Si-based flexible stainless steel structured solar battery and preparation method

A technology of solar cells and stainless steel, applied in circuits, photovoltaic power generation, electrical components, etc., can solve problems such as poor corrosion resistance of thin-film solar cells, and achieve the effects of improving photoelectric conversion efficiency, improving stability, and excellent flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

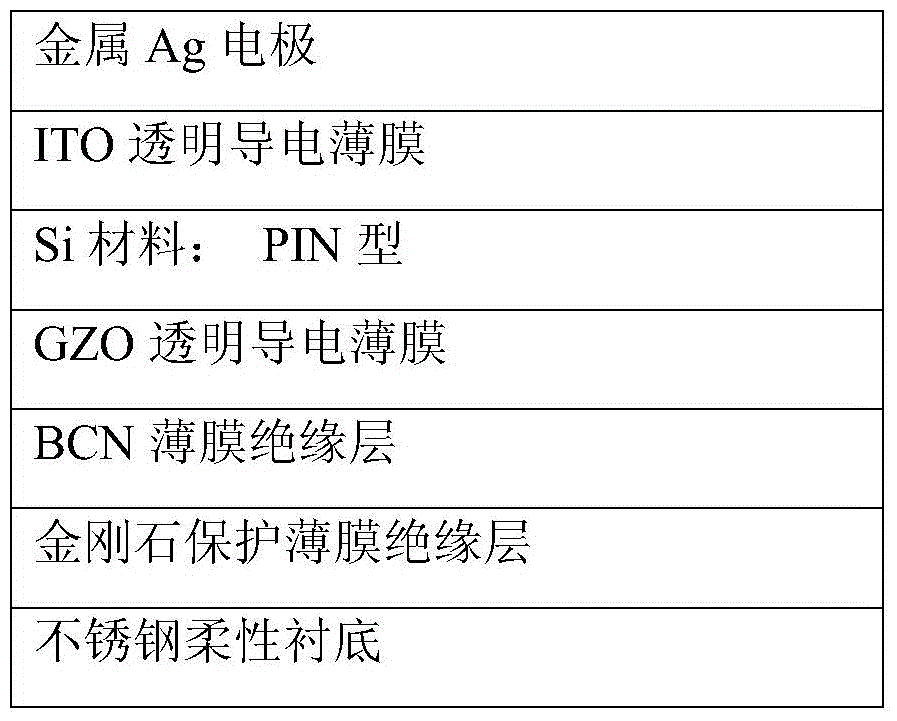

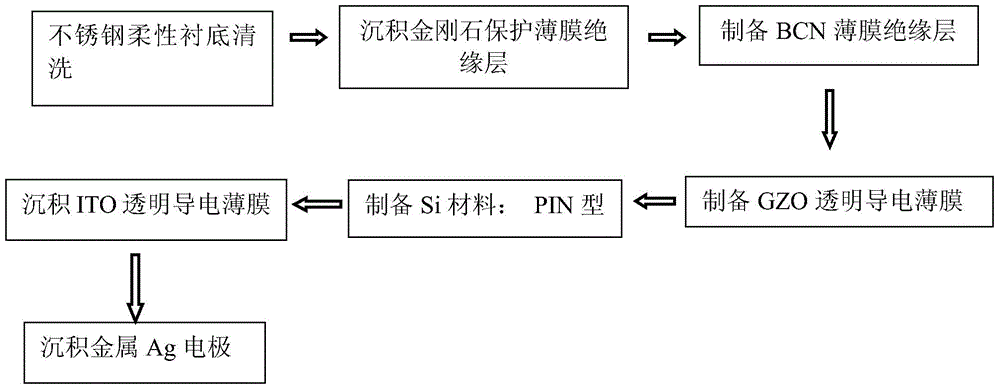

[0031] see figure 1 combine figure 2 ,

[0032] (1), the stainless steel flexible substrate substrate was first cleaned with ion water for 5 minutes, then dried with nitrogen and sent to the PECVD reaction chamber, at 8.0×10 -4 Under the condition of Pa vacuum, the diamond anti-corrosion insulating layer is prepared by deposition. The process parameter conditions are: hydrogen and methane are used as the mixed gas reaction source, the flow ratio of hydrogen and methane is 20:1, the substrate temperature is 300°C, and the deposition time is 10 minutes.

[0033](2) Then send it to the magnetron sputtering reaction chamber to deposit and prepare the BCN insulating layer. The process parameter conditions are: nitrogen and methane as the mixed gas reaction source, the flow ratio of nitrogen and methane is 2:1, the purity of the boron target for reactive sputtering is 99.99%, the substrate temperature is 100°C, and the deposition time is 30 minutes.

[0034] (3), and then prepa...

Embodiment 2

[0041] (1), the stainless steel flexible substrate substrate was first cleaned with ion water for 5 minutes, then dried with nitrogen and sent to the PECVD reaction chamber, at 8.0×10 -4 Under the condition of Pa vacuum, the diamond anti-corrosion insulating layer is prepared by deposition. The process parameter conditions are: hydrogen and methane are used as the mixed gas reaction source, the flow ratio of hydrogen and methane is 20:1, the substrate temperature is 350°C, and the deposition time is 15 minutes.

[0042] (2) Then send it to the magnetron sputtering reaction chamber to deposit and prepare the BCN insulating layer. The process parameter conditions are: nitrogen and methane are used as the mixed gas reaction source, the nitrogen and methane flow ratio is 2:1, the purity of the reactive sputtering boron target is 99.99%, the substrate temperature is 150°C, and the deposition time is 40 minutes.

[0043] (3), and then prepare GZO-based transparent conductive film; ...

Embodiment 3

[0050] (1), the stainless steel flexible substrate substrate was first cleaned with ion water for 5 minutes, then dried with nitrogen and sent to the PECVD reaction chamber, at 8.0×10 -4 Under the condition of Pa vacuum, the diamond anti-corrosion insulating layer is prepared by deposition. The process parameter conditions are: hydrogen and methane are used as the mixed gas reaction source, the flow ratio of hydrogen and methane is 20:1, the substrate temperature is 450°C, and the deposition time is 16 minutes.

[0051] (2) Then send it to the magnetron sputtering reaction chamber to deposit and prepare the BCN insulating layer. The process parameter conditions are: nitrogen and methane as the mixed gas reaction source, the flow ratio of nitrogen and methane is 2:1, the purity of the reactive sputtering boron target is 99.99%, the substrate temperature is 150°C, and the deposition time is 50 minutes.

[0052] (3), and then prepare GZO-based transparent conductive film; its pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com