Nickel slag composite machine-made sand and production method thereof

A technology of machine-made sand and nickel slag, applied in the field of machine-made sand, to achieve the effect of good combination, good environmental benefits and economic benefits, and sufficient sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

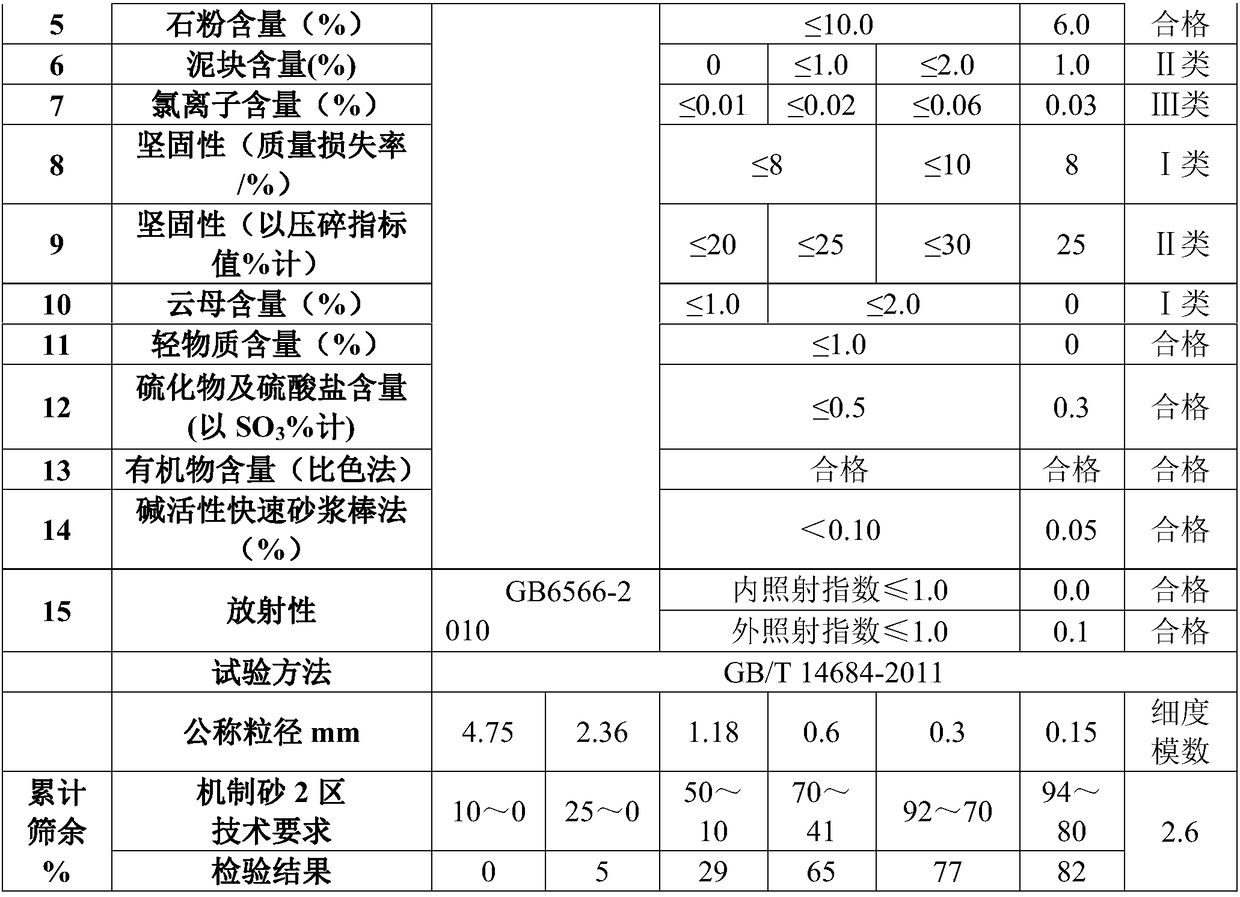

Embodiment 1

[0031] A kind of nickel slag composite machine-made sand preparation, comprises the following steps:

[0032] The mixing ratio is designed as follows: the mass ratio of electric furnace ferronickel slag: dry basis refining mixed slag is 85:15 (the total mass can be 1 ton, the same below).

[0033] (1) Raw material analysis: Raw material analysis is performed on the electric furnace ferronickel slag and refining mixed slag. The analysis results are: the moisture content (by mass) of the electric furnace nickel-iron slag is 0.4%, the moisture content (by mass) of the refining mixed slag is 16.5%, and the particle size of the electric furnace nickel-iron slag used in this embodiment and the refining mixed slag raw material are both 0-10mm.

[0034](2) Drying treatment: the refined mixed slag is transported by a belt conveyor to a dryer for drying treatment to obtain a dry basis refined mixed slag.

[0035] (3) Manufactured sand preparation: transport the electric furnace nickel...

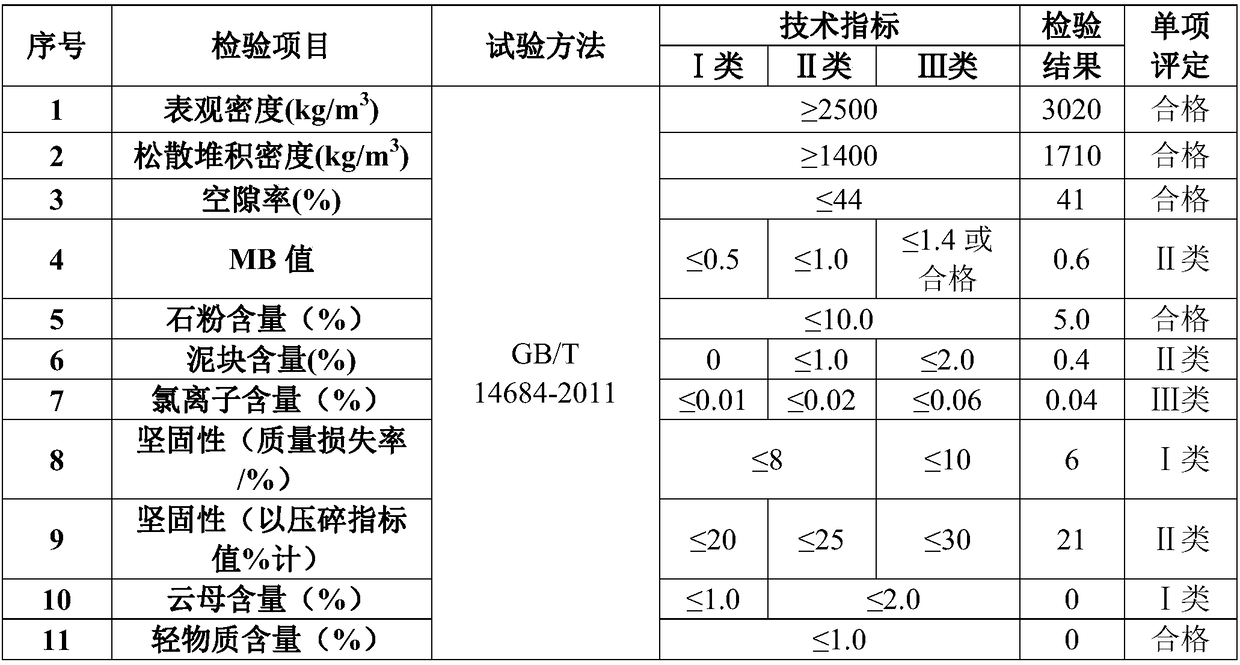

Embodiment 2

[0042] A kind of preparation of nickel slag composite machine-made sand, comprises the following steps:

[0043] The mixing ratio is designed as: electric furnace ferronickel slag: dry base refining mixed slag mass ratio relationship is 90:10.

[0044] (1) Raw material analysis: Raw material analysis is performed on the electric furnace ferronickel slag and refining mixed slag. The analysis results are: the moisture content (by mass) of the electric furnace nickel-iron slag is 0.7%, the moisture content (by mass) of the refining mixed slag is 18.0%, and the particle size of the electric furnace nickel-iron slag used in this embodiment and the refining mixed slag raw material are both 0-10mm.

[0045] (2) Drying treatment: the refined mixed slag is transported by a belt conveyor to a dryer for drying treatment to obtain a dry basis refined mixed slag.

[0046] (3) Manufactured sand preparation: transport the electric furnace nickel-iron slag with a predetermined mass ratio fr...

Embodiment 3

[0053] A kind of preparation of nickel slag composite machine-made sand, comprises the following steps:

[0054] The mixing ratio is designed as: electric furnace ferronickel slag: dry basis refining mixed slag mass ratio relationship is 100:0.

[0055] (1) Raw material analysis: Raw material analysis is performed on the electric furnace ferronickel slag and refining mixed slag. The analysis results are: the moisture content (by mass) of the electric furnace ferronickel slag is 0.6%, and the raw material particle size of the electric furnace ferronickel slag used in this embodiment is 0-10mm.

[0056] (2) Manufactured sand preparation: transport the electric furnace nickel-iron slag with a predetermined mass ratio from the raw material pile to the screening machine for primary screening, and 60% of the electric furnace nickel-iron slag particles with a particle size of 1.18-4.75mm are collected from the raw material pile. After the belt is transported to the vertical shaft im...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com