Ultrafine-grain medical magnesium alloy and preparation method thereof

A magnesium alloy and ultrafine-grained technology, which is applied in the field of binary or multi-elementary ultrafine-grained magnesium alloy implant materials and its preparation, can solve problems that cannot be directly used in production, and achieve room temperature specific tensile strength and elongation Improve, good biocompatibility, improve the effect of mechanical properties and corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Raw material: Mg-Zn binary alloy, wherein, the content of Zn is 5%, and the rest is Mg; the purity of Mg in the raw material is ≥99.95%, and the purity of Zn is ≥99.99%.

[0030] Preparation:

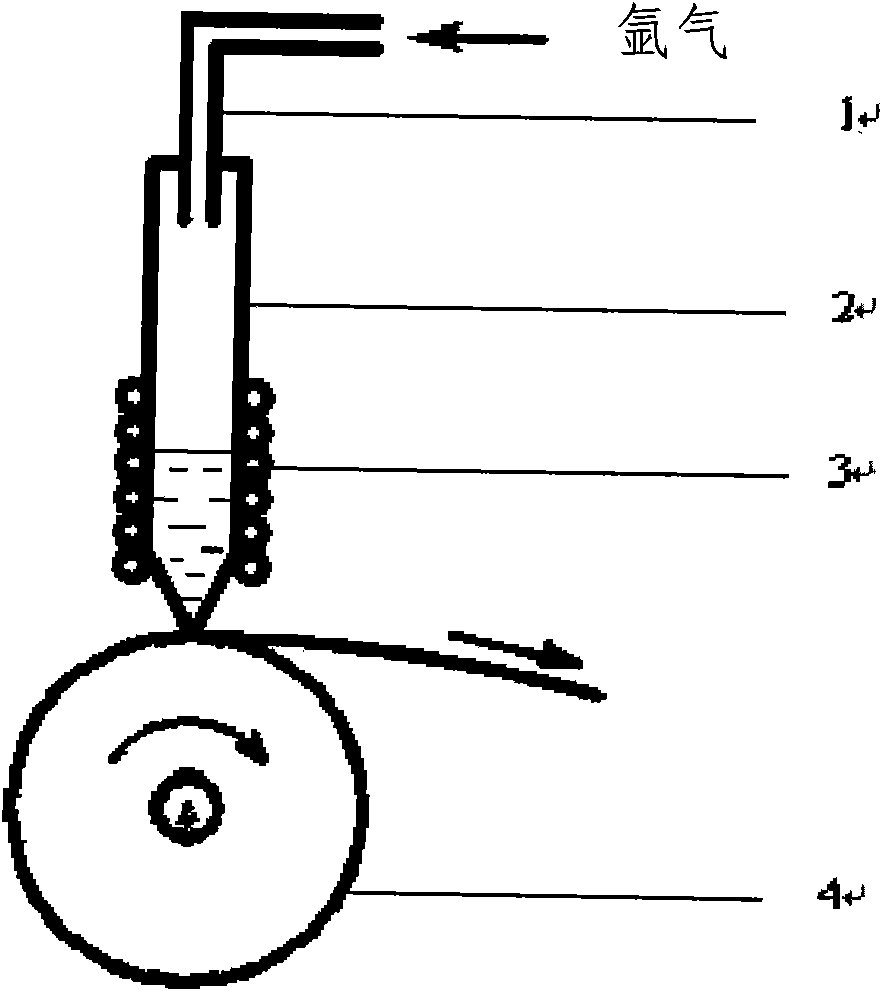

[0031] 1. The preparation of ultrafine-grained magnesium alloy powder adopts such as figure 1 For the device shown, put 3g of raw materials into a quartz tube with a diameter of 0.5mm at the bottom of the size of d16mm×300mm, then place the quartz tube on top of a copper roller equipped with a vacuum cover, and evacuate to 1.0 ×10 -3 After Pa, reverse-fill high-purity argon to 1 atmosphere; after repeated vacuuming and argon filling for 3 to 5 times, use high-frequency induction melting equipment to heat to melt the magnesium alloy and overheat it at 100K, keep it for 2 minutes; then pour it into the quartz tube Blow in 2kPa high-pressure argon, and use the above-mentioned high-pressure argon to shoot the molten magnesium alloy on the surface of the copper roller with a rotatio...

Embodiment 2

[0035] Raw material: Mg-Zn binary alloy, wherein, the content of Zn is 5%, and the rest is Mg; the purity of Mg in the raw material is ≥99.95%, and the purity of Zn is ≥99.99%.

[0036] Preparation:

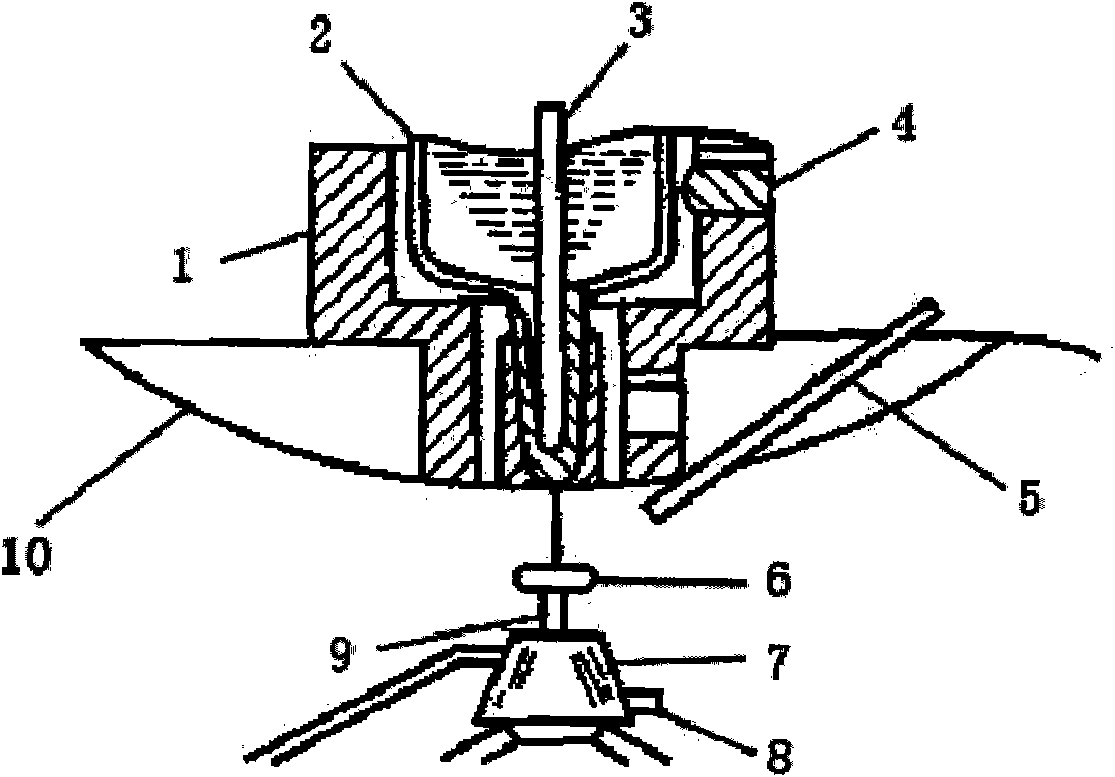

[0037] 1. The preparation of ultrafine-grained magnesium alloy powder adopts such as figure 2 In the device shown, the raw materials are put into a melting pot and heated to melt them, and the molten magnesium alloy is poured into a rotating concave disc made of red copper. The disc rotates at 25,000rpm / min. The liquid is sprayed along the tangential direction and forms droplets; the droplets are cooled by forced convection by jetting helium flow through the gas nozzles installed around the disk, and the cooling rate is about 10 7 K / s, so that the micro-droplets are rapidly solidified into a powder of 100-200 mesh (US sieve size, the same below).

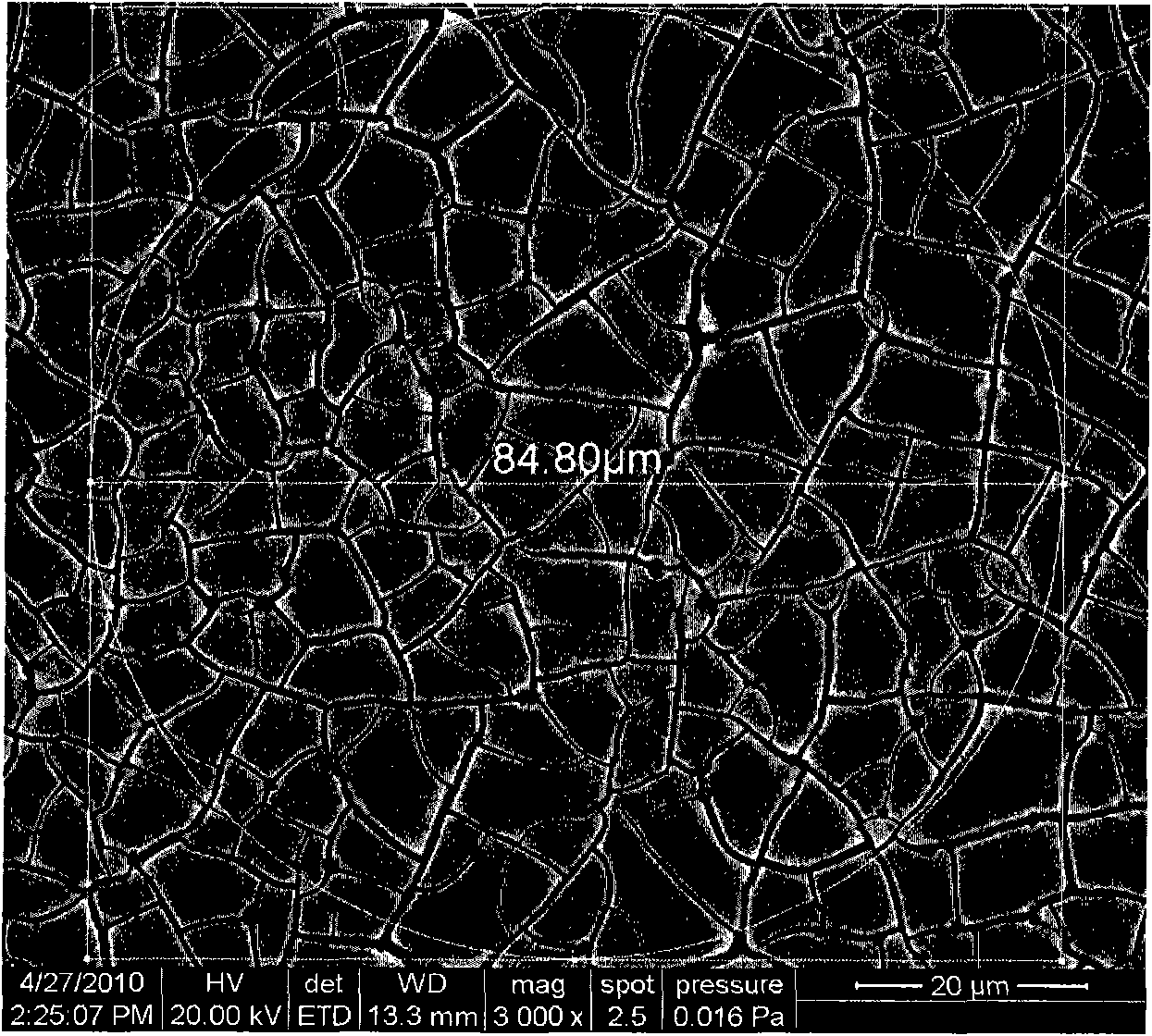

[0038] The rest of the steps are the same as in Example 1, finally making Φ3mm ultrafine-grained magnesium alloy micropipes, the t...

Embodiment 3

[0040] Raw material: Mg-Ca binary alloy, wherein the content of Ca is 1%, and the rest is Mg; the purity of Mg in the raw material is ≥99.95%, and the purity of Ca is ≥99.95%.

[0041] Preparation:

[0042] 1. Preparation of ultra-fine-grained magnesium alloy powder Prepare molten magnesium alloy according to the method in Example 1 and overheat it at 100K. After 5 minutes of heat preservation, the molten magnesium alloy is shot at a speed of 3000rpm and a thermal conductivity of 386W / mK with 1kPa of argon. On the surface of the roll, the liquid magnesium alloy is rapidly cooled on the roll surface, and the cooling rate is about 10 7 K / s, the magnesium alloy is solidified into a thin strip and thrown out along the direction of rotation of the copper roller; the above-mentioned magnesium alloy thin strip is broken into a powder of 35 mesh (powder particle size 500 μm) through a series of high-speed crushing processes.

[0043] 2. Preparation of ultra-fine-grained magnesium all...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Corrosion rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com