Silicon boron carbon nitrogen ceramic and preparation method thereof

A technology of silicon boron carbon nitrogen ceramics and carbon chains, which is applied in the field of silicon boron carbon nitrogen ceramics and its preparation, can solve the problems of high sintering temperature, inability to guarantee the purity and quality of composite materials, and harsh conditions, and achieve excellent high temperature performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

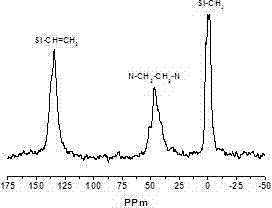

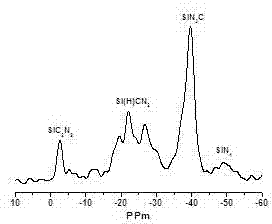

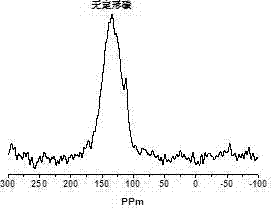

[0030] Example 1: Take 9.58 ml (0.144 mol) of ethylenediamine, 41.74 ml (0.3 mol) of triethylamine, 50 ml of toluene, mix well, take 9.45 ml (0.072 mol) of vinyl chlorosilane, 7.5 ml of methyl hydrochlorosilane ml (0.072 mol) and 100 ml of toluene are mixed evenly, and the two mixtures are mixed and heated to 120 o C reaction. Remove the reaction by-products by filtration, add 12 ml (0.024 mol) of toluene solution of thioether borane to the mixed solution, mix well and cool to 0 o C reaction, the toluene solution of polyborosilamine alkane is obtained. The toluene solvent was distilled off to obtain polyborosilamine. Under the protection of argon atmosphere (helium, nitrogen, air can be used), 1000 o C Pyrolysis of polyborosilamine to produce silicon boron carbon nitrogen ceramics. 13 C solid-state NMR analysis of the structure of polyborosilamide, visible -CH 2 -CH 2 -Characteristic peaks, indicating that polyborosilamine contains two carbon structures, as attached fig...

Embodiment 2

[0031]Embodiment 2: adopt the technology of the present invention, experiment process and condition are the same as embodiment 1, change the amount of the toluene solution that adds thioether borane to be 36 ml (0.072 mol), distill and remove the polyborosilamine that toluene solvent makes, Pyrolyzing the polyborosilamine to prepare silicon-boron-carbon-nitrogen ceramics.

Embodiment 3

[0032] Embodiment 3: adopt the technology of the present invention, experimental process and condition are the same as embodiment 1, change the amount of the toluene solution that adds thioether borane to be 24 ml (0.048 mol), remove toluene solvent by distillation and make polyborosilamine, heat Decompose the polyborosilamine to prepare silicon-boron-carbon-nitrogen ceramics.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com