Mould core for moulded glass and manufacture thereof

A technology of glass mold core and manufacturing method, which is applied to glass manufacturing equipment, glass pressing, manufacturing tools and other directions, can solve the problems of reduced service life of mold core, poor adhesion, increased cost of molding glass, etc., and achieves the effect of long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

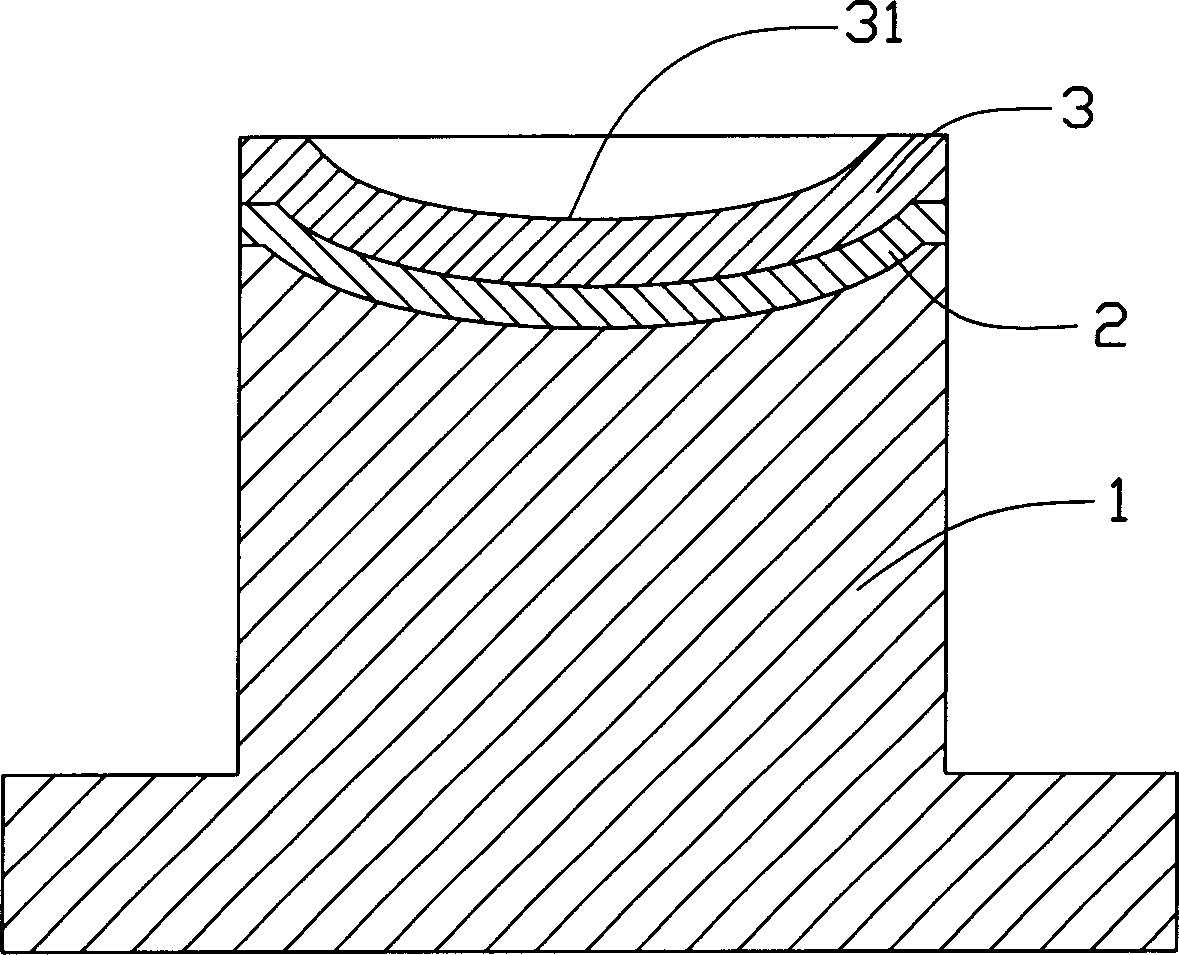

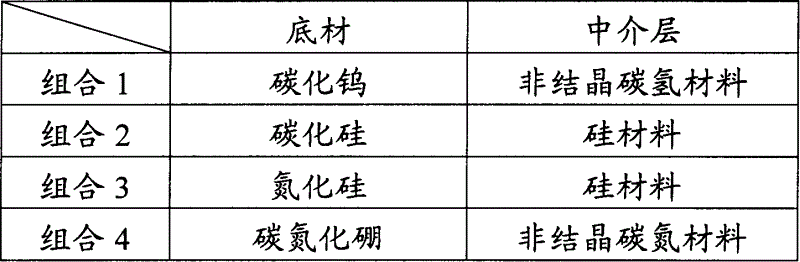

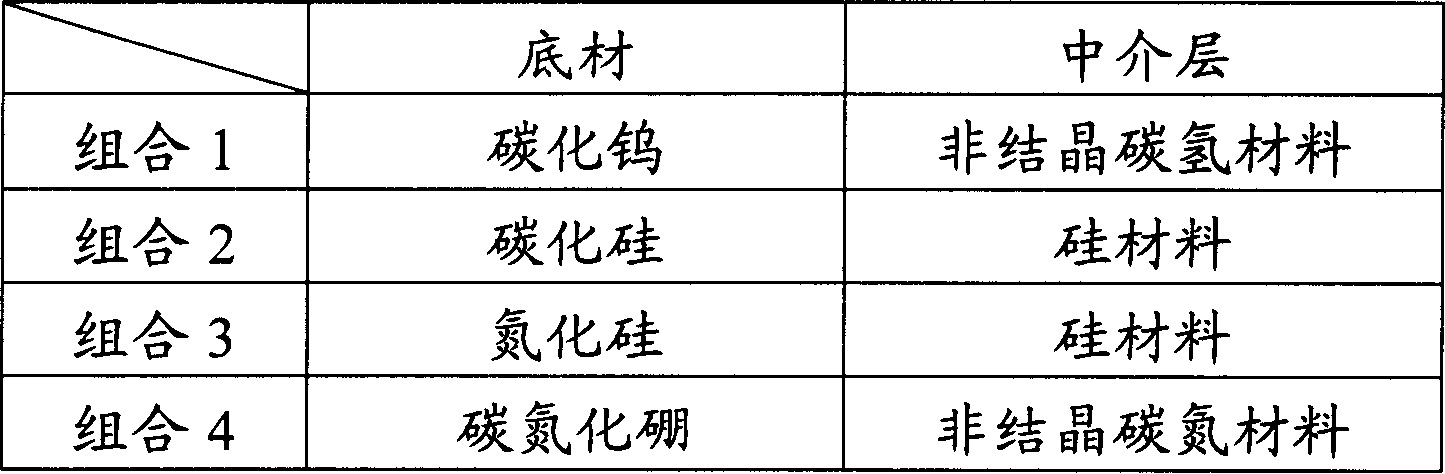

[0023] combined reference figure 1 As shown, the molded glass mold core of the present invention includes a substrate 1, an interposer 2 and a protective film 3, wherein the intermediary layer 2 is located on the substrate 1, the protective film 3 is located on the intermediary layer 2, and the protective film 3 has a The molding surface 31 of the molding groove, the material of the substrate 1 is tungsten carbide (WC), the material 2 of the interposer is a-C:H material, and the material of the protective film 3 is silicon carbide (SiC) or iridium-platinum alloy (Ir-Pt).

[0024] The method for manufacturing the molded glass core comprises the following steps:

[0025] Provide a tungsten carbide substrate 1;

[0026] Depositing a layer of a-C:H intermediary layer 2 on the surface of the substrate 1;

[0027] A protective film 3 is deposited on the surface of the intermediary layer 2 .

[0028] The a-C:H material of the interposer 2 is sputtered on the substrate by one of D...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com