Boron carbonitride nanosheet as well as preparation method and application thereof

A technology of nitrides and nanosheets, applied in the field of nanomaterials, can solve the problems of not extensive sources, time-consuming, complicated operation of hydrothermal method, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

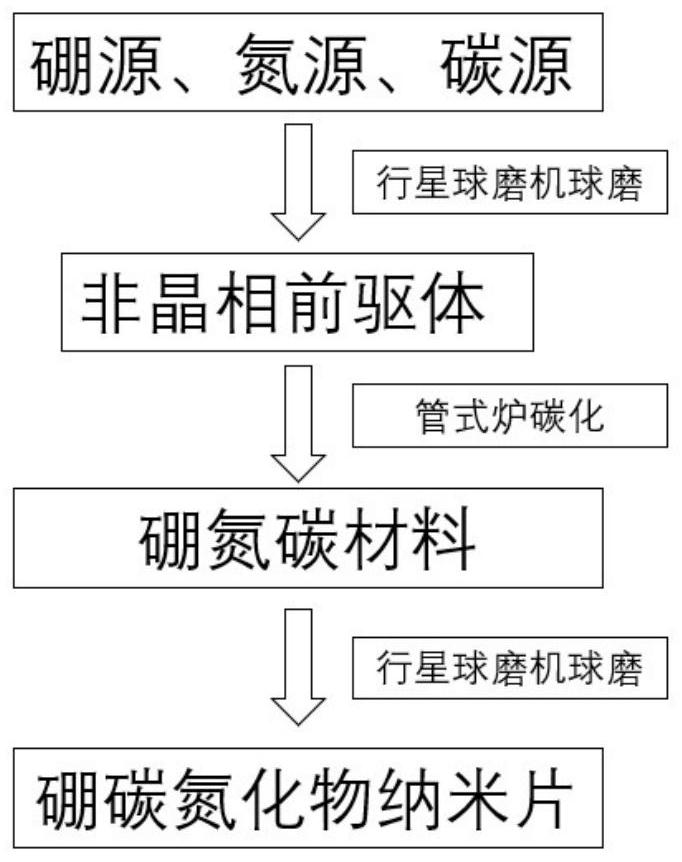

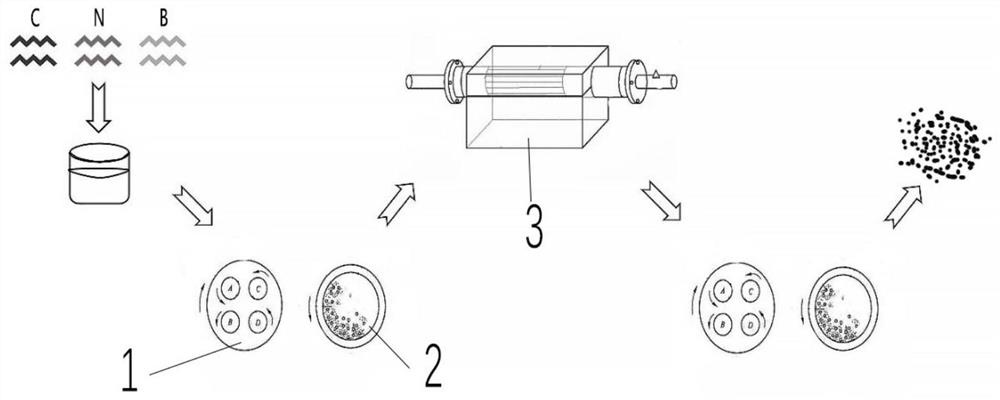

[0050]Such as figure 1 Shown, the preparation method of boron carbon nitride nanosheet of the present invention comprises the steps:

[0051] (1), take boron source, carbon source and nitrogen source and mix, obtain mixed powder;

[0052] (2), the mixed powder is stirred and dried, and placed in a planetary ball mill for uniform grinding to obtain an amorphous phase precursor;

[0053] (3) The amorphous phase precursor is degassed in a tube furnace and heat-treated at 800-1200° C. to obtain treated boron carbon nitride nanosheets (ie, boron-nitrogen-carbon materials);

[0054] (4) The borocarbonitride nanosheets treated in step (3) are ball milled in a planetary ball mill, and then purified to obtain borocarbonitride nanosheets.

[0055] Wherein, in the step (1), the boron source, the carbon source and the nitrogen source are the element mass ratios of B, C and N being 1:(0.05-1):(0.05-1).

[0056] (carbon source)

[0057] In step (1), the carbon source is selected from on...

Embodiment 1

[0084] The preparation method of the boron carbon nitride nanosheet of the present embodiment comprises the following steps:

[0085] (1), after mixing 2.06g boric acid, 2g urea and 0.2g carbon black, obtain mixed powder;

[0086] (2) Dry the mixed powder in an oven at 70°C for 30 minutes, and place it in a planetary ball mill at a speed of 500rmp, turn it for 20 minutes, stop for 5 minutes, turn it for another 20 minutes, mix evenly, grind finely, and obtain an amorphous phase precursor;

[0087] (3), the amorphous phase precursor is carried out degassing treatment, in the N of 100mL / min 2 Heat treatment at 1100°C for 2 hours under the protection of air flow, and cool down;

[0088] (4), place the product of step (3) in the planetary ball mill with a rotating speed of 500rmp, turn for 20min, stop for 5min, then turn for 20min to mix evenly, and grind finely;

[0089] (5) acid treatment with 10 wt% hydrochloric acid solution at room temperature; washing with water and ethano...

Embodiment 2

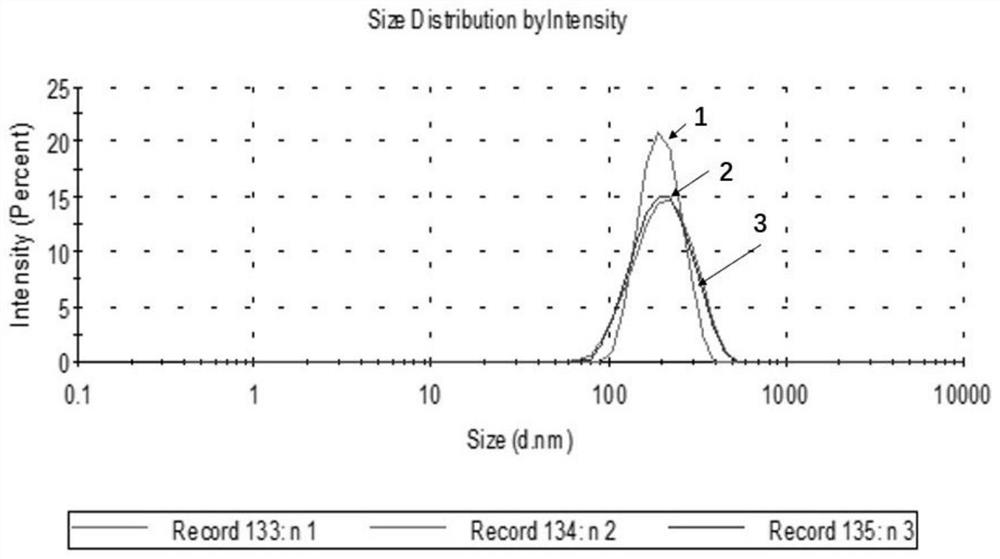

[0091] The preparation method of the boron carbon nitride nanosheet of the present embodiment comprises the following steps:

[0092] (1), after mixing 2.06g boric acid, 2g urea and 0.2g carbon black, obtain mixed powder;

[0093] (2) Dry the mixed powder in an oven at 70°C for 30 minutes, and place it in a planetary ball mill at a speed of 500rmp, turn it for 20 minutes, stop for 5 minutes, turn it for another 20 minutes, mix evenly, grind finely, and obtain an amorphous phase precursor;

[0094] (3), the amorphous phase precursor is carried out degassing treatment, in the N of 100mL / min 2 Heat treatment at 900°C for 2 hours under the protection of air flow, and cool down;

[0095] (4), put the product of step (3) in the ball mill at a speed of 500rmp, turn for 20min, stop for 5min, then turn for 20min to mix evenly, and grind finely;

[0096] (5) acid treatment with 10 wt% hydrochloric acid solution at room temperature; washing with water and ethanol, ultrasonic stripping;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com