Model glass kernel and manufacturing method thereof

A glass mold core and manufacturing method technology, applied in glass manufacturing equipment, glass pressing, manufacturing tools, etc., can solve the problems of reduced mold core service life, poor adhesion, difficult to achieve mold core life, etc., and achieve long service life. , the effect of stabilizing physical and chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

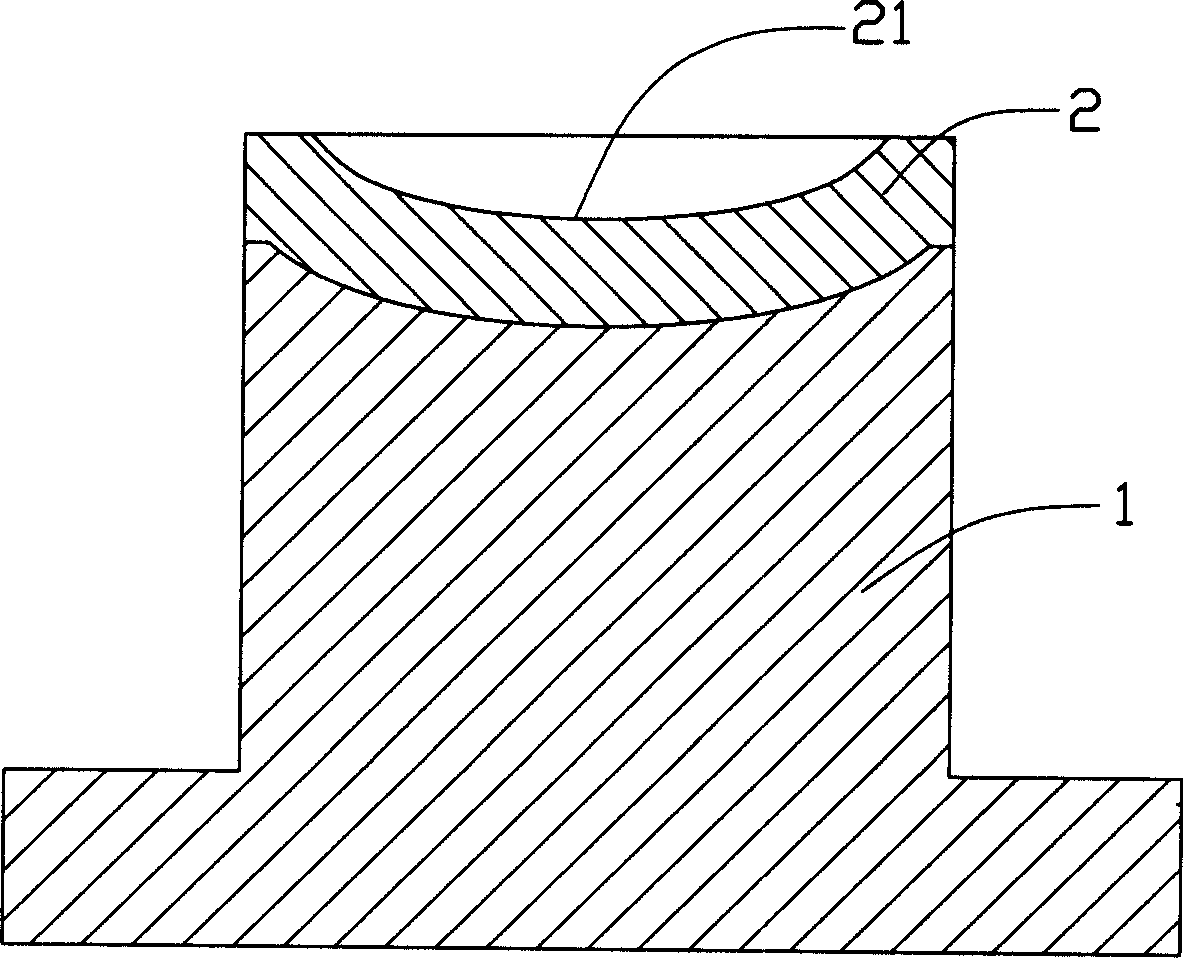

[0021] combined reference figure 1 As shown, the molded glass mold core of the present invention includes a substrate 1 and a protective film 2, wherein the protective film 2 is located on the substrate 1, the protective film 2 has a molding surface 21 for molding grooves, and the material of the substrate 1 is Ceramic material, the material of this protective film 2 is fullerene (Fullerene, such as C 60 or C 70 ).

[0022] The method for manufacturing the molded glass core comprises the following steps:

[0023] Provide a substrate 1 of ceramic material;

[0024] A protective film 2 of a fullerene material is deposited on the surface of the substrate 1 .

[0025] The ceramic material is tungsten carbide, silicon carbide, silicon nitride or boron carbonitride. The fullerene material can be prepared by the graphite arc discharge method, and then the fullerene is plated on the surface of the substrate 1 by the ion beam evaporation method, and the thickness of the protective...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com