Wire saw mechanism and wire saw cutting device based on small-load robot

A wire saw and tensioning device technology, which is applied to sawing equipment, band saws, wood processing appliances, etc., can solve problems such as small adjustment range, and achieve increased tension adjustment range, efficient cutting processing, and uniform force Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0032] Certain directional terms used hereinafter to describe the drawings, such as "inner," "outer," "above," "below" and other directional terms, are to be understood those directions involved in the drawing. Unless otherwise specified, the directional terms described in this specification basically follow the conventional directions understood by those skilled in the art.

[0033] The terms "first", "first", "second", "second" and similar terms used in the present invention do not indicate any order, quantity or importance in the present invention, but Used to distinguish one part from other parts.

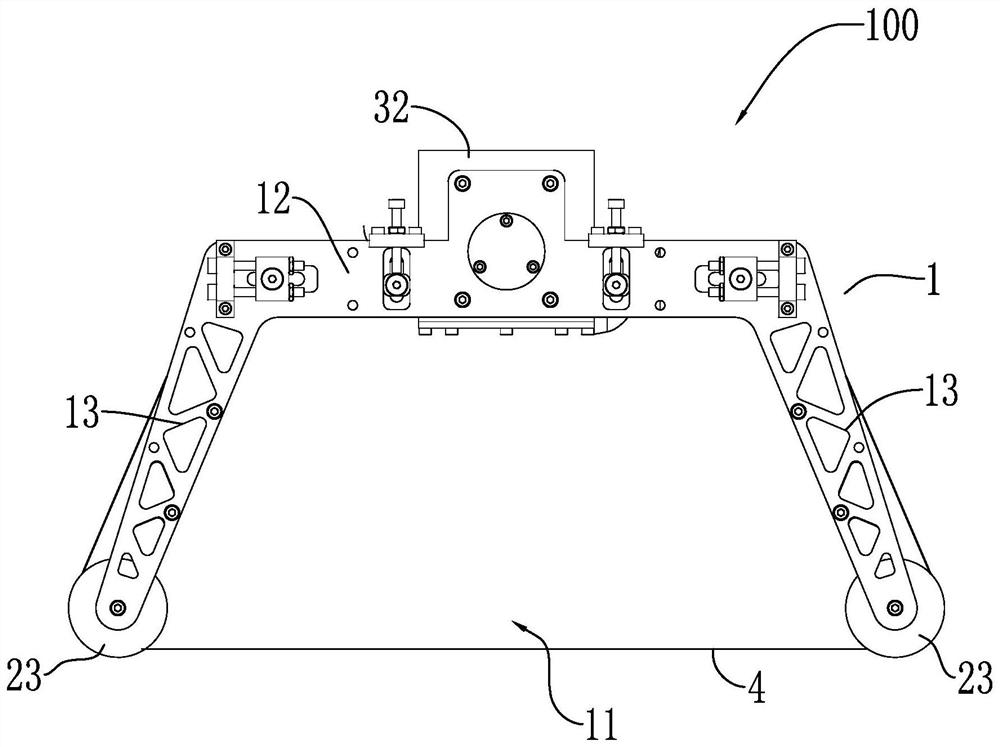

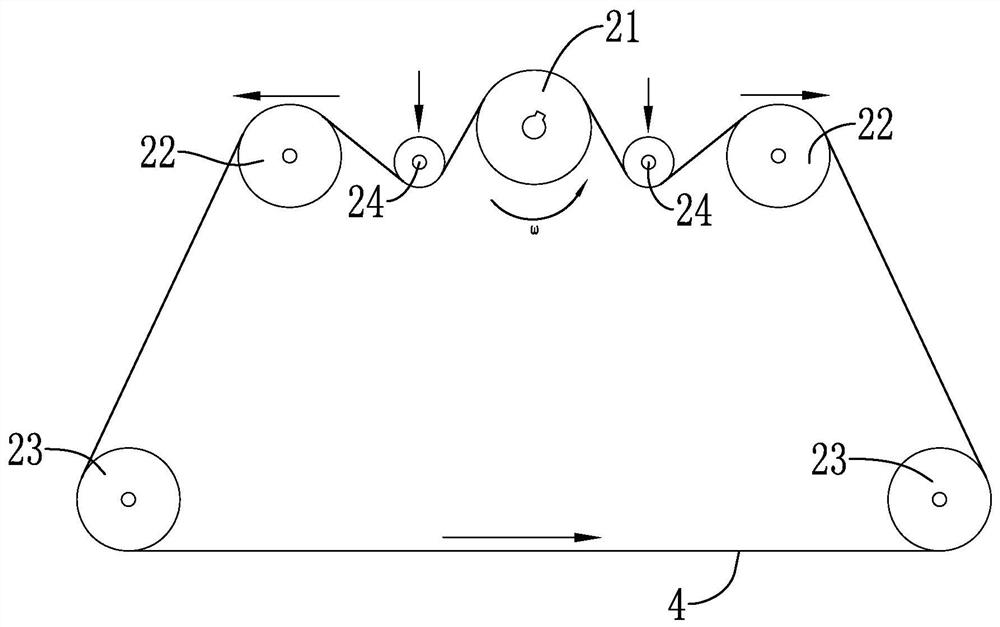

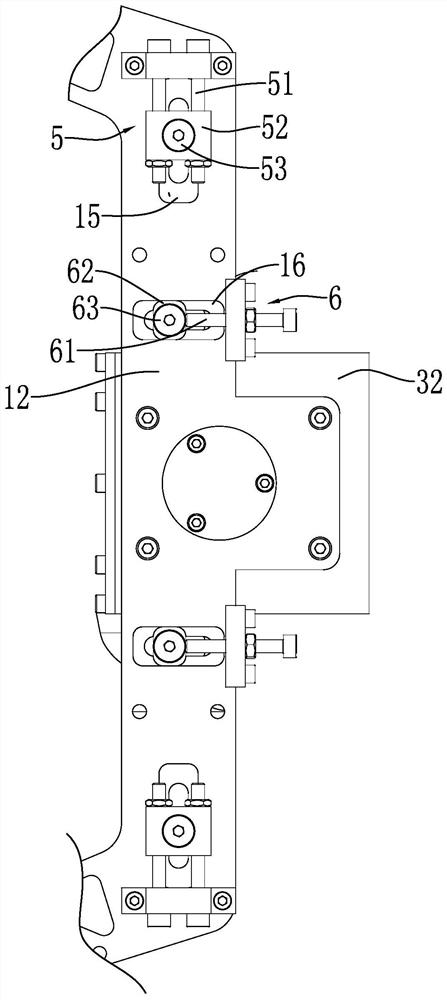

[0034] refer to Figure 1-Figure 5 , a wire saw mechanism 100, the wire saw mechanism 100 includes a frame 1, the frame 1 is arcuate and has an arcuate opening 11, the frame 1 includes a connecting arm 12 and two cantilevers 13, the cantileve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com