Preparation method for multi-element compounds semiconductor single-crystal and growth device thereof

A growth device and compound technology, which is applied in the field of growth device and multi-component compound semiconductor single crystal growth by melt method, can solve the problems of large melt viscosity coefficient, large difference in thermal conductivity between solid and melt, large difference in melting point, etc. Stabilize the solid-liquid interface, achieve flat interface growth, and achieve good crystallization performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

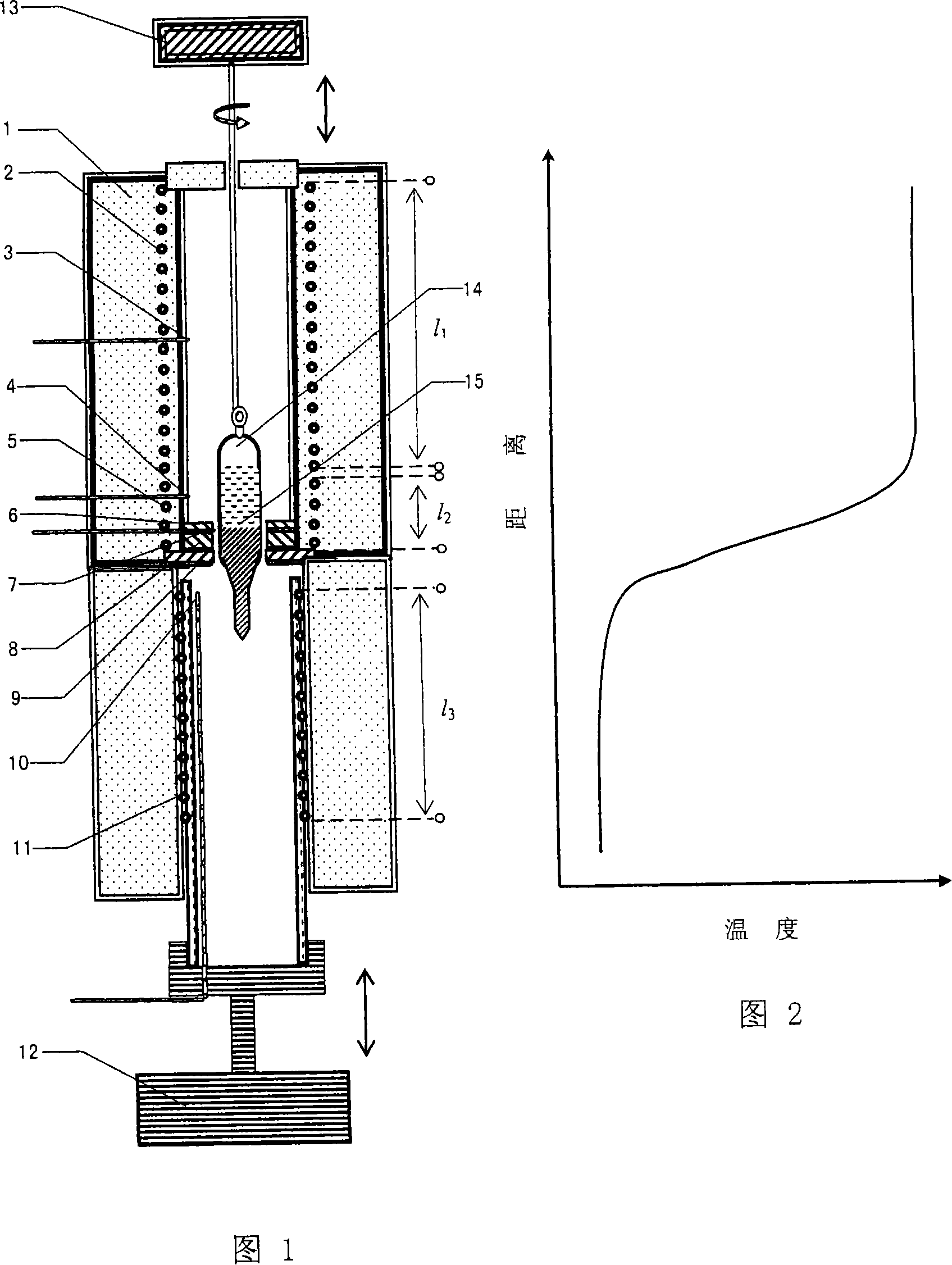

[0030] Example 1: Multicomponent Compound Semiconductor Single Crystal Growth Apparatus

[0031] In this embodiment, the structure of the multi-component compound semiconductor single crystal growth device is shown in FIG. 1, including a furnace body 1, an upper furnace heater, an auxiliary heater, a lower furnace heater, and an upper furnace temperature monitor that are independently heated and temperature-controlled , the lower heat conduction ring 9, the middle heat conduction ring 8, the upper heat preservation and heat insulation ring 6, the lower lifting mechanism 12, and the upper lifting mechanism 13.

[0032] The heating element 2 of the upper furnace heater and the heating element 5 of the auxiliary heater are sequentially installed on the furnace body from top to bottom along the axial direction of the furnace body, and the heating assembly 11 of the lower furnace heater is installed on the lower lifting mechanism 12, Its main body extends into the furnace body and ...

Embodiment 2

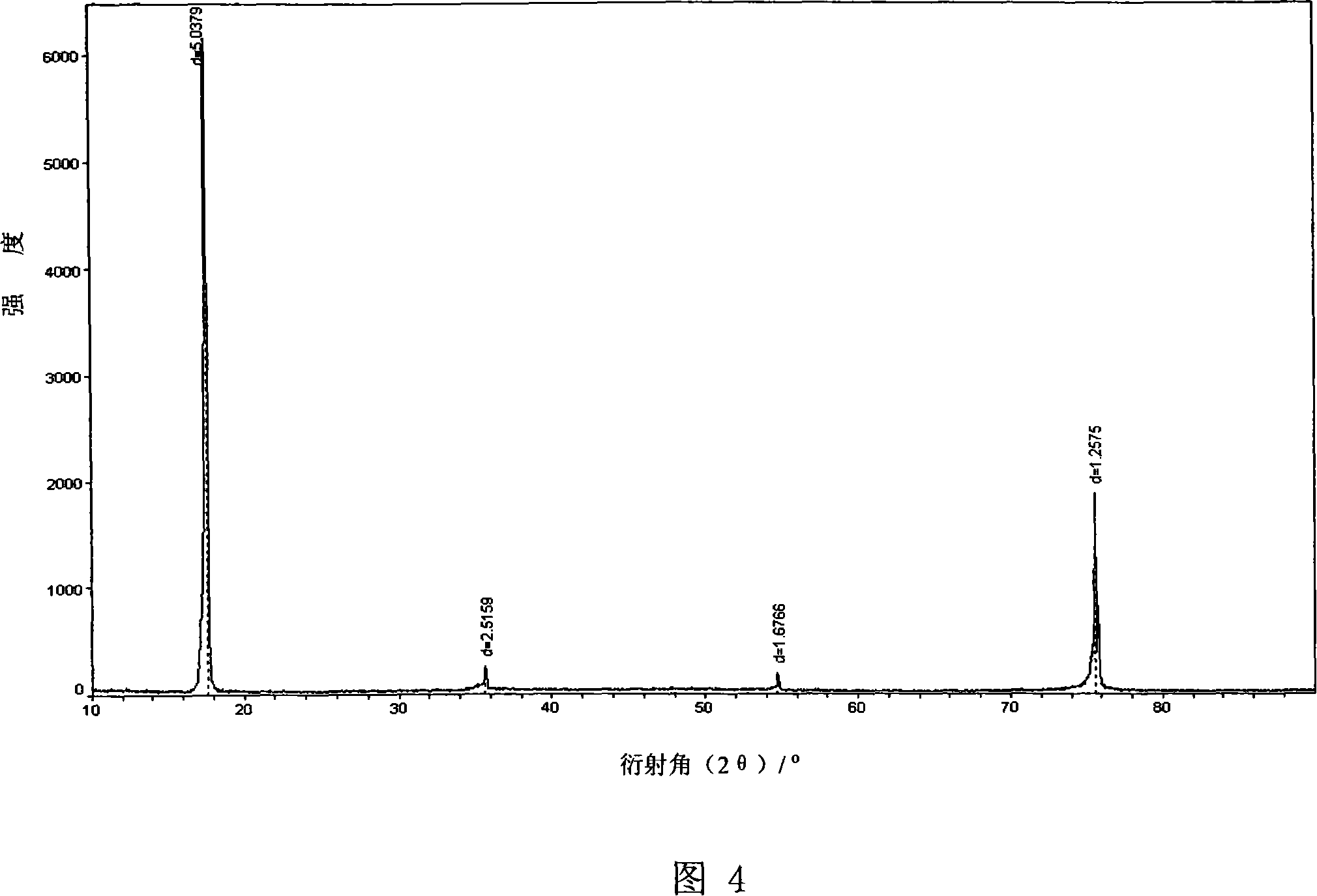

[0036] Example 2: AgGaS 2 Preparation of single crystals

[0037] In this embodiment, AgGaS is used 2 The polycrystalline powder was used as the raw material, the quartz crucible was used as the growth vessel, and the crystal growth device described in Example 1 was used. In this device, the auxiliary heater heating element distribution area 1 2 The length is 12cm. The preparation method includes the following process steps in turn:

[0038] ①Clean the crucible

[0039] The cleaning process of the crucible is a combination of comprehensive cleaning and vacuum baking. First, the inner wall of the crucible is soaked and rinsed with tap water, then soaked in hydrofluoric acid for 3 minutes, then rinsed with tap water until neutral, and finally placed in an ultrasonic cleaning tank to oscillate. Clean for 8 minutes and rinse with high-resistance deionized water repeatedly, place the cleaned crucible in a vacuum oven, control the temperature at 130 °C, and bake for 3.5 hours; ...

Embodiment 3

[0048] Example 3: CdGeAs 2 Preparation of single crystals

[0049] In this embodiment, CdGeAs is used 2 The polycrystalline powder was used as the raw material, the quartz crucible was used as the growth vessel, and the crystal growth device described in Example 1 was used. In this device, the auxiliary heater heating element distribution area 1 2 The length is 8cm. The preparation method includes the following process steps in turn:

[0050] ①Clean the crucible

[0051] The cleaning process of the crucible is a combination of comprehensive cleaning and vacuum baking. First, the inner wall of the crucible is soaked and rinsed with tap water, then soaked in hydrofluoric acid for 3 minutes, then rinsed with tap water until neutral, and finally placed in an ultrasonic cleaning tank to oscillate. Wash for 8 minutes and repeatedly rinse with high-resistance deionized water, place the cleaned ampoules in a vacuum oven, control the temperature at 130 °C, and bake for 3.5 hours; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com