LED chip and method for manufacturing LED chip

A technology of LED chips and heat-conducting substrates, which is applied in semiconductor devices, electrical components, circuits, etc., can solve the problems of epitaxial luminous body slivers and differences in thermal expansion coefficients, and achieve the goals of improving thermal mismatch, prolonging service life, and improving slivers. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

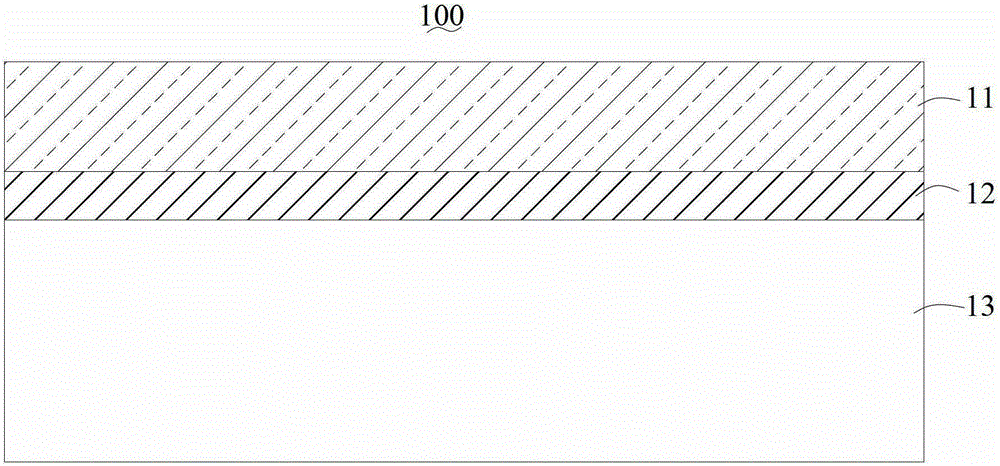

[0025] Refer to figure 1 The LED chip 100 according to the first embodiment of the present invention includes an epitaxial light-emitting body 11, a thermally conductive buffer layer (not labeled), and a thermally conductive substrate 13.

[0026] The epitaxial light-emitting body 11 is generated from a sapphire or silicon carbide substrate (not shown) and forms an existing LED chip (not shown) with it. In order to improve the heat dissipation performance of the existing LED chip, the epitaxial light-emitting body 11 is peeled off from the sapphire or silicon carbide substrate for later use.

[0027] The thermally conductive substrate 13 is a substrate with better heat dissipation performance than sapphire and silicon carbide, such as metal or ceramic. In this embodiment, the thermally conductive substrate 13 has a flat plate shape. The thermally conductive buffer layer is disposed on one side of the thermally conductive substrate 13. In this embodiment, the thermally conductive b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com