Preparation method of flexible sensor

A flexible sensor and flexible substrate technology, applied in the field of sensors, can solve the problems of high cost of nanomaterials, high manufacturing cost, and difficult optimization of process parameters, and achieve flexible and controllable shape, improved stability, and good combination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

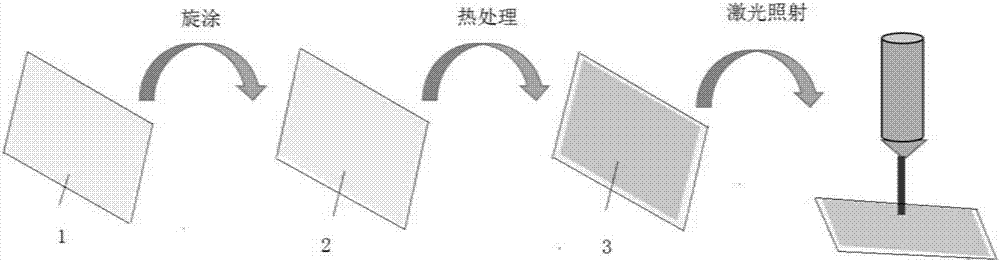

[0051] figure 1 It is the preparation flowchart of the piezoresistive flexible sensor of this embodiment, and the specific steps are as follows:

[0052] First, 1.5 g of precursor solution, which is N,N'-dimethylacetamide solution of polyamic acid, was spin-coated on A4 paper 1 to form polyamic acid-A4 paper composite matrix 2.

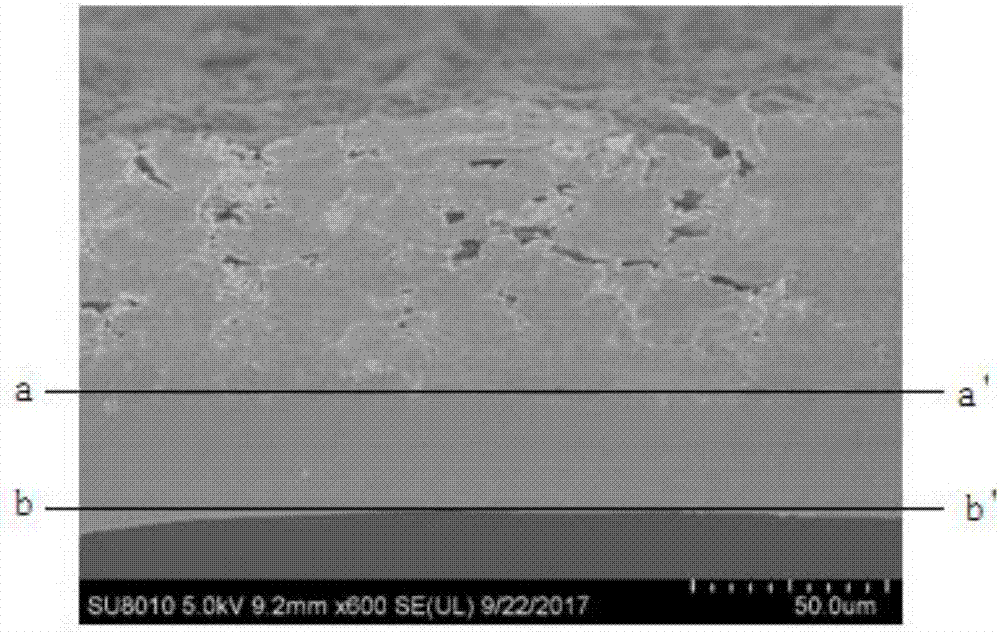

[0053] Heat treatment was performed on the spin-coated polyamic acid-A4 paper composite substrate 2, specifically removing water at 100° C. for 0.5 h, and then removing solvent at 150° C. for 1.5 h. In order to prevent the A4 paper 1 from being curled by heat and cause uneven heating, the A4 paper 1 can be fixed with a heat-resistant adhesive tape. After heat treatment, polyamic acid is amidated into polyimide to form polyimide-A4 paper composite matrix 3 . figure 2 is the cross-sectional scanning electron microscope image of polyimide-A4 paper composite substrate 3, the part above the solid line a-a' in the figure is A4 paper 1, and the part betwe...

Embodiment 2

[0059] First, 1.5 g of precursor solution, which is N,N'-dimethylacetamide solution of polyamic acid, was scraped on A4 paper to form polyamic acid-A4 paper composite matrix.

[0060] Heat treatment is performed on the polyamic acid-A4 paper composite substrate after scraping coating, specifically removing water at 100° C. for 0.5 h, and then removing solvent at 150° C. for 1.5 h. In order to prevent A4 paper from being curled by heat and causing uneven heating, heat-resistant tape can be used to fix A4 paper. After heat treatment, the polyamic acid is amidated into polyimide to form a polyimide-A4 paper composite matrix.

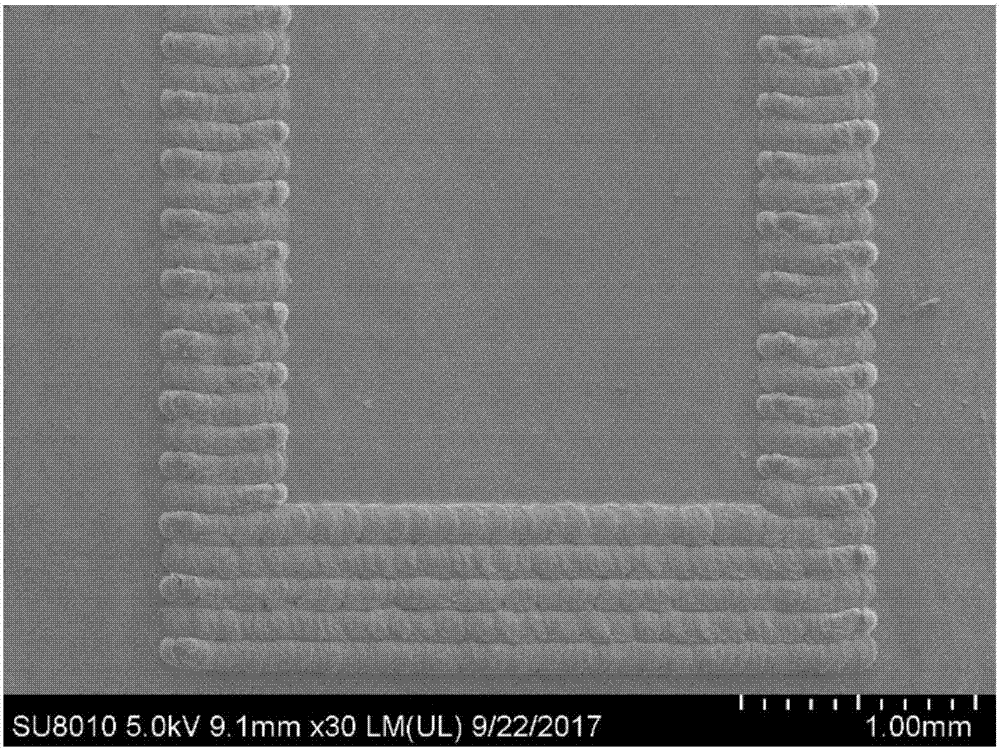

[0061] Put the polyimide-A4 paper composite substrate in a laser cutting machine for laser scanning carbonization, the laser light source used is CO 2 Laser, the laser power is controlled at 1W, the laser scanning speed is 20mm / s, along the vertical direction, the laser is irradiated every 0.13mm, and the irradiated area roughly forms a U-shaped pattern ( ...

Embodiment 3

[0064] First, spin-coat 0.5g of precursor solution on A4 paper, which is N,N'-dimethylacetamide solution of polyamic acid. The spin-coating speed is 1000rpm (A4 paper can be completely soaked at this speed), The time is 1 min, and the same method is used to spin coat three times to form a polyamic acid-A4 paper composite matrix.

[0065] Heat treatment was performed on the spin-coated polyamic acid-A4 paper composite substrate, specifically removing water at 100° C. for 0.5 h, and then removing solvent at 150° C. for 1.5 h. In order to prevent the A4 paper from being curled by heating and causing uneven heating, it can be pressed with an appropriate weight after removing water. After heat treatment, the polyamic acid is amidated into polyimide to form a polyimide-A4 paper composite matrix.

[0066] Put the polyimide-A4 paper composite substrate in a laser cutting machine for laser dot carbonization. The laser light source used is carbon dioxide laser, the laser power is contr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com