Patents

Literature

340 results about "OPE compound" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

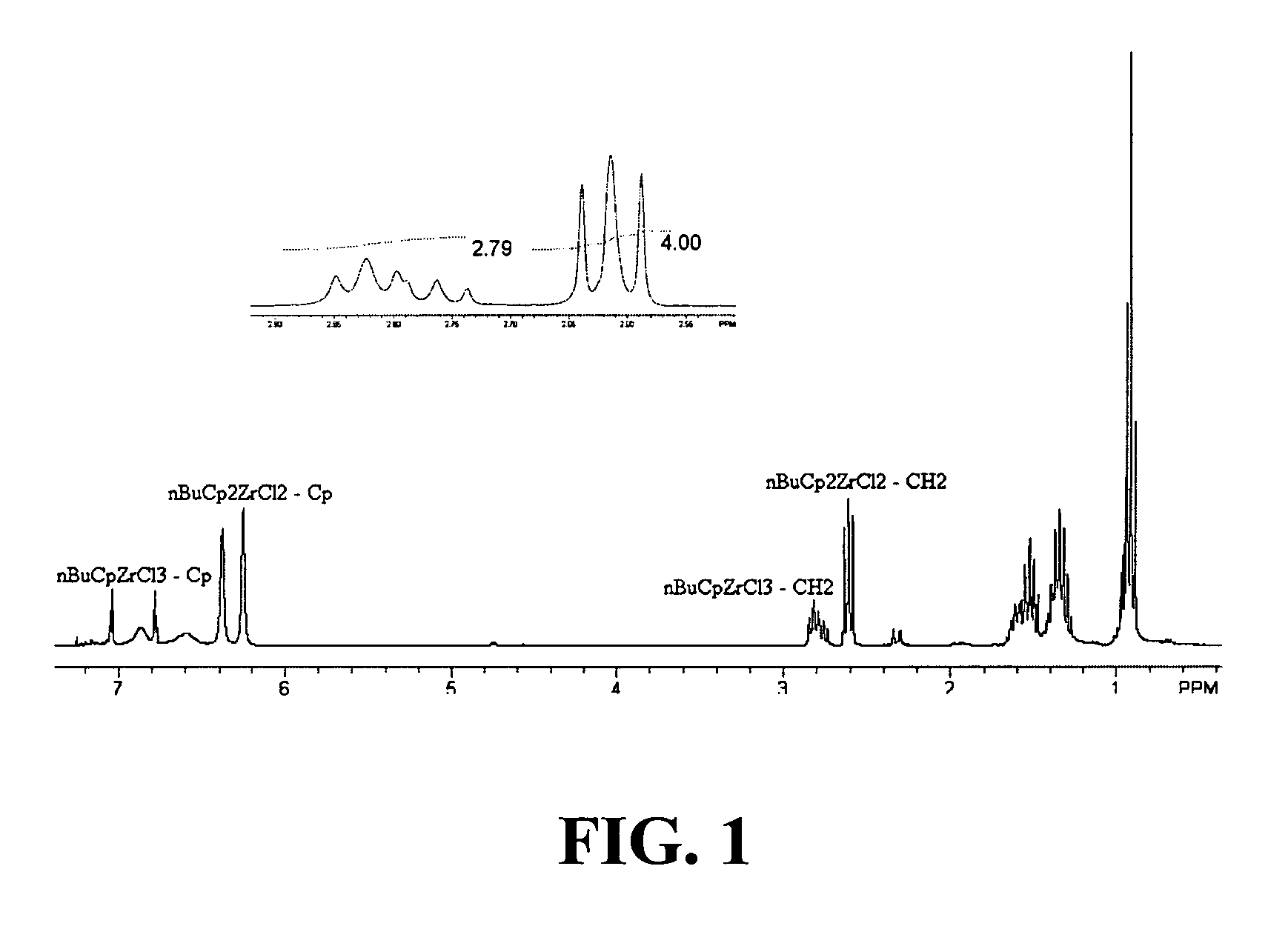

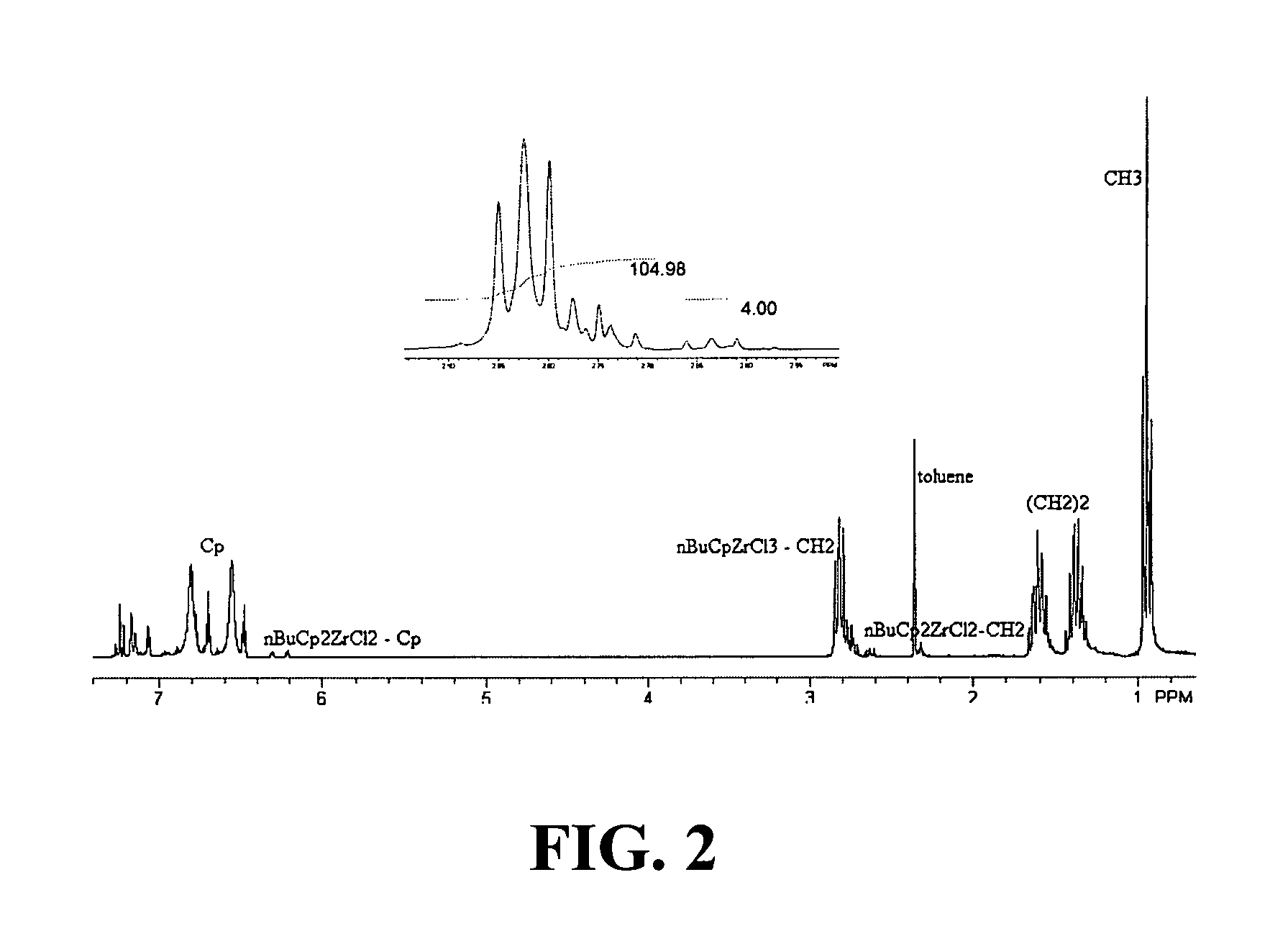

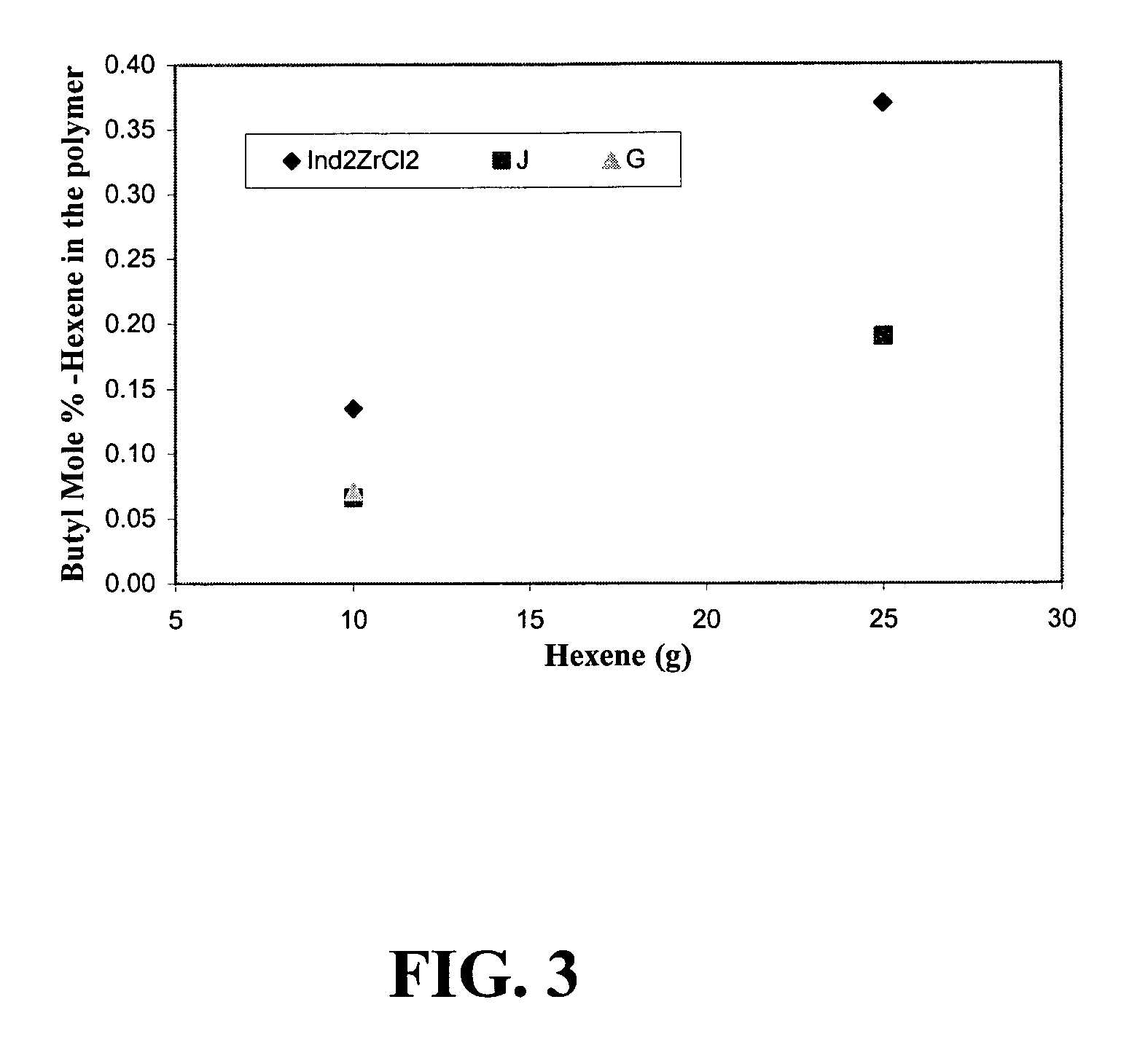

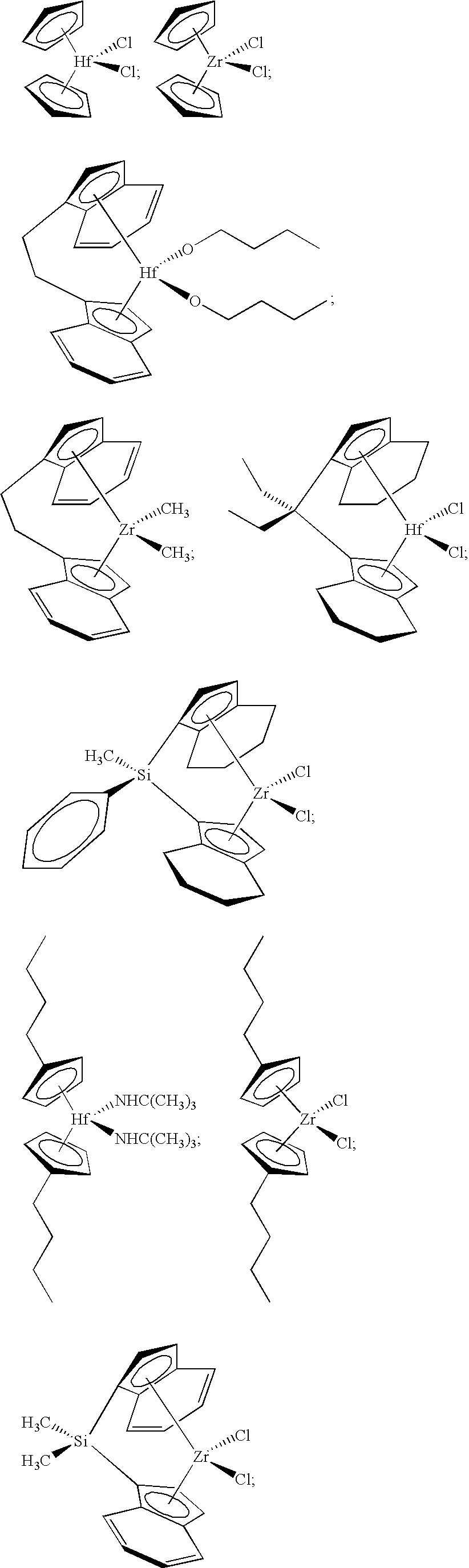

Polymerization catalysts and process for producing bimodal polymers in a single reactor

ActiveUS7226886B2Outstanding balance of stiffnessHigh impact strengthOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationPolyolefinImproved method

Catalyst compositions comprising a first metallocene compound, a second metallocene compound, an activator-support, and an organoaluminum compound are provided. An improved method for preparing cyclopentadienyl complexes used to produce polyolefins is also provided.

Owner:CHEVRON PHILLIPS CHEMICAL CO LP

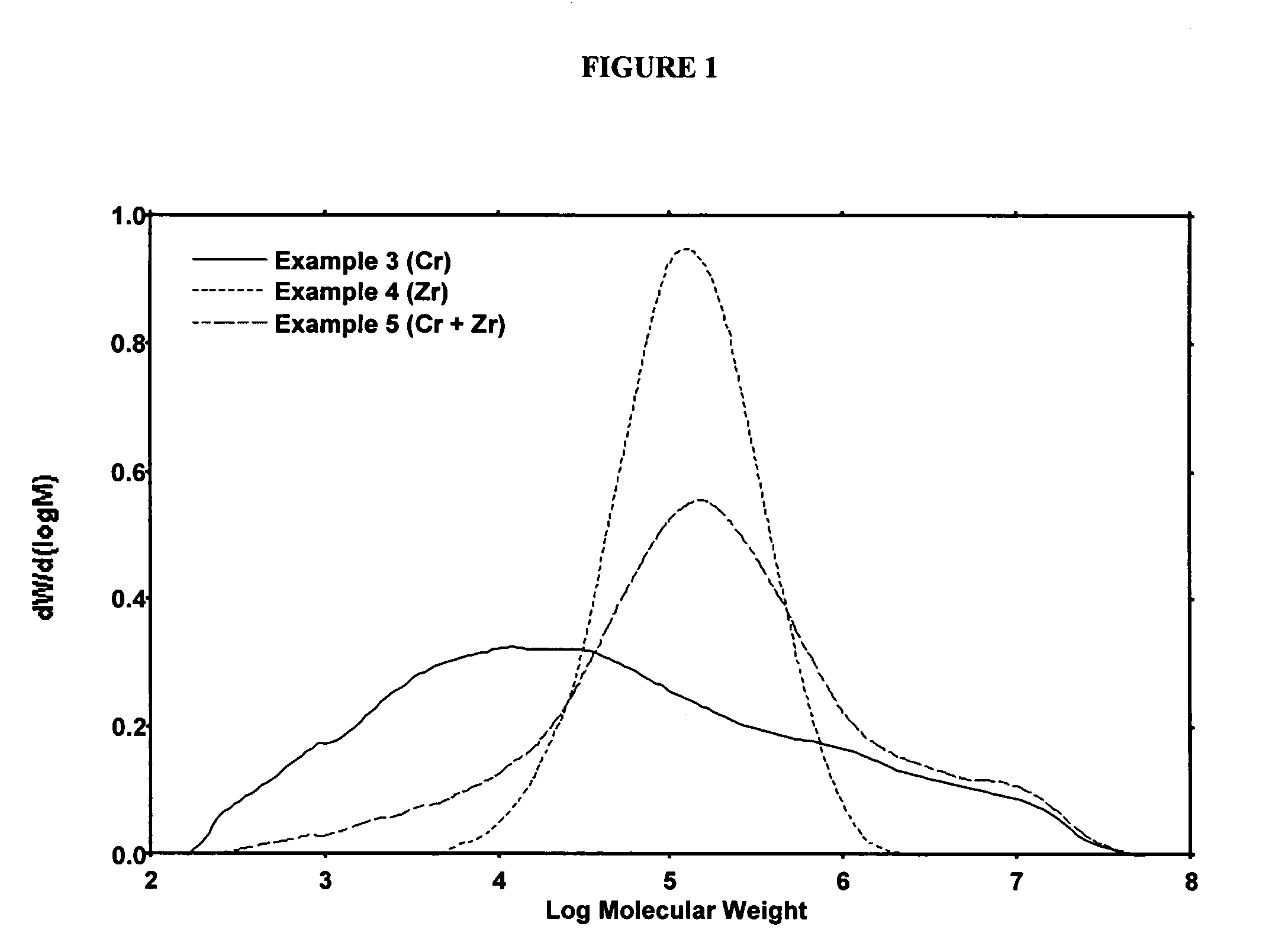

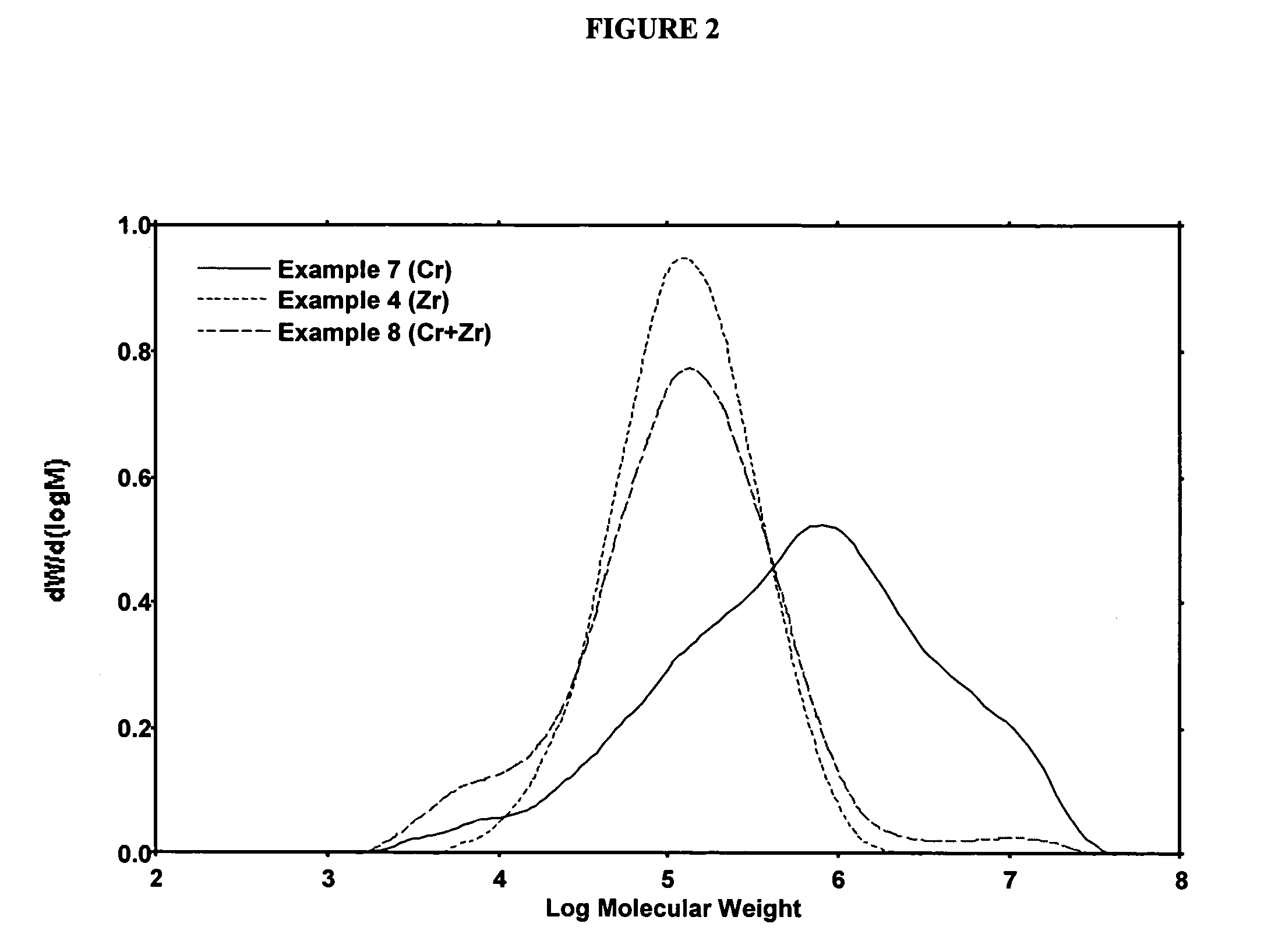

Organochromium/metallocene combination catalysts for producing bimodal resins

ActiveUS7163906B2Organic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationChemical treatmentOlefin polymerization

This invention relates to the field of olefin polymerization catalyst compositions, and methods for the polymerization and copolymerization of olefins, including polymerization methods using a supported catalyst composition. In one aspect, the present invention encompasses a catalyst composition comprising the contact product of at least one metallocene compound, at least one organochromium compound, at least one chemically-treated solid oxide, and at least one organoaluminum compound.

Owner:CHEVRON PHILLIPS CHEMICAL CO LP

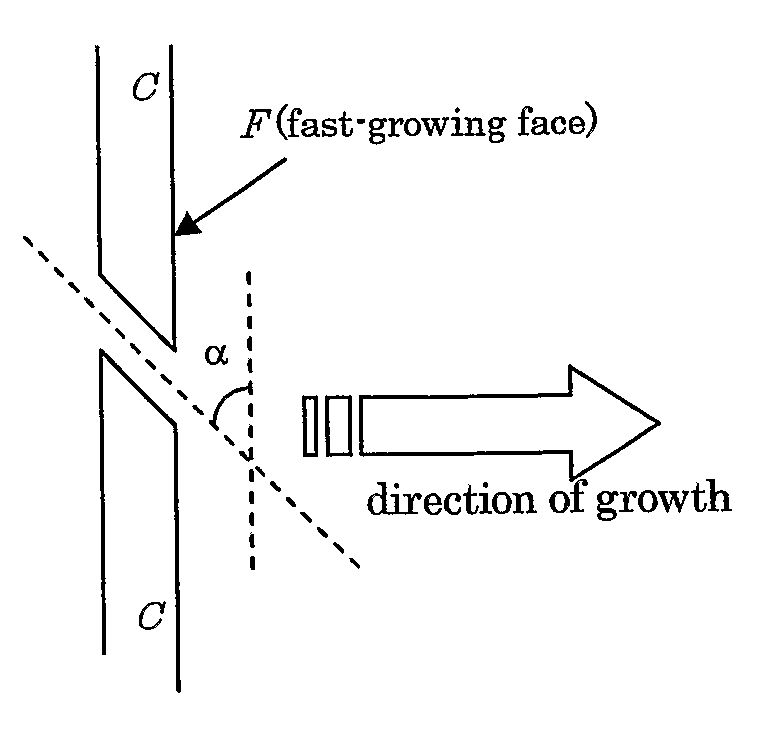

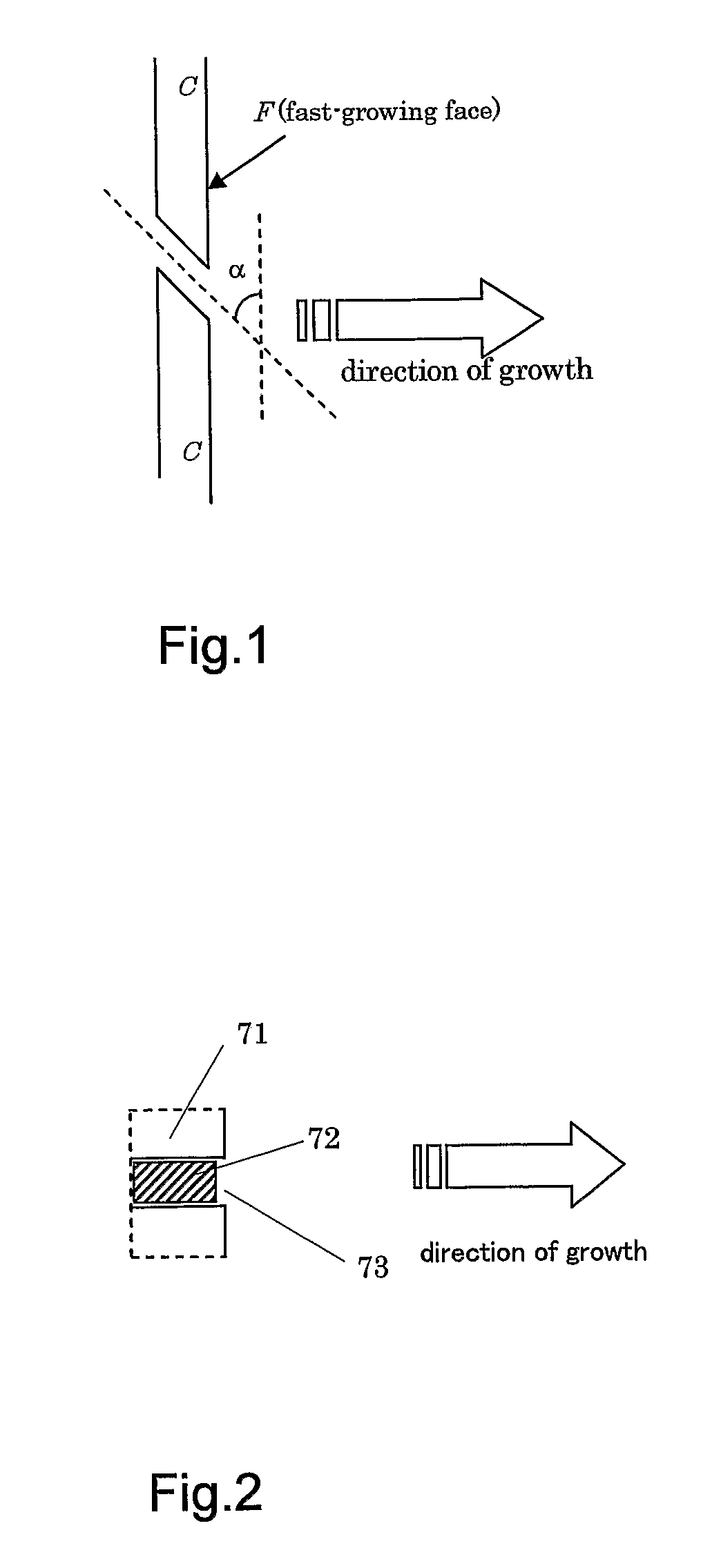

Nitride Single Crystal Seeded Growth in Supercritical Ammonia with Alkali Metal Ion

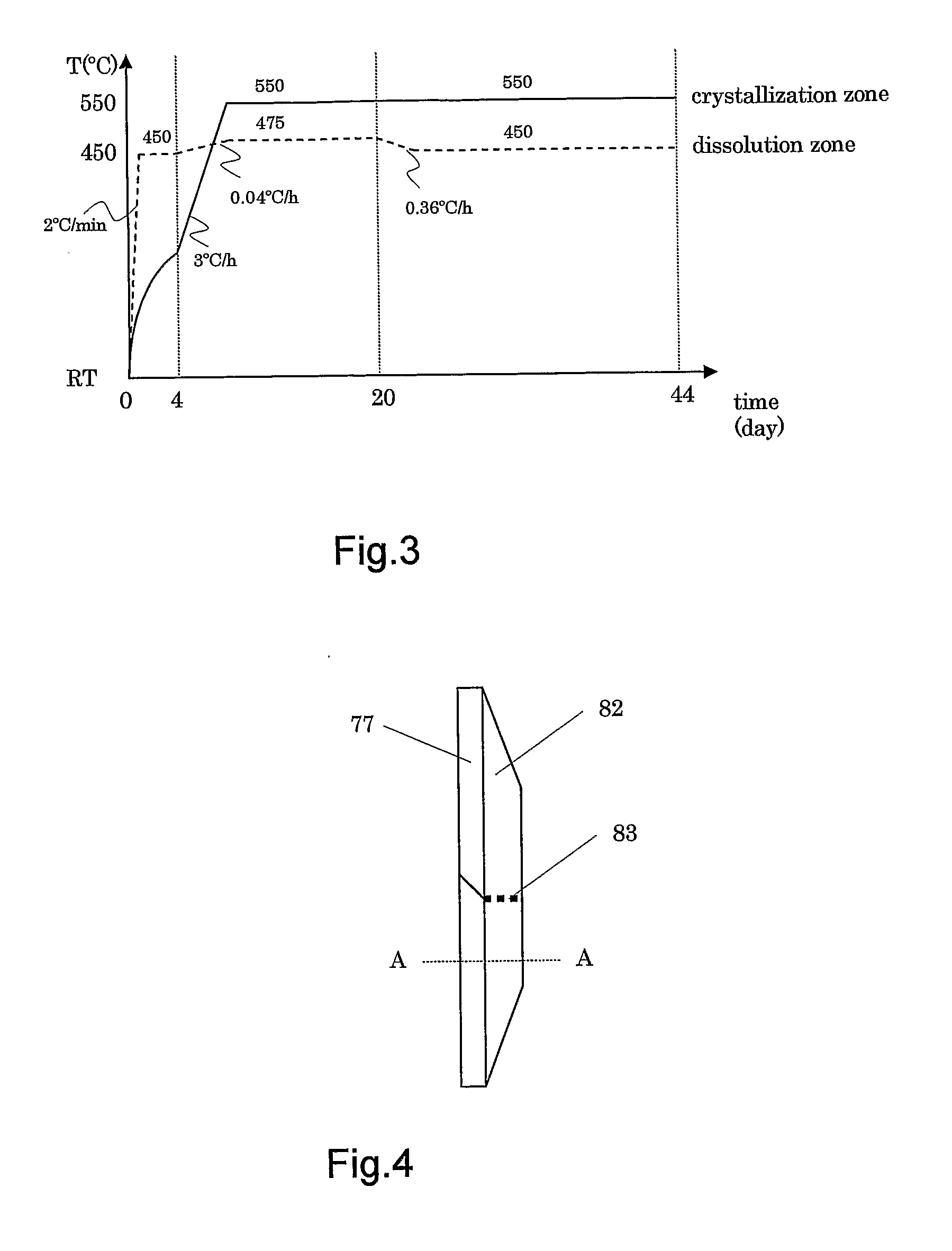

ActiveUS20080156254A1Increase in sizeShorten the timePolycrystalline material growthLaser detailsDissolutionSingle crystal

The present invention is related to a process for obtaining a larger area substrate of mono-crystalline gallium-containing nitride by making selective crystallization of gallium containing nitride on a smaller seed under a crystallization temperature and / or pressure from a supercritical ammonia-containing solution made by dissolution of gallium-containing feedstock in a supercritical ammonia-containing solvent with alkali metal ions, comprising: providing two or more elementary seeds, and making selective crystallization on the two or more separate elementary seeds to get a merged larger compound seed. The merged larger compound seed is used for a seed in a new growth process and then to get a larger substrate of mono-crystal gallium-containing nitride.

Owner:AMMONO SP Z O O (PL) +1

Liquid crystal display element, liquid crystal composition, aligning agent, method for producing liquid crystal display element, and use of liquid crystal composition

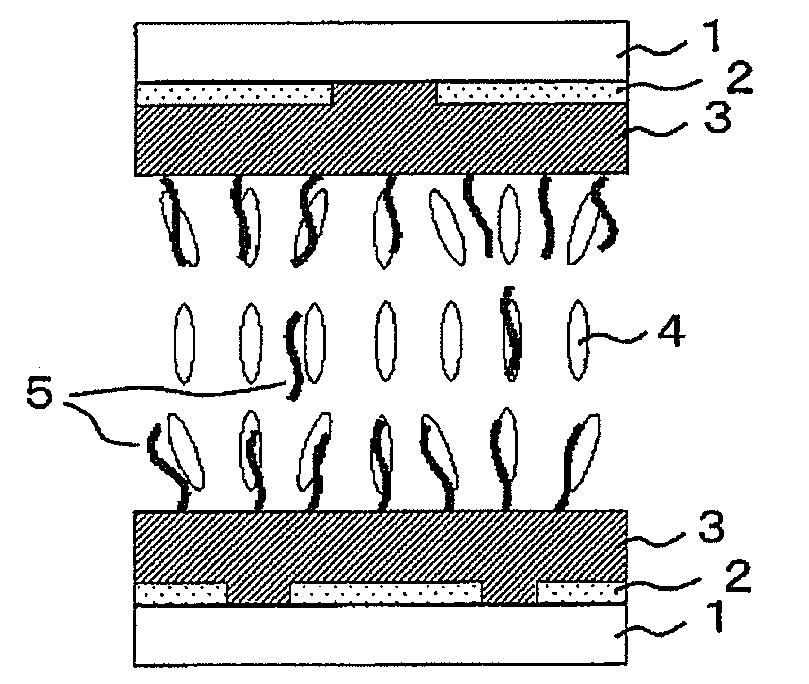

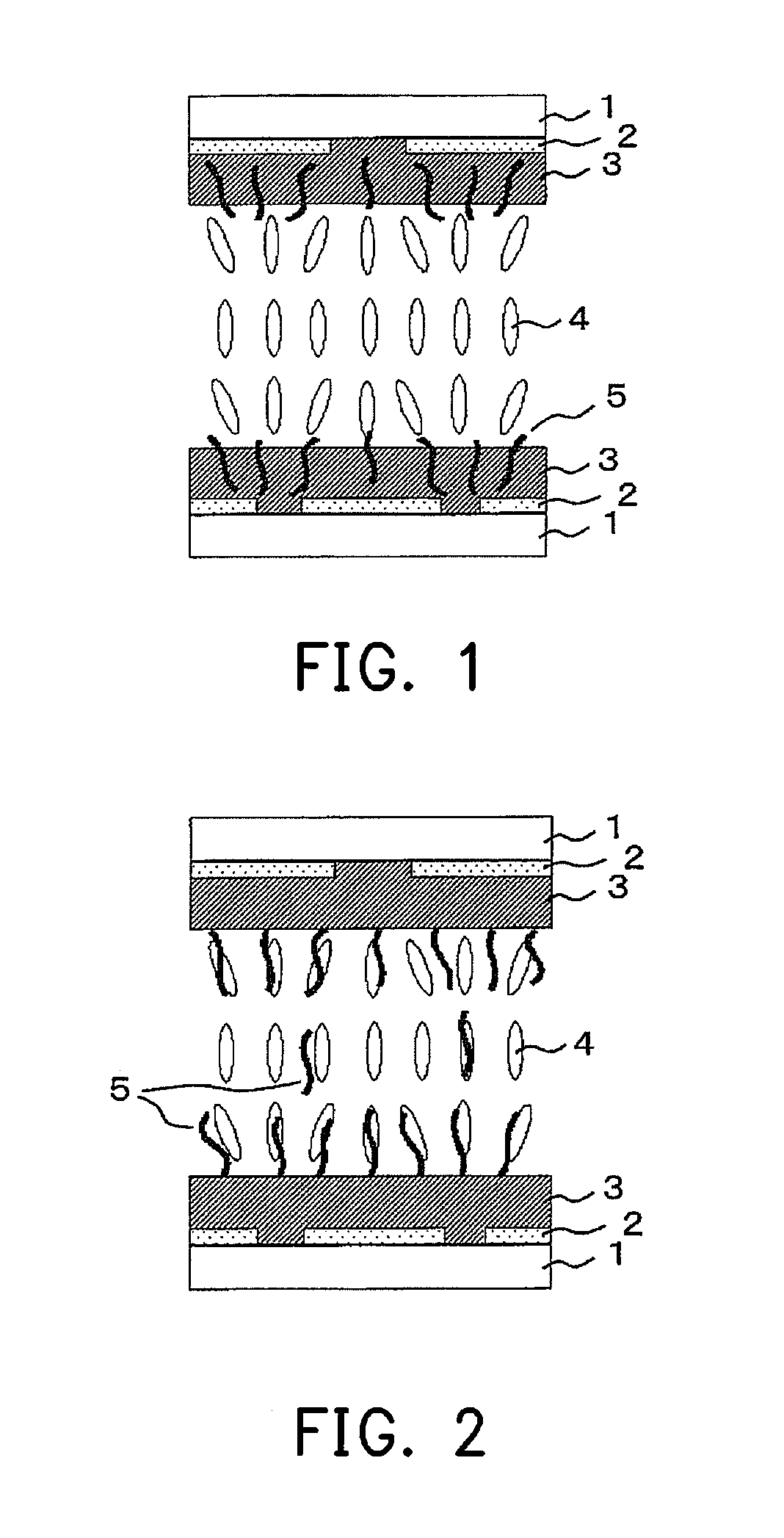

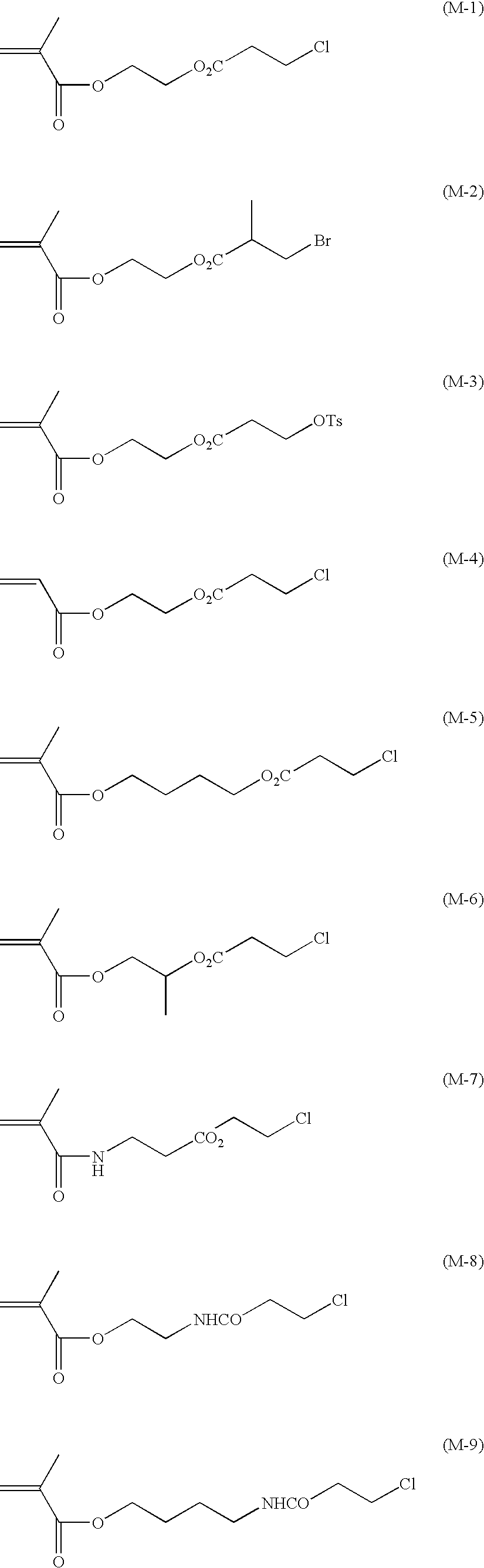

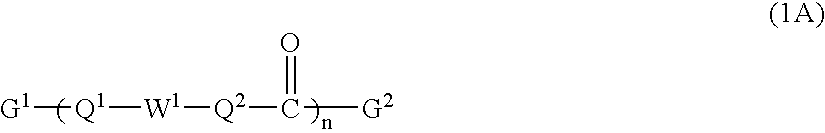

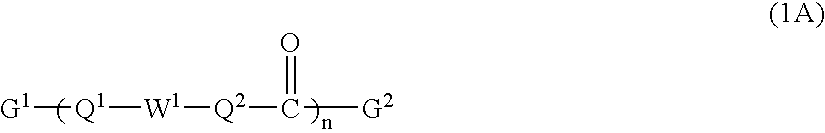

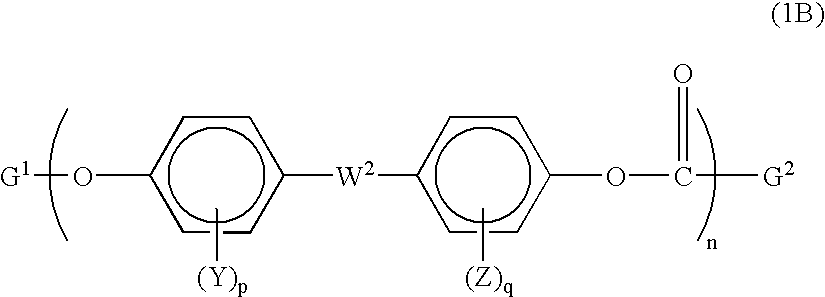

InactiveUS20120229744A1Good benefitLiquid crystal compositionsThin material handlingHalogenLiquid-crystal display

Disclosed is a liquid crystal display element which is composed of a pair of substrates (1) at least one of which is transparent. The liquid crystal display element comprises, between the pair of substrates, a transparent electrode (2), an aligning agent (3) that contains at least reactive monomers and / or oligomers (5), and a liquid crystal layer. The liquid crystal display element is characterized in that an alignment layer is obtained by polymerizing the reactive monomers or oligomers contained in the aligning agent, and the liquid crystal layer is composed of a liquid crystal composition that contains a compound (4) having at least one benzene ring in each molecule, said benzene ring containing at least one fluorine atom and being disubstituted by halogen atoms.

Owner:JNC CORP +1

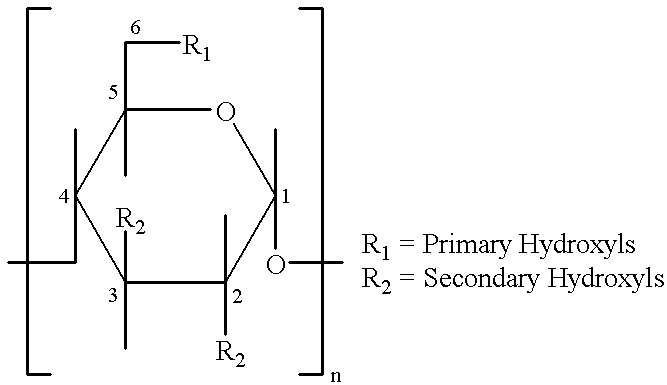

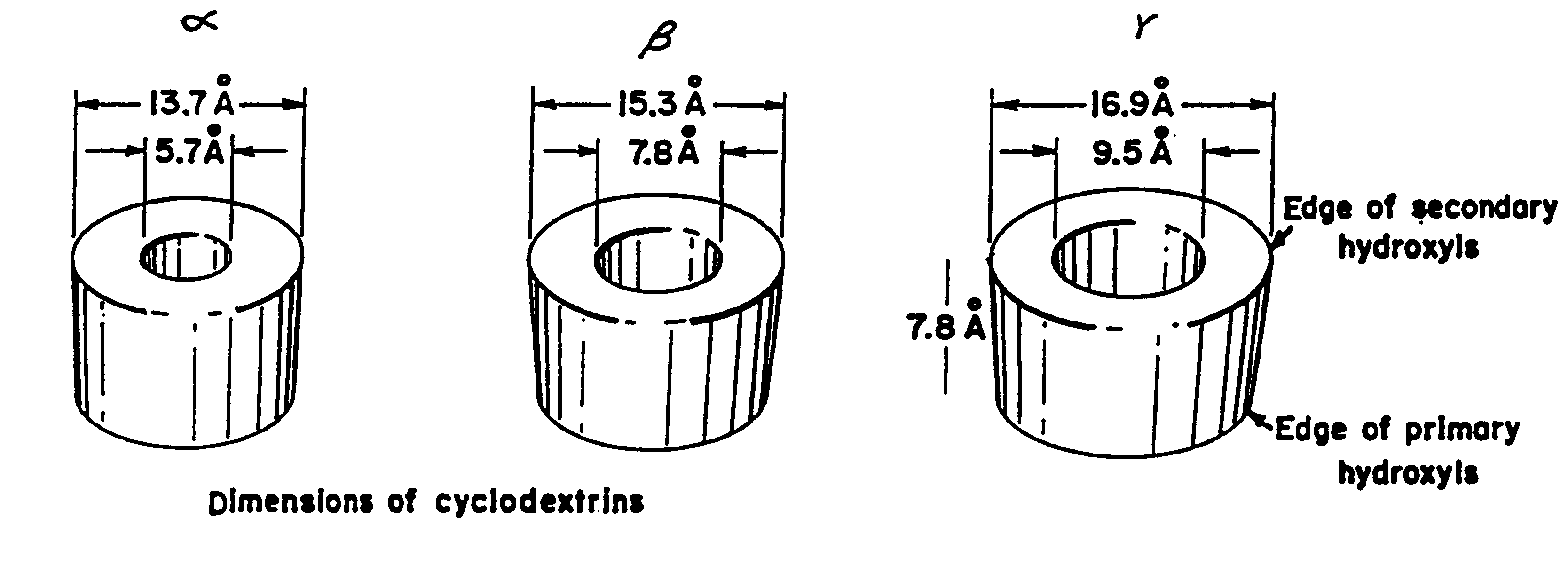

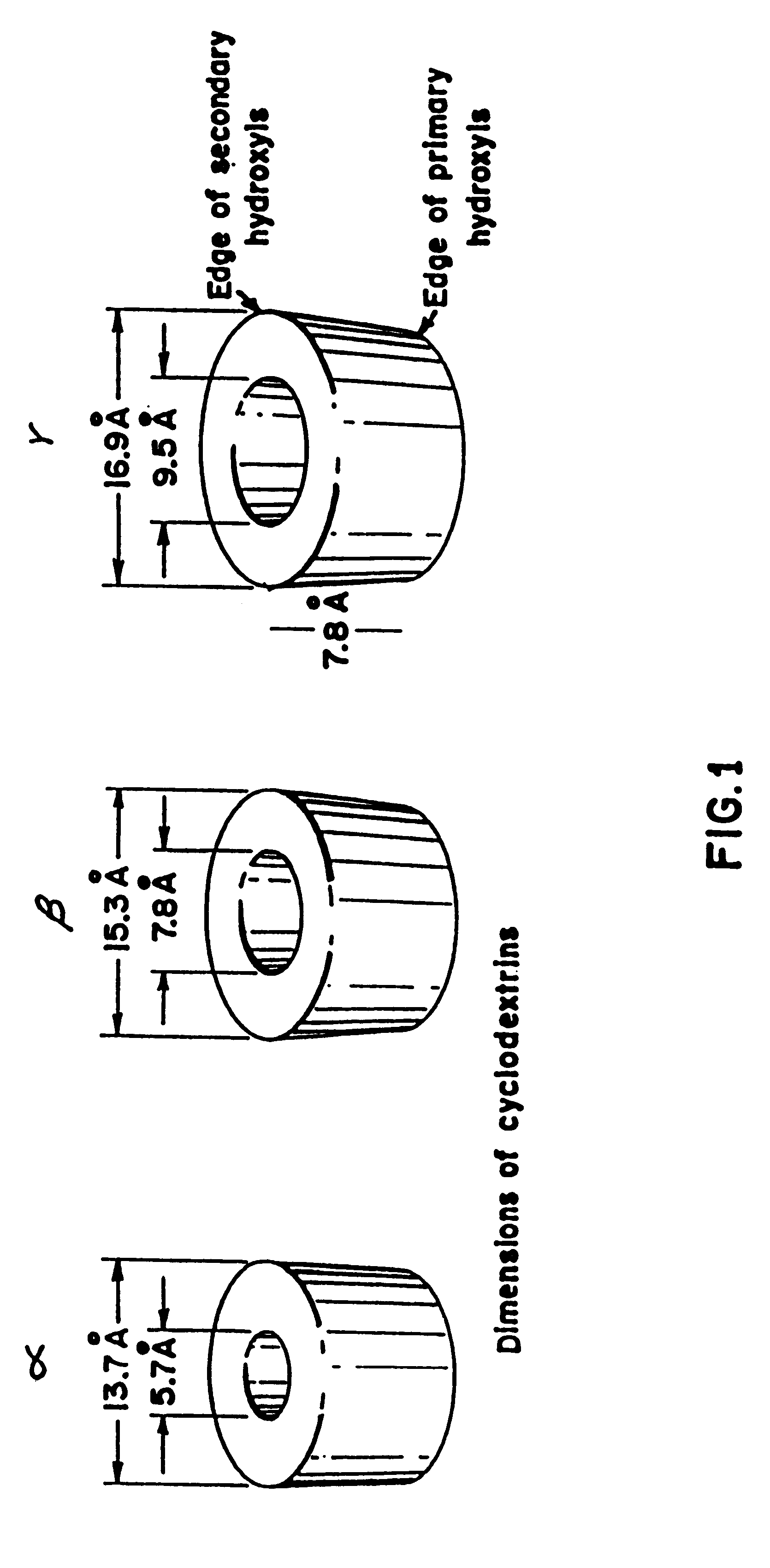

Barrier material comprising a thermoplastic and a compatible cyclodextrin derivative

InactiveUS6218013B1Easy to derivatizeImprove surface propertiesSemi-permeable membranesFlexible coversThermoplasticMoisture

A barrier film composition can comprise a thermoplastic web comprising a thermoplastic polymer and a dispersed cyclodextrin composition having substituents that compatibilize the cyclodextrin in the film. The thermoplastic / cyclodextrin film obtains substantial barrier properties from the interaction between the substituted cyclodextrin in the film material with a permeant. The substituents on the cyclodextrin molecule causes the cyclodextrin to be dispersible and stable in the film material resulting in an extrudable thermoplastic. Such materials can be used as a single layer film material, a multilayer film material which can be coated or uncoated and can be used in structural materials wherein the thermoplastic is of substantial thickness resulting in structural stiffness. The cooperation between the cyclodextrin and the thermoplastic polymer provides barrier properties to a web wherein a permeant can be complexed or entrapped by the cyclodextrin compound and held within the film preventing the permeant from passing through the film into the interior of a film, an enclosure or container. The permeant can comprise a variety of well known materials such as moisture, aliphatic or aromatic hydrocarbons, monomer materials, off flavors, toxic compounds etc.

Owner:CELLRESIN TECH

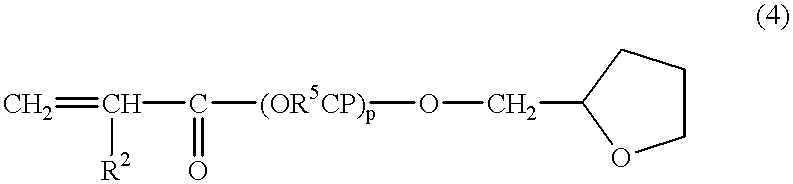

Liquid curable resin composition

InactiveUS6180741B1Low water absorptionEasy to disassembleCladded optical fibreFibre mechanical structuresFiberMeth-

A liquid curable resin composition exhibiting superior storing stability and suitable for use as a material for optical fiber ribbon matrix, a bundling material, and a material for up-jacketing fibers. The composition contains a first polydimethylsiloxane compound which contains (i) at least two urethane bonds, (ii) an unreactive organic group attached to at least one end of the first polydimethyl-siloxane, and (iii) a (meth)acrylol group attached to at least one end of the first polydimethylsiloxane, and a second polydimethylsiloxane compound which contains (i) at least two urethane bonds and (ii) an unreactive organic group attached to at least one end of the second polydimethylsiloxane, and optionally a third polysiloxane compound which does not contain urethane bonds.

Owner:DSM NV +1

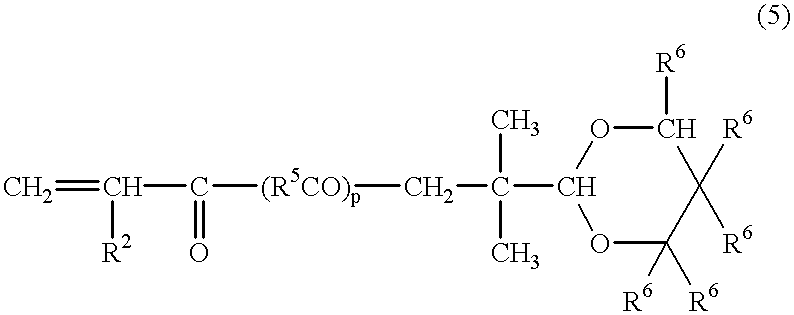

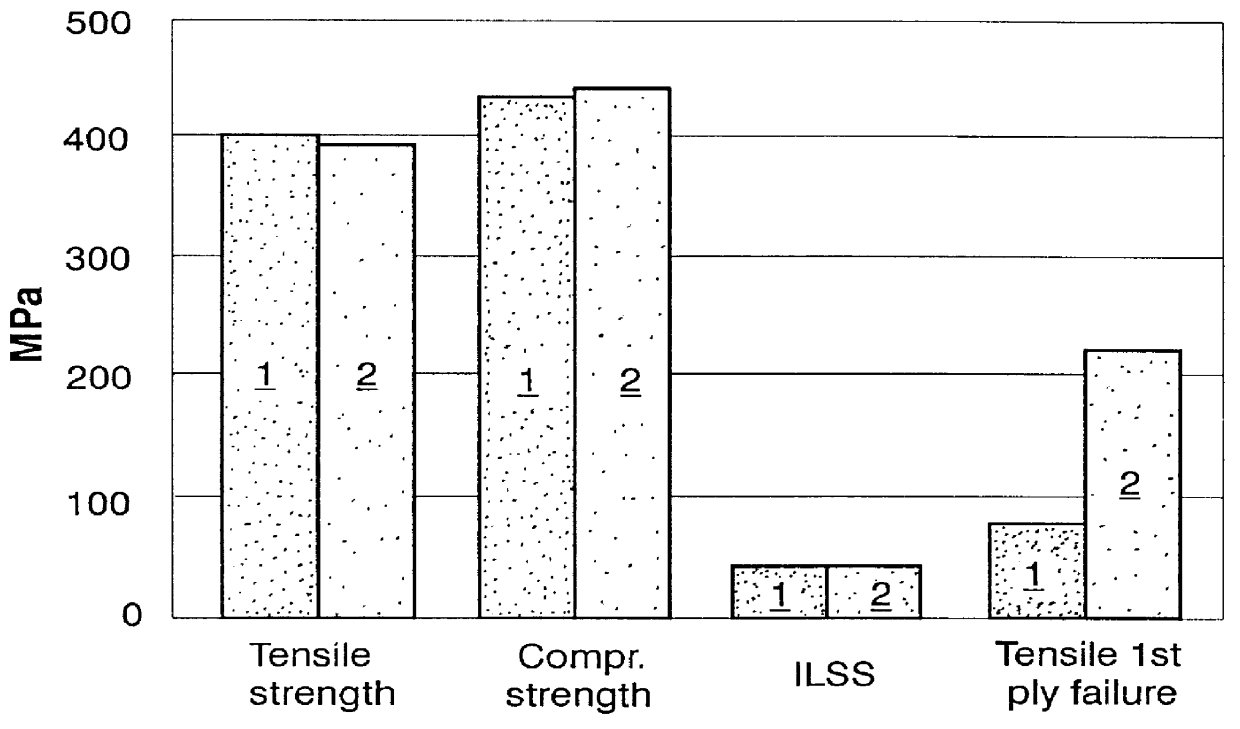

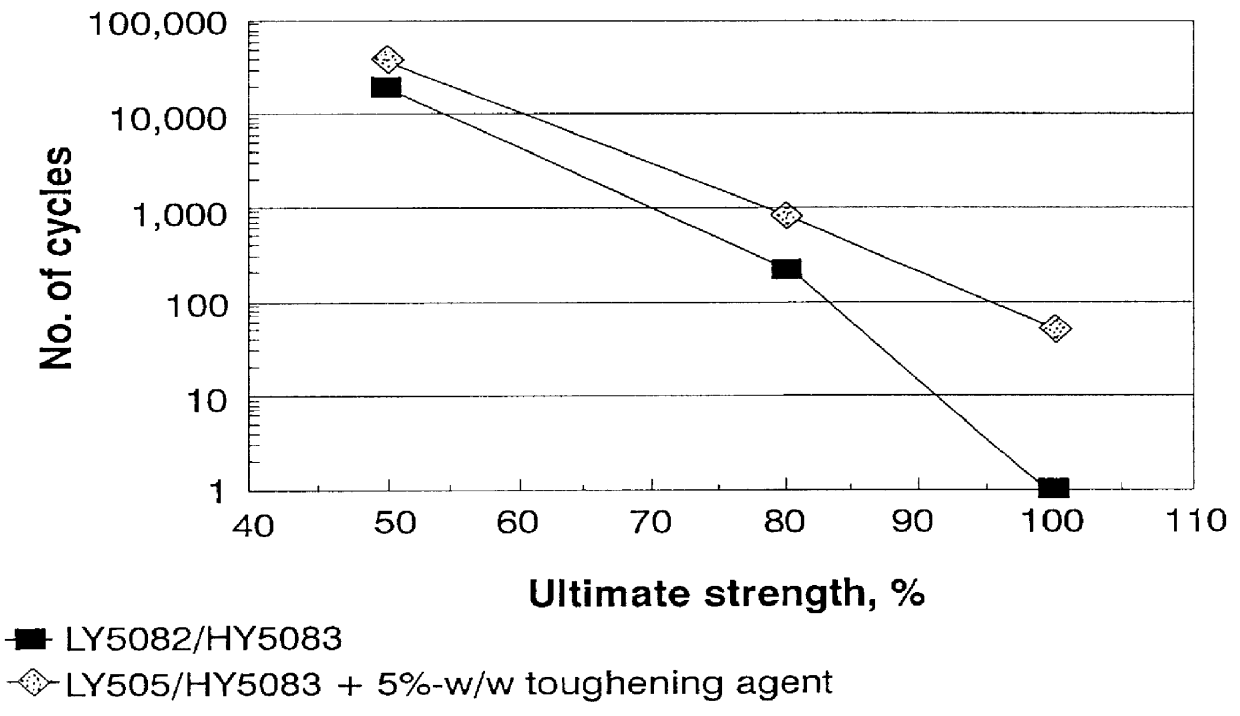

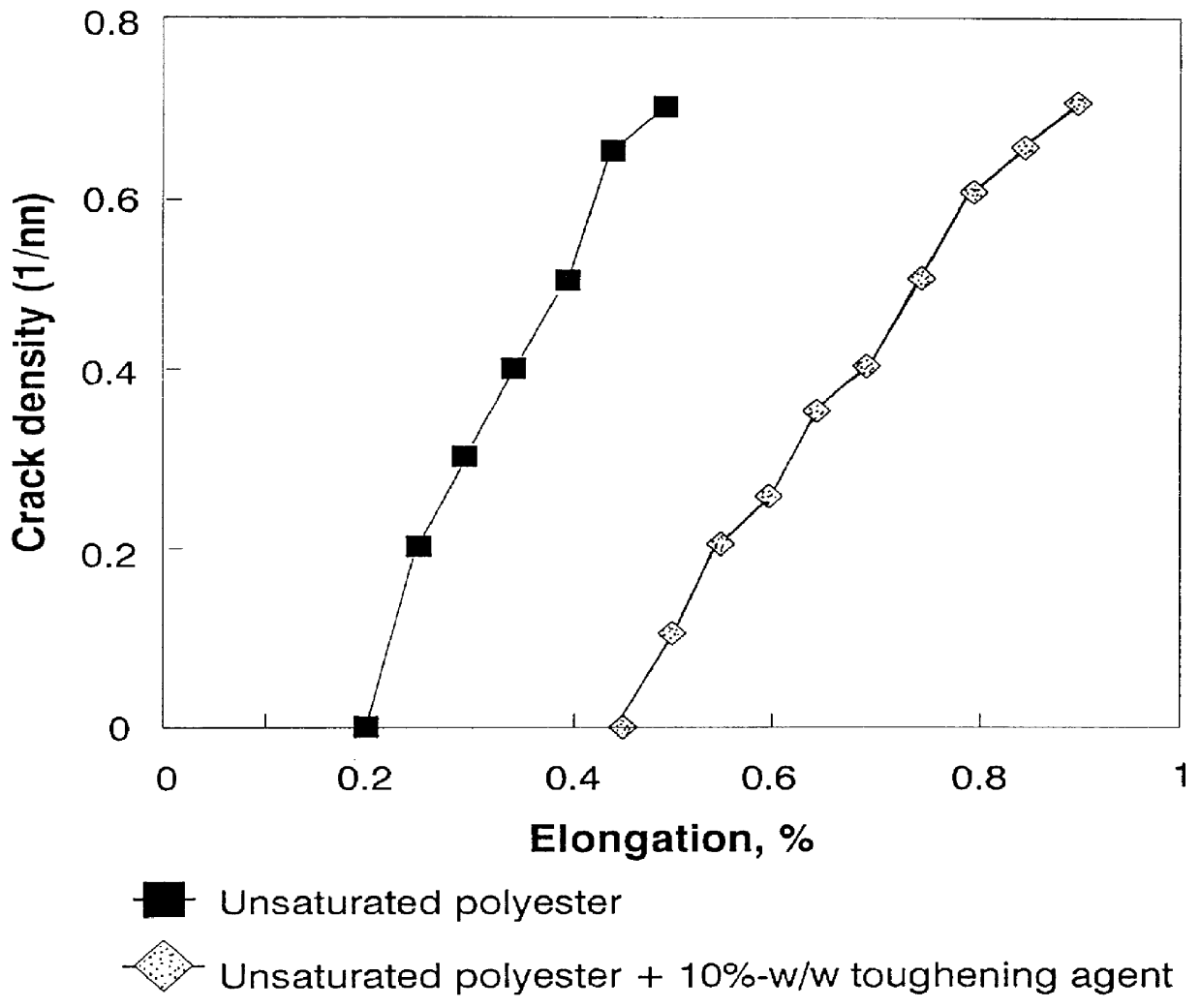

Dendritic polyester macromolecule in thermosetting resin matrix

A partially or fully cured thermosetting product which includes a cured and molded product of a thermosetting composition. The composition includes 70% to 99% by weight of at least one thermosetting resin or compound and 1% to 30% by weight of at least one toughening agent. The toughening agent is at least one hyperbranched dendritic macromolecule formed of ester units, optionally in combination with ether units.

Owner:PERSTORP AB

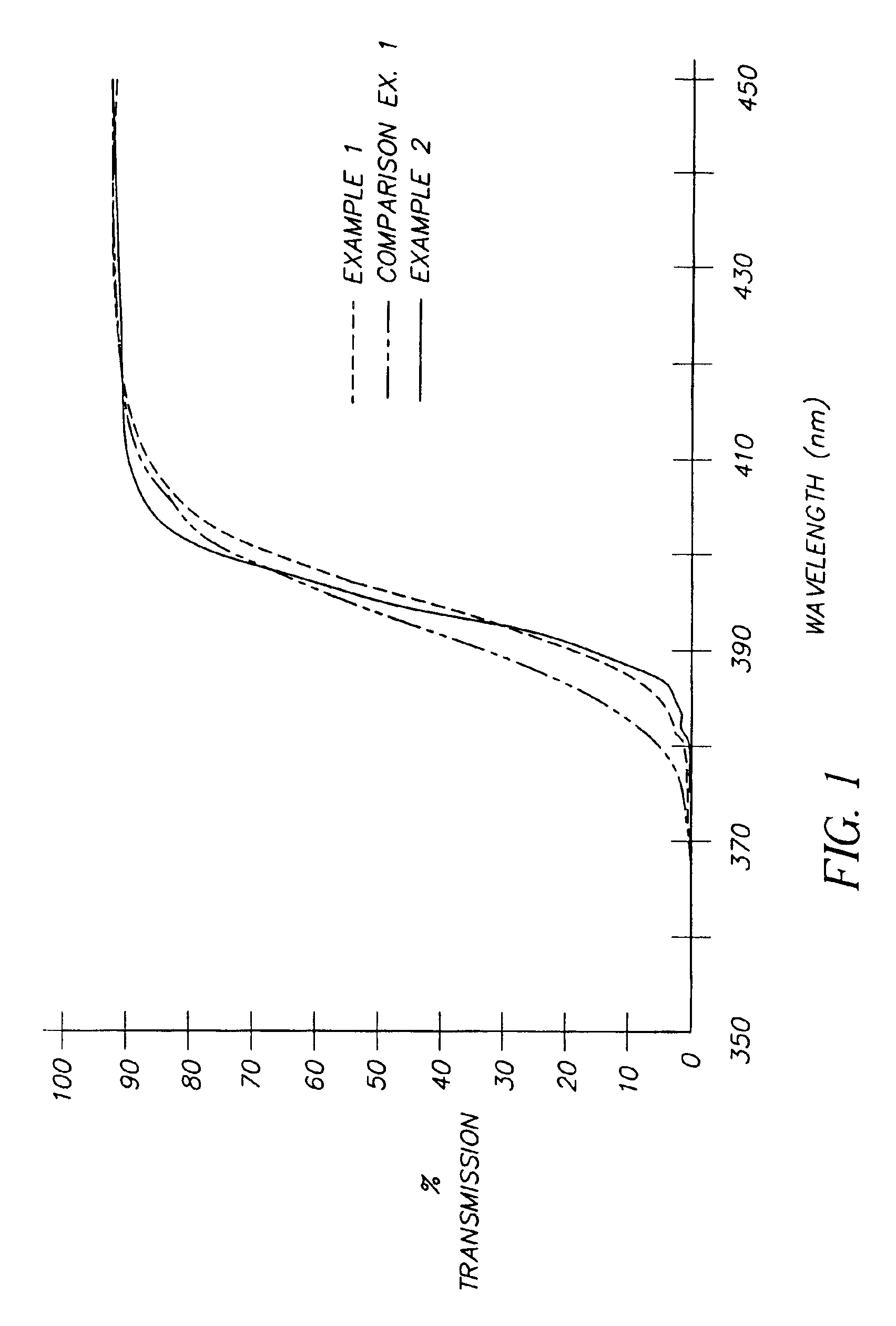

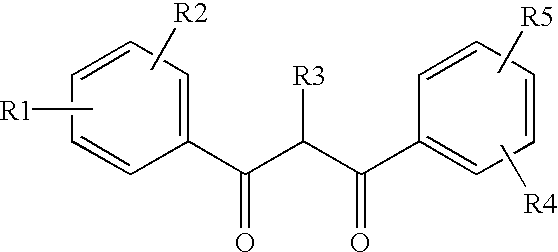

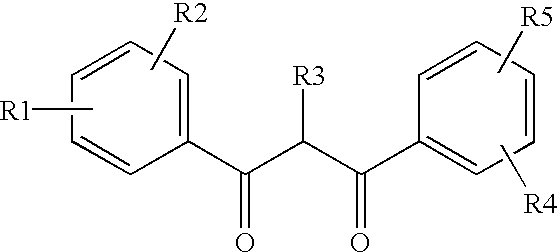

Ultraviolet light filter element

InactiveUS6872766B2Increased durabilityAvoid lightLiquid crystal compositionsOther chemical processesThio-Display device

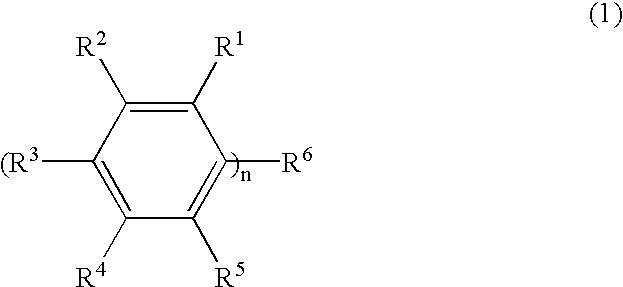

Ultraviolet light absorbing polymer film, coating, or molded article UV filter elements are described which comprise a polymer phase having molecularly dispersed therein a) a first ultraviolet absorbing dibenzoylmethane compound of formula (I) where R1 through R5 are each independently hydrogen, halogen, nitro, or hydroyxl, or further substituted or unsubstituted alkyl, alkenyl, aryl, alkoxy, acyloxy, ester, carboxyl, alkyl thio, aryl thio, alkyl amine, aryl amine, alkyl nitrile, aryl nitrile, arylsulfonyl, or 5-6 member heterocylce ring groups, and b) a second ultraviolet light absorbing compound which absorbs ultraviolet light at a wavelength for which the first compound is deficient at absorbing. In particular embodiments, the second ultraviolet light absorbing compound may comprise a hydroxyphenyl-s-triazine, hydroxyphenylbenzotriazole, formamidine, benzoxazinone, or benzophenone compound. In a specific embodiment of the invention, the above UV absorbing compounds are employed in cellulose acetate film for the fabrication of a protective film for polarizers for use in display applications.

Owner:EASTMAN KODAK CO

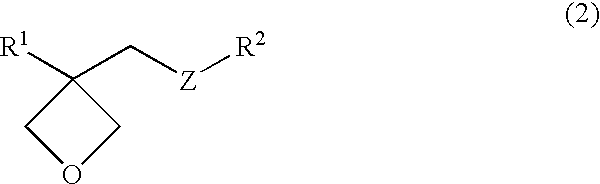

Photocurable resin composition for sealing material and method of sealing

InactiveUS6586496B1Liquid crystal compositionsNon-fibrous pulp additionCationic polymerizationHeat resistance

A photo-curable resin composition for sealing material, which is superior in the photo-curing performance and in the prompt curing property and is better in the adhesive property, in the resistance to moisture permeation and in the heat resistance, the photo-curable resin composition comprising(A) a compound having oxetane ring,(B) a photoinitiator for cationic polymerization and(C) a silane coupling agent,wherein the composition has a viscosity in the range from 0.01 to 300 Pa.s at 25° C.

Owner:MITSUI CHEM INC

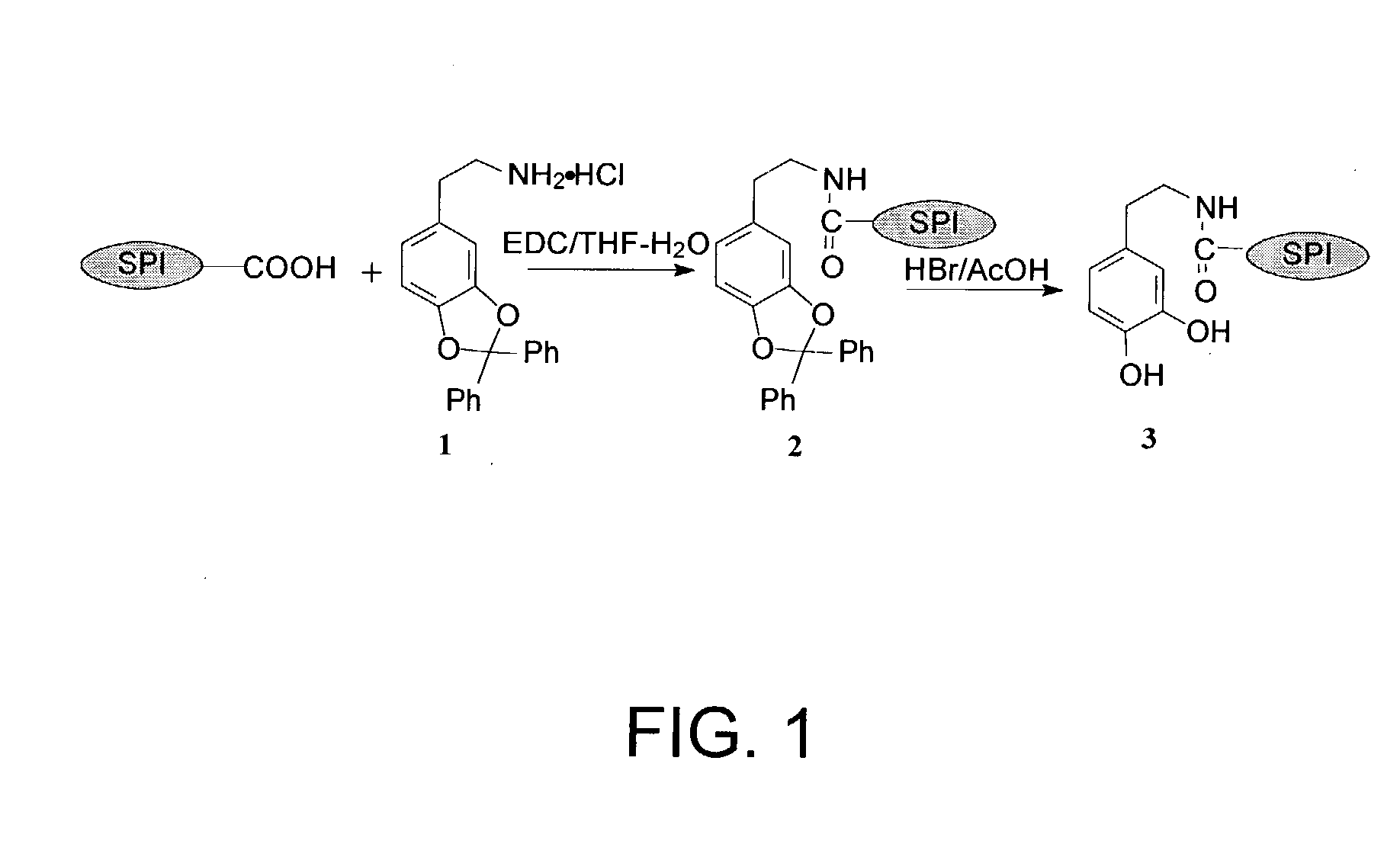

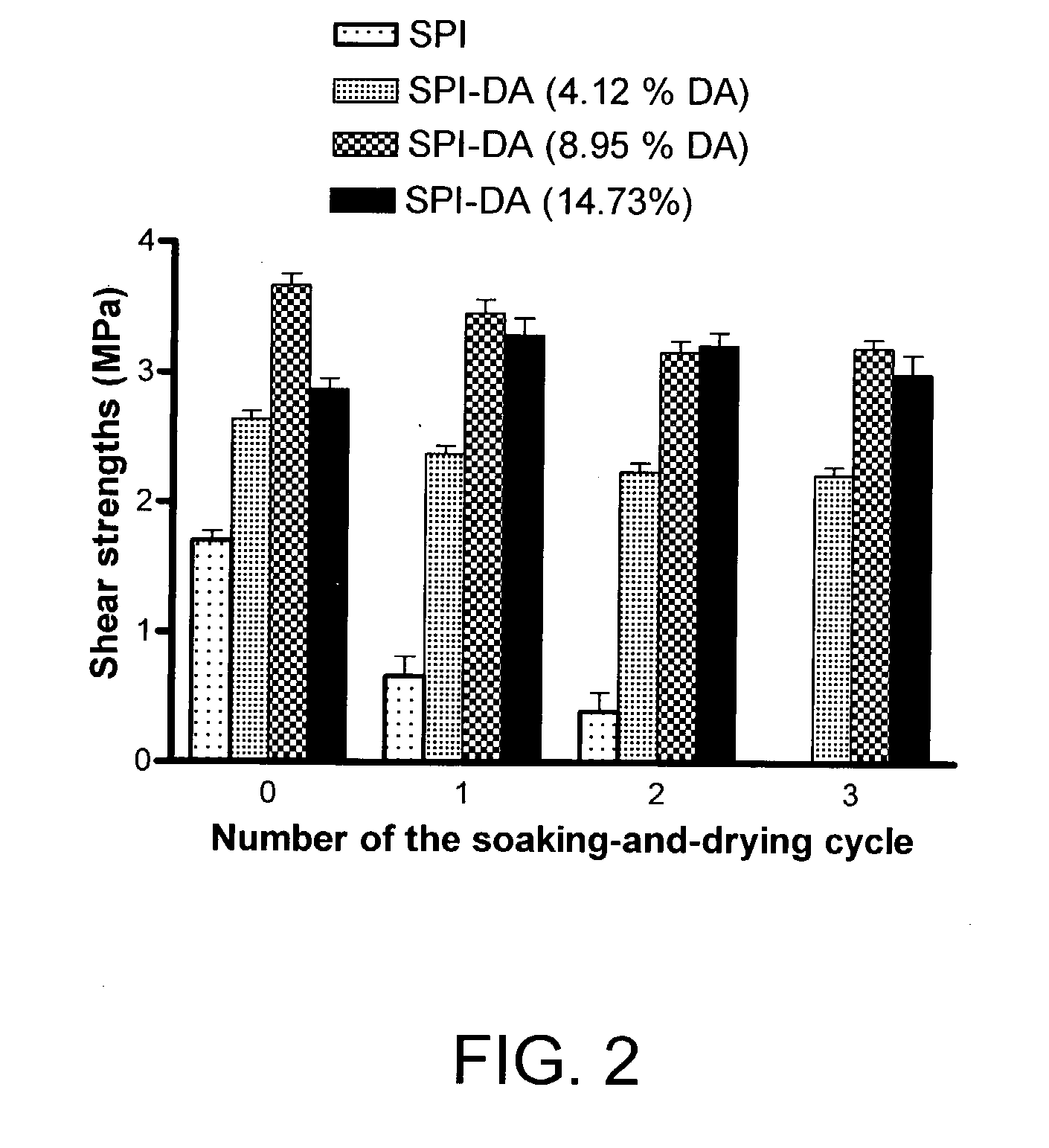

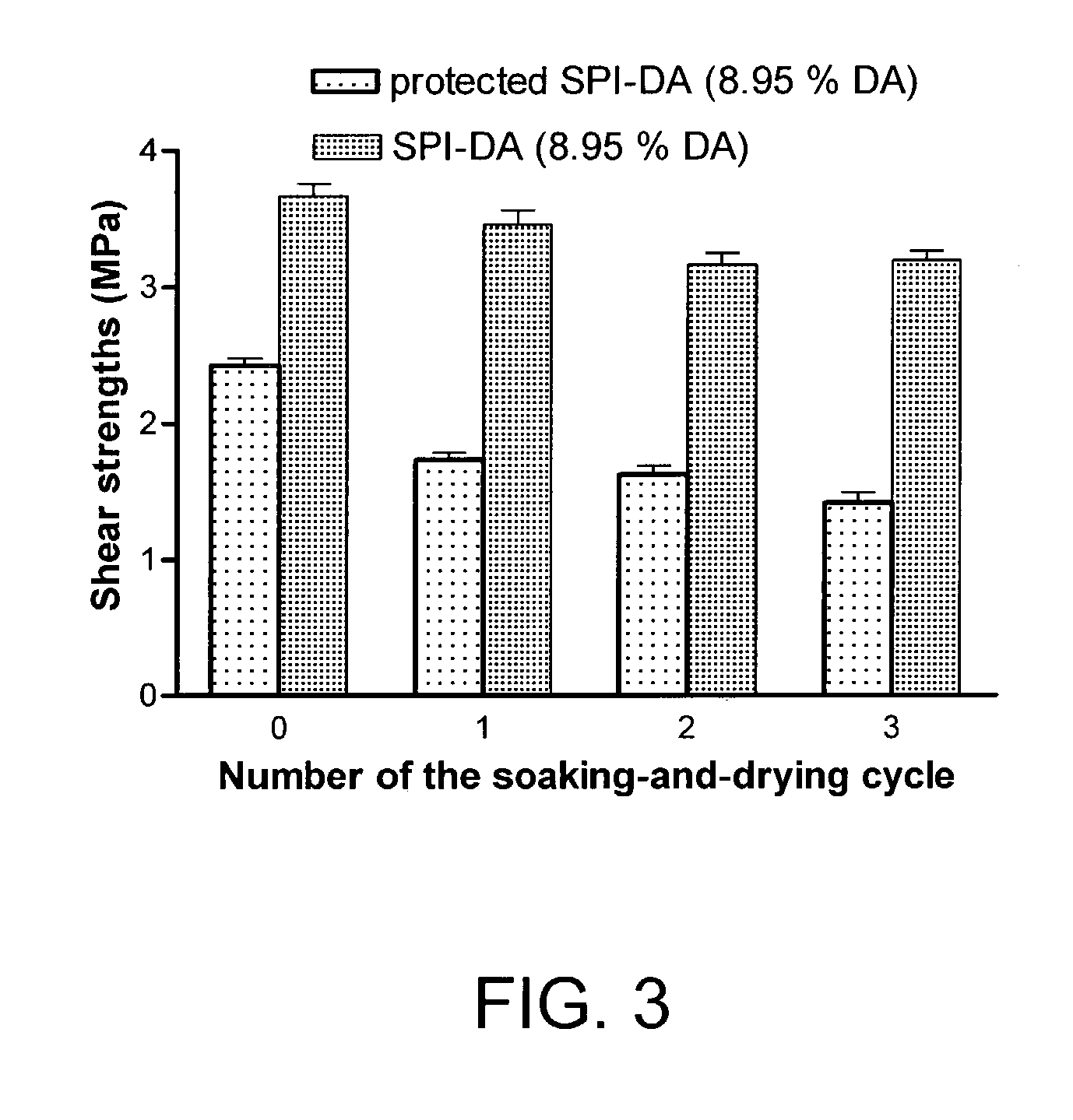

Modified protein adhesives and lignocellulosic composites made from the adhesives

An adhesive composition made by reacting a soy protein with at least one compound under conditions sufficient for introducing additional phenolic hydroxyl functional groups, amine functional groups, and / or thiol functional groups into the soy protein structure.

Owner:THE STATE OF OREGON ACTING BY & THROUGH THE OREGON STATE BOARD OF HIGHER EDUCATION ON BEHALF OF OREGON STATE UNIV

Method of manufacturing GaN ingots

InactiveUS6562124B1Low costSimple growth processSemiconductor/solid-state device manufacturingBy pulling from meltSemiconductor materialsIngot

A novel method for growing semiconductor material including GaN is disclosed. The method involves placing a first substance into a growth reactor, supplying a second gaseous substance into the grouth reactor, and applying electrical field to the second gaseous substance to produce the cry stalline compound material.

Owner:OSTENDO TECH INC

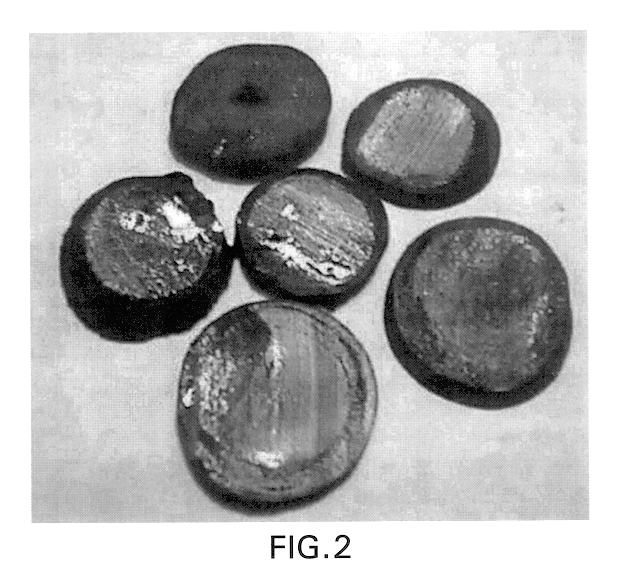

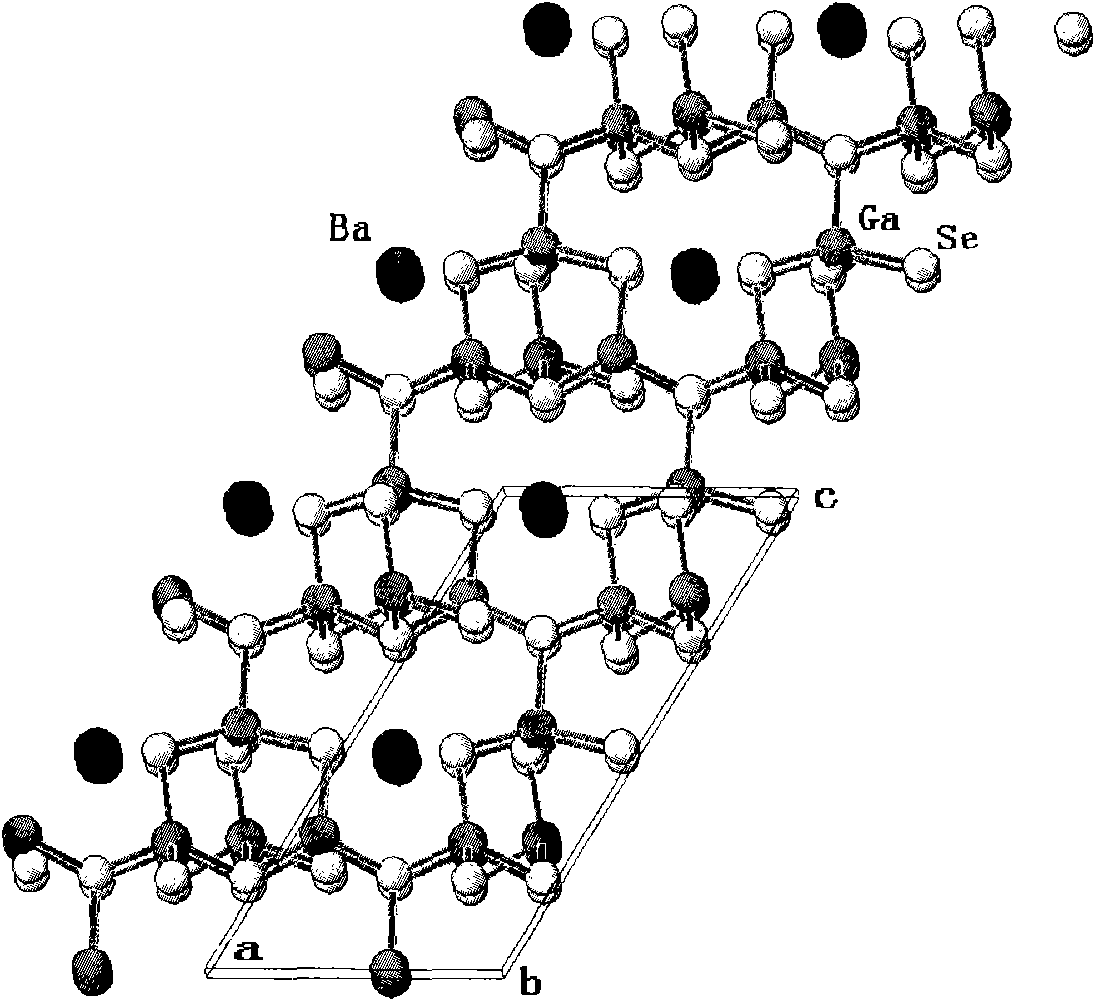

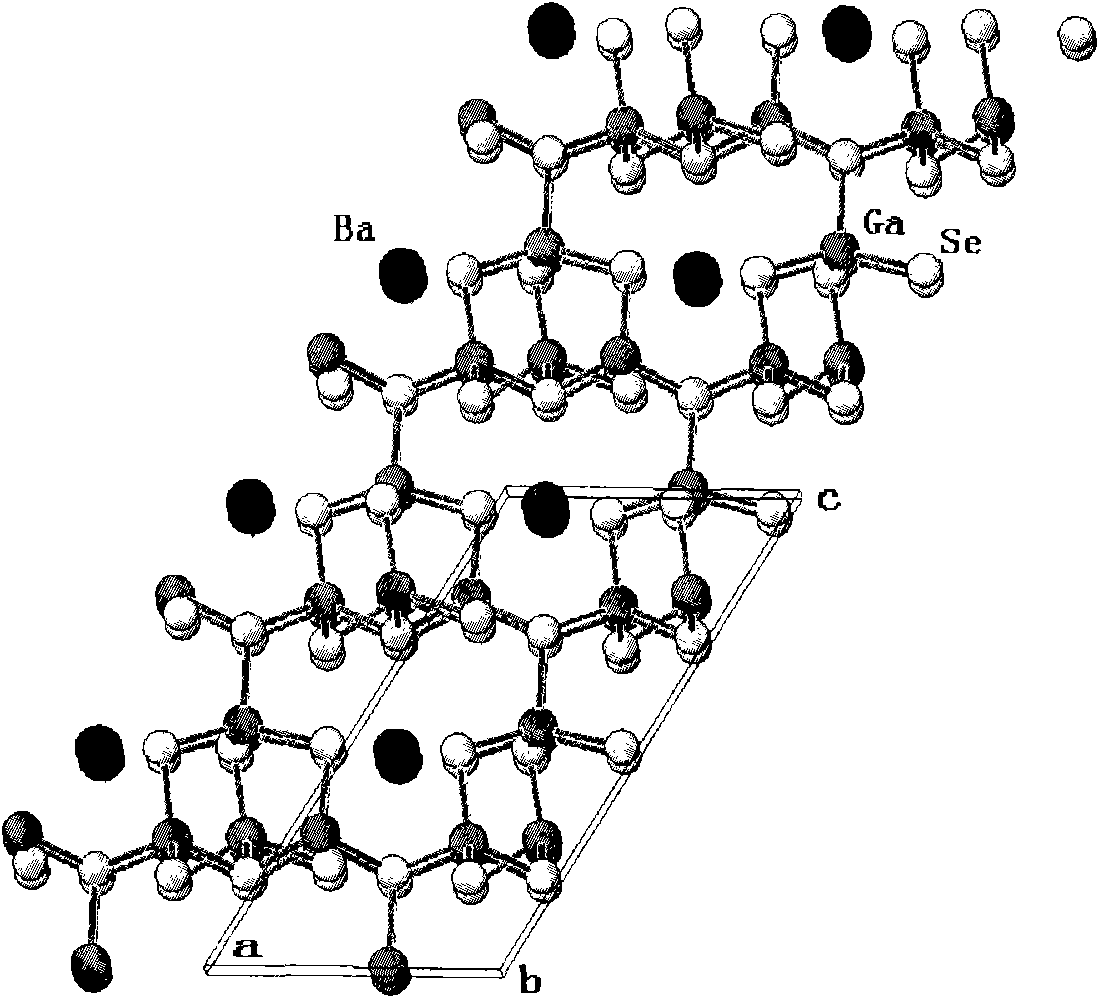

BaCa4Se7 compound, BaCa4Se7 nonlinear optical crystal, preparation method and application

ActiveCN101767778AWide band of light transmissionHigh hardnessPolycrystalline material growthAfter-treatment detailsNonlinear optical crystalOptical transparency

The invention relates to a BaCa4Se7 compound, a BaCa4Se7 nonlinear optical crystal, a preparation method and application. The BaCa4Se7 compound is prepared by adopting a solid-phase reaction, and the BaCa4Se7 nonlinear optical crystal is grown by adopting a high-temperature melt spontaneous crystallization method, a flux growth method or a Bridgman method. In the growth of the BaCa4Se7 nonlinear optical crystal, the crystal is easy to grow and transparent and has no package and the advantages of higher growing speed, low cost, easy obtaining of a crystal in a larger size, and the like. The obtained BaCa4Se7 nonlinear optical crystal has the advantages of wider optical transparency range, larger hardness, good mechanical property, difficult cracking and deliquescence, easy processing and storage, and the like. The BaCa4Se7 nonlinear optical crystal can be used for preparing a nonlinear optical device.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

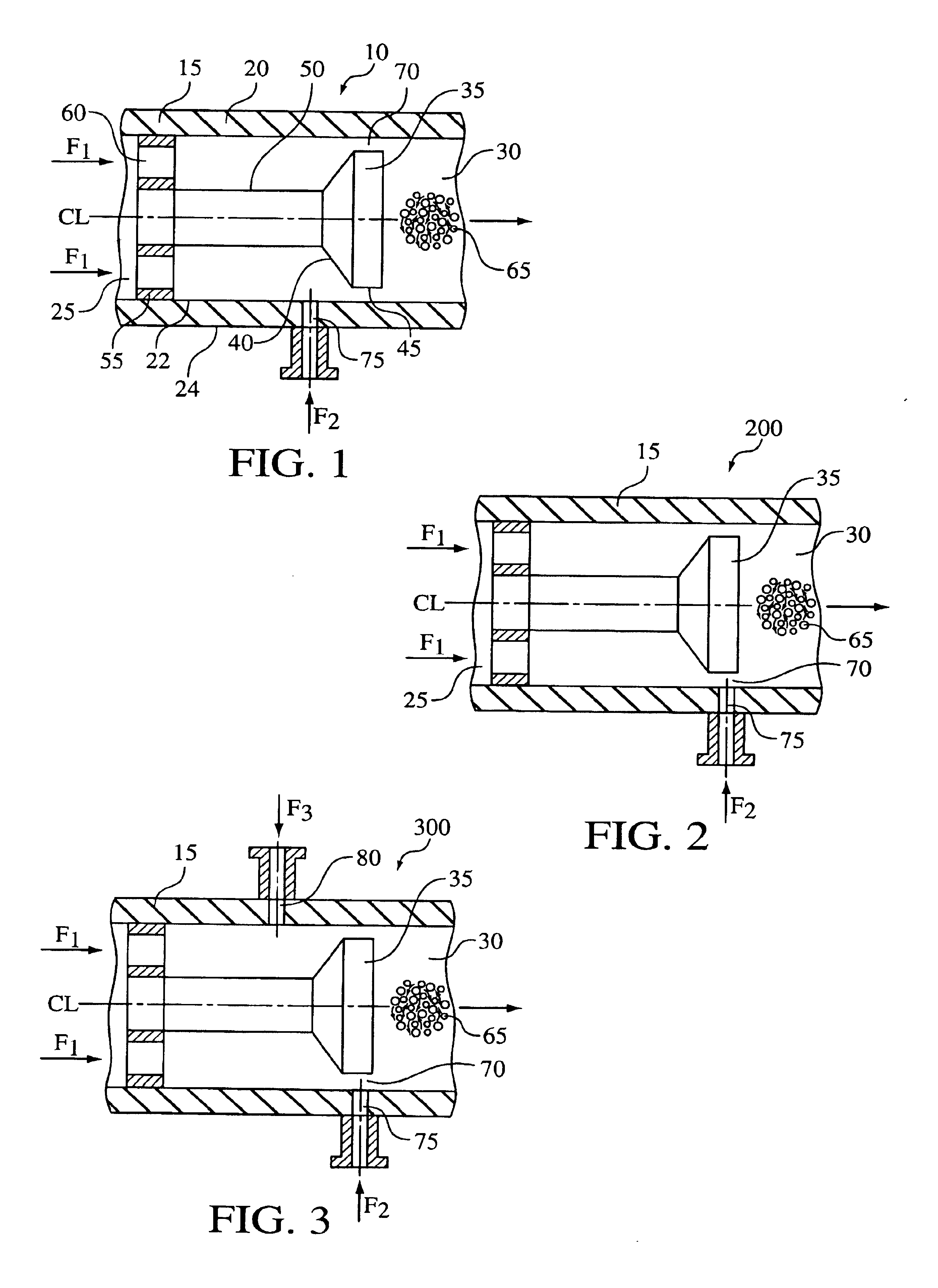

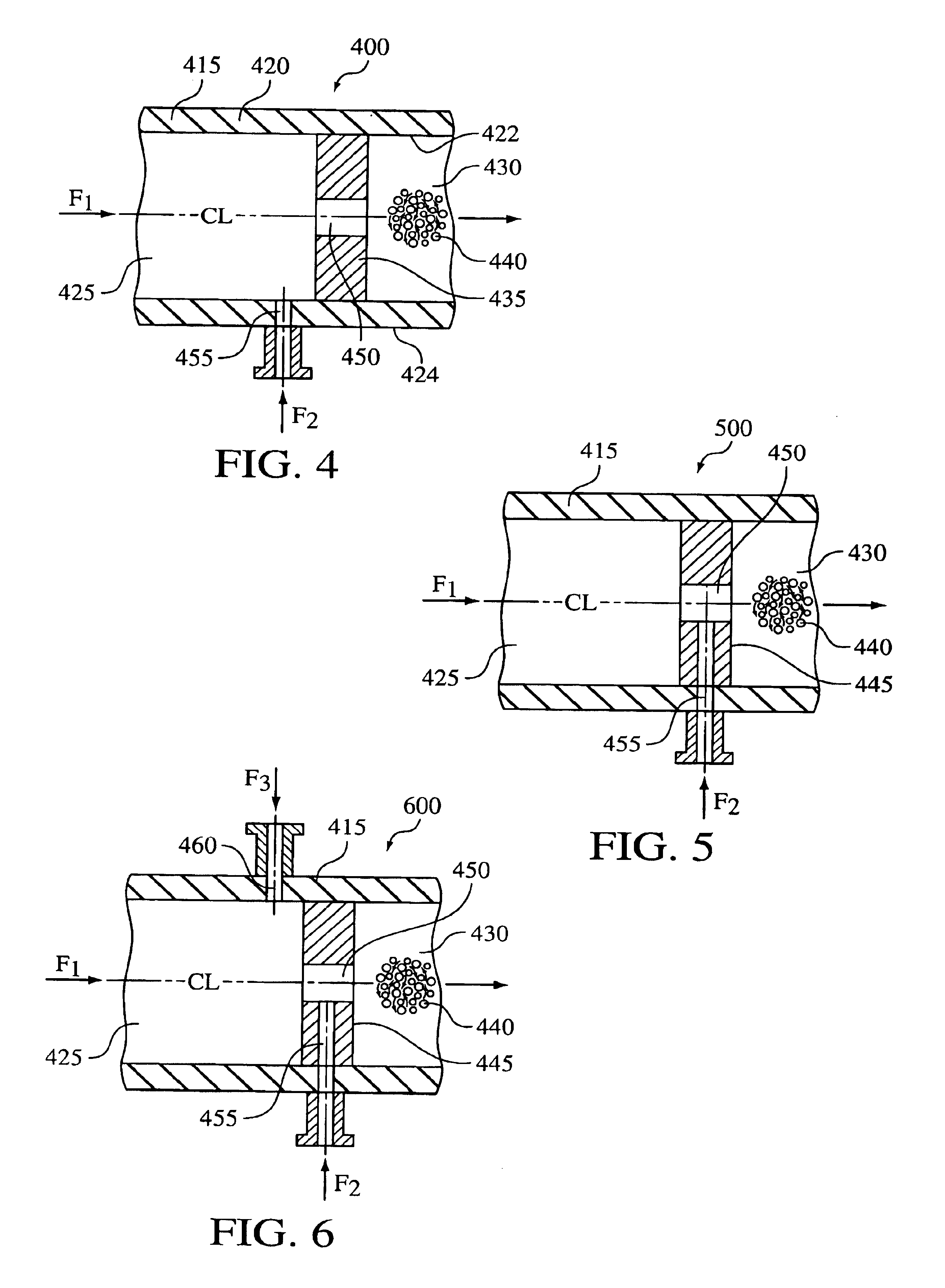

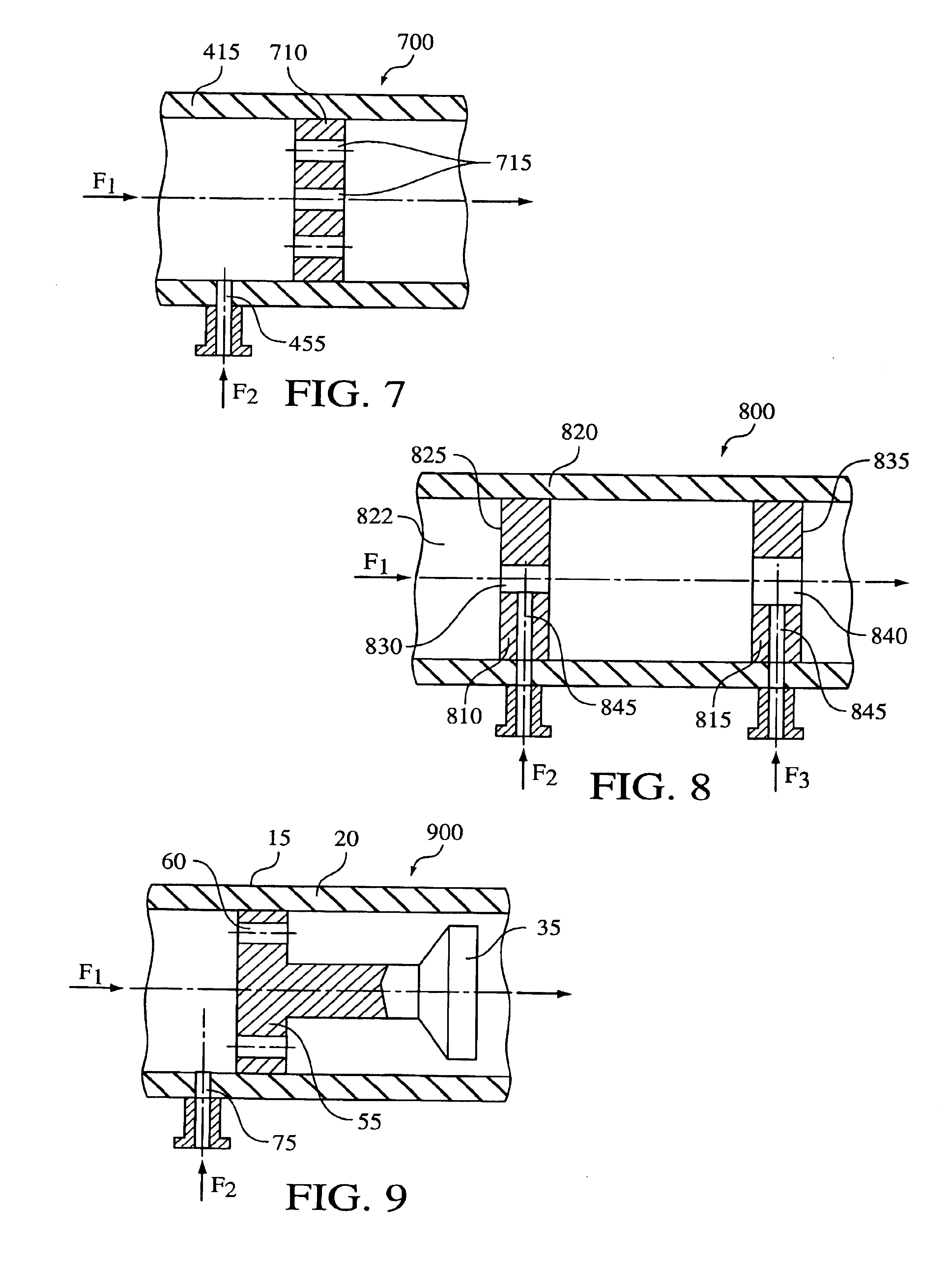

Hydrodynamic cavitation crystallization process

A device and process for crystallizing a compound using hydrodynamic cavitation comprising the steps of mixing at least one stream of a solution of such compound to be crystallized with at least one stream of an anti-solvent and passing the mixed streams at an elevated pressure through a local constriction of flow to create hydrodynamic cavitation thereby causing nucleation and the direct production of crystals.

Owner:ARISDYNE STSTEMS INC

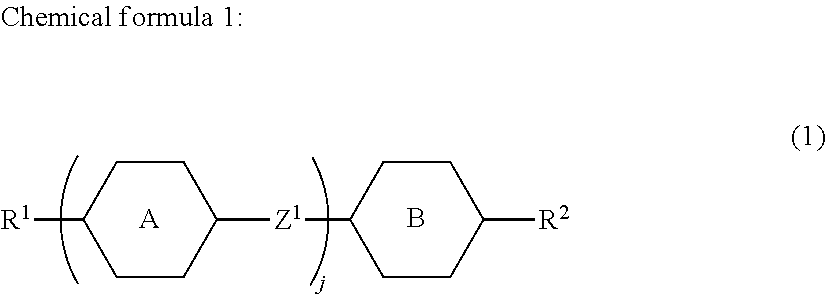

Catalyst for polymerization or copolymerization of olefin

InactiveUS6291385B1Yield can be minimalHigh bulk densityOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationSilanesAluminium

The present invention relates to a catalyst for polymerization or copolymerization of an olefin. The catalyst is produced by first reacting a mixture of a magnesium compound and an aluminum compound with an ester compound which has at least one hydroxy group and a silane compound which has at least one alkoxy group, and next reacting with a titanium compound. The catalyst may be used in the polymerization or copolymerization of ethylene and propylene. The catalyst is believed to have the following formula:where, R1~R3=hydrocarbon group, X1~X2=halogen atoms, ExED=silane compounds comprising an alkoxy group, ED=an ester compound having at least one hydroxy group and a hydrogen of the hydroxy group is removed, and 0<a+b+c<=1; 0<=j<=2, 0<=k<=3, 0<=1<=1; 0<=m<=4; 0<=n<=4; 0<=m+n<=4; and a, b, c, l, m, and n are all positive numbers.

Owner:SAMSUNG GENERAL CHEMICALS CO. LTD

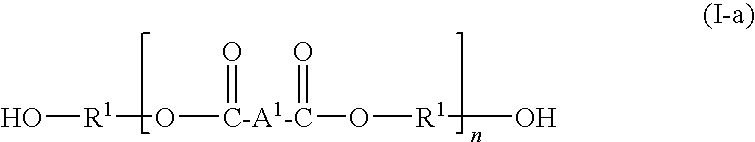

Plasticized polyester compositions and films therefrom

An aliphatic polyester stretched film which has excellent flexibility and heat resistance and manifests no bleeding of a plasticizer, an aliphatic polyester composition which is a raw material of the stretched film, and a package using the stretched film. The film can be prepared from an aliphatic polyester composition comprising 10 to 60 parts by weight of at least one compound selected from (A) a compound represented by the general formula: R1OCH2CH(OR2)CH2OR3 (wherein, at least one of R1, R2 and R3 represents an acyl group having 6 to 18 carbon atoms, and remaining groups represent a hydrogen atom or an acetyl group.) and (B) a compound which is a reaction product of a condensate of 1 to 10 glycerin units with a carboxylic acid having 6 to 18 carbon atoms, based on 100 parts by weight of an aliphatic polyester. The aliphatic polyester stretched film can have a crystallinity of 20 to 60% which is obtained by molding the composition, and the film can be formed into a package obtained.

Owner:MITSUI CHEM INC

Rubber composition and pneumatic tire

InactiveUS6506849B1Improve heat resistanceImprove steering stabilitySpecial tyresTyresPolymer scienceNitrogen

There are provided a rubber composition having a high modulus of elasticity and a good workability, and a pneumatic tire.A rubber composition comprising at least one of natural rubber and synthetic diene rubbers as a rubber ingredient, at least one maleimide compound, and at least one nitrogen-containing compound selected from the group consisting of polyaniline, hydrazide, and amine compound is used in a tread.

Owner:BRIDGESTONE CORP

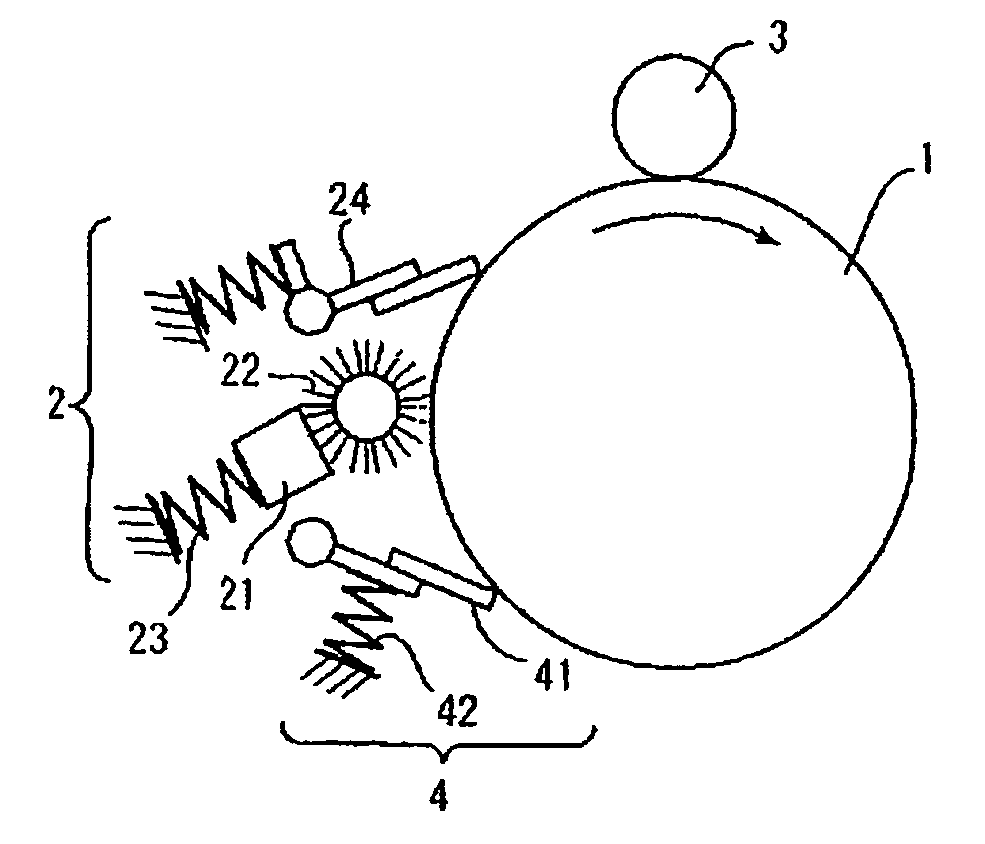

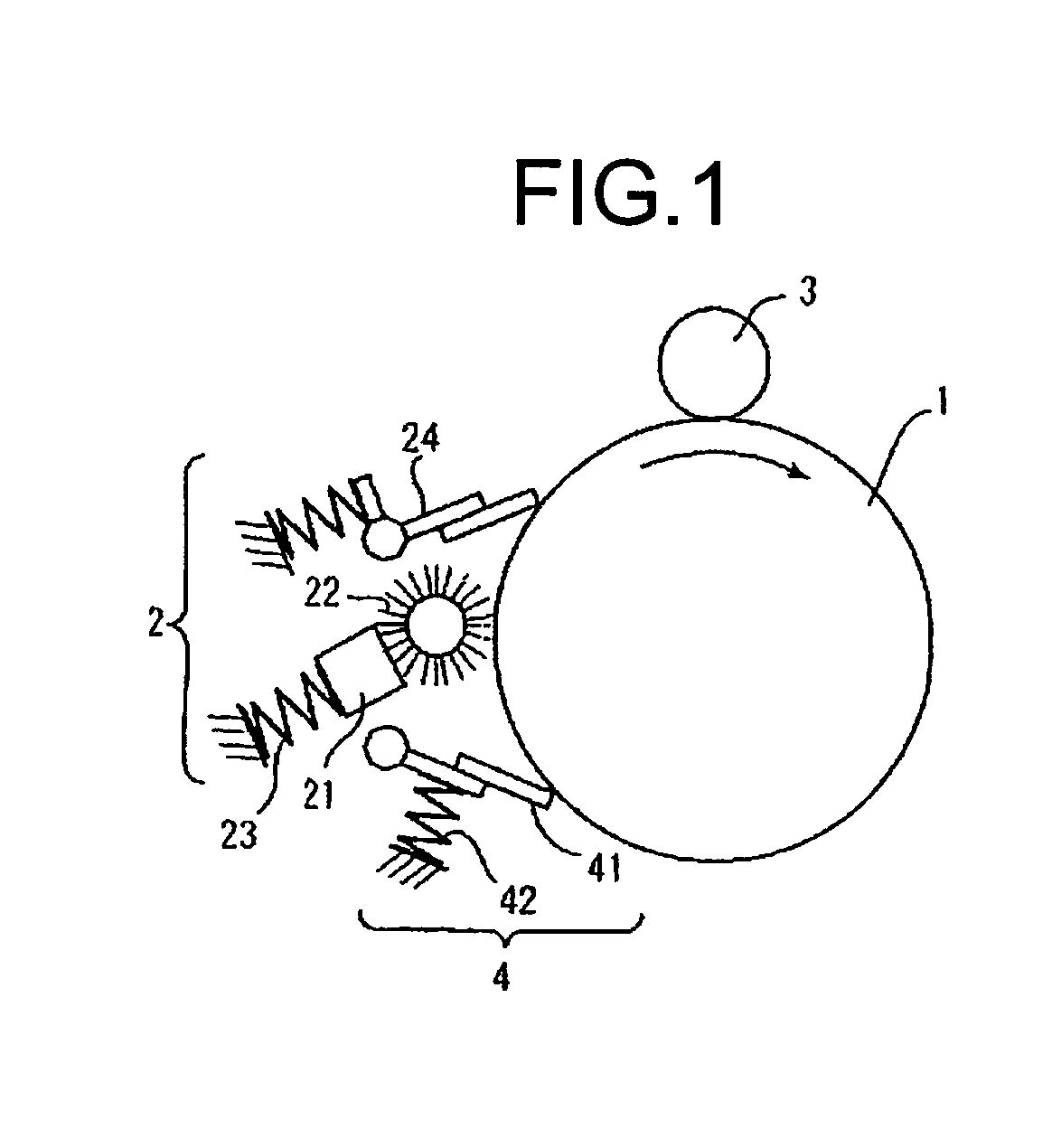

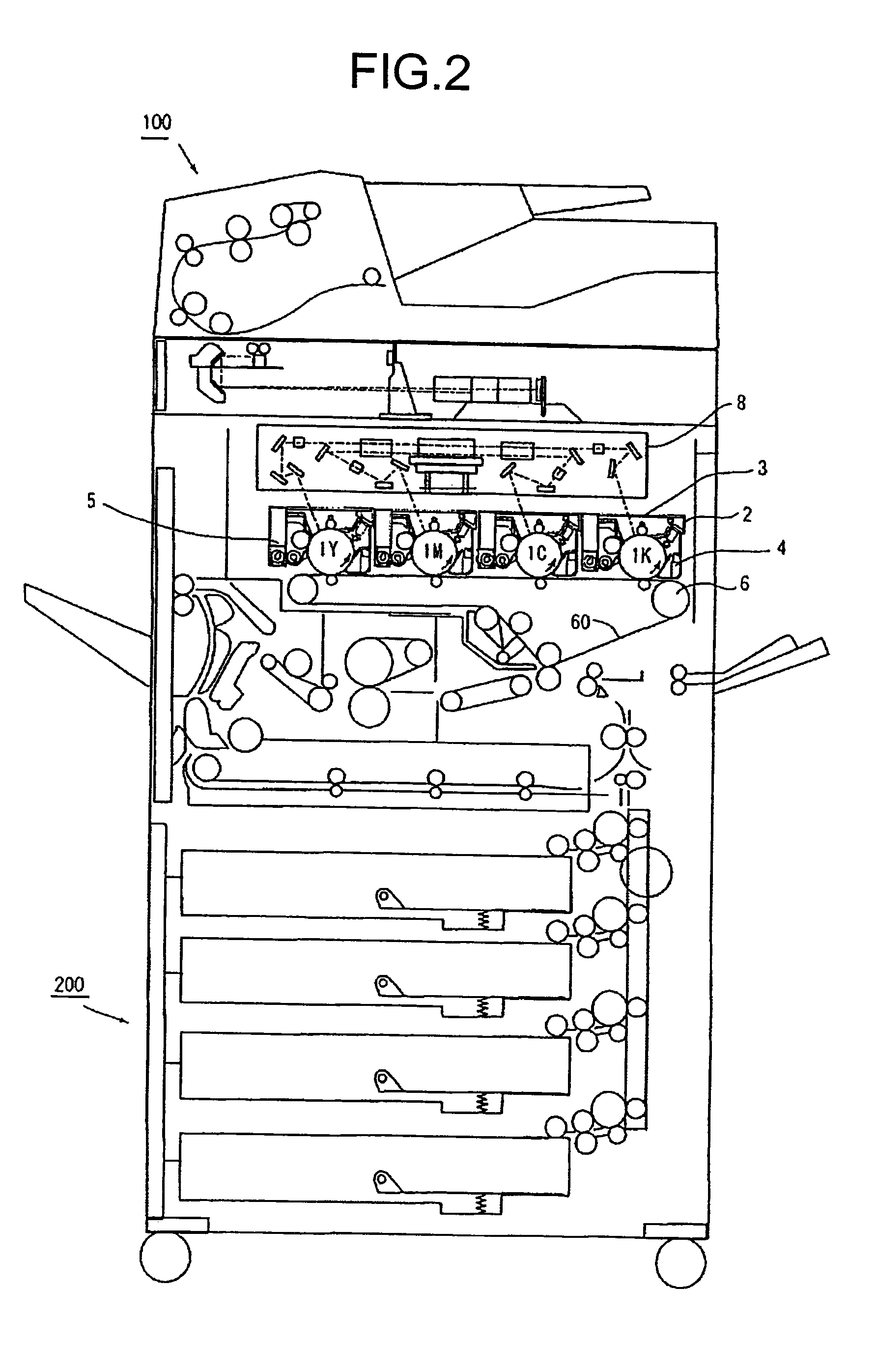

Protective agent, image forming apparatus, and process cartridge

A protective agent for forming a protective layer on the surface of an image carrier includes at least a hydrophilic organic compound and an amphiphilic organic compound at a ratio of 1 / 99 to 20 / 80. Preferably, the hydrophilic organic compound contains at least one selected from a polysaccharide and a polyether compound, or the amphiphilic organic compound contains a nonionic surfactant.

Owner:RICOH KK

Curable resin composition for column spacer,column spacer, and liquid crystal display panel

InactiveUS20090128767A1Excellent developabilityImprove solubilityOrganic chemistryMixing methodsSolubilityLiquid-crystal display

It is an object of the present invention to provide a curable resin composition for a column spacer which has excellent developability and solubility and is capable of forming a clearly patterned column spacer without leaving a development residue at the time of pattern formation of the column spacer to be used in producing a liquid crystal display panel.The present invention is directed to a curable resin composition for a column spacer, which contains a compound having two or more polymerizable unsaturated bonds in a molecule, an alkali-soluble polymer compound, and a photo-reaction initiator, the compound having two or more polymerizable unsaturated bonds in a molecule being an oxide-modified compound having two or more polymerizable unsaturated bonds in a molecule.

Owner:SEKISUI CHEM CO LTD

Expandable Resol Type Phenolic Resin Molding Material and Phenolic Resin Foam

InactiveUS20090270005A1Improve flame retardant performanceExcellent in fireproofnessWoven fabricsWood layered productsFoaming agentAliphatic hydrocarbon

This invention relates to a foamable resol type phenolic resin forming material comprising a liquid resol type phenolic resin, a foaming agent, a foam stabilizer, an additive and an acid curing agent, said additive containing a nitrogen-containing bridged cyclic compound and said foam stabilizer containing a chlorinated aliphatic hydrocarbon compound having 2 to 5 carbon atoms, and a phenolic resin foam product obtained by foaming and curing this forming material.

Owner:KINGSPAN HLDG (IRL) LTD

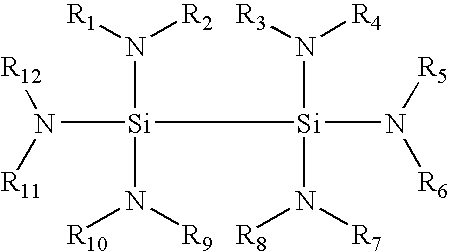

Composition and method for low temperature deposition of silicon-containing films

ActiveUS20040138489A1Silicon organic compoundsPolycrystalline material growthLow temperature depositionGas phase

This invention relates to silicon precursor compositions for forming silicon-containing films by low temperature (e.g., <300° C.) chemical vapor deposition processes for fabrication of ULSI devices and device structures. Such silicon precursor compositions comprise at least one disilane derivative compound that is fully substituted with alkylamino and / or dialkylamino functional groups.

Owner:ENTEGRIS INC

Carbon black

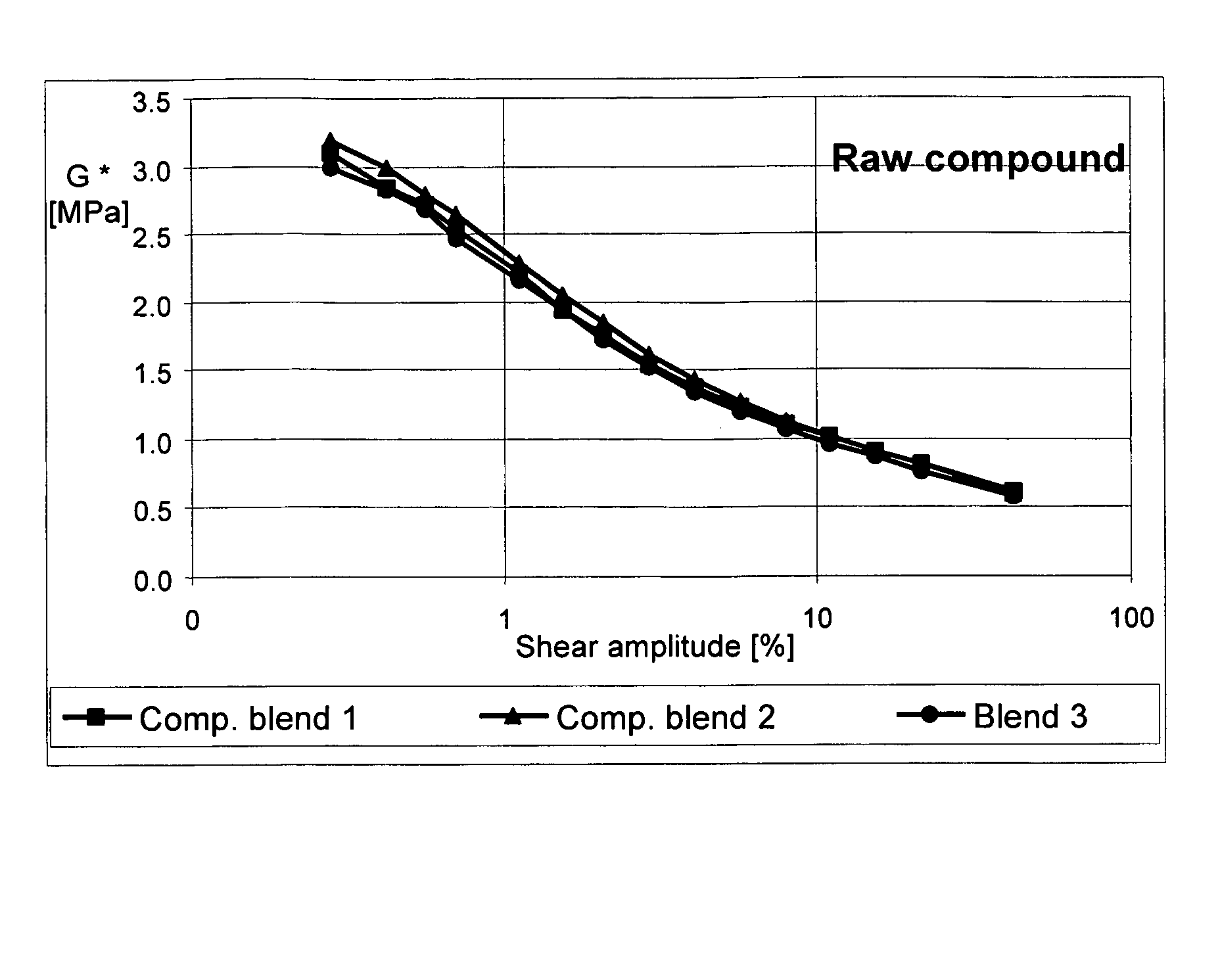

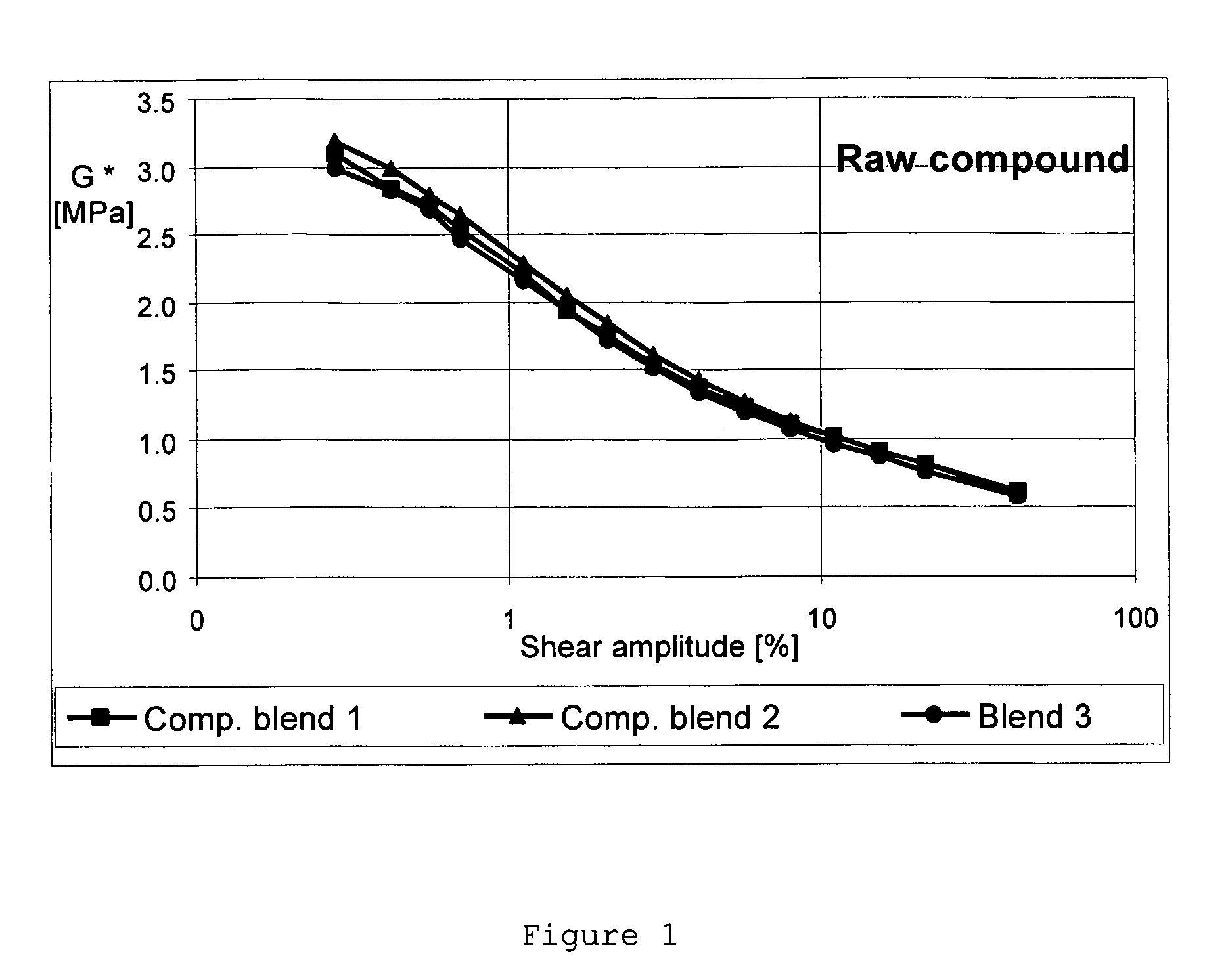

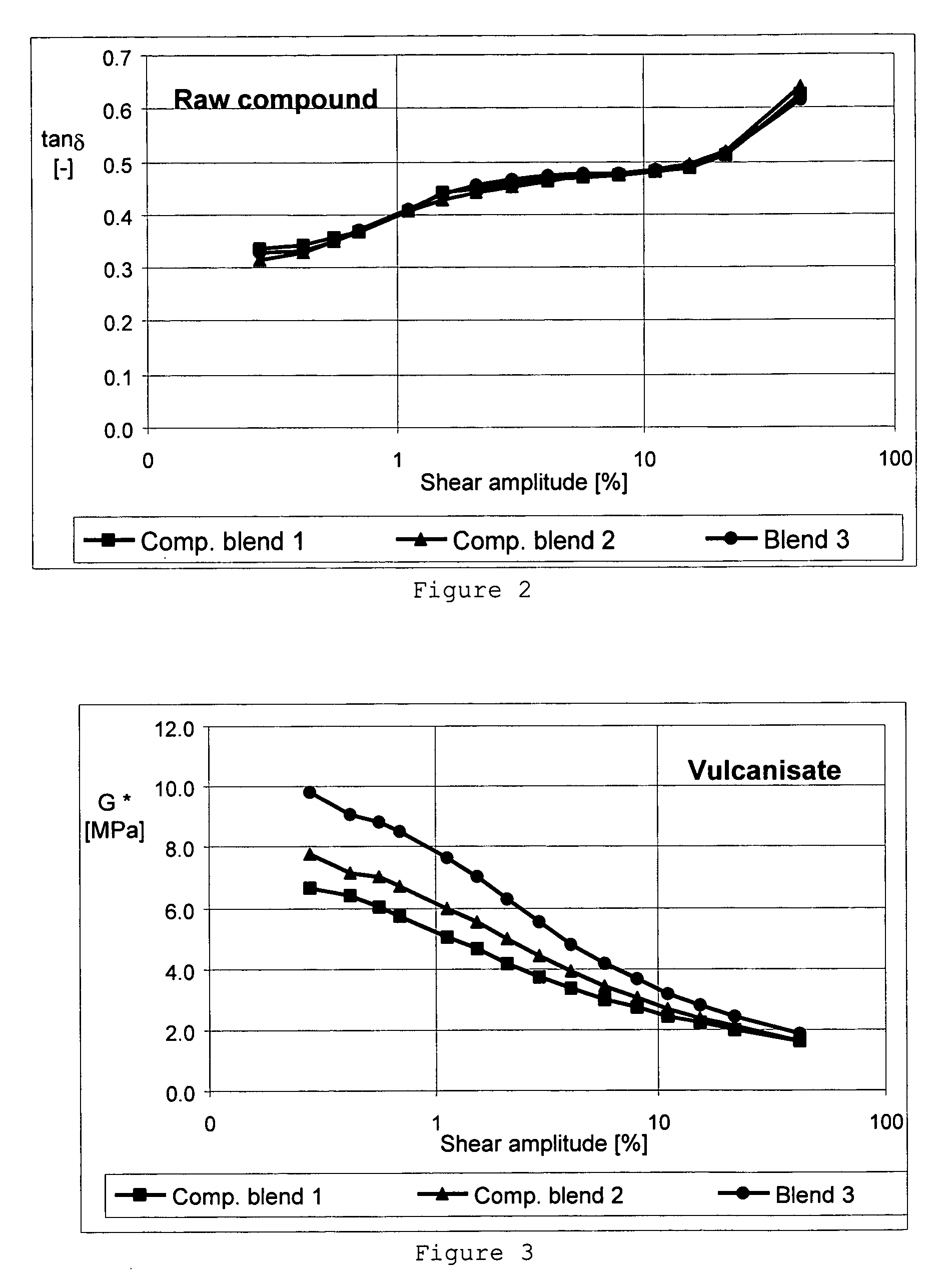

ActiveUS7300964B2Improve dynamic rigidityReduce hysteresisOrganic chemistryOther chemical processesOrganic groupOrganic compound

Carbon black having organic groups, the organic group containing a thiocyanate group. Also described is a process for the production of the carbon black, wherein carbon black is reacted with organic compounds containing a C—C double or triple bond, which is not part of an aromatic system, whose C—C double or triple bond is activated by at least one substituent, and the organic compound contains at least one thiocyanate group. The carbon black according to the invention can be used in rubber compounds.

Owner:UBS AG

High activity catalyst component for olefin polymerization and method of using the same

InactiveUS8227370B2Organic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationElectron donorEther

Owner:WR GRACE & CO

Biological-degradable starch/polyester plastic completely and production thereof

A complete biological degradable starch / polyester plastics and its production are disclosed. It consists of thermoplastic starch, fatty-aromatic block co-mixed polyester, long-chain unsaturated carboxylic acid or acid anhydride graft modified ingredient, organic peroxidate initiator, polyhydric alcohol ester compound plasticizer, organic compound or polyhydric alcohol stabilizer or lubricant. The process is carried out by mechanical-chemical modification and thermoplastic treating, melt mixing fatty-aromatic block co-mixed polyester material with initiator, modifier and stabilizer in high-speed mixer, graft reacting, milling, cooling, breaking, reaction extruding by second bi-screw reaction extruder and granulating. Its advantages include excellent physical and mechanical properties, complete degradation. It can be used for agriculture, medicine, sanitation, engineering materials, refuse bag and packing materials.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

Curable composition, color filter using the same and manufactuirng method therefor, and solid image pickup element

InactiveUS20080171272A1High sensitivityLittle development residuePhotomechanical apparatusOriginals for photomechanical treatmentDouble bondColor filter array

The present invention provides a curable composition containing a resin, a compound containing an ethylenically unsaturated double bond and a photopolymerization initiator, wherein the resin is manufactured by polymerizing at least a monomer having a dipole moment of 2.0 or more as a copolymerization component, a color filter using the same and a manufacturing method therefor, and a solid image pickup element.

Owner:FUJIFILM CORP

Polycarbonate composition, write once read many optical disc substrate and write once read many optical disc using same and process for production of write once read many optical disc

InactiveUS6875491B2Good coloring matter coatabilityImprove antistatic performanceSynthetic resin layered productsRecord information storagePolycarbonateAromatic hydrocarbon

A polycarbonate composition excellent in both antistatic property and coloring matter coatability containing (a) a polycarbonate obtained by an ester exchange process, and (b) a compound having a molecular weight of from 300 to 8,000 and having any of ester bond, carbonate bond, amide bond and urethane bond in its molecule and an aromatic hydrocarbon group substituted by at least one alkyl group at the molecular end thereof, a write once read many optical disc substrate and a write once read many optical disc using the same and a process for the production of a write once read many optical disc are described.

Owner:MITSUBISHI CHEM CORP

Thermal interface materials

InactiveUS6908669B2Minimize size of deviceHeat storage plantsSemiconductor/solid-state device detailsPolymer scienceElectronic component

A crosslinkable thermal interface material is produced by combining at least one rubber compound, at least one amine resin and at least one thermally conductive filler. This interface material takes on the form of a liquid or “soft gel”. The gel state is brought about through a crosslinking reaction between the at least one rubber compound composition and the at least one amine resin composition. Once the foundation composition that comprises at least one rubber compound, at least one amine resin, and at least one thermally conductive filler has been prepared, the composition must be compared to the needs of the electronic component, vendor, or electronic product to determine if a phase change material is needed to change some of the physical properties of the composition. A method for forming the crosslinkable thermal interface materials disclosed herein comprises a) providing at least one saturated rubber compound, b) providing at least one amine resin, c) crosslinking the at least one saturated rubber compound and the at least one amine resin to form a crosslinked rubber-resin mixture, d) adding at least one thermally conductive filler to the crosslinked rubber-resin mixture, and e) adding a wetting agent to the crosslinked rubber-resin mixture. This method can also further comprise adding at least one phase change material to the crosslinked rubber-resin mixture. The contemplated thermal interface material can be provided as a dispensable liquid paste, a gel, a tape, or a film. Applications of the contemplated thermal interface materials described herein comprise incorporating the materials into a layered material, an electronic component or a finished electronic product.

Owner:HONEYWELL INT INC

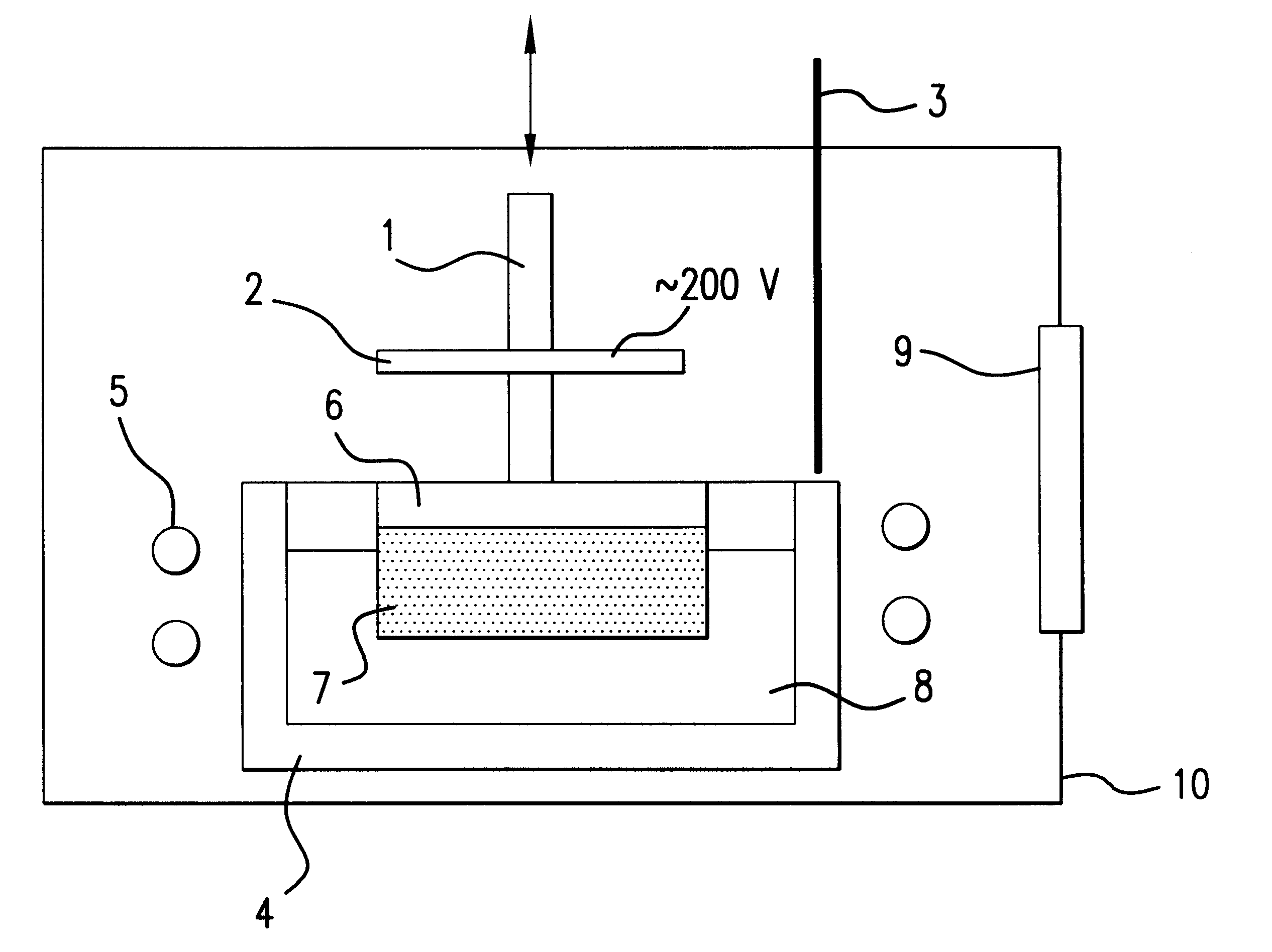

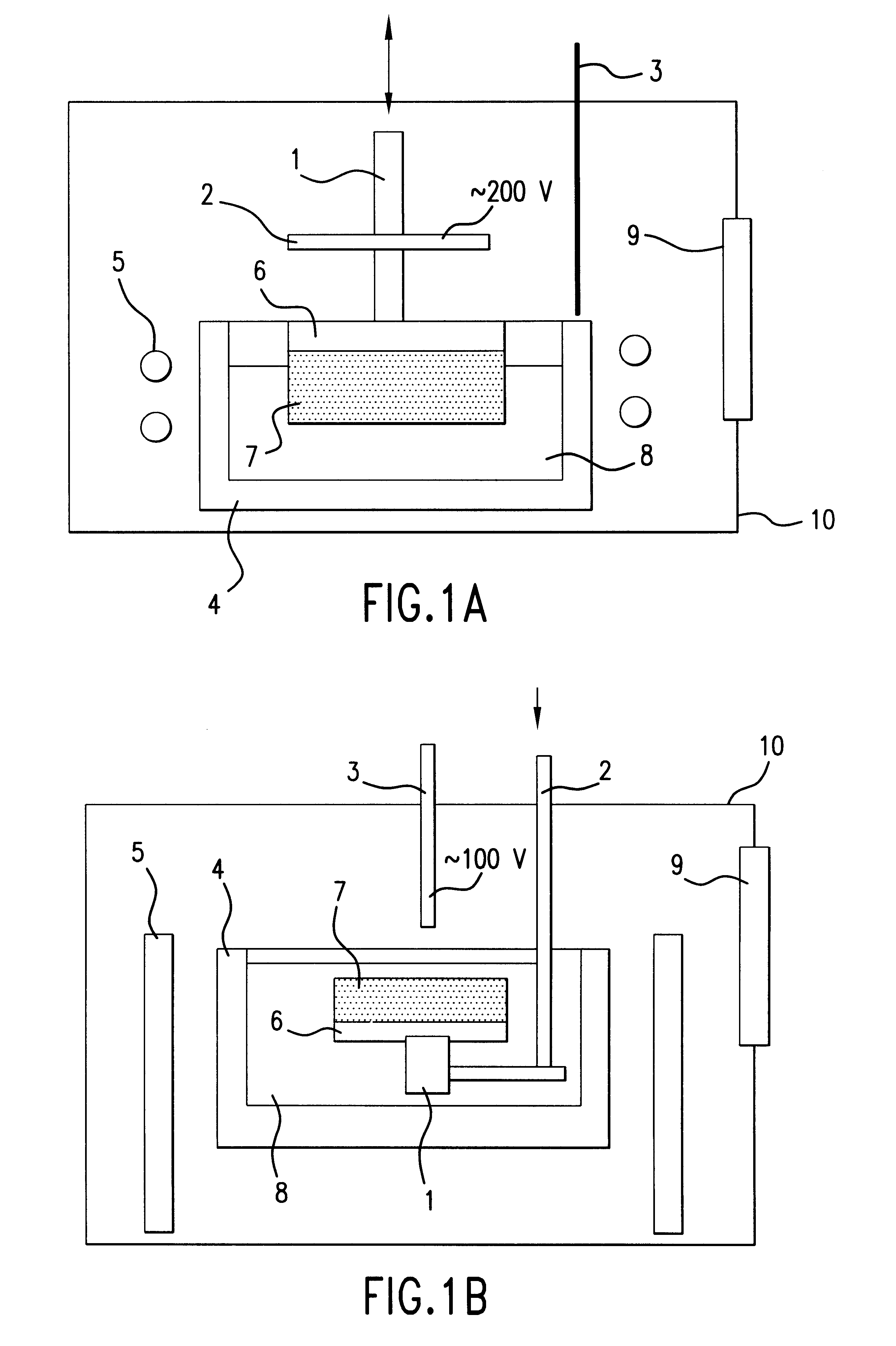

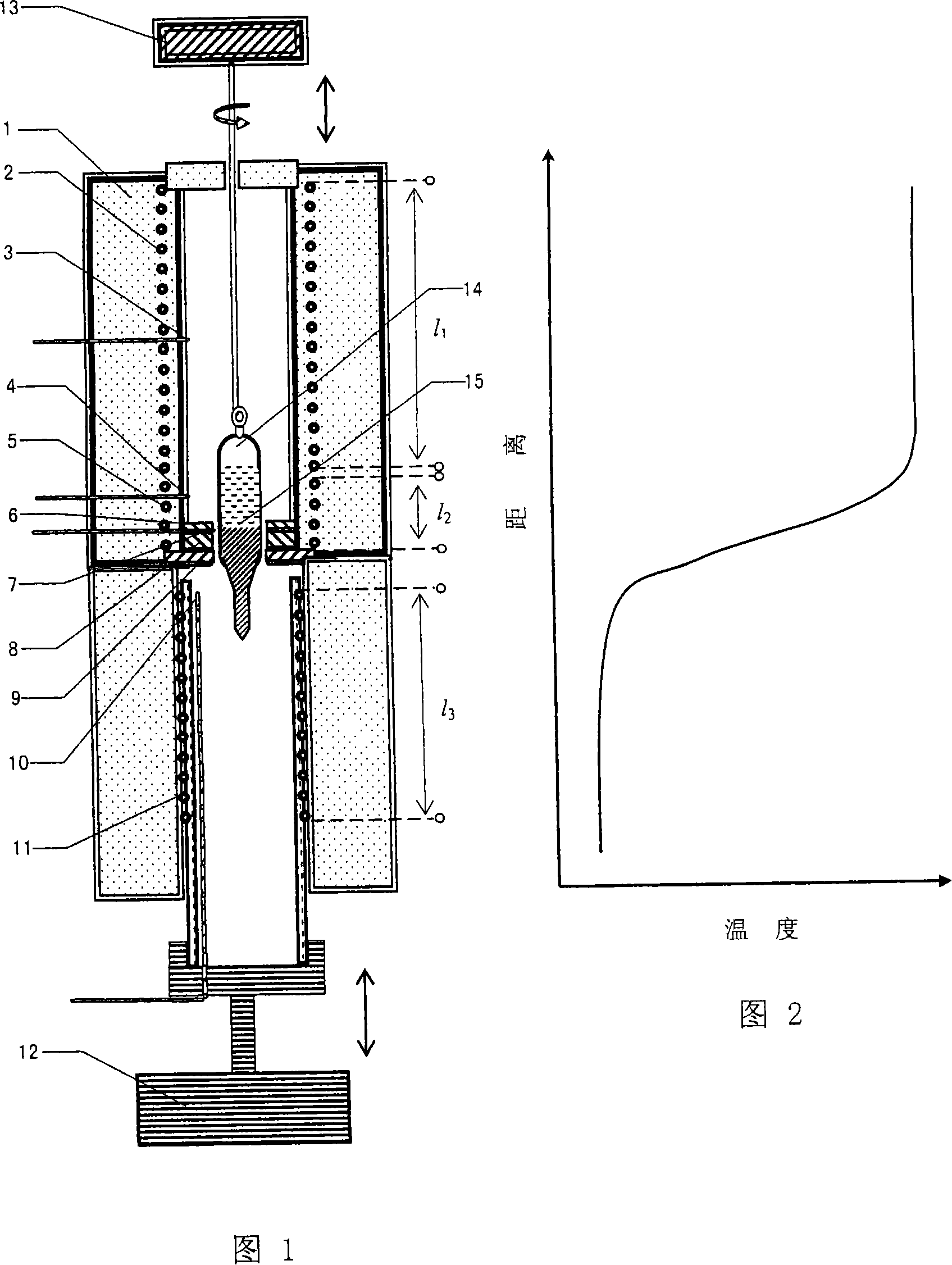

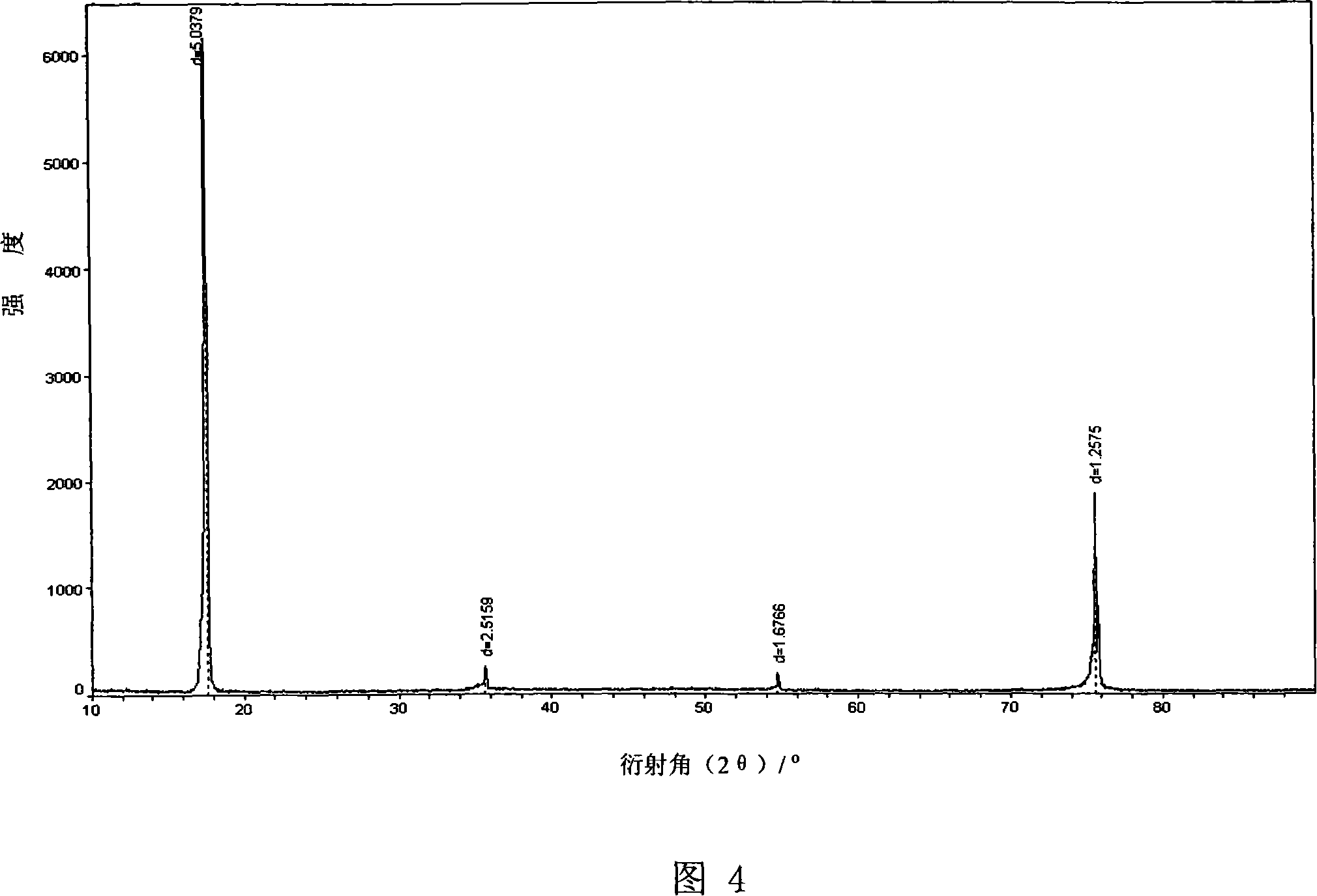

Preparation method for multi-element compounds semiconductor single-crystal and growth device thereof

InactiveCN101122045ARealize temperature field adjustmentComplete appearanceFrom frozen solutionsCrucibleSingle crystal

A method for preparing a multi-component semiconductor single crystal, the process steps are: (1) cleaning a crucible, (2) charging and degassing and sealing, (3) crystal growth, and (4) annealing and cooling. The single crystal growth device matched with this method includes a movable lower furnace heater and a single crystal growth furnace with an auxiliary heater in the middle, which can flexibly adjust the temperature field in the crystallization temperature gradient area according to the crystallization habit of the multi-component compound, and obtain The narrow temperature zone and large temperature gradient crystallization temperature field distribution required for the growth of compound single crystals maintain the stability of the solid-liquid interface and realize the flat interface growth of single crystals. Using the growth device, various multi-element compound semiconductor single crystals with complete appearance and good crystallization performance can be successfully grown by adopting the crucible descending method.

Owner:SICHUAN UNIV

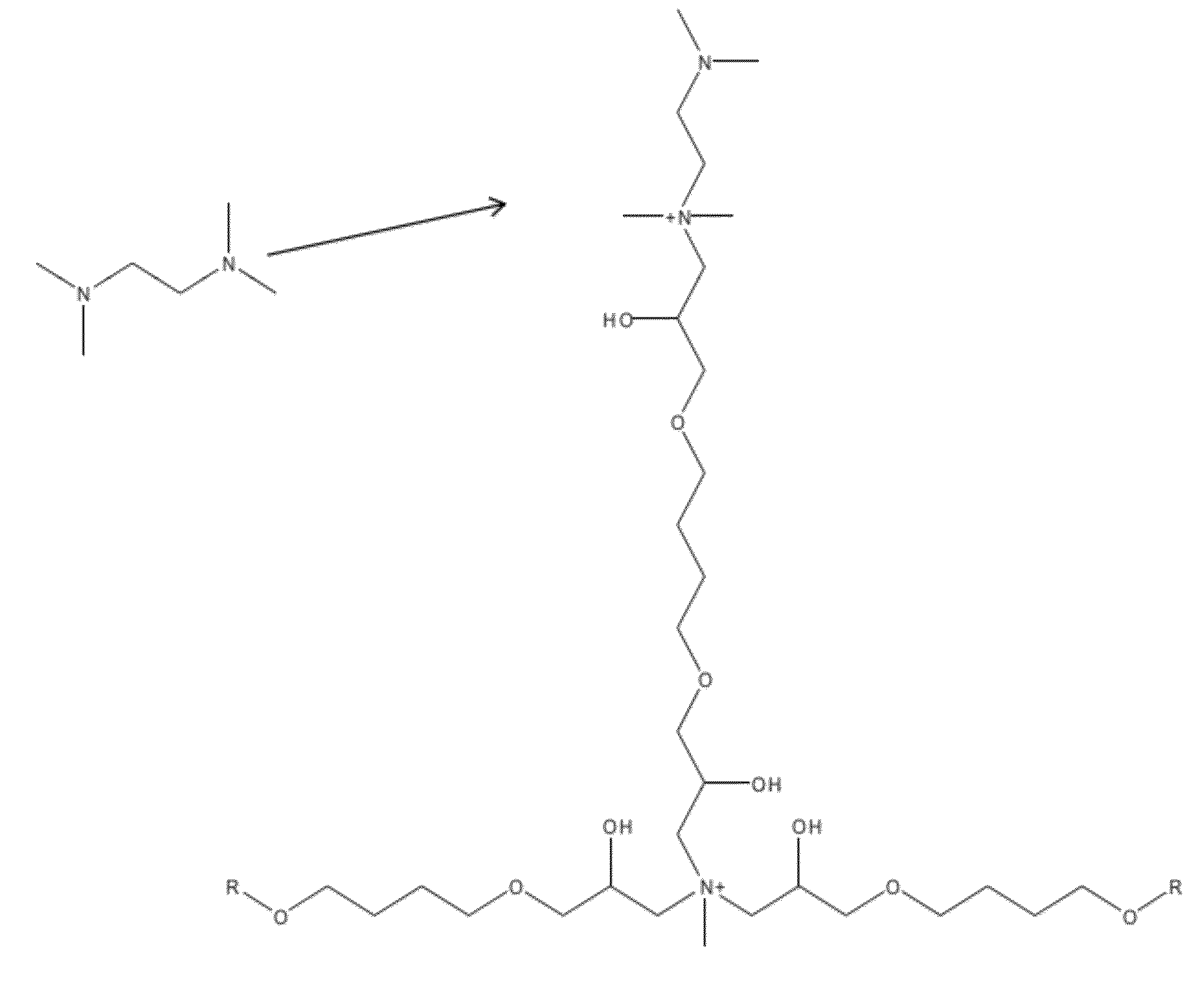

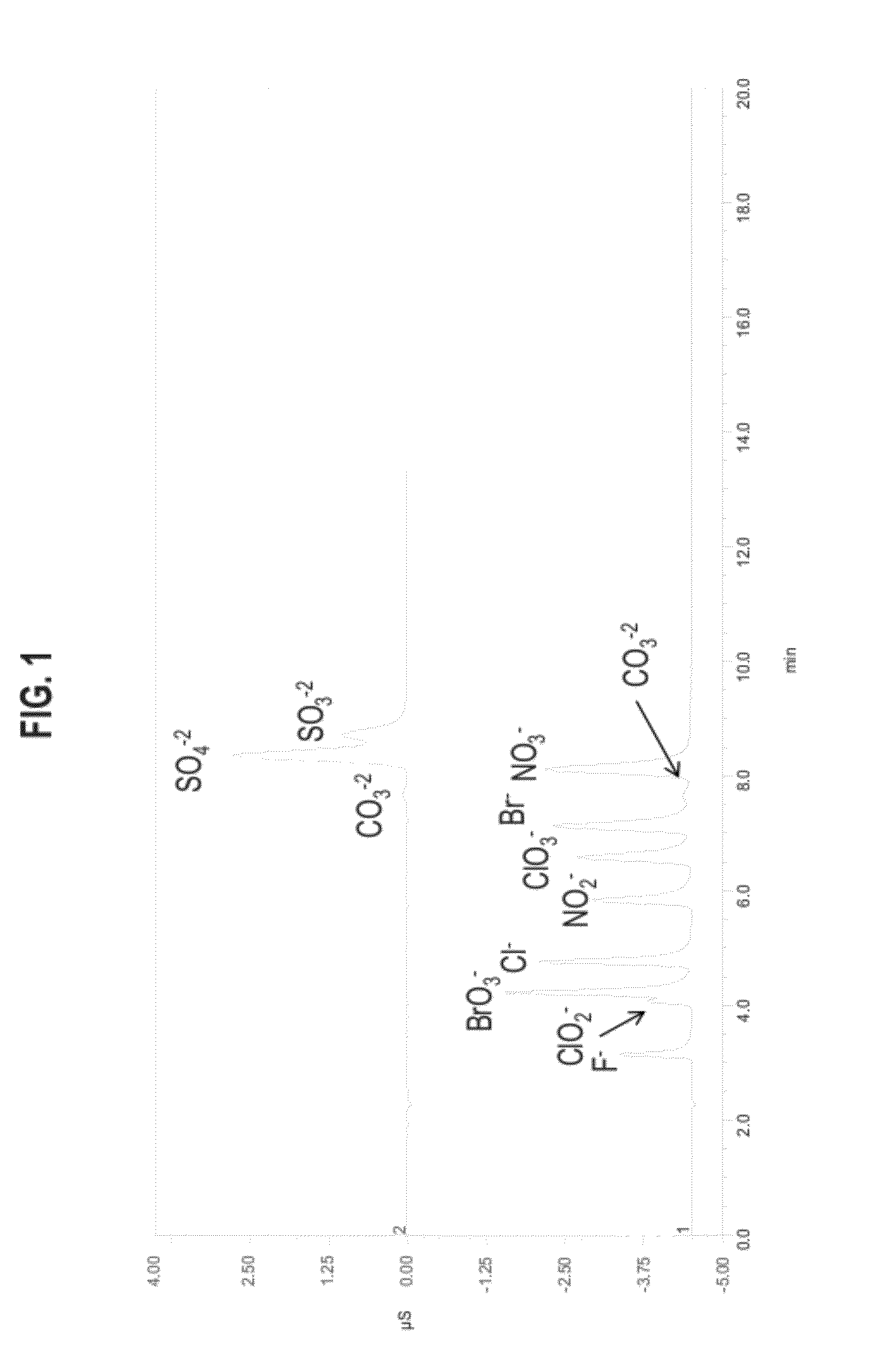

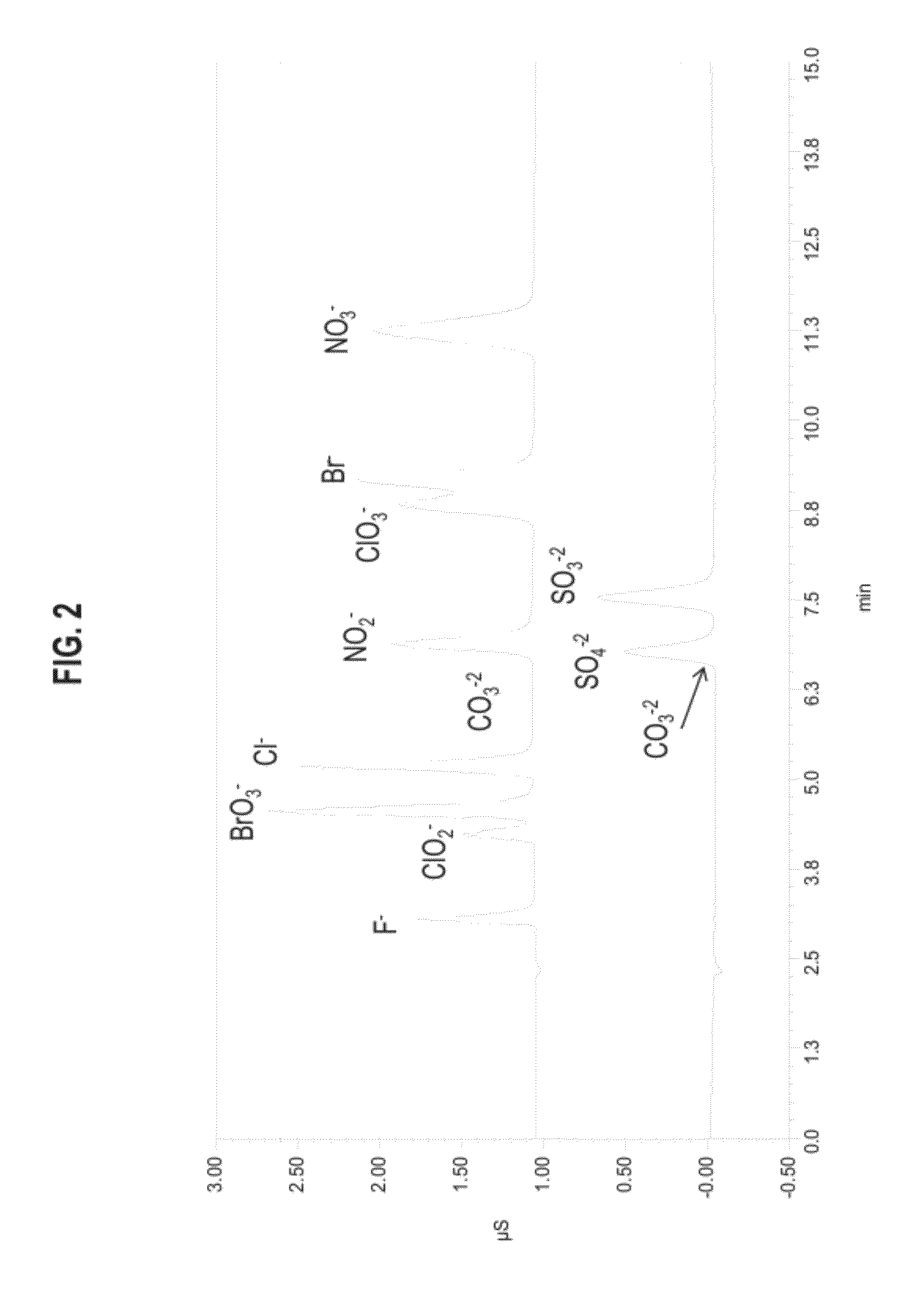

Electrostatically bound hyperbranched anion exchange surface coating prepared via condensation polymerization using ditertiary amine linkers for improved divalent anion selectivity

ActiveUS20120231195A1Easy to separatePoor peak shapeChromatographic cation exchangersIon-exchanger regenerationIon chromatographyIon exchange

The present invention provides a new design for high capacity stationary phases for dianion selective ion chromatography. The stationary phases include one or more layers which are products of condensation polymerization. Multiple components are of use in forming the first polymer layer and the condensation polymer structure, thereby providing a stationary phase that can be engineered to have a desired property such as ion capacity, ion selectivity, and the like. Exemplary condensation polymers are formed by the reaction of at least one polyfunctional compound with at least one compound of complimentary reactivity, e.g., a nucleophilic polyfunctional compound reacting with an electrophilic compound.

Owner:DIONEX CORP

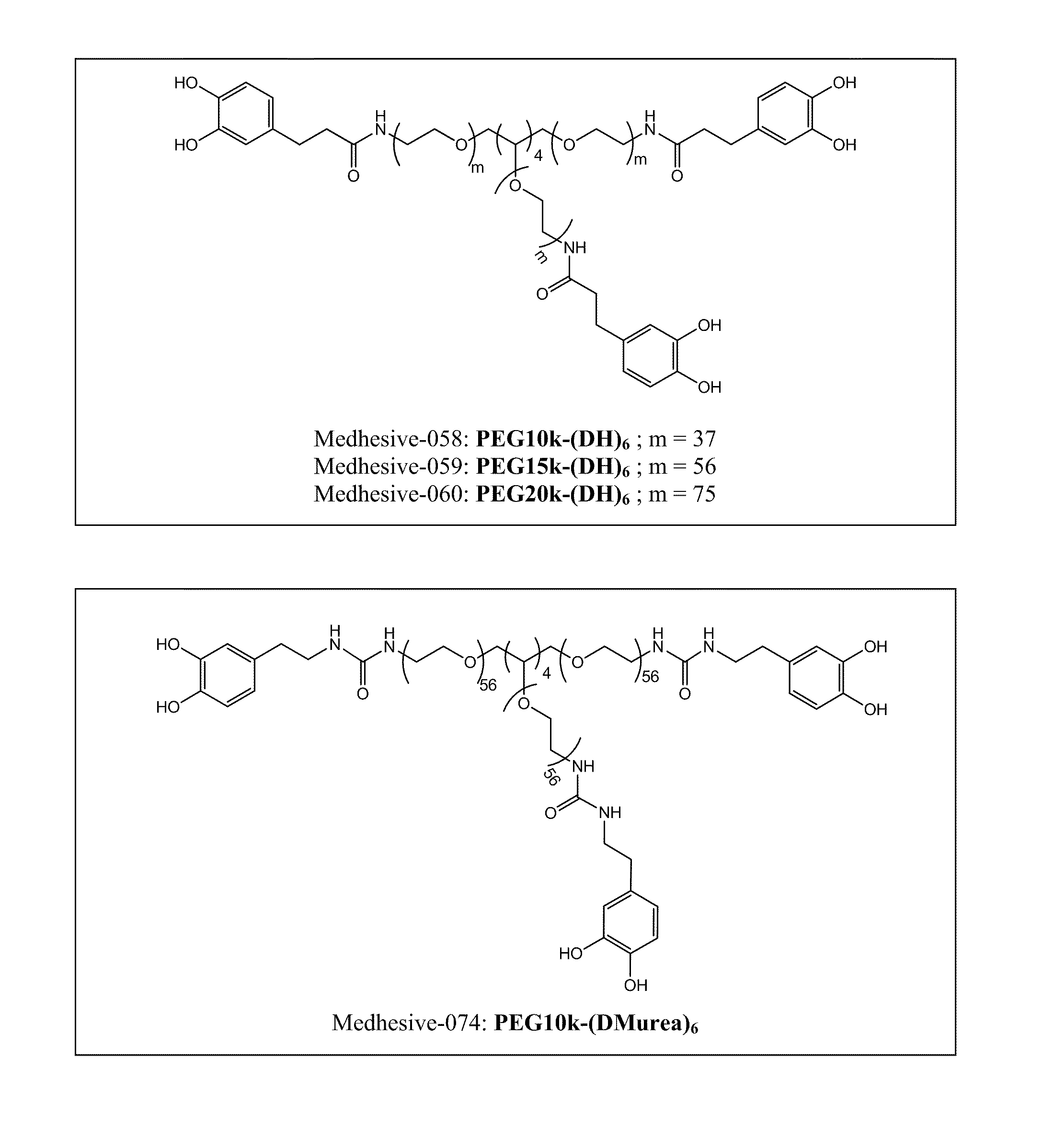

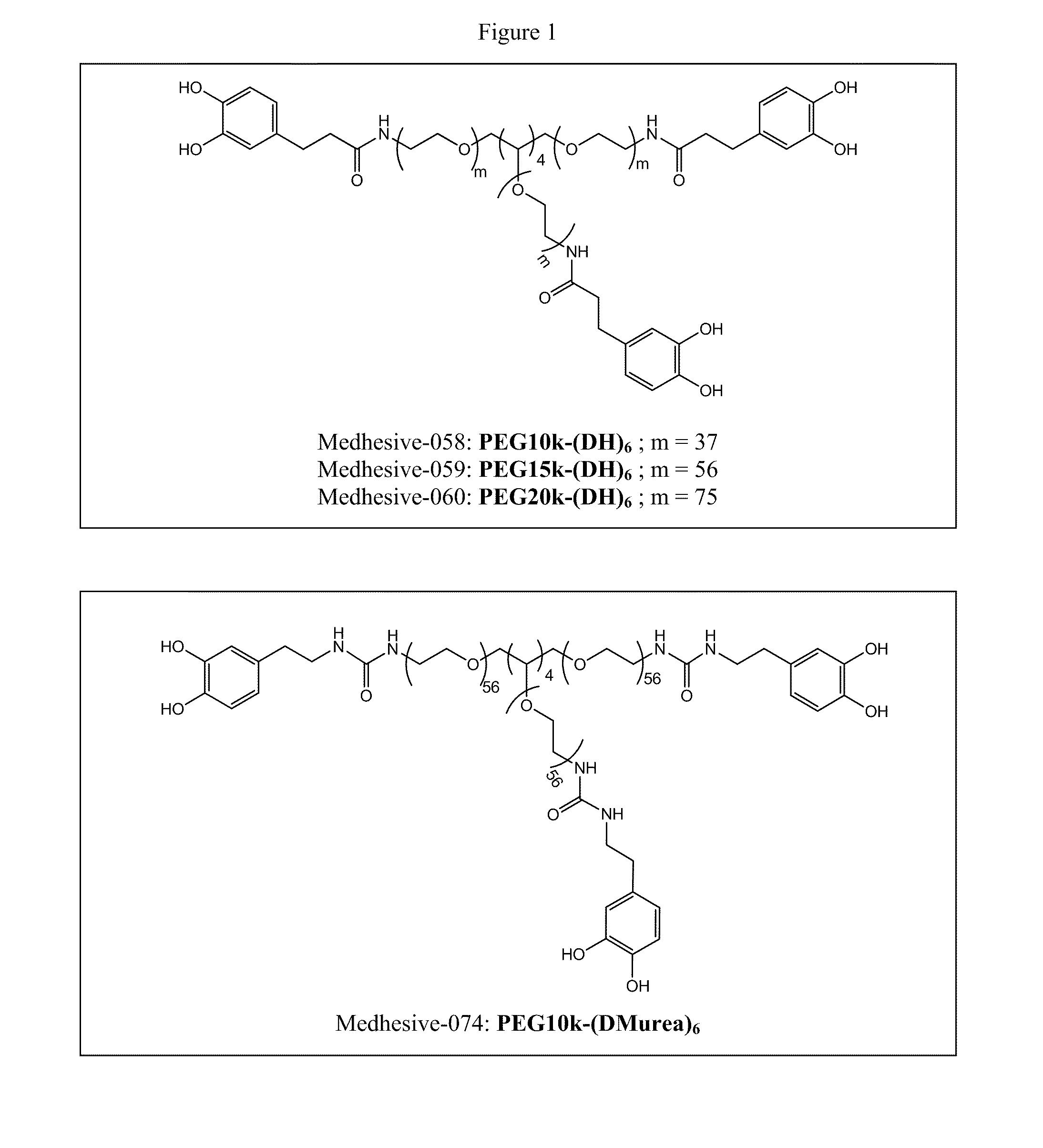

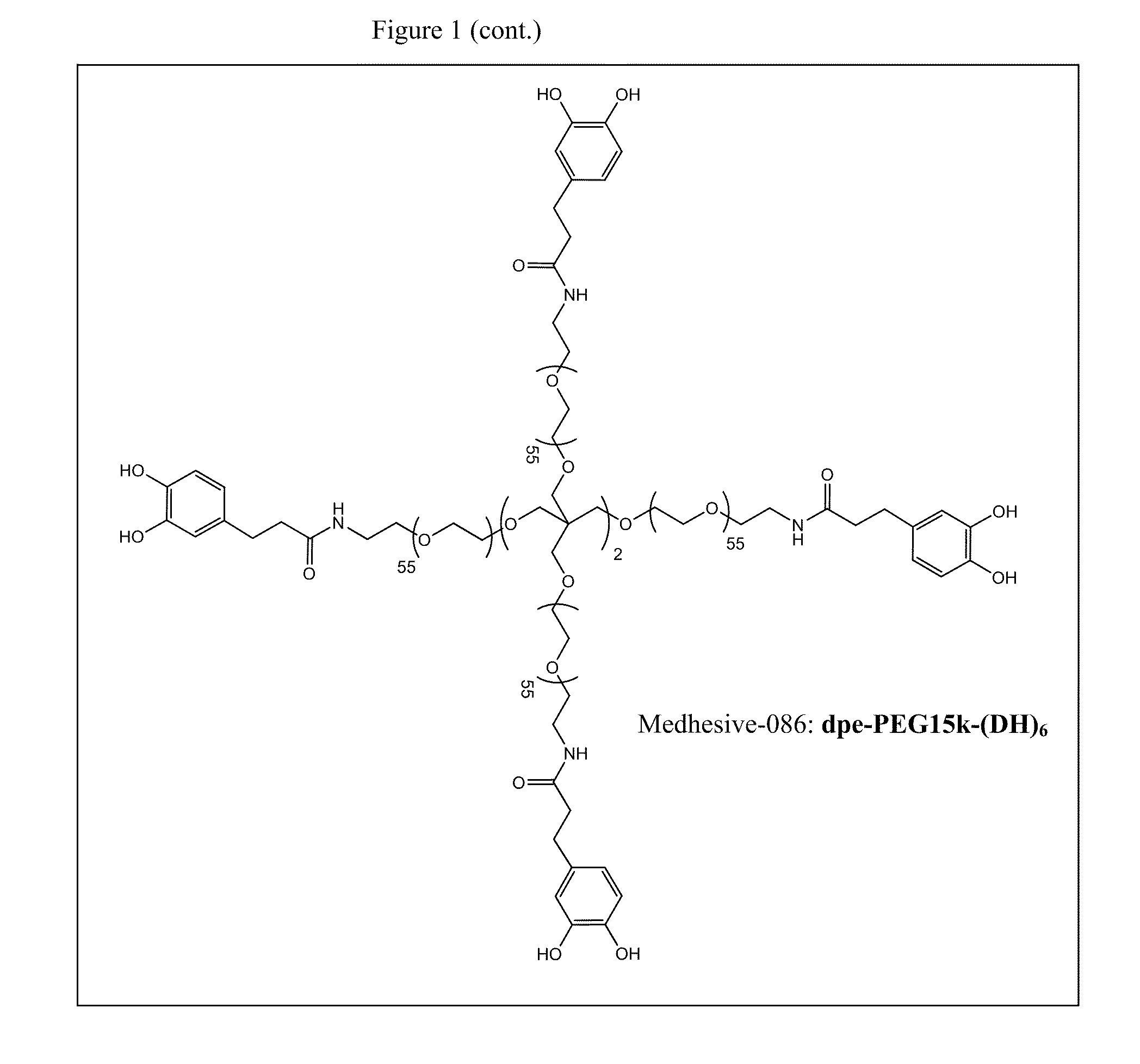

Multi-armed catechol compound blends

ActiveUS20100113828A1Inhibits and reduces growth of biofilmControl bleedingSuture equipmentsBiocideProviding materialPhenyl group

The invention describes families of compounds that utilize multihydroxyl phenyl groups to provide adhesive properties. Selection of the multihydroxy phenyl group along with linkers or linking groups and the linkages between the linkers or linking groups with polyalkylene oxides, provides materials that can be engineered to afford controllable curing time, biodegradation and / or swelling.

Owner:DSM IP ASSETS BV

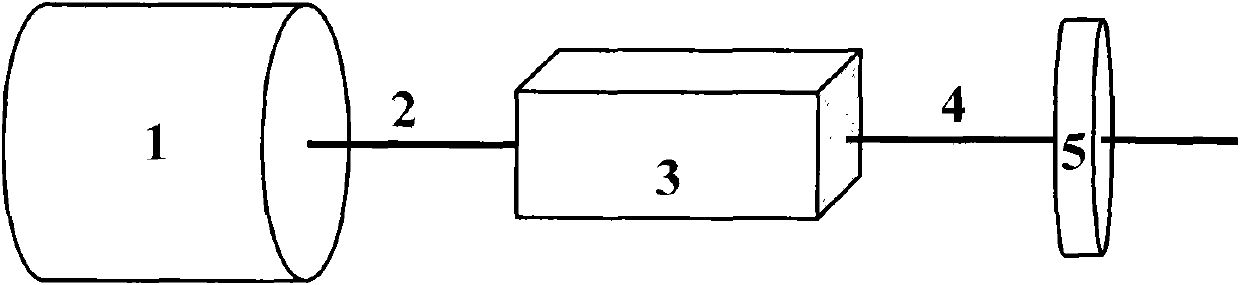

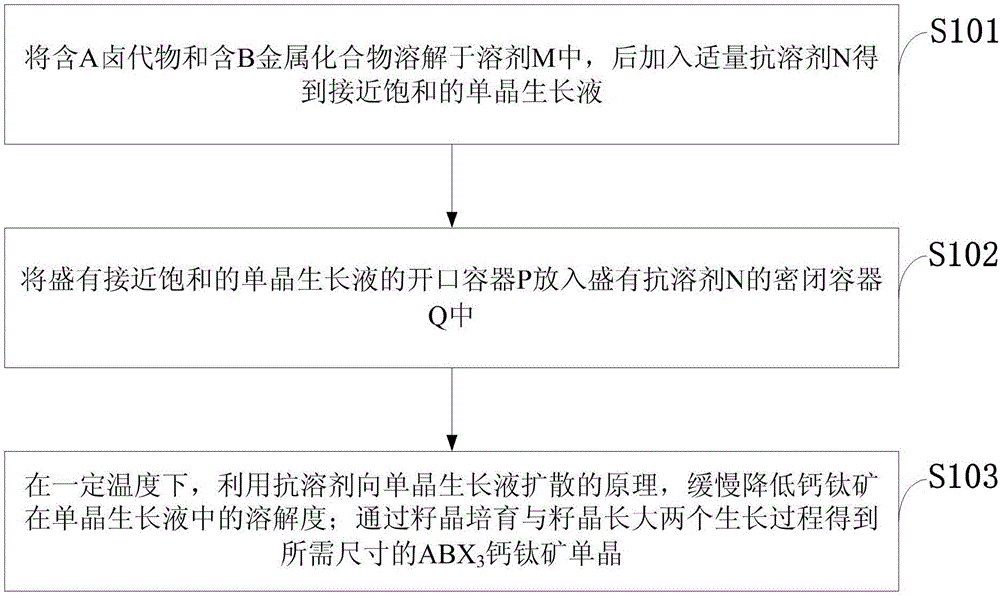

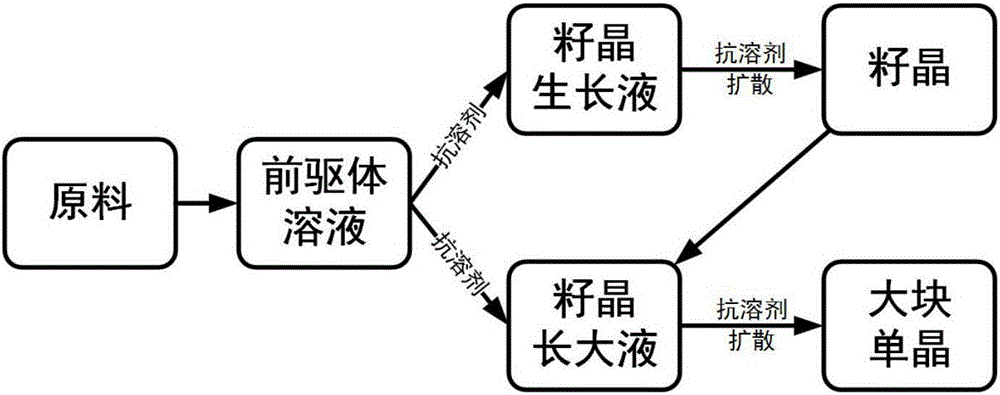

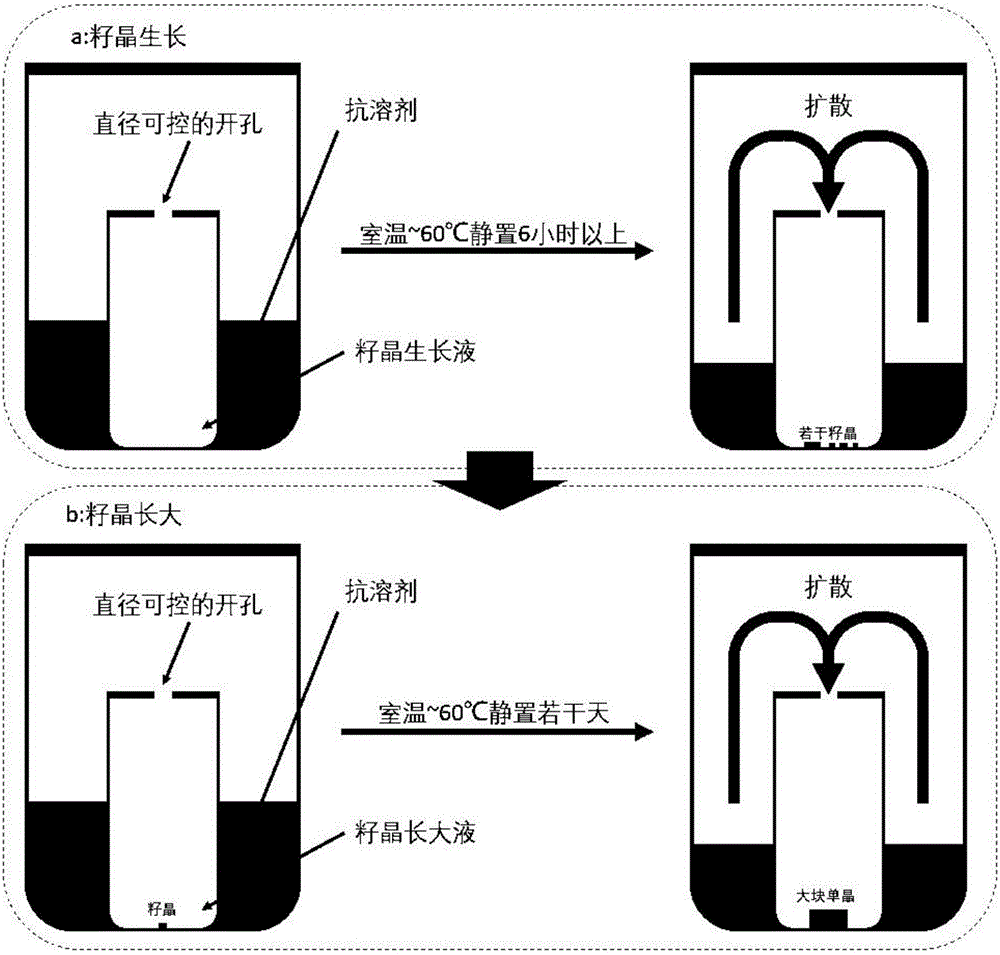

Method for growing ABX3 perovskite single crystal by antisolvent diffusion

InactiveCN106757342AReduce solubilitySmall sizePolycrystalline material growthFrom normal temperature solutionsSolubilitySolvent

The invention discloses a method for growing an ABX3 perovskite single crystal by antisolvent diffusion. The method comprises the following steps: dissolving an A-containing halide and a B-containing metal compound in a solvent M, and adding a right amount of antisolvent N to obtain an approximately saturated single crystal growth solution, wherein the mole ratio of the A-containing halide to the B-containing metal compound is 1:(0.1-2); putting the open container P containing the approximately saturated single crystal growth solution into the closed container Q containing the antisolvent N; and at a certain temperature, carrying out seed crystal culture and seed crystal growth (two growth processes) to obtain the ABX3 perovskite single crystal with required size. According to the method for preparing the high-quality perovskite single crystal, the principle that the antisolvent diffuses to the single crystal growth solution is utilized to slowly lower the solubility of perovskite in the single crystal growth solution, so that the solution precipitates the perovskite single crystal. The method has the advantages of large size and high quality of the obtained single crystal, high utilization ratio of raw materials, simple facility request, simple technique, low environmental hazard and the like.

Owner:KUNMING UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com