Apparatus for rotating point cutting large size silicon-carbide crystal

A large-size, silicon carbide technology, applied in the field of rotating point cutting large-size silicon carbide crystal devices, can solve the problems of easy deformation of the basic structure, limited cutting space, low Z-axis speed, etc., to improve the surface quality and solve the problem of precision. , the effect of high basic precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

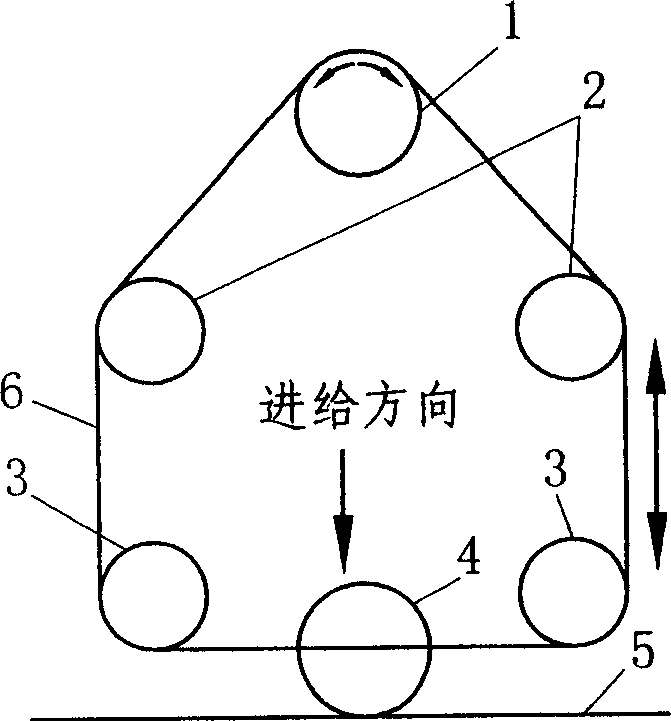

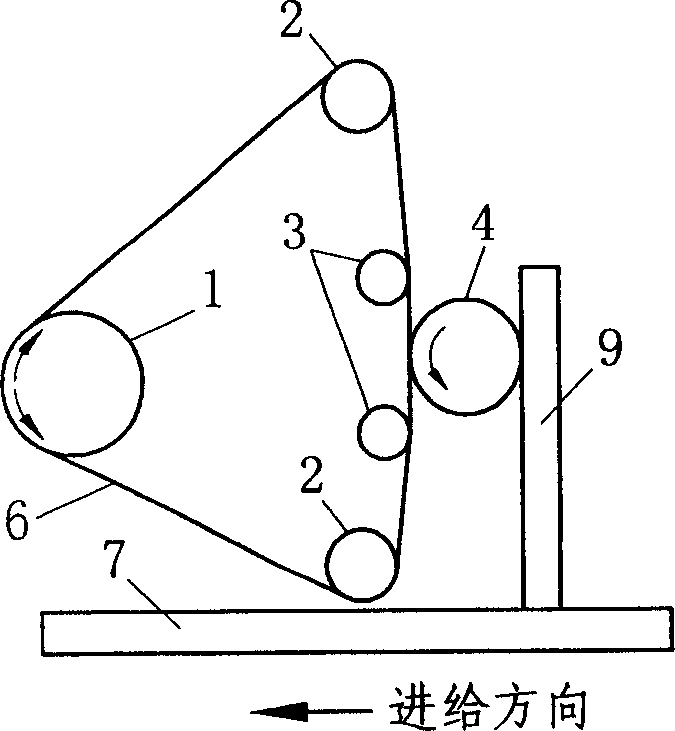

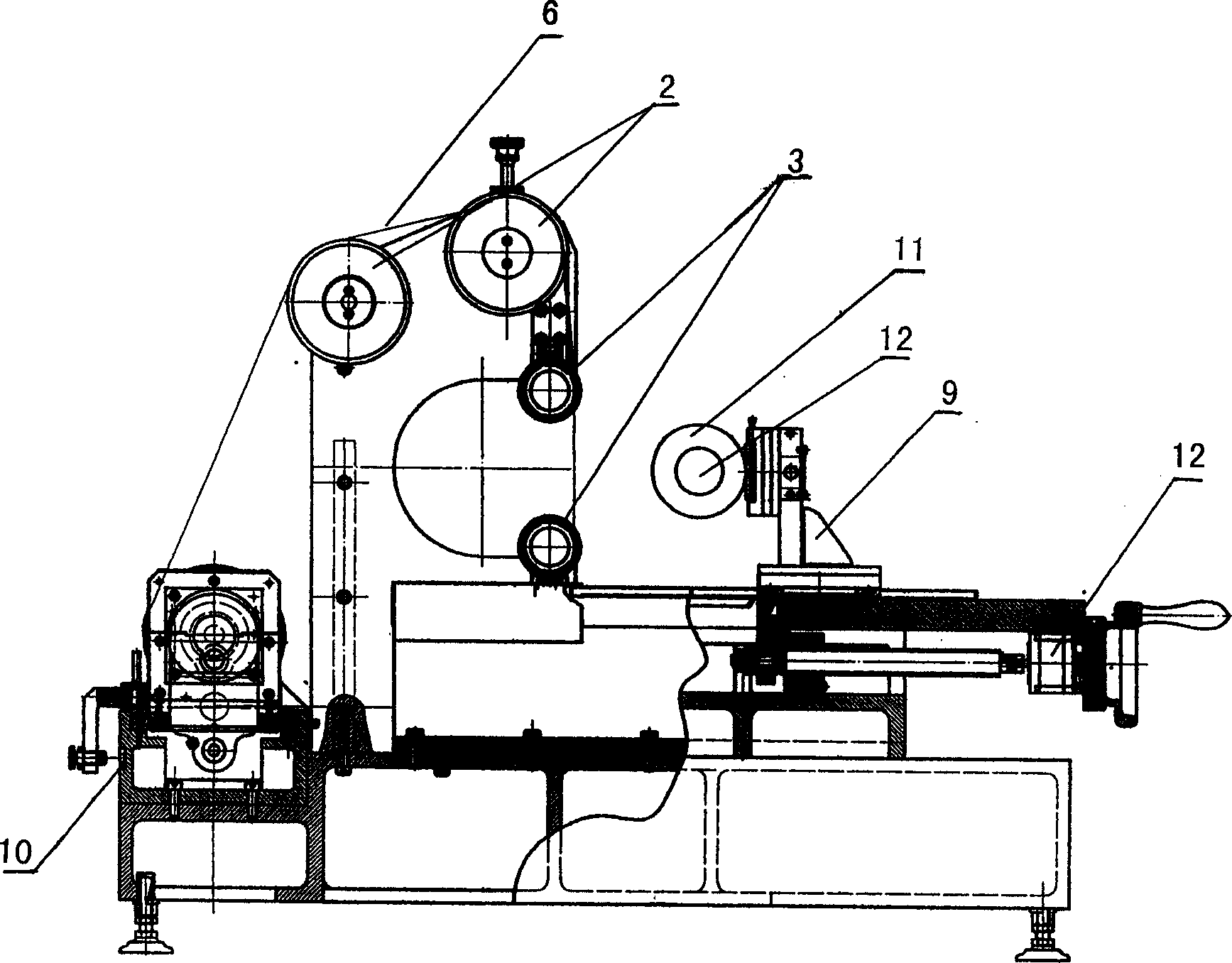

[0026] The rotating point cutting device for large-size silicon carbide crystals consists of a base (5), a sensor (10), a diamond saw wire (6), a pneumatic tensioning wheel (2), a working roller (3), a DC servo motor (13), two Dimensional fixture mechanism (9) is formed. The two-dimensional fixture mechanism (9) is composed of a rotating manipulator (11) and a stepping motor (12), the Y-axis moving platform (21) is connected with a horizontal angle adjustment turntable (20), and the horizontal angle adjustment turntable (20) is connected with a The vertical angle adjusts the turntable (22), the stepper motor (12) is connected on the adjustable support plate (19), and is connected with the material clamp (16) through the rotating shaft (18). Clamp cover (8) is arranged on clamp (16), and top wire (15) is housed on clamp cover (8), the center position of adjustment material, the rear portion of clamp is equipped with rolling bearing (17).

[0027] As shown in the figure: the de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com