Method for depositing silicon carbide high radiation coating on cobalt based high-temperature alloy surface

A technology of high radiation coating and superalloy, applied in metal material coating process, coating, sputtering and other directions, can solve the problems of poor film deposition effect, difficult to combine silicon carbide coating and cobalt-based superalloy, etc. , to achieve the effect of enhanced adhesion, elimination of interface defects and residual stress, and high emissivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

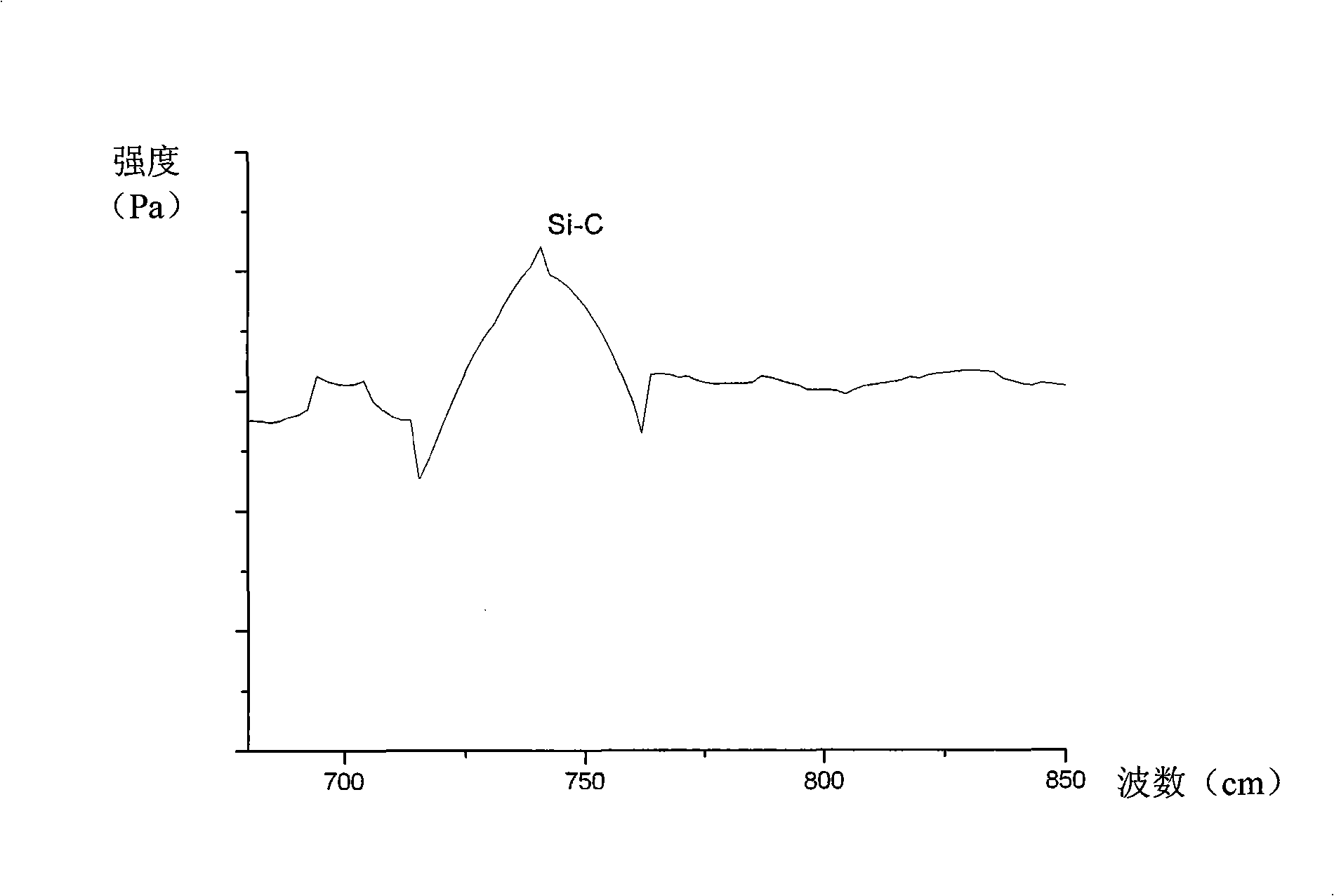

[0013] Specific implementation mode one: the following combination figure 1 To illustrate this embodiment, the method for depositing a silicon carbide high-radiation coating on the surface of a cobalt-based superalloy in this embodiment includes the following steps:

[0014] Step 1. Clean the cobalt-based superalloy with hydrofluoric acid for 10-20 minutes; then put it into the acetone solution and clean it with ultrasonic waves for 10-20 minutes; then put it into the alcohol solution and clean it with ultrasonic waves for 10-20 minutes; finally use Wash with deionized water for 10-20 minutes;

[0015] Step 2. Send the treated cobalt-based superalloy into the magnetron sputtering vacuum chamber, and evacuate the magnetron sputtering vacuum chamber. When the vacuum degree in the magnetron sputtering vacuum chamber reaches 10 -4 Pa, heat the cobalt-based superalloy at a temperature of 25-500°C, and then keep it warm for 10 minutes to 2 hours;

[0016] Step 3: Introduce Ar gas ...

specific Embodiment approach 2

[0032] Embodiment 2: The difference between this embodiment and Embodiment 1 is that in step 1, the cobalt-based superalloy is cleaned with hydrofluoric acid for 15 to 20 minutes; then put into acetone solution and cleaned with ultrasonic waves for 15 to 20 minutes; Then put it into the alcohol solution, clean it with ultrasonic waves for 15-20 minutes; finally wash it with deionized water for 15-20 minutes. Others are the same as the first embodiment.

specific Embodiment approach 3

[0033] Embodiment 3: The difference between this embodiment and Embodiment 1 is that in step 2, the heating temperature is 25-200° C., and then the heat preservation is carried out for 40-80 minutes. Others are the same as the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com