Dual-cold-loop divertor structure suitable for future Tokamak fusion reactor

A tokamak and cold loop technology, applied in the field of divertors of tokamak fusion reactors, can solve problems such as damage of chromium-zirconium-copper cooling tubes, thermal and mechanical performance degradation of copper and copper alloys, and equipment downtime maintenance, etc. The number of maintenance, rapid cooling, the effect of reducing the pressure drop along the way

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] See attached picture.

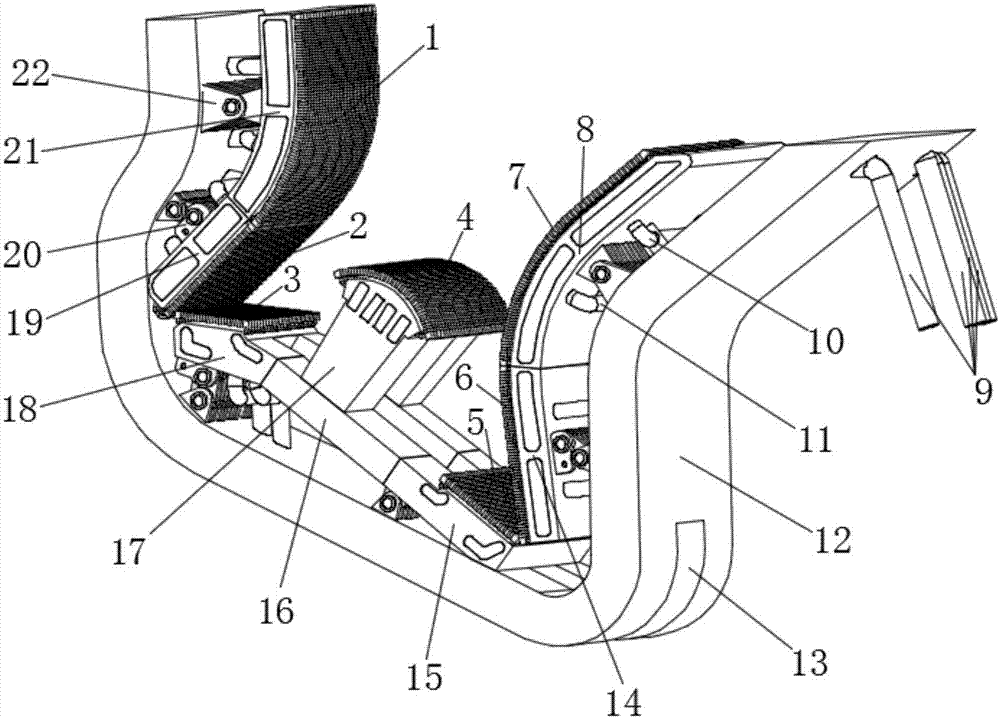

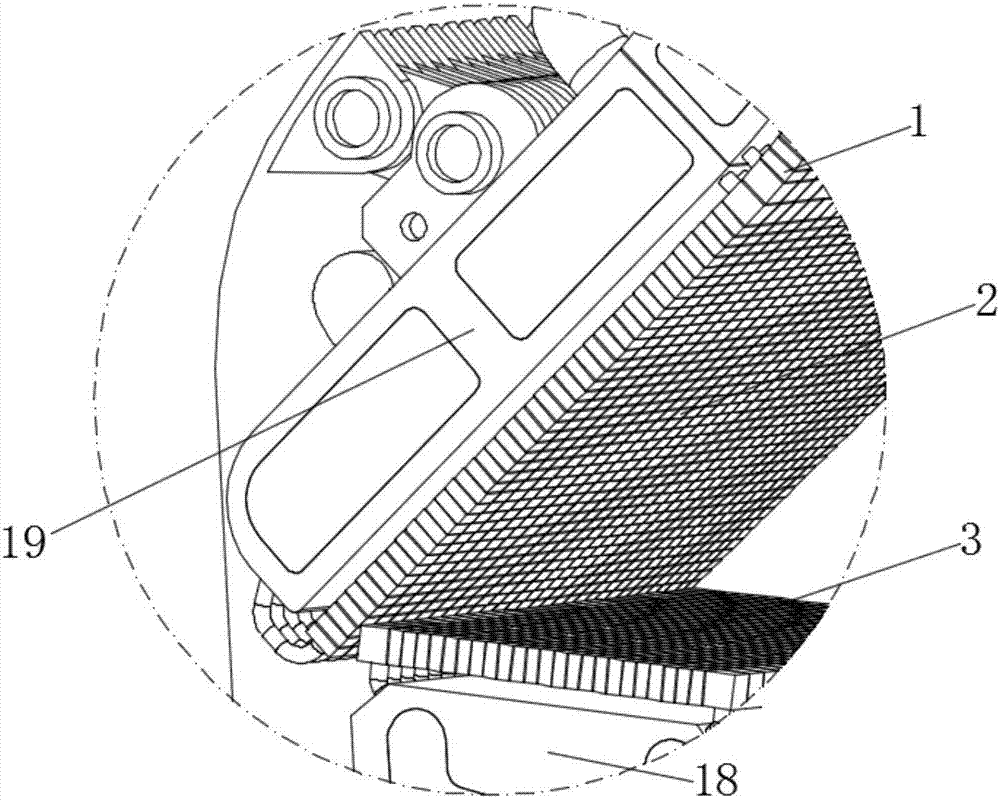

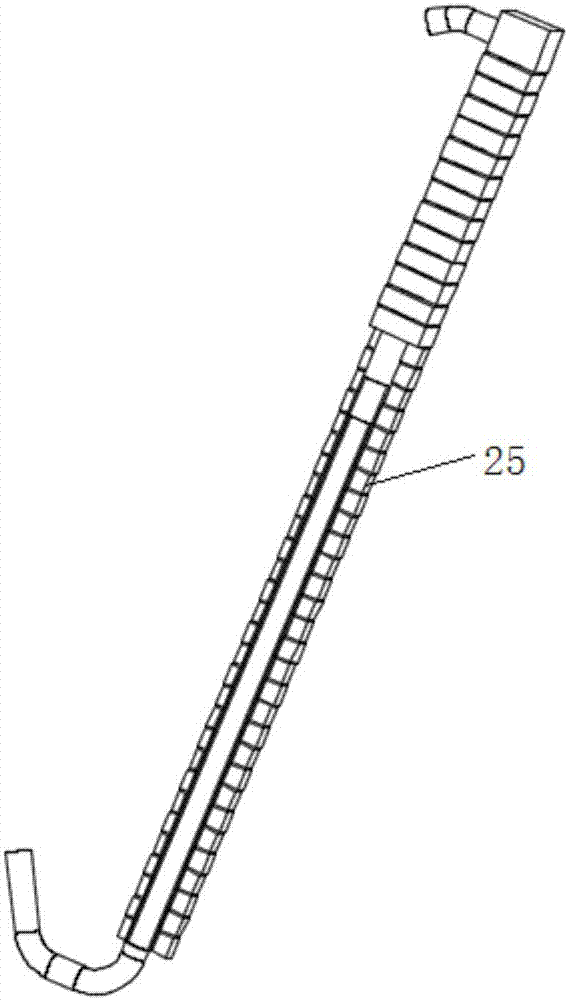

[0023] A dual-cold circuit divertor structure suitable for future Tokamak fusion reactors is characterized in that: the divertor structure is composed of an inner baffle 1, an inner striking plate 2, an inner return plate 3, an arch top plate 4, and an outer Return plate 5, outer striking plate 6, outer baffle 7, transition support one 8, transition support two 14, transition support three 15, transition support four 17, transition support five 18, transition support six 19, transition support seven 21, The box body support 12, the cooling pipe 9 and the related fixing plate 22, the connecting plate 21 and the connecting piece pin, etc.; The arch area is composed of the inner return plate, the transition support five, the dome plate, the transition support four, the outer return Composed of flow plate, transition support three and intermediate support.

[0024] The inner striking plate 2 and the outer striking plate 6 are made up of a tungsten block ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com