Method for preparing polymer material with gradient distributed surface biomacromolecule

A technology for biomacromolecules and polymer materials, which is applied in the field of preparing polymer materials with gradient distribution of biomacromolecules on the surface, can solve the problems of long time consumption, many steps, poor gradient control effect, etc. Effects from a wide range of sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

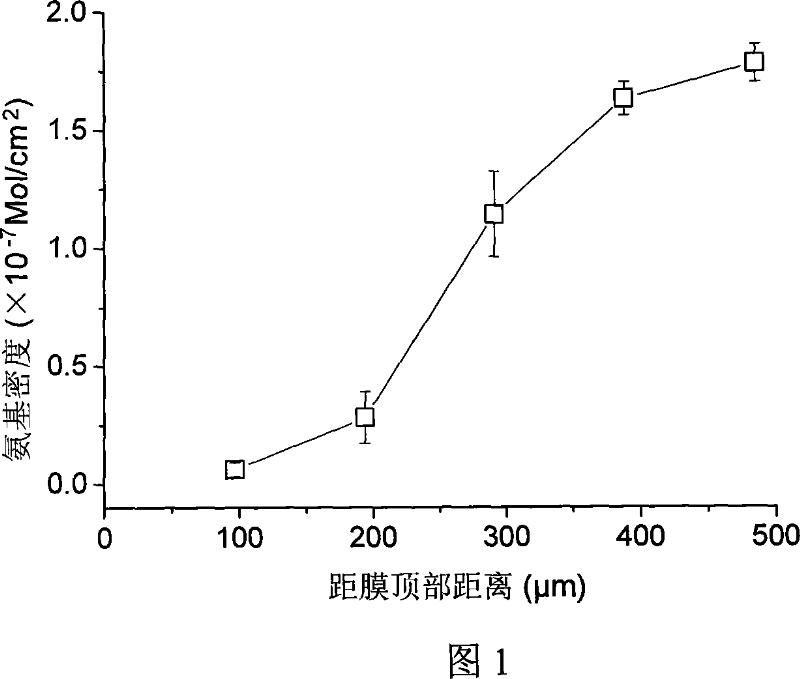

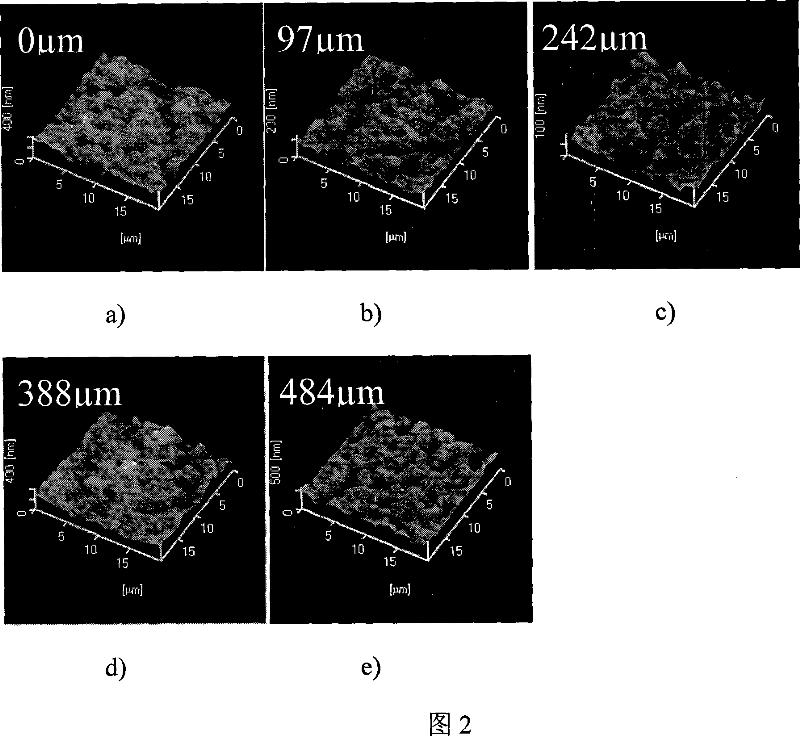

[0020] 1) Dissolving hexamethylenediamine in n-propanol to form a homogeneous solution with a weight / volume concentration of 6%, as an aminolysis solution. The polylactic acid film was fixed vertically in a glass test tube with a diameter of 13.2 mm. The aminolysis solution was injected into the test tube with a micro-syringe at an injection rate of 0.4 ml / h, while the aminolysis temperature was controlled at 60° C. and the injection time was 10 minutes. The distribution curve of amino group concentration on the membrane surface after aminolysis is shown in Figure 1; the surface morphology is shown in Figure 2.

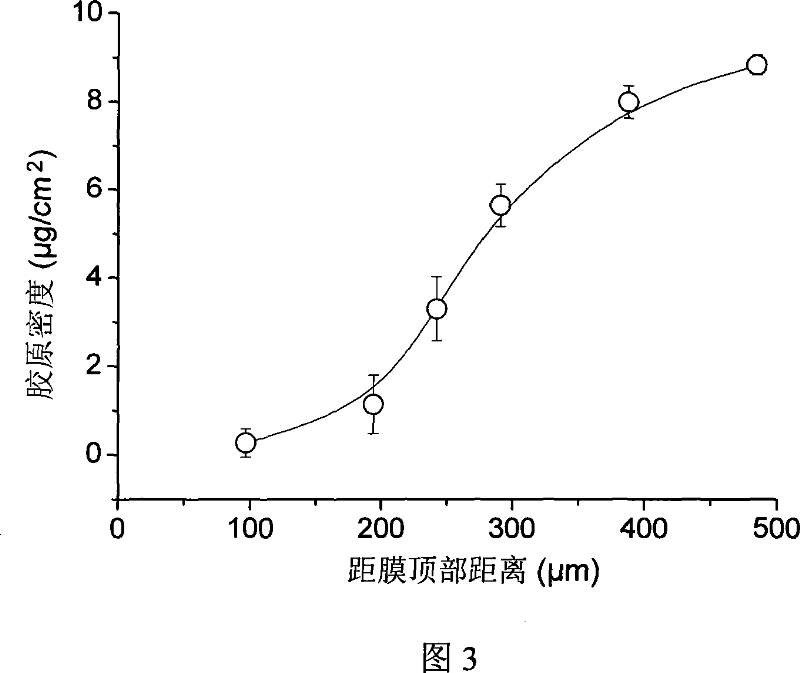

[0021] 2) After the polylactic acid film of gradient aminolysis was washed with three-distilled water, it was immersed in a glutaraldehyde solution with a mass concentration of 1% at room temperature for 3 hours, and then it was taken out and cleaned with three-distilled water to obtain a polylactic acid film with a gradient distribution of aldehyde groups on the surf...

Embodiment 2

[0024] 1) Dissolving hexamethylenediamine in n-propanol to form a homogeneous solution with a weight / volume concentration of 3%, as an aminolysis solution. The polylactic acid film was fixed vertically in a glass test tube with a diameter of 20 mm. The aminolysis solution was injected into the test tube with a micro-syringe at an injection speed of 5 ml / h, while the aminolysis temperature was controlled at 60° C., and the injection time was 10 minutes.

[0025] 2) After the polylactic acid film of gradient aminolysis was washed with three-distilled water, it was immersed in a glutaraldehyde solution with a mass concentration of 0.3% at room temperature for 6 hours, and then it was taken out and cleaned with three-distilled water to obtain a polylactic acid film with a gradient distribution of aldehyde groups on the surface. Lactic acid film.

[0026] Step 3) Same as in Example 1, obtaining a polylactic acid film with a surface collagen gradient immobilized.

Embodiment 3

[0028] Hexamethylenediamine was dissolved in n-propanol to form a homogeneous solution with a weight / volume concentration of 10%, which was used as an aminolysis solution. The polylactic acid film was fixed vertically in a glass test tube with a diameter of 13.2 mm. The aminolysis solution was injected into the test tube with a micro-syringe at an injection speed of 0.8 ml / h, while the aminolysis temperature was controlled at 50° C., and the injection time was 15 minutes.

[0029] Step 2) and step 3) are the same as in Example 1 to obtain a polylactic acid film with a collagen gradient immobilized on the surface.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com