Sandwich structure divertor module and integral form manufacturing method thereof

A manufacturing method and divertor technology are applied in the directions of additive manufacturing, reduction of greenhouse gases, improvement of process efficiency, etc., which can solve the problems of inability to realize continuous change of W-Cu material gradient, high cost, long process flow, etc., and achieve good thermal stability. Stress relaxation effect, good bonding strength, effect of simplifying the process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

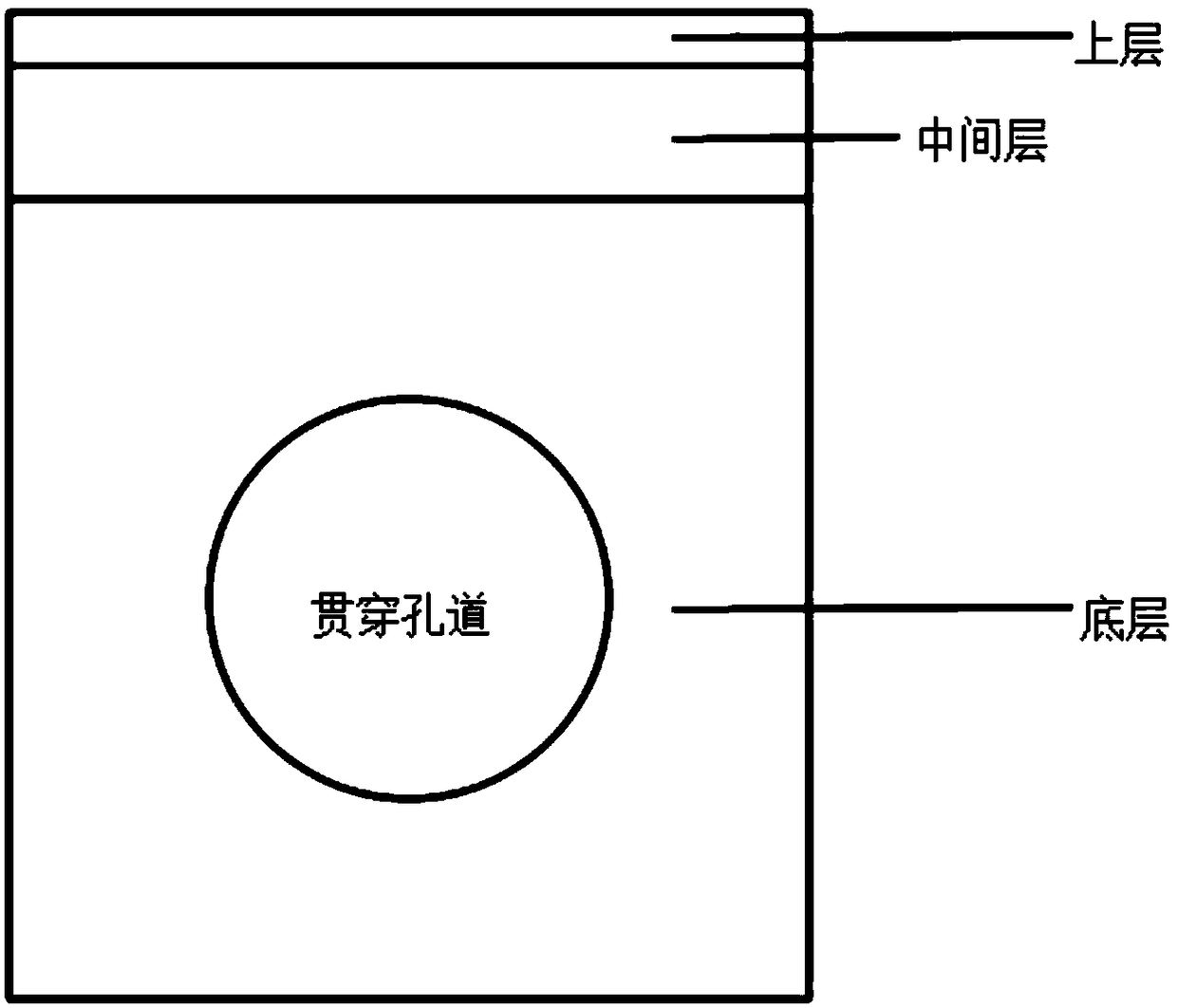

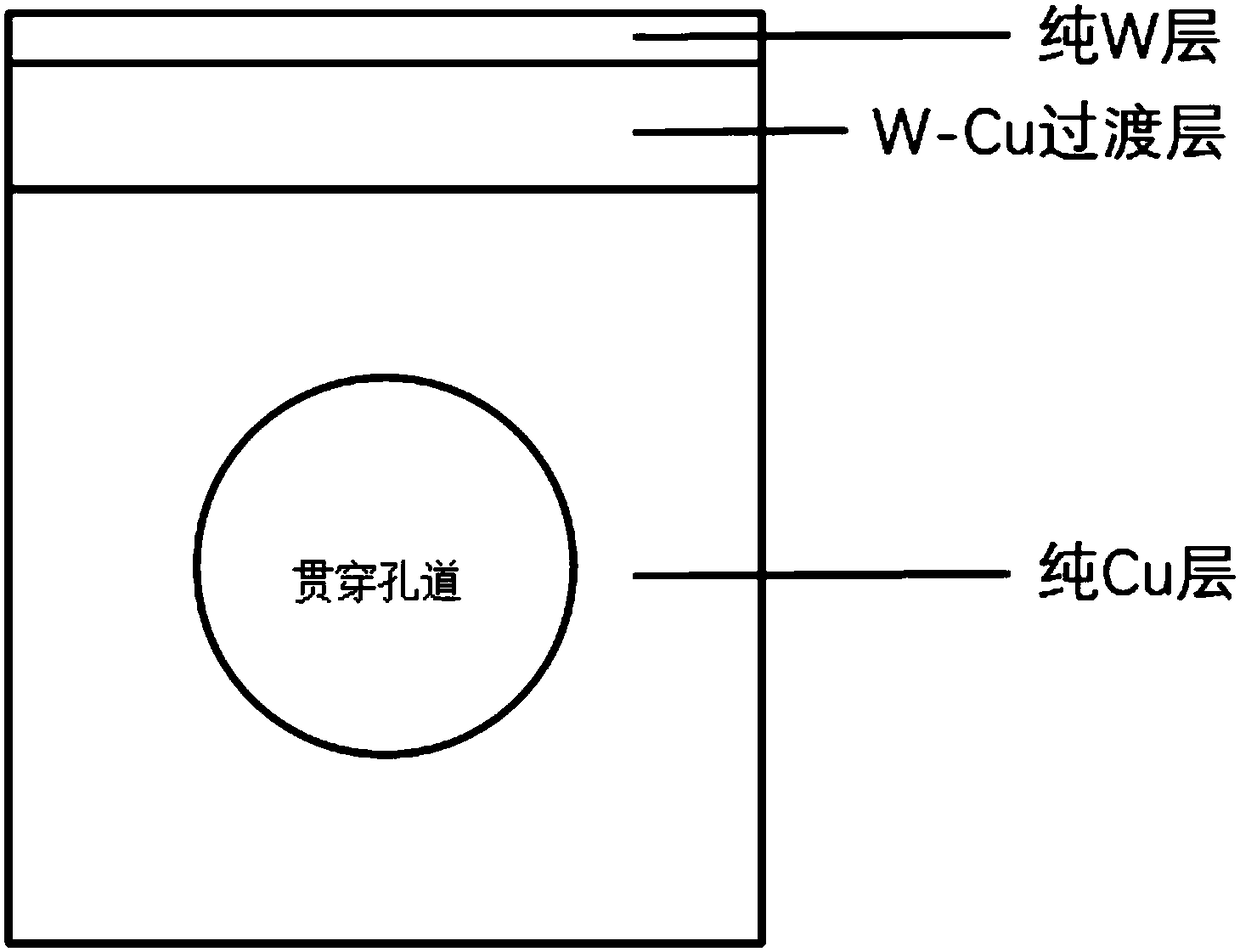

[0062] refer to image 3 , the sandwich structure divertor module of Example 1 of the present invention comprises a pure W layer, a W-Cu transition layer and a pure Cu layer from top to bottom, the height of the pure W layer is 1mm, and the height of the W-Cu transition layer is 5mm , the height of the pure Cu layer is 30mm, and the pure Cu layer is provided with a circular through hole with a diameter of 12mm, which is used to connect to the cooling channel. From the pure Cu layer to the pure W layer, the mass percentage of Cu element is gradually reduced from 100%. to 0, while the mass percentage of W element gradually increased from 0 to 100%.

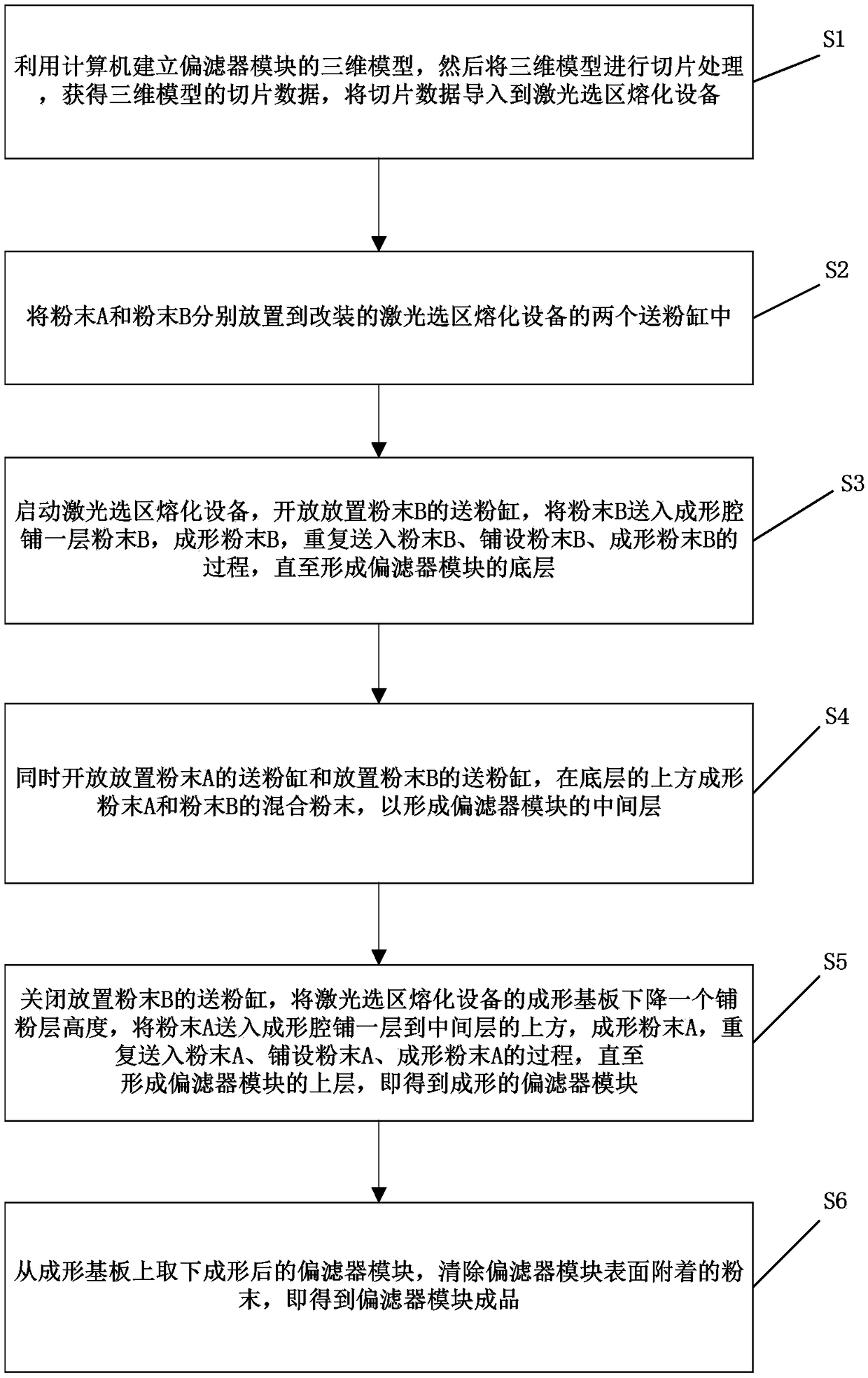

[0063] The process of integrally forming the sandwich structure divertor module of embodiment 1 by selecting laser melting technology is: using computer 3D design software to establish a three-dimensional model of the sandwich structure divertor module of embodiment 1, and then importing the three-dimensional model into the slicing ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com