Preparation method for high-strength pure titanium panels

A high-strength, pure titanium technology, applied in the field of metal materials, can solve the problems of difficulty in preparing large-volume materials, severe plastic deformation, and small size of deformed pure titanium, achieving high local shear sensitivity and less slip system. , the effect of increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

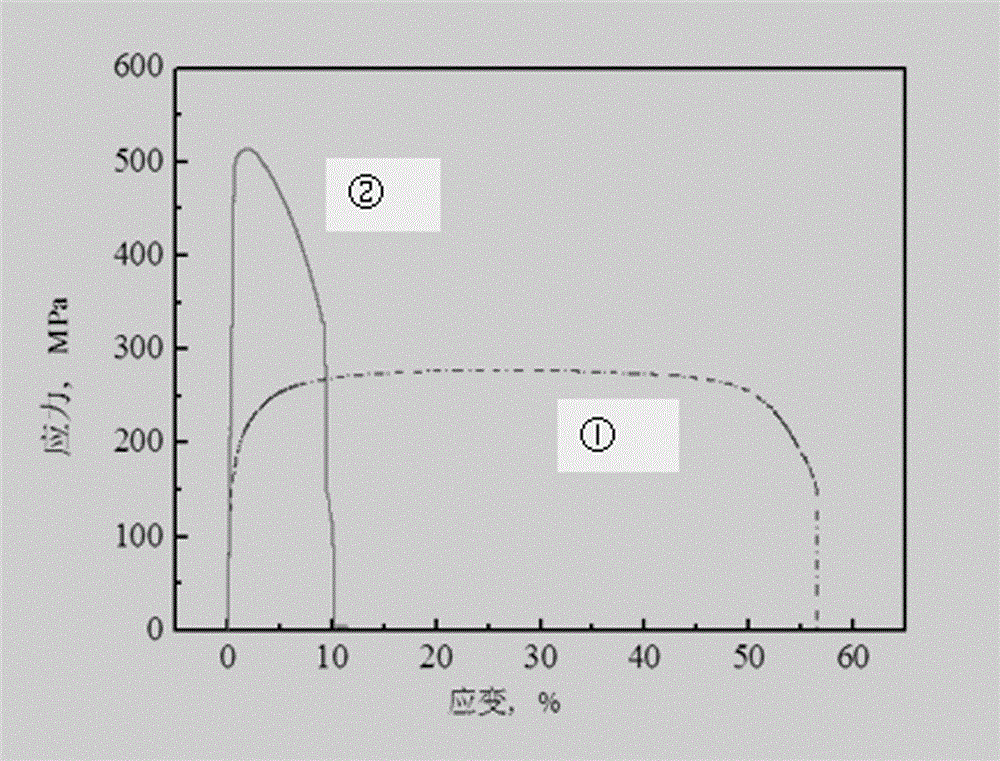

[0025] The method for preparing a high-strength pure titanium plate by using the pure titanium plate TA1 with a size of 78×78×2mm as a raw material is carried out according to the following process steps:

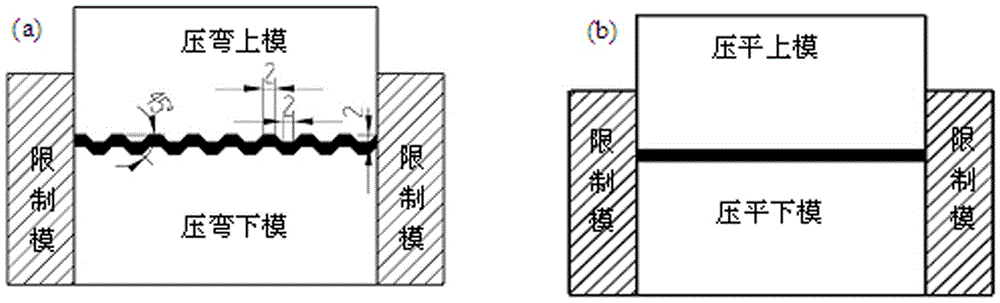

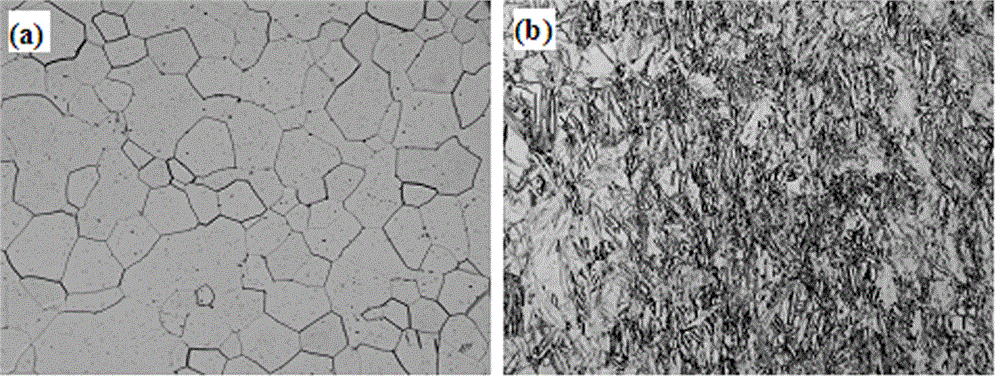

[0026] (1) Use a controllable pressure testing machine to limit the severe plastic deformation of the pure titanium plate TA1 at room temperature. The process parameters are: the tooth width of the bending die of the molding die is 2mm, the tooth height is 2mm, and the deformation rate is 10~20mm / min , 3-pass deformation;

[0027] (2) Perform electric pulse annealing treatment on the pure titanium plate between each pass to limit the molding deformation, that is, electric pulse annealing treatment. The process parameters are: pulse current density is 0.3~0.6kA / mm 2 , the pulse current frequency is 20~30Hz, the pulse width is 30μs, the processing time is 2~10min, and the number of electric pulse annealing treatments is 2 times;

[0028] (3) A high-strength pure titanium pla...

Embodiment 2

[0031] The method for preparing a high-strength pure titanium plate using the pure titanium plate TA1ELI with a size of 102×102×1.5mm as a raw material is carried out according to the following process steps:

[0032] (1) Use a controllable pressure testing machine to limit the severe plastic deformation of the pure titanium plate TA1ELI at room temperature. The process parameters are: the tooth width of the bending die of the molding die is 1.5mm, the tooth height is 1.5mm, and the deformation rate is 3~10mm / min, 2-pass deformation;

[0033] (2) Perform electric pulse annealing treatment on the pure titanium plate between each pass to limit the molding deformation, that is, electric pulse annealing treatment. The process parameters are: pulse current density is 0.2~0.4kA / mm 2 , the pulse current frequency is 10~30Hz, the pulse width is 10μs, the processing time is 1~5min, and the frequency of electric pulse annealing treatment is 1 time;

[0034] (3) A high-strength pure ti...

Embodiment 3

[0037] The method for preparing a high-strength pure titanium plate with a size of 52×52×3mm pure titanium plate TA2 as a raw material is carried out according to the following process steps:

[0038] (1) Use a controllable pressure testing machine to limit the severe plastic deformation of the pure titanium plate TA2 at room temperature. The process parameters are: the tooth width of the bending die of the molding die is 3mm, the tooth height is 3mm, and the deformation rate is 30~40mm / min , 3-pass deformation;

[0039] (2) Perform electric pulse annealing treatment on the pure titanium plate between each pass to limit the molding deformation, that is, electric pulse annealing treatment. The process parameters are: pulse current density is 0.5~0.8kA / mm 2 , the pulse current frequency is 20~40Hz, the pulse width is 20μs, the processing time is 5~15min, and the number of electric pulse annealing treatments is 2 times;

[0040] (3) A high-strength pure titanium plate is obtaine...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com