Surface wear resistance strengthening treatment method for agricultural soil touching part

A technology for strengthening treatment and workpiece surface, applied in the field of agriculture, can solve problems such as complex process, achieve the effect of good bonding, small soil friction coefficient, and reduce agricultural farming costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

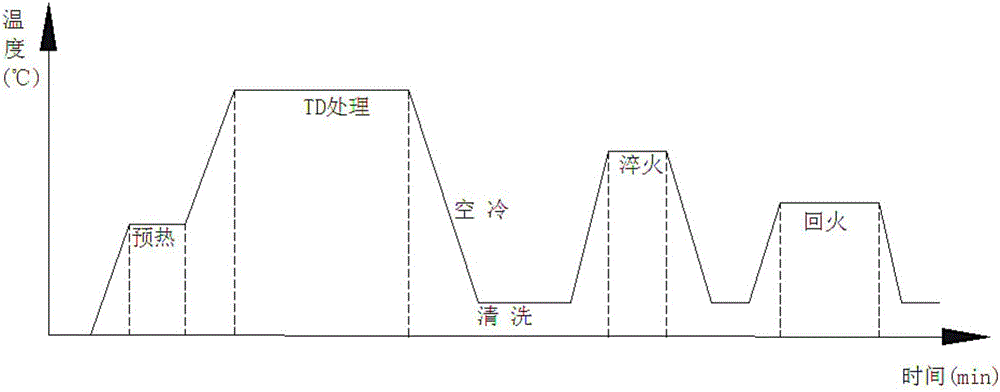

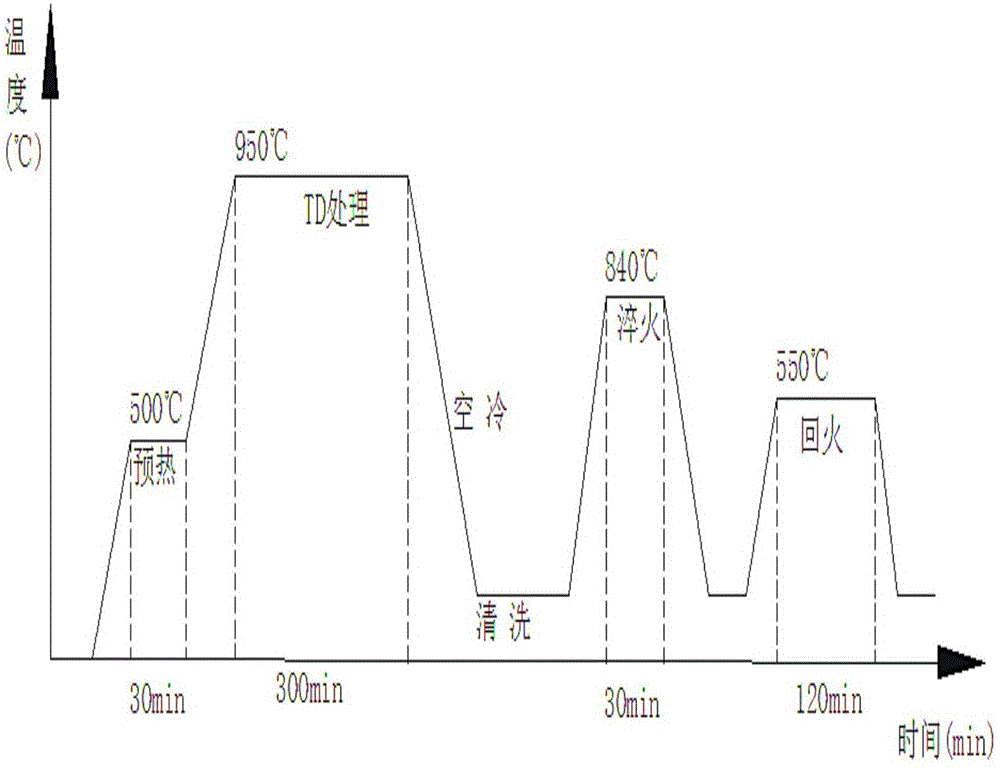

[0030] Such as figure 2 As shown, the working surface of the 65Mn steel plowshare or subsoiling shovel head is polished with a fine grinding wheel and metallographic sandpaper. Requirements: the polished working surface has no deep scratches or a few scratches but the direction of the scratches is the same.

[0031] Use 20% NaOH solution to degrease the polished 65Mn steel plowshare or subsoiling shovel head in boiling water. After the degreasing is completed, soak it in 5% HCl solution at room temperature for 8 minutes for derusting cleaning, and then clean it; finally use 3% Soak in nitric acid solution for 8 seconds for activation treatment.

[0032] Place the pretreated plowshare or subsoiling shovel head in a low-temperature heating furnace for preheating at 500°C for 30 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com