Cr-O-N active diffusion blocking layer and production method thereof

A barrier layer, active technology, applied in coatings, mechanical equipment, metal material coating processes, etc., to achieve the effects of low preparation cost, strong operability, and improved anti-oxidation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

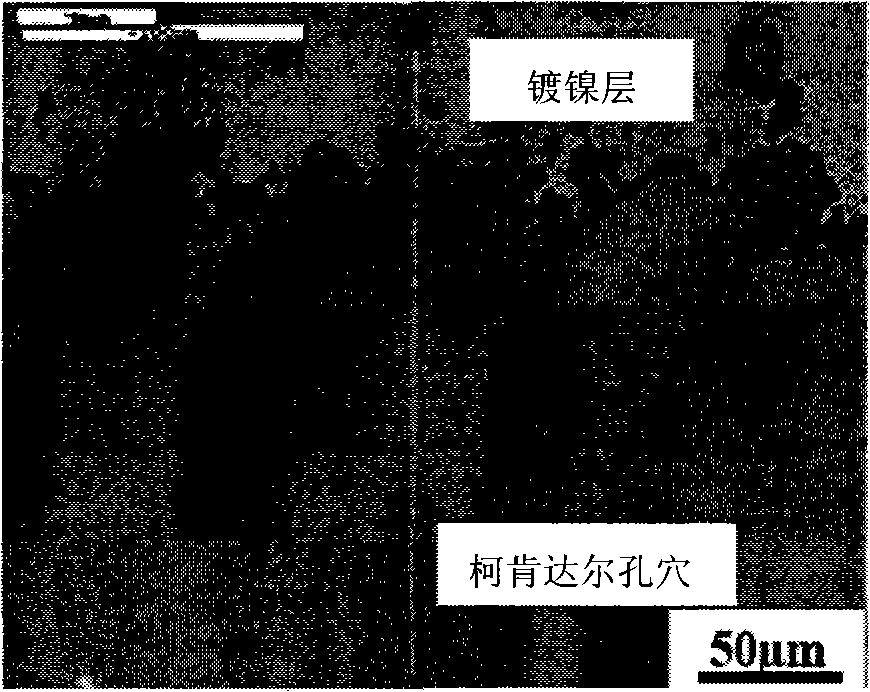

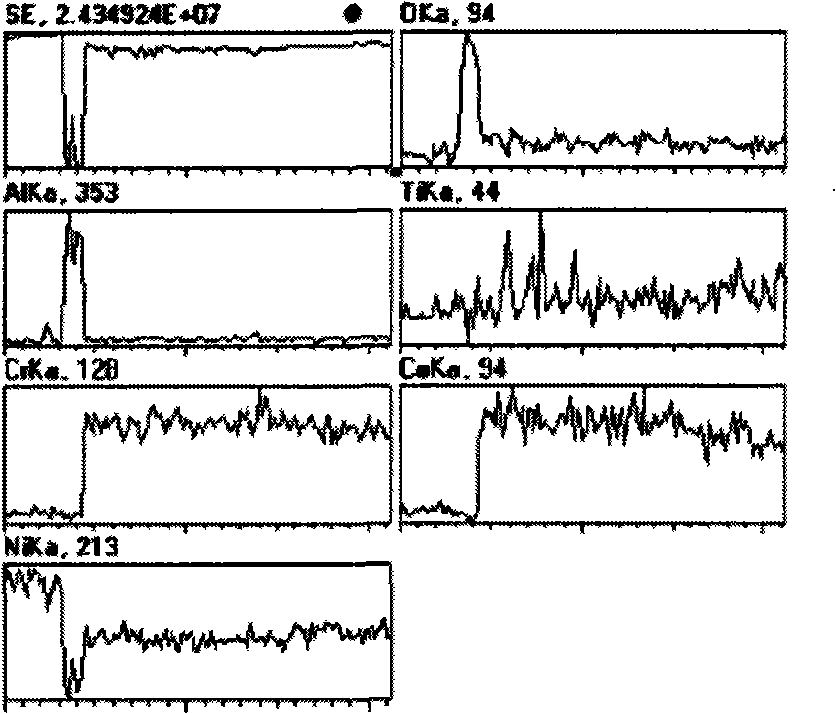

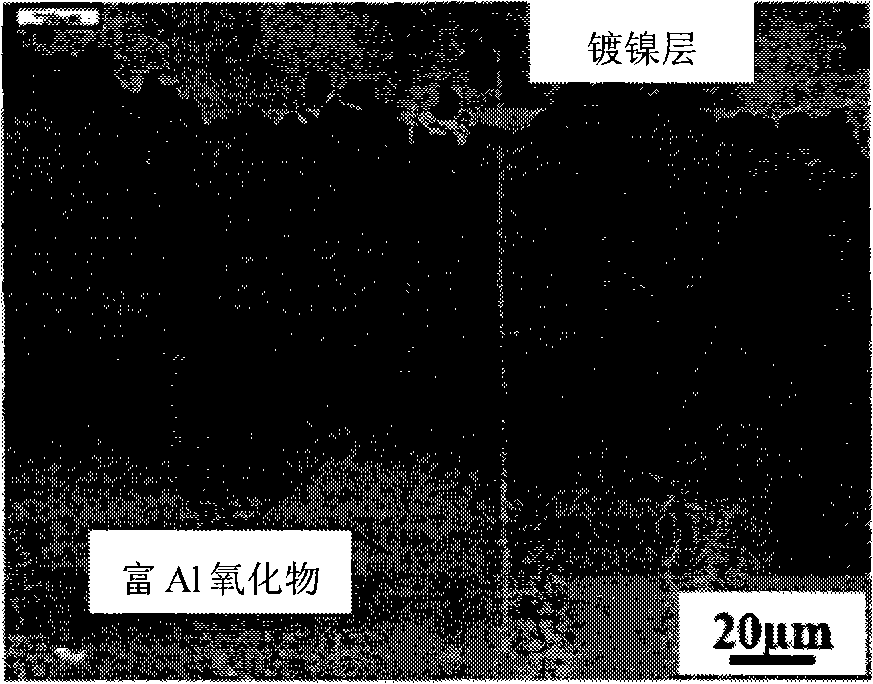

[0022] The base material is superalloy DSM11, the sample size is 15mm×10mm×2mm, and the target is pure chromium target. Grinding, sandblasting and cleaning the substrate before ion plating, and grinding the prepared sample to 1000 with metallographic sandpaper # ; Use glass balls with a particle size of 60-200 mesh to sandblast the sample under 2-5 atmospheres; during the sandblasting process, keep the spray gun at an angle of 70-80 degrees to the surface of the sample; after sandblasting, use absolute alcohol , Ultrasonic cleaning of the sample with distilled water. After the sample is loaded into the furnace, the sample chamber is pumped to 6.0×10 -3 Pa, into the Ar gas to a pressure of 7 × 10 -2 Pa, bombard the surface of the substrate with a bias voltage of -1000V for 4 minutes, the arc current is 60-70A, and the arc voltage is 20-30V; are 110, 20 and 0 sccm, the pulse bias is -300V, the duty cycle is 30%, the deposition time is 0.5h, and the thickness of the diffusion ...

Embodiment 2

[0029] The base material is superalloy DSM11, the sample size is 15mm×10mm×2mm, and the target is pure chromium target. The base material is ground, sand blasted and cleaned before ion coating. After the sample is loaded into the furnace, the sample chamber is pumped to 6.0×10 -3 Pa, through Ar gas to a pressure of 2×10 -1 Pa, bombard the surface of the substrate at the bias voltage of -800 and -600V for 3min and 2min respectively, the arc current is 50-80A, and the arc voltage is 10-40V; , the corresponding nitrogen flow rate is 226, 144 and 62sccm, and the working pressure is 6×10 -1 Pa, the pulse bias voltage is -150V, the duty ratio is 20-30%, the deposition time is 35-45min, and the prepared barrier layer has a thickness of 1-2 μm. Use arc ion plating equipment to deposit a Ni-30Cr-8Al-0.5Y (wt.%) coating with a thickness of about 30 to 50 μm on the barrier layer. The specific process parameters are that the Ar gas pressure is 3×10 -1 Pa, bias voltage -150~-250V, arc ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com