Electronic device shell and manufacturing method thereof

A technology for electronic devices and casings, which is applied in the direction of surface coating liquid devices, electrical equipment shells/cabinets/drawers, electrical components, etc. It can solve problems such as easy loosening, large gaps, affecting product strength and appearance, etc., to achieve The effect of beautiful appearance and high bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The electronic device casing and the manufacturing method thereof of the present invention will be further described in detail with reference to the accompanying drawings and preferred embodiments.

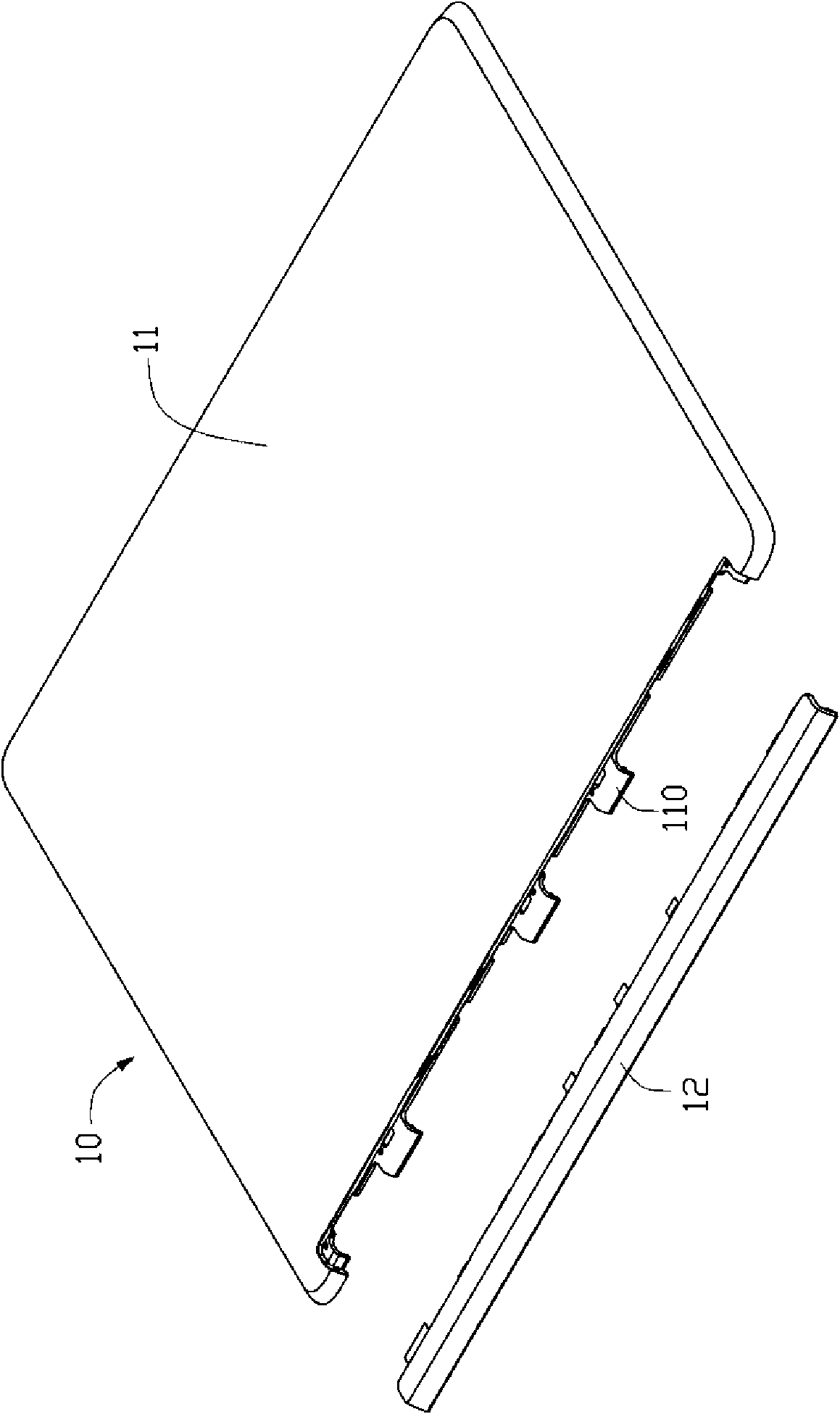

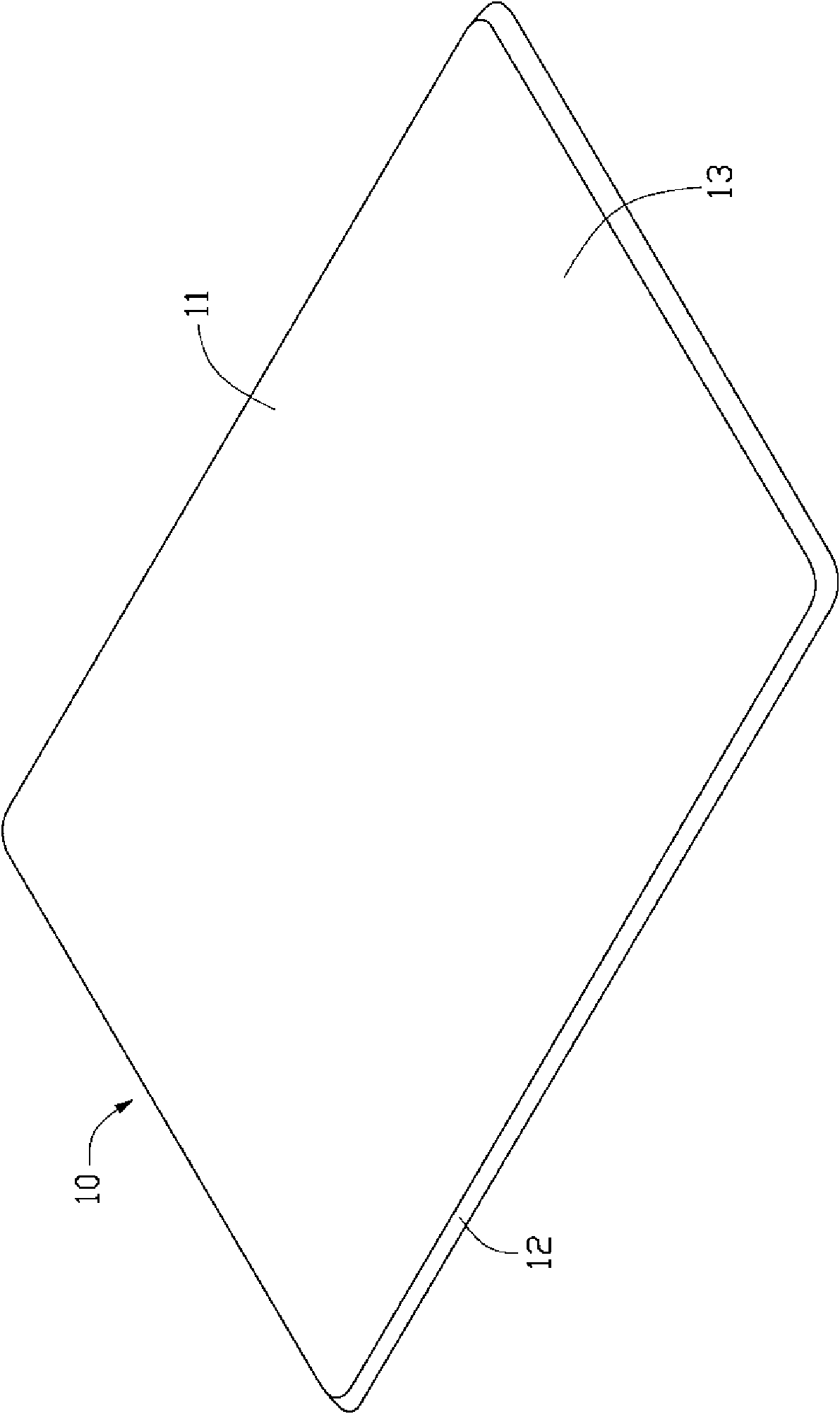

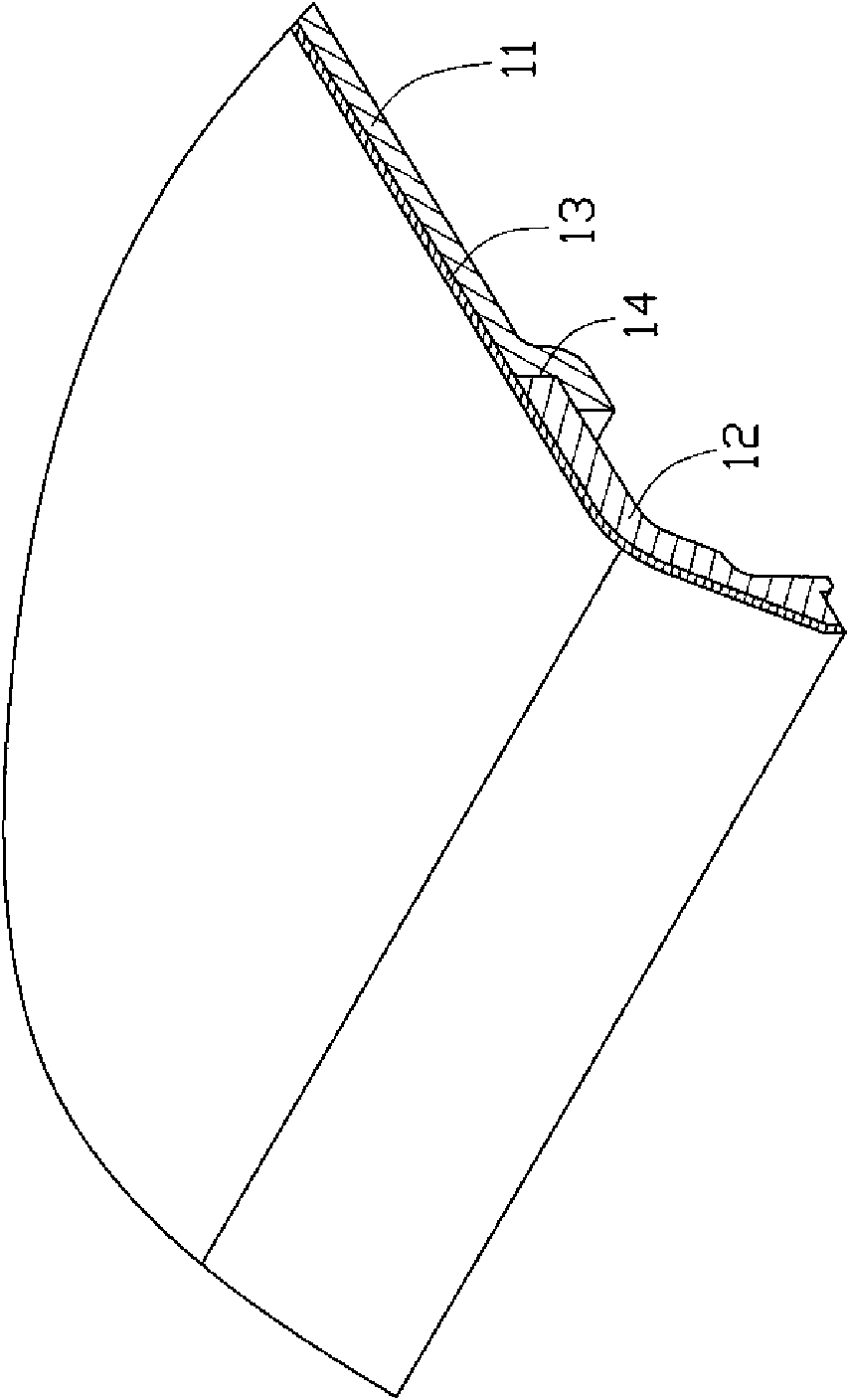

[0018] See figure 1 , shows an electronic device casing 10 according to a preferred embodiment of the present invention, which includes a metal body 11 and a plastic antenna cover 12 .

[0019] The metal body 11 is generally a rectangular metal cover, and one side thereof is provided with a plurality of fastening portions 110 for tightly fastening with the plastic antenna cover 12 during the molding process to form a fastening structure. The metal body 11 is made of alloy material, preferably magnesium alloy, aluminum alloy or titanium alloy.

[0020] The plastic antenna cover 12 is generally a long strip of cover plate, which can be formed on one side of the metal body 11 provided with the fastening portion 110 . The material of the plastic antenna cover 12 is required t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com