Ni3(Si,Ti)-WC composite coating material and preparation method thereof

A composite coating and coating material technology, applied in the coating, metal material coating process, manufacturing tools, etc., can solve the problems of composite material performance degradation, etc., to achieve good bonding, high hardness, high temperature resistance to sulfide corrosion and Excellent erosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] (1) Ni powder, Si powder and Ti powder are proportioned according to the atomic percentage of Ni78Si13Ti9; WC particles with a weight percentage of 8wt% are added; in addition, 5 ppm of B powder is added.

[0019] (2) The purity of Ni powder, Si powder and Ti powder is greater than 99%, and the particle size of the powder is 100-300 mesh.

[0020] (3) Put the mixed powder into a mortar, grind and mix evenly, and then dry it as a coating material. Laser multi-layer and multi-pass cladding is carried out in the way of pre-set powder.

[0021] (4) The laser process parameters are: output power 1200-1300W, scanning speed 4-8mm / s, spot diameter 4mm, each overlap 1.8mm.

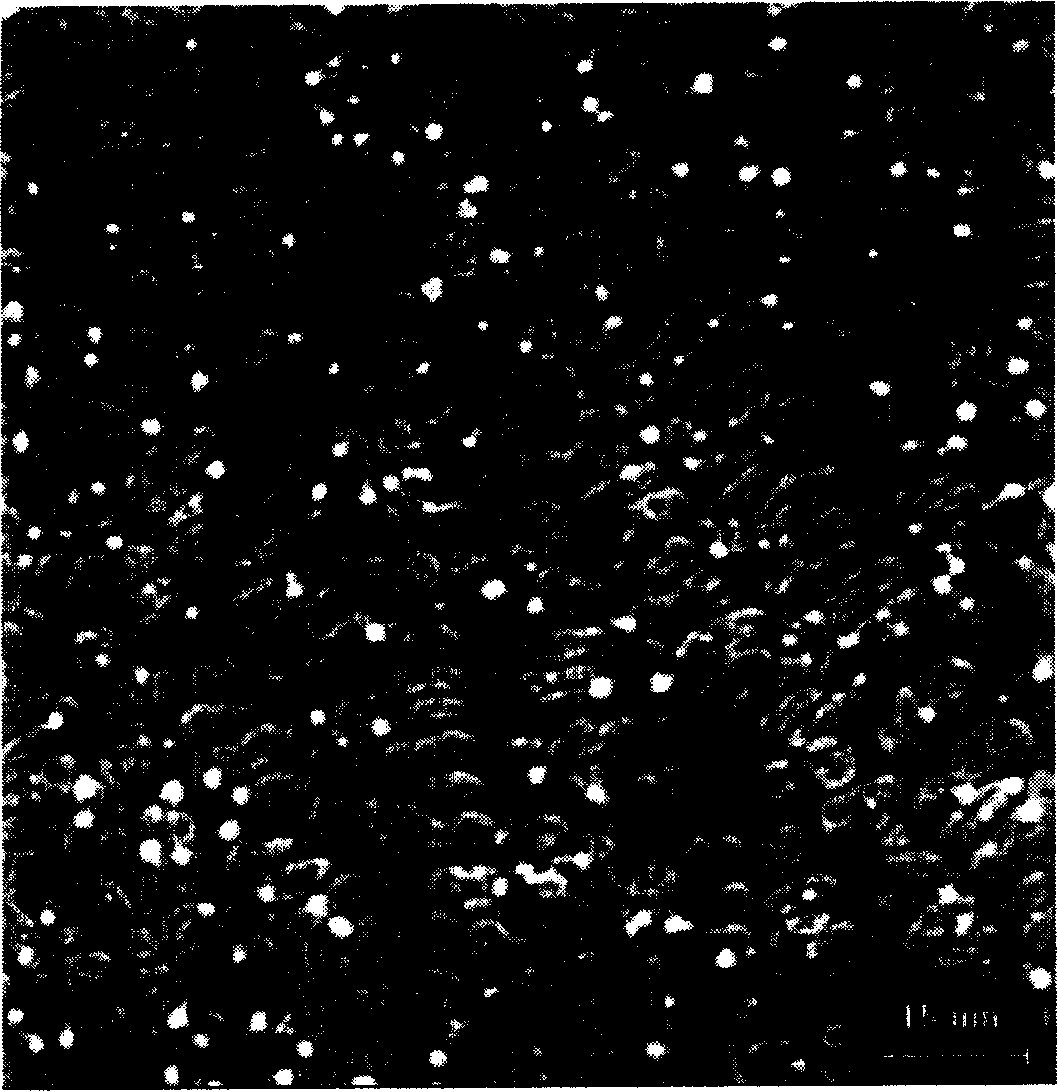

[0022] The prepared cladding layer has a thickness of about 1.0mm, a Vickers hardness of 480Hv, and a ceramic phase volume fraction of 3%, such as figure 1 As shown, the main structure of the coating is Ni 3 (Si, Ti) intermetallic compounds, Ni(Si) solid solution and a small amount of irregular block WC a...

Embodiment 2

[0024] (1) The ratio of Ni powder, Si powder and Ti powder is Ni78Si13Ti9 according to the atomic percentage; WC particles with a weight percentage of 15 wt% are added; in addition, 5 ppm of B powder is added.

[0025] (2) The purity of Ni powder, Si powder and Ti powder is greater than 99%, and the particle size of the powder is 100-300 mesh.

[0026] (3) Put the mixed powder into a mortar, grind and mix evenly, and then dry it as a coating material. Laser multi-layer and multi-pass cladding is carried out in the way of pre-set powder.

[0027] (4) The laser process parameters are: output power 1300-1400W, scanning speed 4-6mm / s, spot diameter 4mm, each overlap 1.8mm.

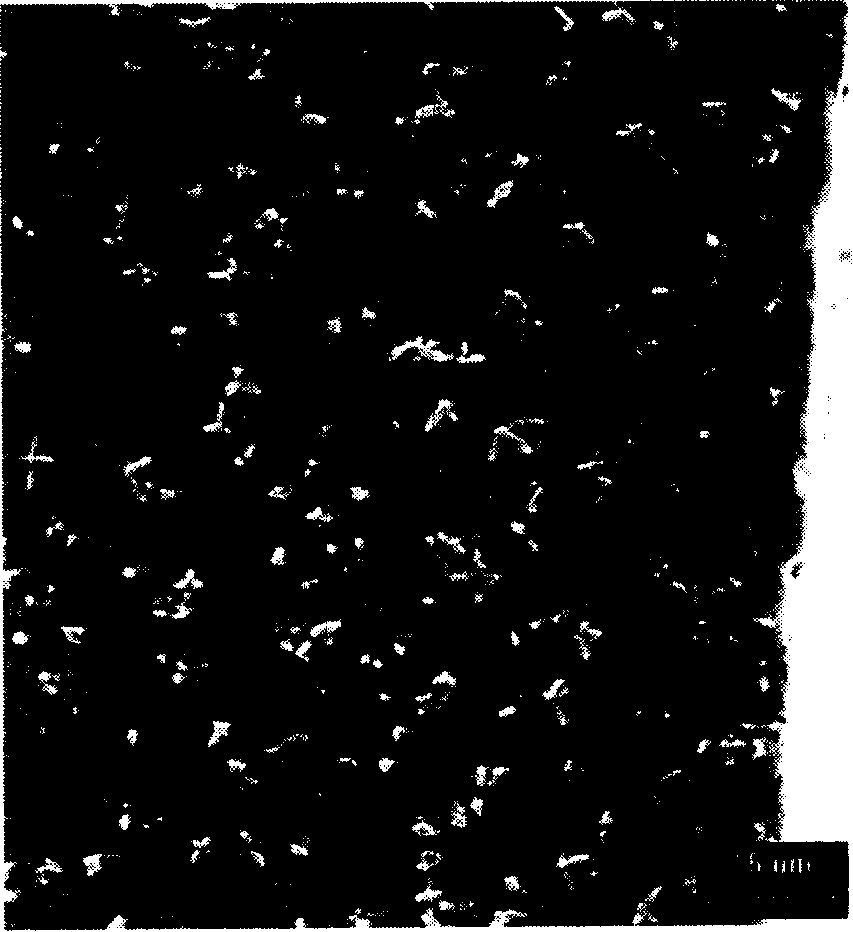

[0028] The prepared cladding layer has a thickness of about 1.0mm, a Vickers hardness of 520Hv, and a ceramic phase volume fraction of 6%, such as figure 2 As shown, the main structure of the coating is Ni 3 (Si, Ti) intermetallic compound, Ni(Si) solid solution and petal-shaped TiC / WC composite ceramic ph...

Embodiment 3

[0030] (1) The ratio of Ni powder, Si powder and Ti powder is Ni78Si13Ti9 by atomic percentage; 20 wt% of WC particles are added; in addition, 5 ppm of B powder is added.

[0031] (2) The purity of Ni powder, Si powder and Ti powder is greater than 99%, and the particle size of the powder is 100-300 mesh.

[0032] (3) Put the mixed powder into a mortar, grind and mix evenly, and then dry it as a coating material. Laser multi-layer and multi-pass cladding is carried out in the way of pre-set powder.

[0033] (4) The laser process parameters are: output power 1400-1500W, scanning speed 4-6mm / s, spot diameter 4mm, each overlap 1.8mm.

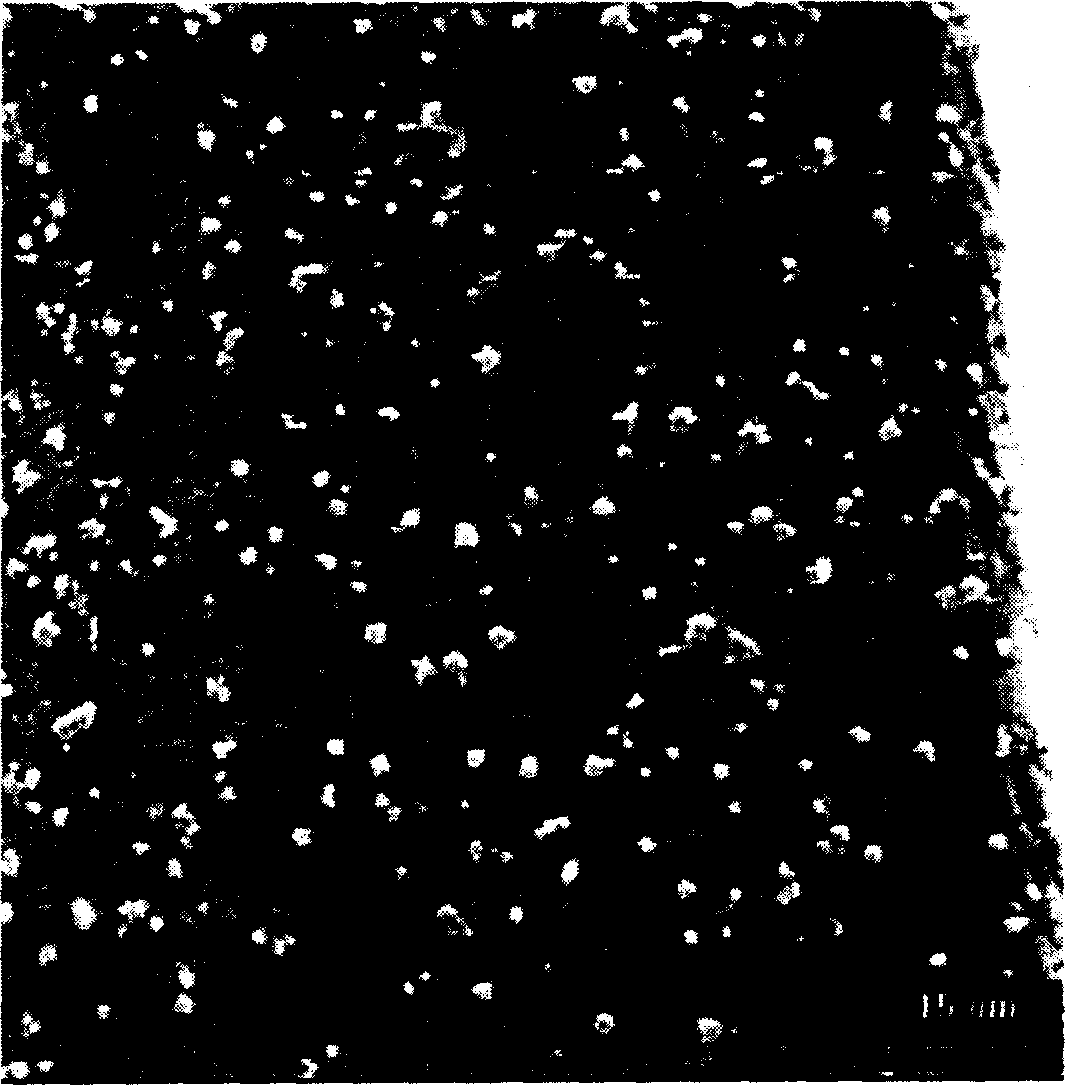

[0034] The prepared cladding layer has a thickness of about 1.0mm, a Vickers hardness of 540Hv, and a ceramic phase volume fraction of 12%, such as image 3 As shown, the main structure of the coating is Ni 3 (Si, Ti) intermetallic compound, Ni(Si) solid solution, irregular WC and petal-like TiC coated WC composite ceramic phase.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com