Method for determining pipeline critical burial depth in debris flow areas

A determination method, technology of debris flow, applied in the direction of pipeline laying and maintenance, pipes/pipe joints/fittings, mechanical equipment, etc., can solve the problems of weak anti-risk, anti-disaster ability, lack of science and objectivity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

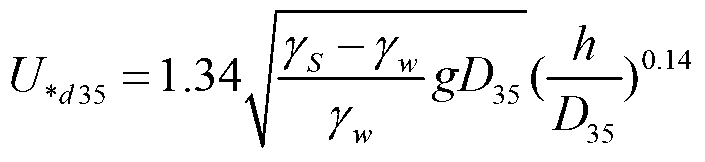

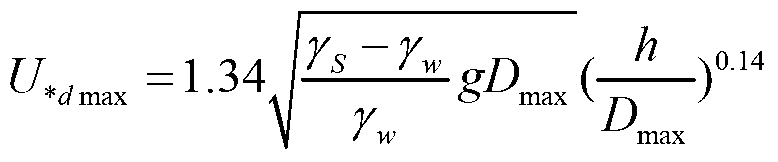

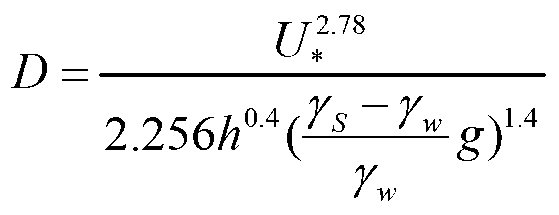

Method used

Image

Examples

Embodiment Construction

[0064] A method for determining the critical buried depth of a pipeline in a debris flow area, comprising the following steps:

[0065] Step 1. Determine the basic types of debris flow:

[0066] According to the local hydrometeorological data and the debris flow area survey guide, the type of a certain large-scale debris flow in a certain debris flow ditch can be obtained:

[0067] (1) If the clay content in the soil is less than 3% and the viscosity of the debris fluid is less than 0.3Pa·s, the volume concentration C of the soil in the debris flow is V 3 (Mud flow is 1200-1500kg / m 3 ); turbulent movement, no obvious gust flow; accumulations are clearly sorted, and the soil particles are thicker than the original soil where the debris flow occurred; then it is determined to be a rare debris flow;

[0068] (2) If the clay content in the soil is >3%, and the viscosity of the debris fluid is >0.3Pa·s, the volume concentration C of the soil in the debris flow is V >50%, bulk de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com