Method of preparing bone injury repair member made of titanium

A technology for bone damage repair and manufacturing method, applied in medical science, prosthesis, etc., can solve problems such as unsuitability for small batches, diversified production needs, poor accuracy, etc., and achieve low manufacturing cost, high processing accuracy, and production short cycle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

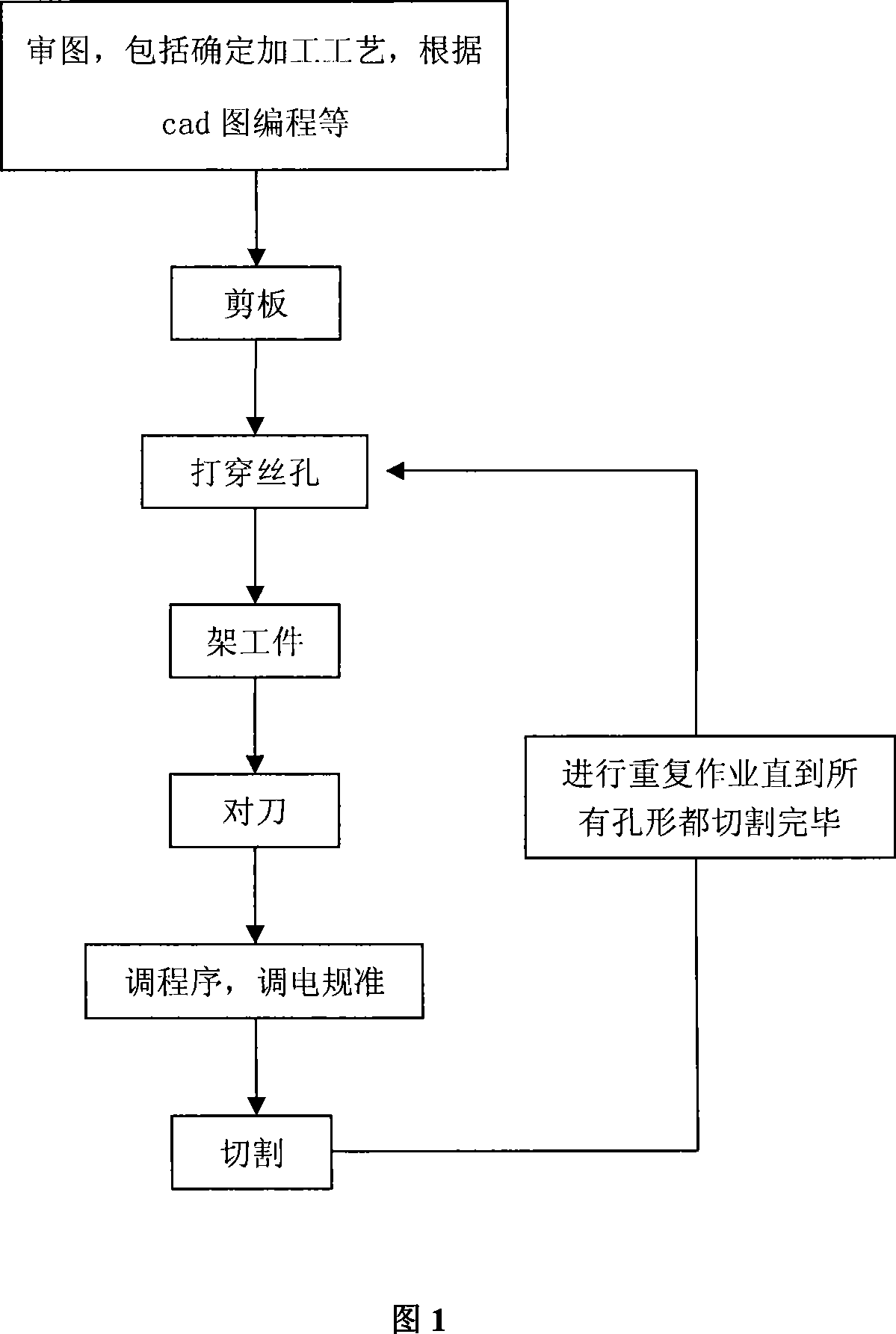

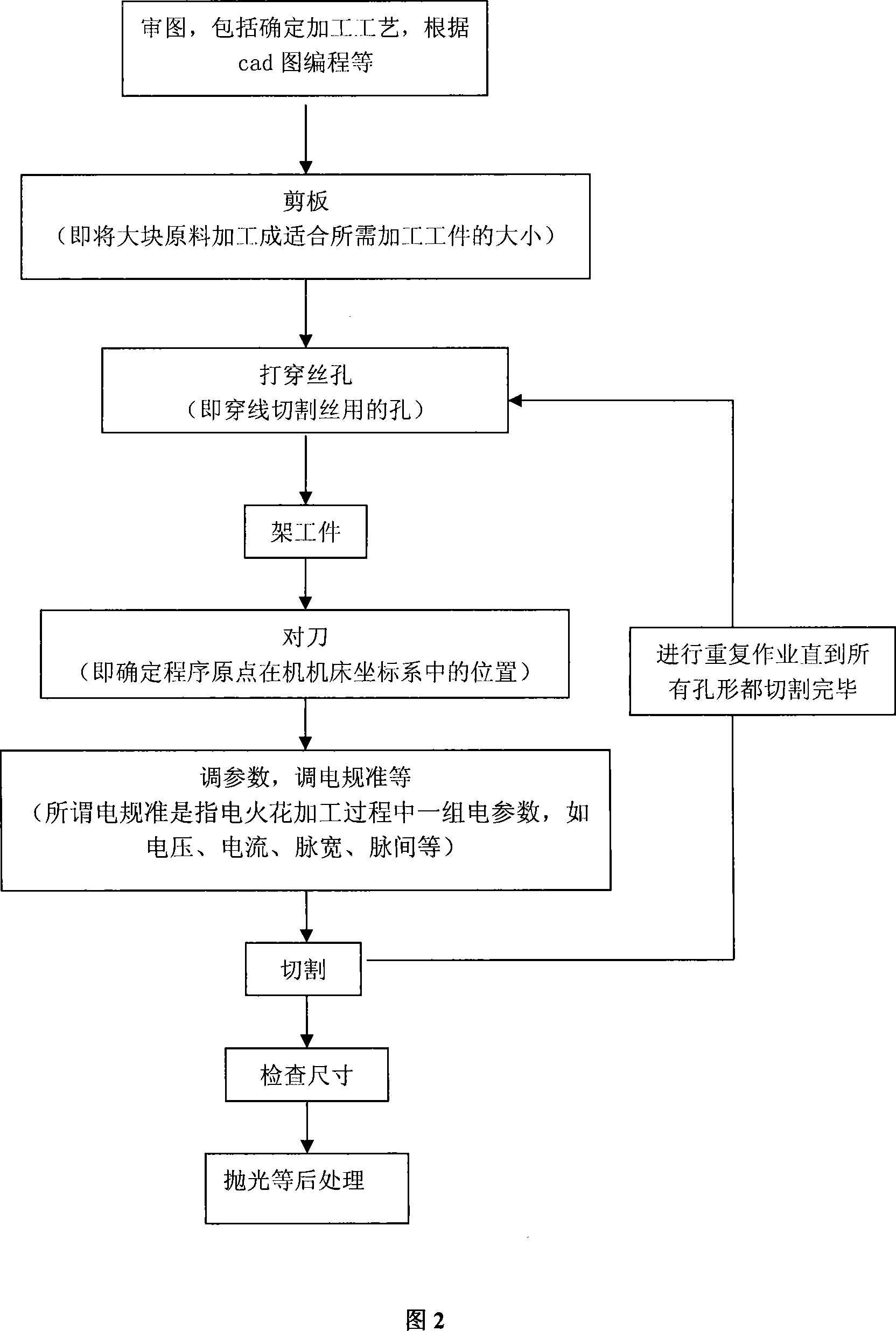

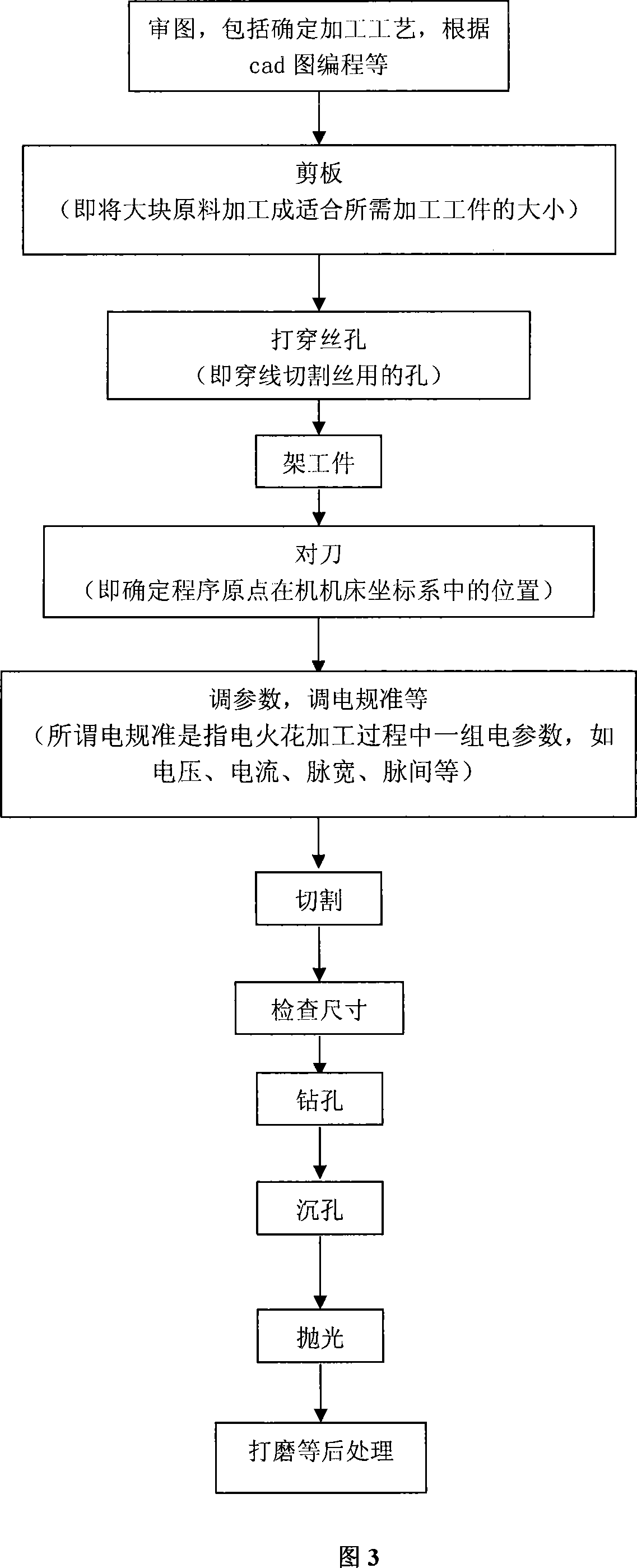

[0030] The present invention will be further described below in conjunction with accompanying drawings (Fig. 1-Fig. 5).

[0031] A brief description of CNC wire cutting machine tools is as follows:

[0032] CNC wire cutting machine tool is processed by the principle of high energy density electric spark discharge ablation, which belongs to the category of special processing, and it can only process conductive materials. The process of EDM CNC wire cutting mainly includes the following three parts:

[0033] (1) When the CNC wire cutting machine is processing, a DC pulse voltage is applied between the cutting tool (copper wire or molybdenum wire) and the workpiece. Pulse discharge between the electrode wire and the workpiece. When the distance between the tool and the workpiece is close enough (about 0.01mm), the voltage breaks through the cooling cutting fluid medium, and discharges uniformly over the entire length of the cutting tool and the workpiece. The instantaneous temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com