Preparation method of nano graphene copper foil

A nano-graphene, graphene technology, applied in nanotechnology, electrode carrier/current collector, electrical components, etc., to achieve the effect of improving strength and refining grain structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

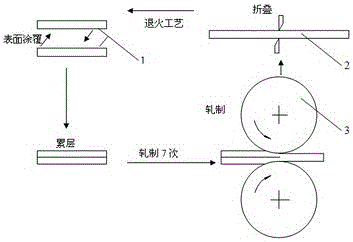

[0020] In the first step, graphene, acetylene black, and PVB are weighed according to the weight ratio of (85):(10):(5), and dispersed in NMP at 30°C for 1 hour before use;

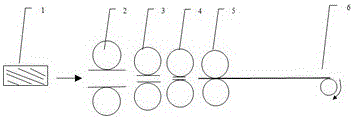

[0021] In the second step, the uniformly dispersed slurry in the first step is evenly coated on a copper strip with a width of 1000 mm and a thickness of 0.3 mm to form a graphene coating, and then dried at 90 ° C to obtain a graphene-coated surface. Copper strip;

[0022] In the third step, the side of the copper strip attached with graphene is folded in half from the middle, and folded into the same size so as to be re-stacked for the next cycle. The copper strip is annealed at 330°C for 1 hour;

[0023] In the fourth step, the rolled graphene copper strip is processed according to the second and third steps. This process is repeated 7 times to accumulate enough strain, and the grains are refined. At the same time, the graphene is evenly distributed on the copper strip. For the inner nano-graphene cop...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com