Binary alloy coating seamless steel tube top and manufacture method thereof

A technology of seamless steel pipe and double alloy, which is applied in metal material coating process, coating, metal rolling, etc., can solve the problems of complex manufacturing method, high cost, and the service life of the plug needs to be further improved. Cracks, the effect of eliminating stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

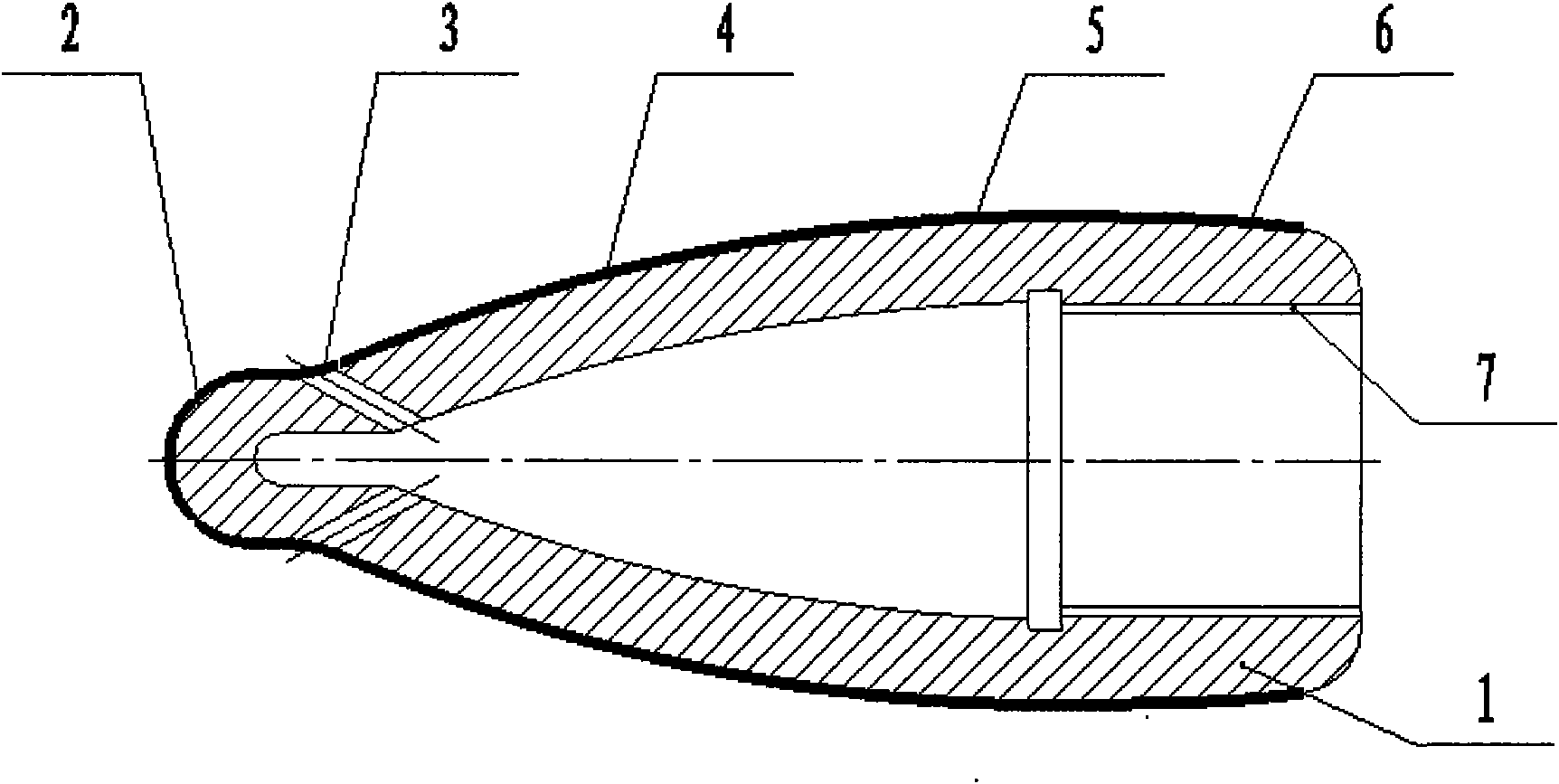

[0020] (1) Select 3Cr2W8 as the plug base material, and obtain the casting blank;

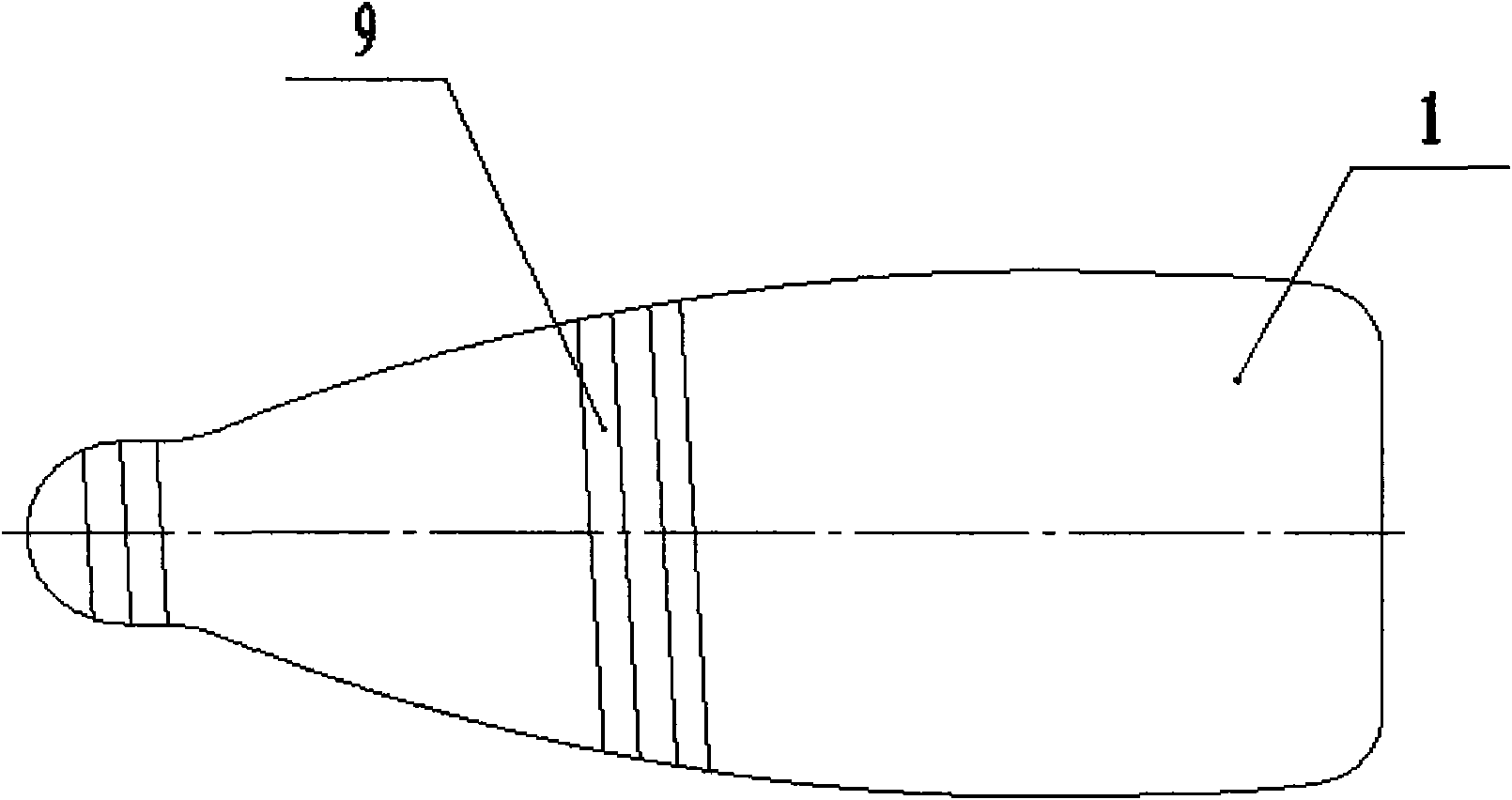

[0021] (2) Carry out conventional mechanical processing on the plug blank, reserve 1.0mm thickness on the outer surface of the plug for the laser cladding process, and use the plug thread 7 to realize clamping and fixing before laser cladding;

[0022] (3) Adopt laser broadband cladding process, lateral powder feeding, see the applicant's authorized patent ZL200520121771.2 for the nozzle, double-barrel powder feeding method, one of which is filled with nickel-based alloy powder, and the other is filled with iron-based alloy powder;

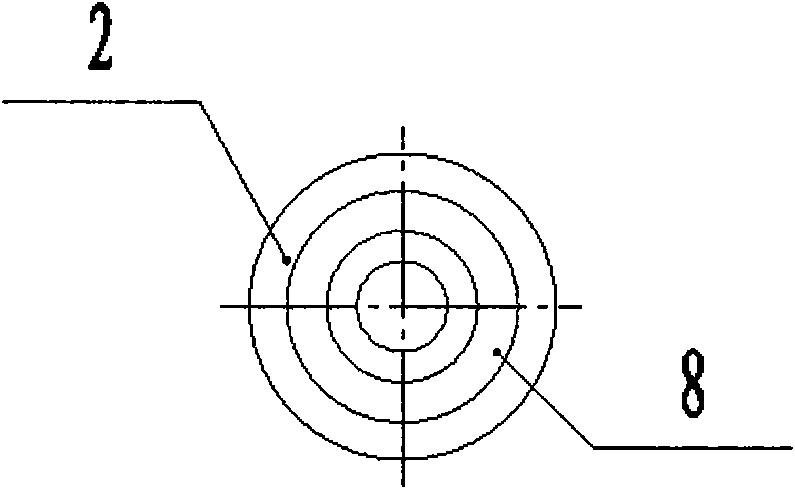

[0023] (4) First use nickel-based alloy powder to carry out laser cladding on the top of the nose, the cladding track is a circular line, and the overlap rate is 40%;

[0024] (5) Laser cladding is carried out on the side of the nose and the working part. The cladding powder material is nickel-based alloy powder, and then the laser is used to continuously complete ...

Embodiment 2

[0029] (1) choose 20CrNi4 as the plug base material, and obtain the casting blank;

[0030] (2) Carry out conventional mechanical processing on the plug blank, reserve 3.0mm thickness on the outer surface of the plug for the laser cladding process, and use the plug thread 7 to realize clamping and fixing before laser cladding;

[0031] (3) Adopt laser broadband cladding process, side powder feeding nozzle, double-barrel powder feeding method, one of which is filled with nickel-based alloy powder, and the other is filled with iron-based alloy powder;

[0032] (4) First use nickel-based alloy powder to carry out laser cladding on the top of the nose, the cladding track is a circular line, and the overlap rate is 60%;

[0033] (5) Laser cladding is carried out on the side of the nose and the working part. The cladding powder material is nickel-based alloy powder, and then the laser is used to continuously complete the laser cladding of the straightening part and parallel part wit...

Embodiment 3

[0038](1) Select 35CrMo as the base material of the plug, and obtain the casting blank;

[0039] (2) Carry out conventional mechanical processing on the plug blank, reserve 1.5mm thickness on the outer surface of the plug for the laser cladding process, and use the plug thread 7 to realize clamping and fixing before laser cladding;

[0040] (3) Laser broadband cladding process is adopted, powder is fed laterally, and powder is fed by double cylinders, one of which is filled with cobalt-based alloy powder and the other is filled with iron-based alloy powder;

[0041] (4) Cobalt-based alloy powder is first used for laser cladding on the top of the nose, the cladding track is a circular line, and the overlap rate is 50%;

[0042] (5) Laser cladding is carried out on the side of the nose and the working part. The cladding powder material is cobalt-based alloy powder, and then the laser is used to continuously complete the laser cladding of the straightening part and parallel part ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com