Method for preparing graphene reinforced aluminum-based composite with multi-layer graphene nanoplatelets as raw materials

A technology of graphene microflakes and reinforced aluminum matrix, which is applied in the field of graphene-reinforced aluminum-based composite materials, can solve the problems of difficult dispersion and high cost of graphene-reinforced aluminum-based composite materials, and achieve simple process methods and easy industrial production And application, to overcome the effect of lower stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

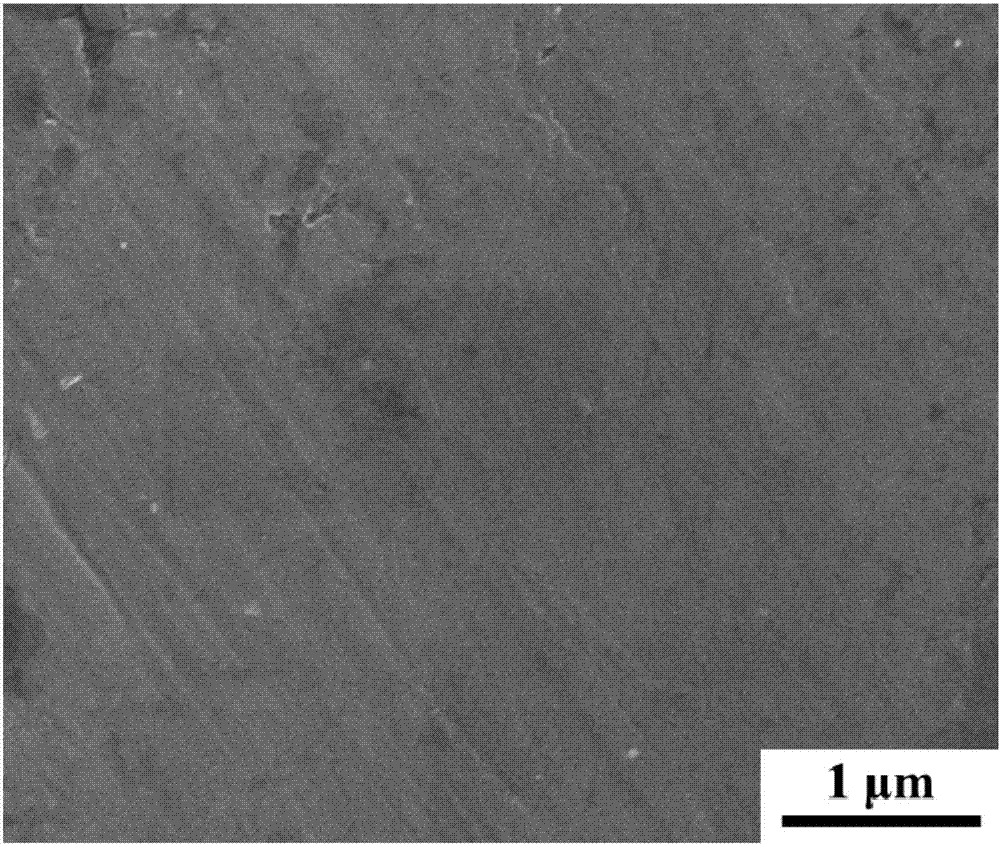

Image

Examples

specific Embodiment approach 1

[0044] Specific embodiment one: present embodiment is a kind of method for raw material preparation graphene reinforced aluminum matrix composite material with multi-layer graphene microchip, and this method is carried out according to the following steps:

[0045] 1. Weighing

[0046] Take by weighing 0.5%~4% multilayer graphene microchip and 96%~99.5% aluminum metal powder by mass fraction; Industrial pure aluminum block, the weight ratio of industrial pure aluminum block and above-mentioned aluminum metal powder is (3~10 ):1;

[0047] 2. Dispersion of multilayer graphene microflakes and prefabricated block formation

[0048] Put the multilayer graphene microflakes and aluminum metal powder weighed in step 1 into a ball mill tank, ball mill the obtained mixed powder at a speed of 100-400rpm for 4-15 hours, and put the mixed powder obtained after ball milling into a cold-press mold Carry out cold pressing to obtain multilayer graphene microchip / aluminum prefabricated body; ...

specific Embodiment approach 2

[0063] Embodiment 2: This embodiment differs from Embodiment 1 in that: the average diameter of the multilayer graphene microflakes in Step 1 is 100 nm to 10 μm, and the average thickness is 6 to 50 nm. Other steps and parameters are the same as those in the first embodiment.

specific Embodiment approach 3

[0064] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the average particle size of the aluminum metal powder in Step 1 is 1-30 μm. Other steps and parameters are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Elastic modulus | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com