Surface strengthening method for metal component by vibration-assisted laser shock treatment

A metal component and impact treatment technology, which is applied in the field of metal surface strengthening treatment and surface strengthening layer, can solve the problems of inability to achieve strengthening effect and the influence of material surface roughness, etc., to prevent initiation and expansion, improve mechanical properties, The effect of improving fatigue life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solution of the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0023] The sample base material used in this embodiment is 304 stainless steel, and its geometric size is 60mm×30mm×10mm.

[0024] A kind of example using above-mentioned strengthening method processing sample, its steps are:

[0025] (1) After the metallographic sandpaper is used to grind the sample to be treated step by step, put it in an alcohol solution and use an ultrasonic cleaner to remove dust and oil stains on the surface;

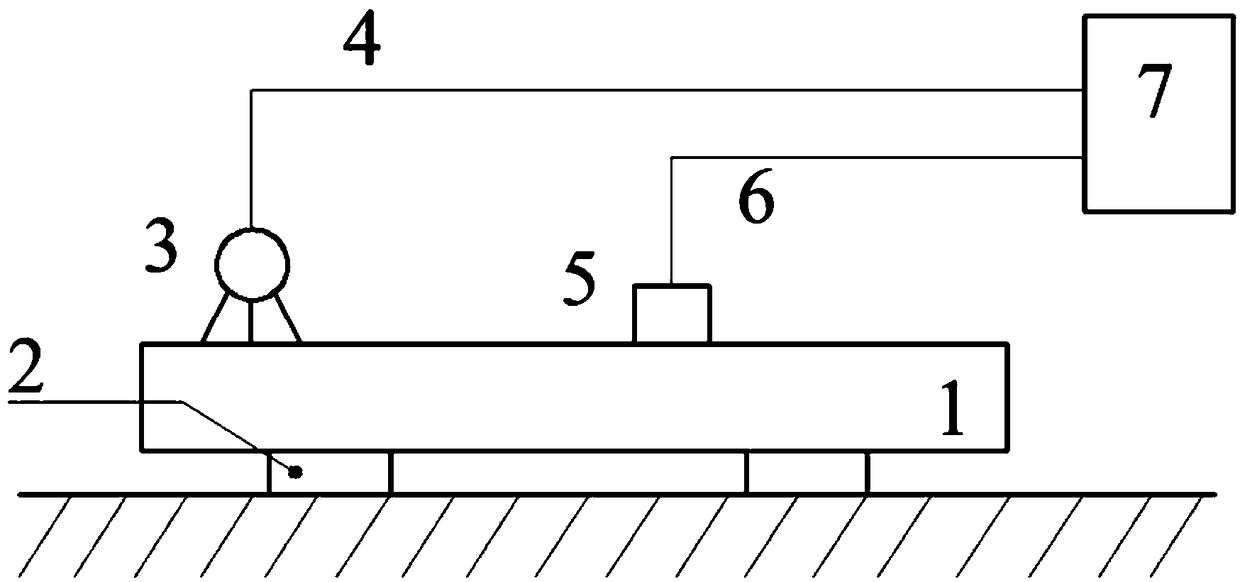

[0026] (2) The vibrator 3 is fixed on the 304 stainless steel sample 1 to be processed, and the vibrator 3 is connected to the controller 7 through the motor cable 4;

[0027] (3) sensor 5 is placed on the surface of the 304 stainless steel sample, fixed on the sample by the magnet at its bottom, sensor 5 is connected to the controller 7 by shielded cable 6;

[0028] (4) Instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com