperature resistant ceramic matrix composite coating.

[0048]Experiments have proved that when the alkynyl conten...

Embodiment 1

[0053] Polysilazane 12g (44%) was diluted with a certain amount of toluene, propargyl phenolic resin 12g (44%) was diluted with a certain amount of toluene, mixed evenly, and then added ZrO 150nm ground in advance 2 3g powder (12%), mix and stir to disperse evenly, take a certain amount of carbon fiber and immerse in the mixed liquid, take it out of the oven and cure it at 150°C for 2h, and in Ar atmosphere, pyrolyze it at 1300°C (heating rate: 10°C / min) for 2h , XRD analysis of pyrolysis products found that SiBNC, ZrO 2 (t,m) and free C generation.

Embodiment 2

[0055] Polysilazane 15g (75%) was diluted by adding a certain amount of xylene, aryl acetylene resin 3g (15%) was diluted by adding a certain amount of toluene, mixed uniformly, then added 2g (10%) of ZrC powder that had been ground in advance to 200nm, mixed Stir and disperse evenly, take a certain amount of carbon fiber and immerse it in the mixed solution, take it out of the oven and solidify at 200°C for 1.5h, A is pyrolyzed in Ar atmosphere at 900°C (heating rate is 5°C / min) for 2h, and analyze the pyrolysis products. In addition to ZrC, there are also SiNC and free C generation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com