Light emitting diode (LED) light source with cooling device

A technology of LED light source and heat dissipation device, applied in the field of LED light source, can solve the problems of diamond-like carbon layer peeling, failure of light emitting diode light source, etc., and achieve the effects of good combination, improvement of thermal mismatch problem, and prolongation of service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

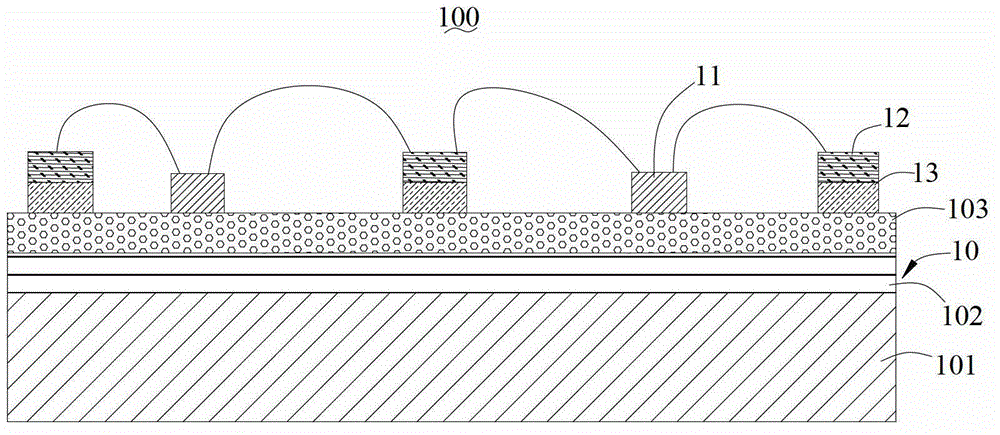

[0026] refer to figure 1 According to the first embodiment of the present invention, the LED light source 100 includes a heat sink 10 , an LED chip 11 , an electrode layer 12 and a transition layer 13 . The heat sink 10 includes a substrate 101 , a transition layer 102 and a diamond-like carbon (DLC, Diamond-like carbon) layer 103 . The LED chip is disposed on the diamond-like carbon layer 103 , and the electrode layer 12 is also disposed on the diamond-like carbon layer 103 ; and the LED chip 11 is electrically connected to the electrode layer 12 through wires (not shown). In this embodiment, the LED chips 11 are LED chips with a horizontal structure.

[0027] The substrate 101 is substantially plate-shaped. The substrate 101 can be selected from materials with better thermal conductivity, such as metal, ceramics, or plastics with high thermal conductivity. The transition layer 102 is attached between the substrate 101 and the diamond-like carbon layer 103, and the adhesio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com