Fast-flow high temperature resistant nylon composite material

A nylon composite material and high-temperature-resistant technology, which is applied in the field of fast-flowing high-temperature-resistant nylon and its preparation, can solve the problems of reducing material strength and rigidity, low molecular weight, material mechanical properties and heat resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~10

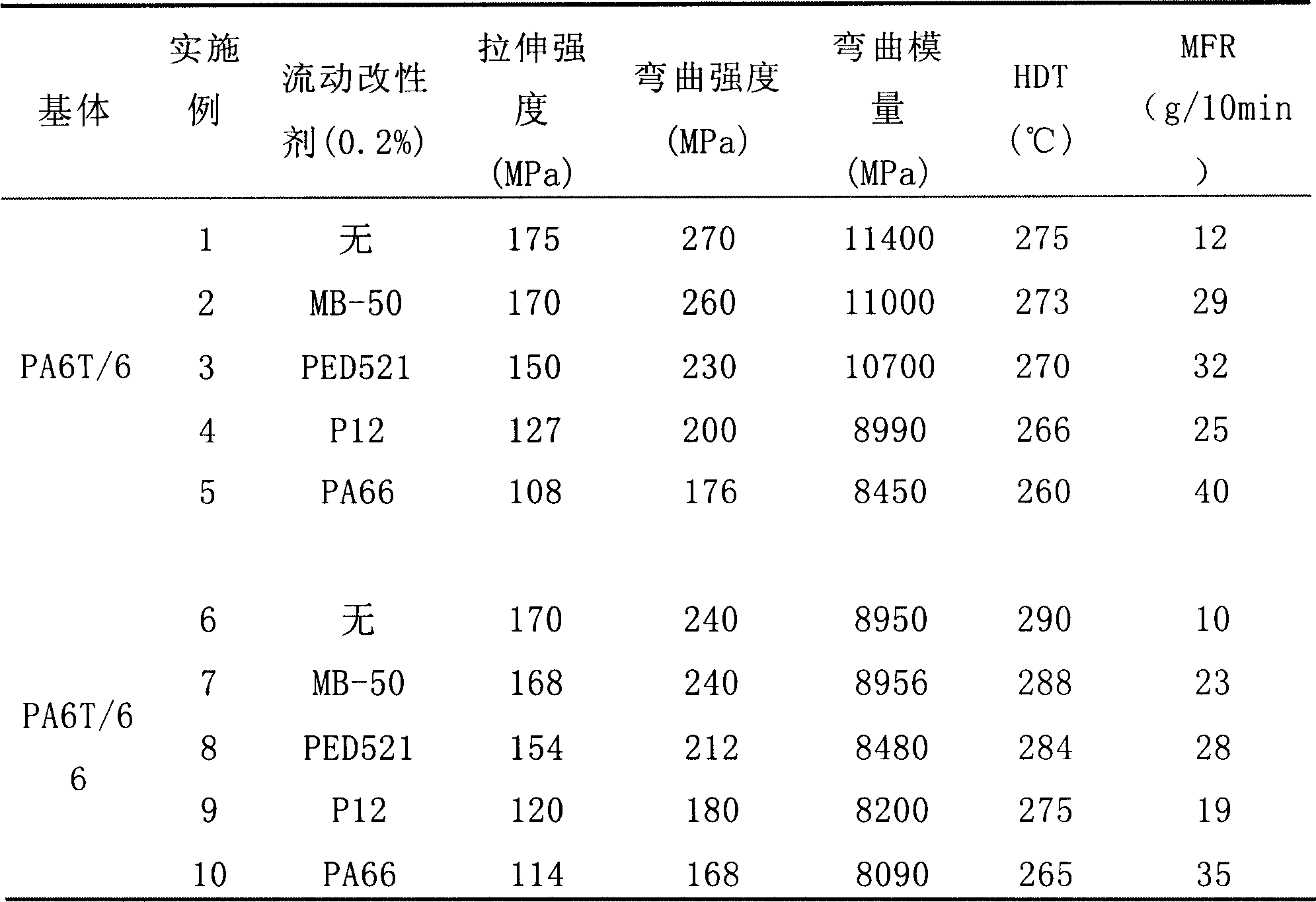

[0086] In the examples, the rheological properties, mechanical properties, and heat resistance properties of the fast-flowing high-temperature-resistant nylon composite material provided by the present invention are tested according to the following methods.

[0087] Rheological properties

[0088] On the RL-11B type melting rate flow meter that Shanghai Scientist Instrument Co., Ltd. produces, measure composite material at 325 ℃, under the pressure of 2.16kg, flow through a certain diameter (used diameter among the present invention is 2.09mm) in 10 minutes ) of the capillary weight. This weight in grams is referred to as the melt flow rate (MFR).

[0089] mechanical properties

[0090] Tensile test is carried out according to the standard ISO 527-1, 2-1993, and the bending test is tested according to ISO 178-2003 on the electronic universal testing machine produced by Shenzhen Xinsansi.

[0091] Heat resistance

[0092] The heat distortion temperature is tested on the XW...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com