Multi-lithium-ball-projectile accurate automatic supply system special for plasma fracturing protecting

A plasma and supply system technology, which is applied in the field of precise automatic supply system for multi-lithium ball projectiles, can solve the problems of difficult access, complex structure of projectile injection system, and can only be injected into the plasma edge area, etc., so as to accurately control the number of projectiles , the effect of reducing weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

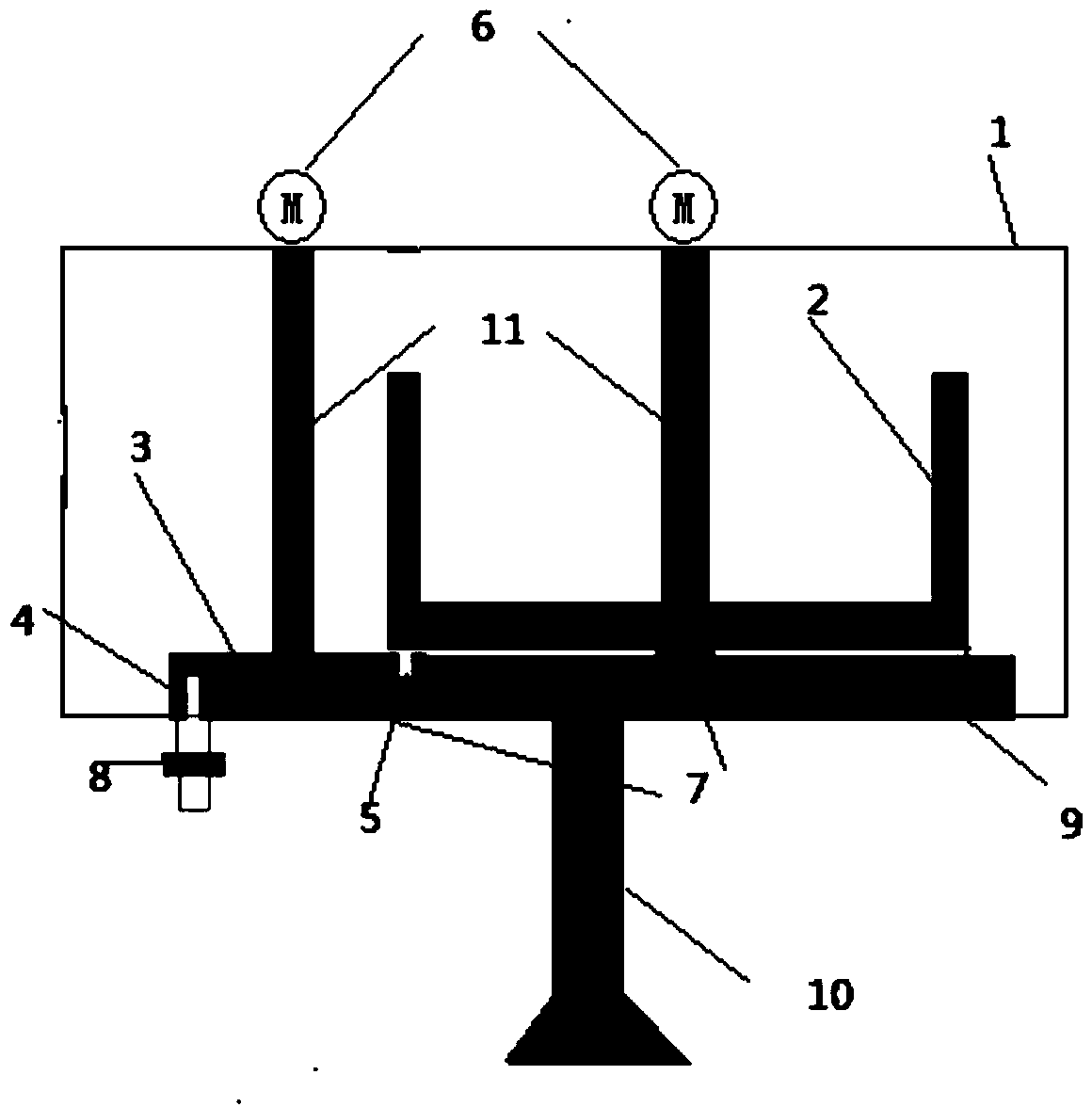

[0016] see figure 1 , a precise automatic replenishment system for multi-lithium ball projectiles dedicated to plasma rupture protection, including a projectile storage tray 2, a projectile transfer tray 3, and a fixed tray 9, characterized in that: the projectile storage tray 2 is mounted on a rotating bearing 7 One side of the fixed disk 9 has a U-shaped structure, and the U-shaped edge is provided with a circle of closely-arranged cylindrical projectile storage holes. The thin circular plate-shaped projectile transfer disk 3 is installed on the other side of the fixed disk 9 through the rotating bearing 7 , there is a projectile transfer hole 5 on the edge, which is encapsulated in a vacuum chamber as a whole, and the rotating bearing 7 is connected to the stepper motor 6 outside the vacuum chamber through a stepper motor coupling 11, and a certain amount of lithium is stored in the projectile storage tray 2. Ball projectiles, the stepper motor system 6 can control the rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com