Method for preparing Ti-TiBw/Ti laminar composite material in diffusion welding mode

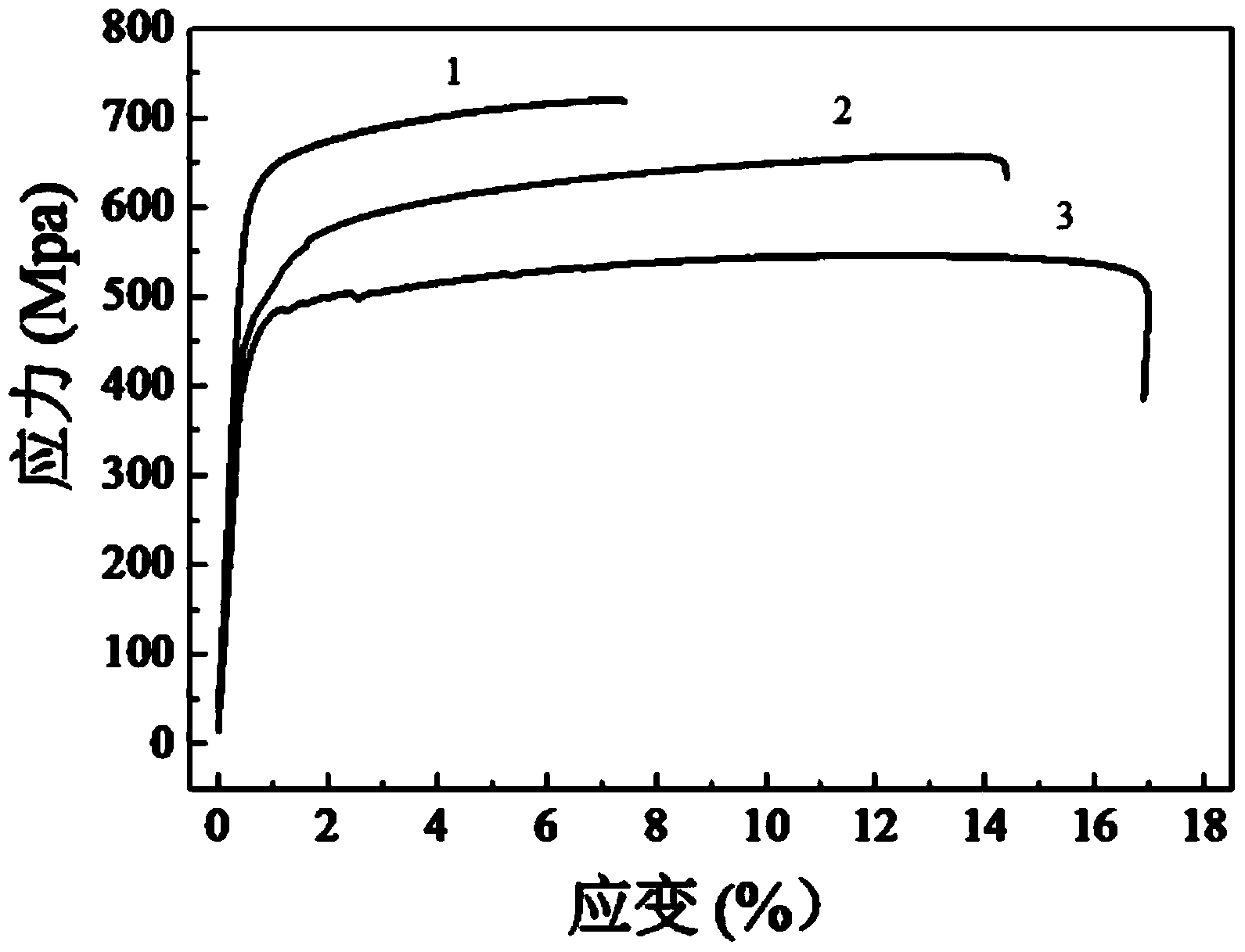

A layered composite material, diffusion welding technology, applied in the direction of welding equipment, welding/welding/cutting items, non-electric welding equipment, etc., can solve the problem that the flatness and uniformity of the layered titanium-based composite material layer are difficult to guarantee, and achieve Improves uniform plastic deformation ability, high work hardening rate, and achieves strong plasticity and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0015] Specific embodiment one: the method for preparing Ti-TiBw / Ti layered composite material by diffusion welding of the present embodiment is carried out according to the following steps:

[0016] 1. Weigh raw materials: Weigh Ti foil, spherical Ti powder and reinforcement material; the mass ratio of the Ti foil to spherical Ti powder is 1: (1-3), and the Ti foil and reinforcement The mass ratio of the bulk material is 100: (3-8), and the reinforcing body material is a single substance powder or a compound powder that can react with Ti in situ to form particles and whiskers; the said reinforcing material can react with Ti in situ The particle size of the elemental powder or compound powder that generates particles and whiskers is 3 μm to 8 μm; the thickness of the Ti foil is 50 μm to 500 μm; the particle size of the spherical Ti powder is 80 μm to 200 μm;

[0017] 2. Preparation of TiBw / Ti composite material: The spherical Ti powder and reinforcement material weighed in ste...

specific Embodiment approach 2

[0021]Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the elemental powder or compound powder that can react with Ti in situ to form particles and whiskers described in step 1 is TiB 2 powder, C powder, B 4 C powder or BN powder. Other steps and parameters are the same as those in Embodiment 1.

[0022] TiB in this embodiment 2 powder, C powder, B 4 C powder and BN powder are elemental powders or compound powders that can react with Ti in situ to form particles and whiskers.

specific Embodiment approach 3

[0023] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the mass ratio of Ti foil to spherical Ti powder in step 1 is 1:2. Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com