Integral twice separation dust cup of dust collector

An integrated, vacuum cleaner technology, applied in suction filters and other directions, can solve the problems of large volume of vacuum cleaner dust cups, high consumption of raw materials, high cost, and achieve the effect of improving cleaning effect, reducing wind pressure loss and compact structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

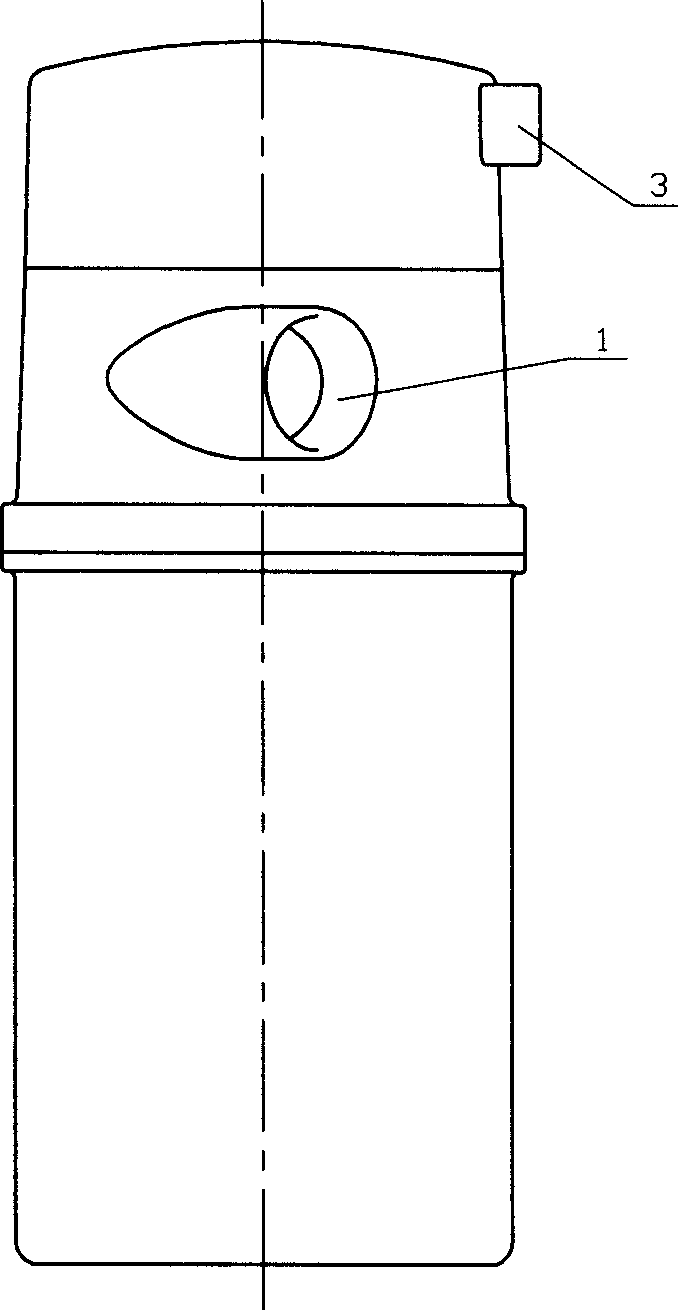

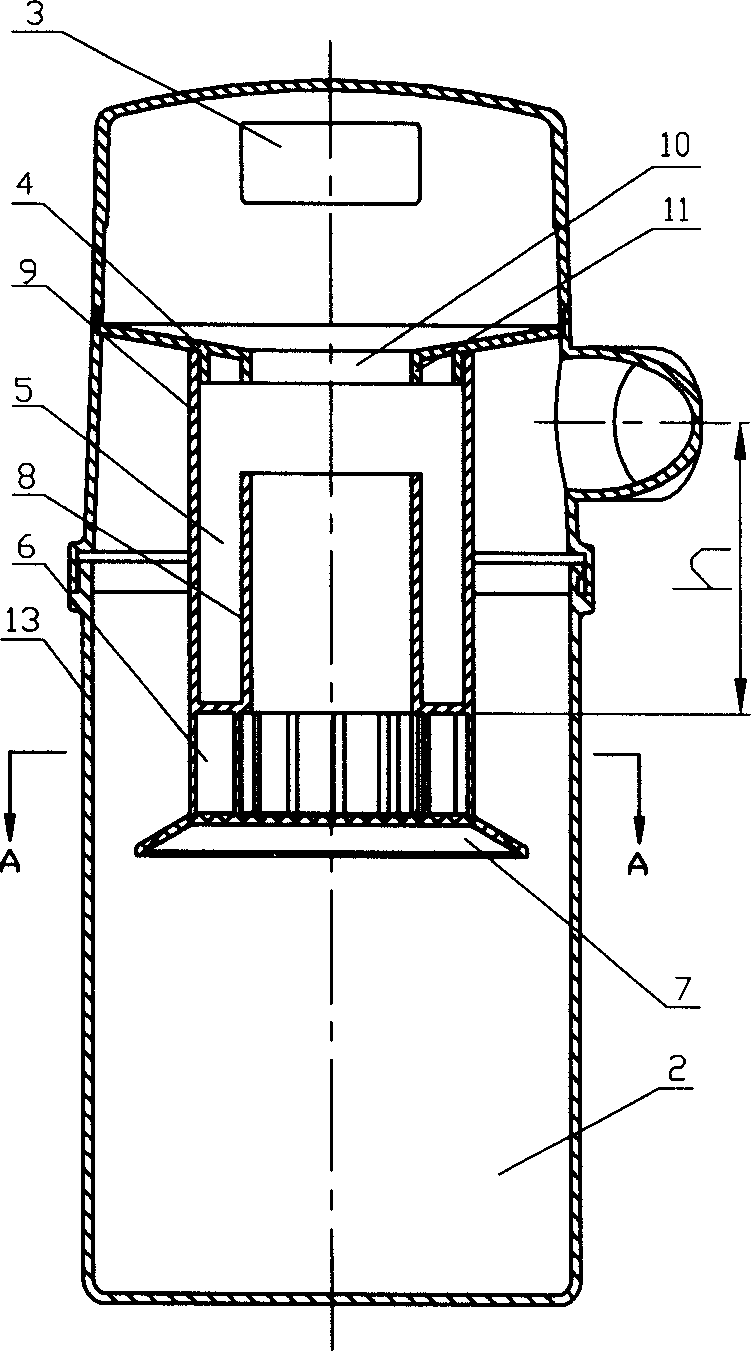

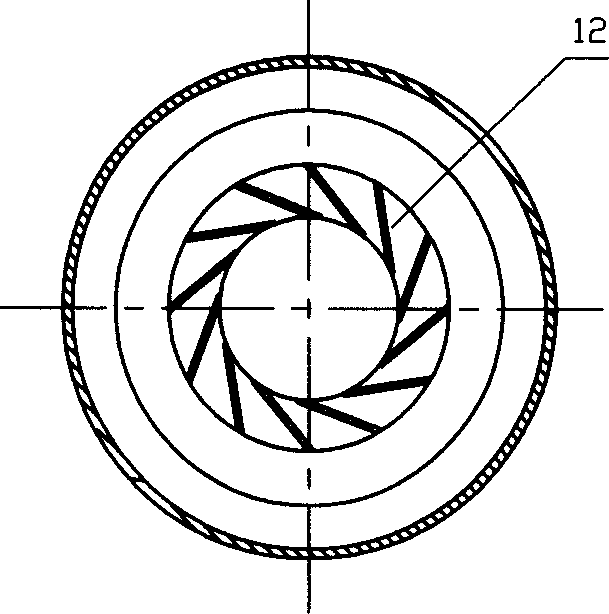

[0014] Figure 1 to Figure 3 Shown is embodiment one of the product of the present invention. It includes the dust cup shell 13, the dust cup air inlet 1 that is tangent to the dust cup shell 13 peripheral wall, the dust cup air outlet 3 that is opened on the cup cover that is closed with the cup body, and placed in the dust cup. The separator in the separator is provided with an air inlet 6, and an isolation cover 7 is arranged below the air inlet 6, and the air inlet 6 of the separator communicates with the dust cup air inlet 1. The upper part of the air inlet of the separator is connected with two coaxial inner and outer pipes 8, 9, and the lower part is connected with a trumpet-shaped isolation cover 7. The outer wall of the inner tube 8 is closed and connected to the bottom of the inner wall of the outer tube 9 , wherein the inner tube 8 communicates with the air outlet 3 of the dust cup, and the inner tube 8 is shorter than the outer tube 9 . There is a connecting brac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com