Patents

Literature

43results about How to "Meet cutting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

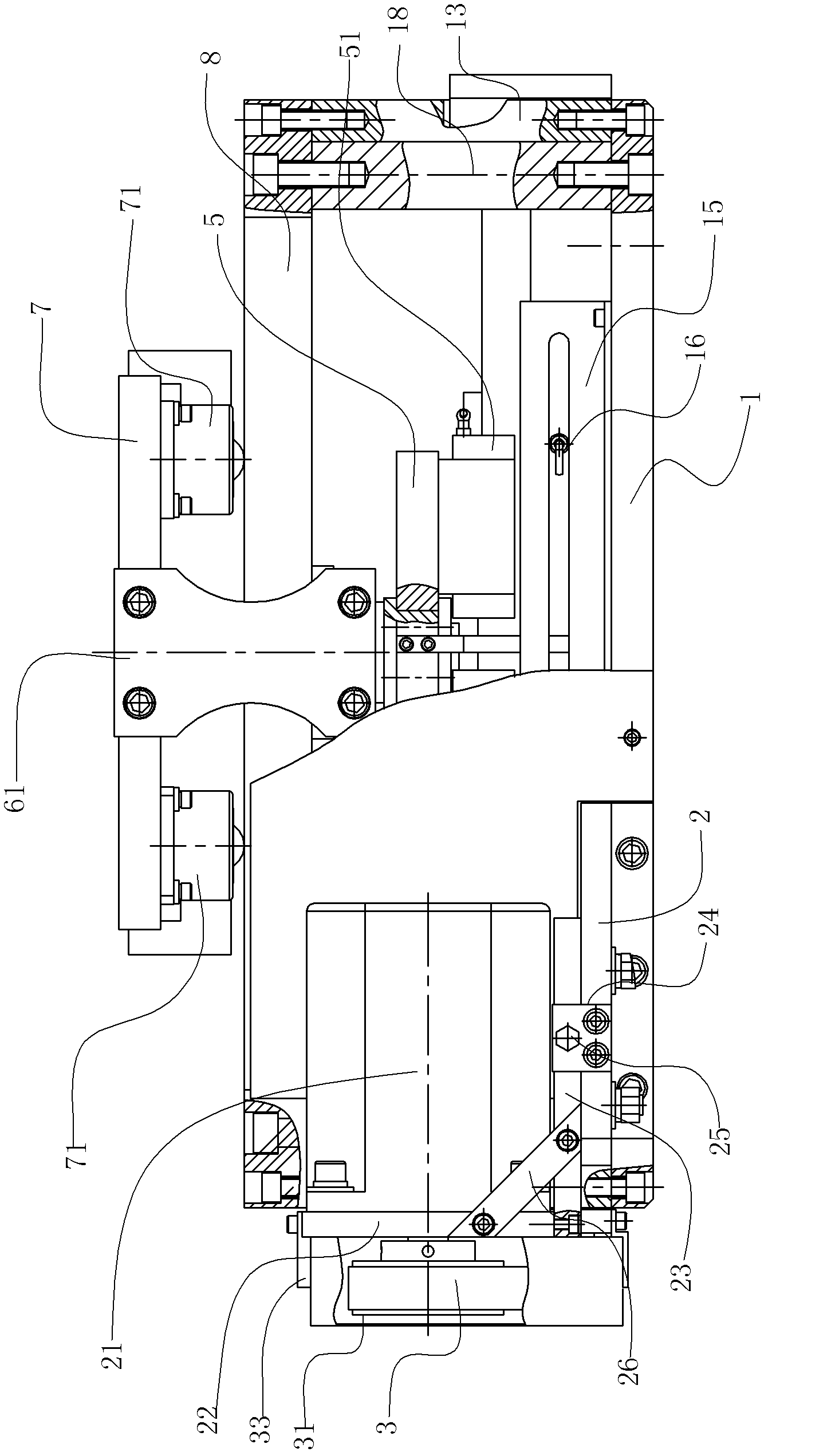

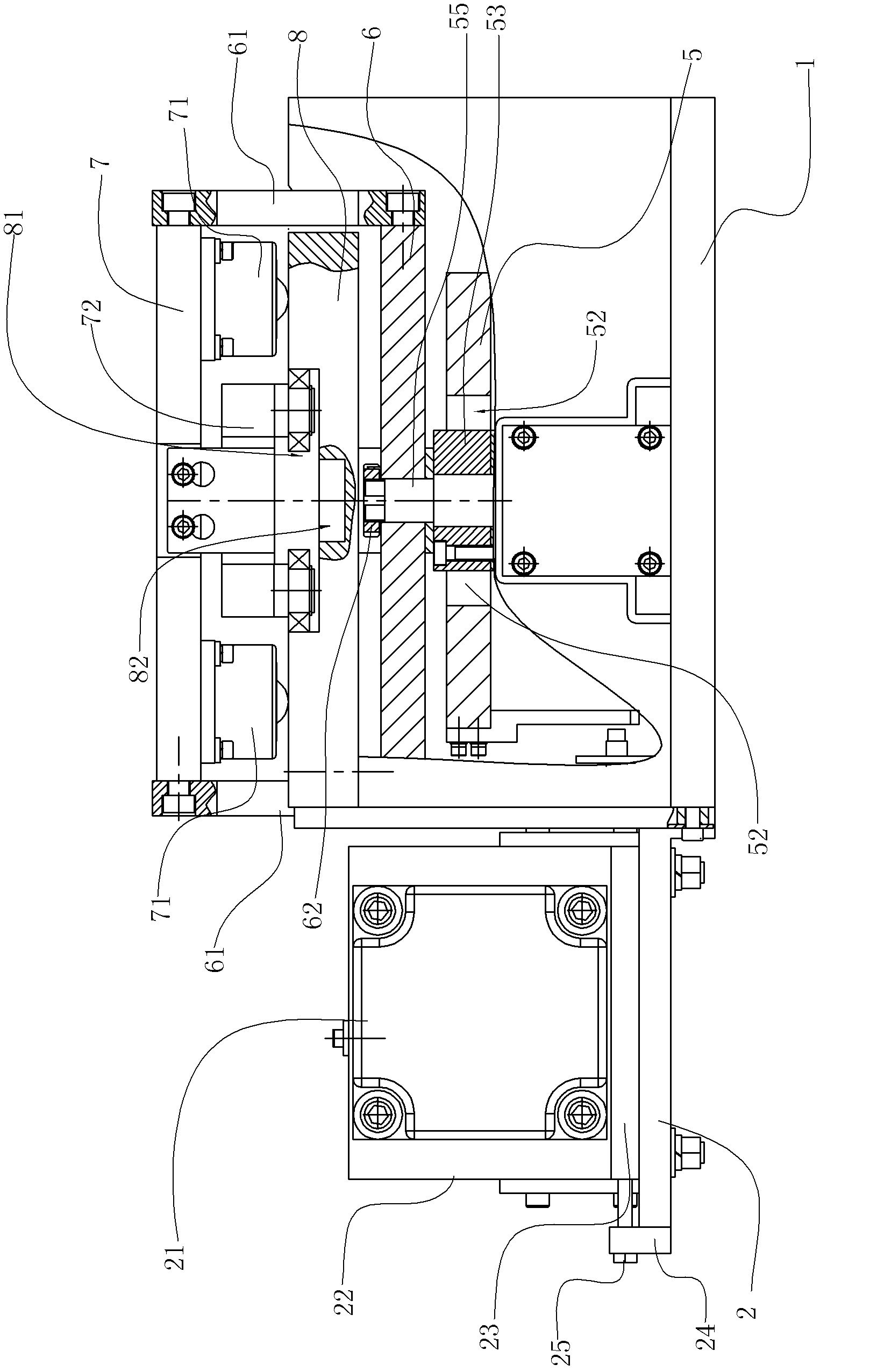

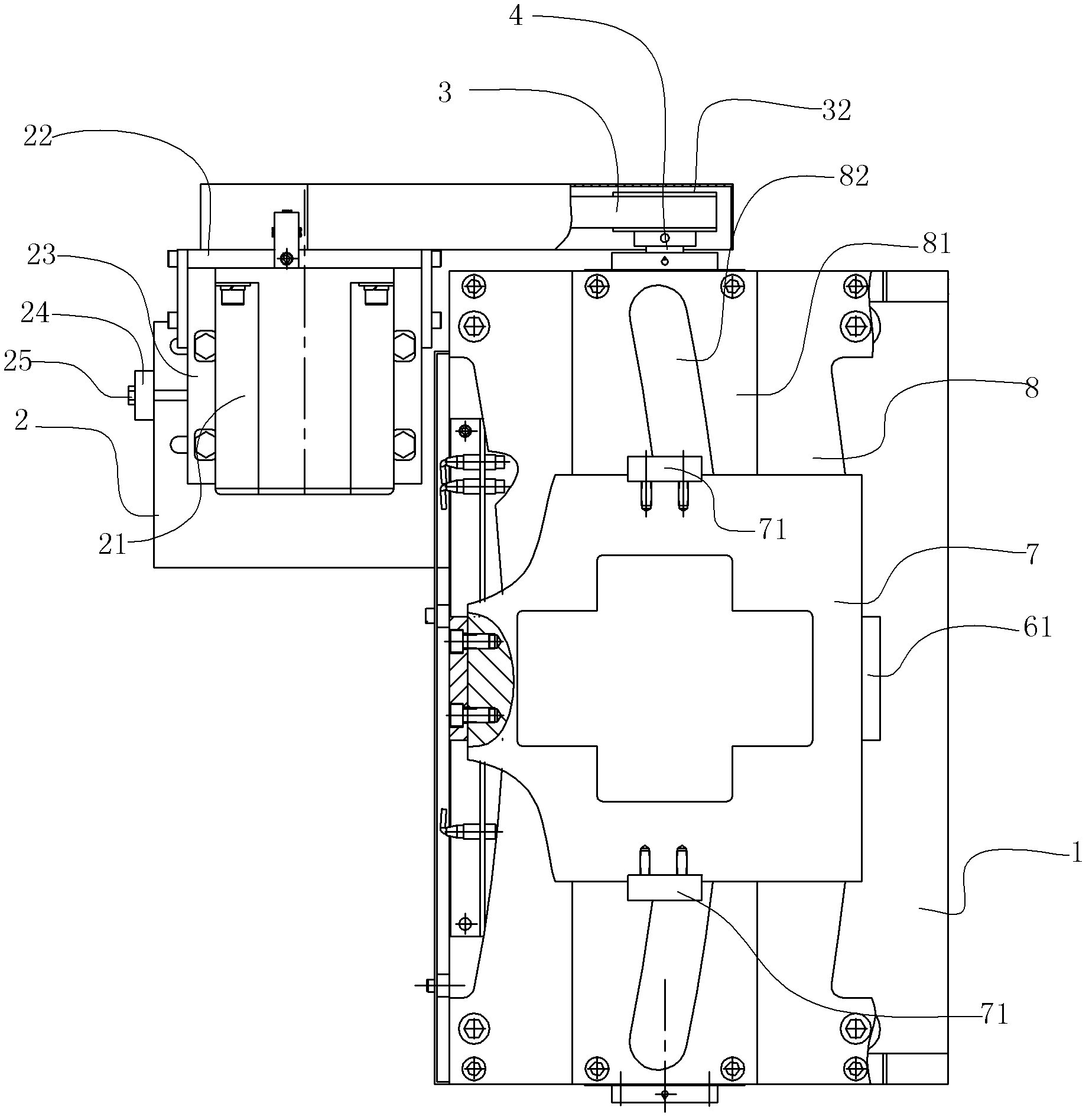

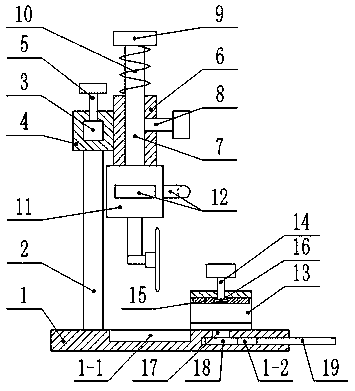

Automatic cutting machine

ActiveCN106735531AReduce impactEnsure measurementShearing machinesShearing machine accessoriesEngineeringMachine tool

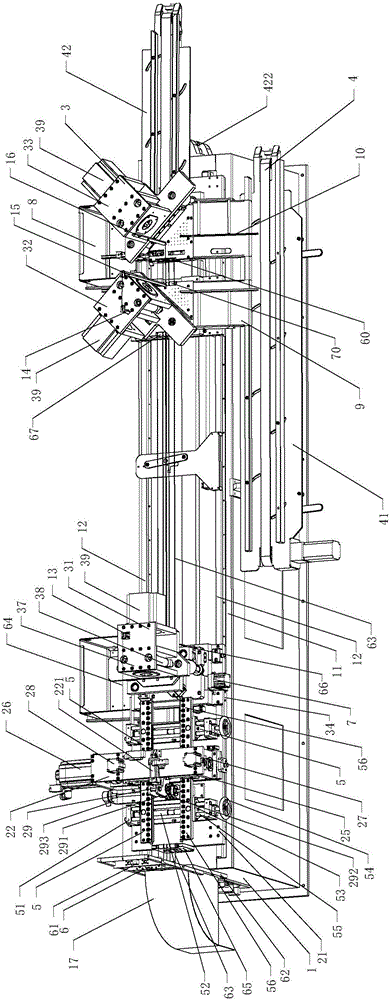

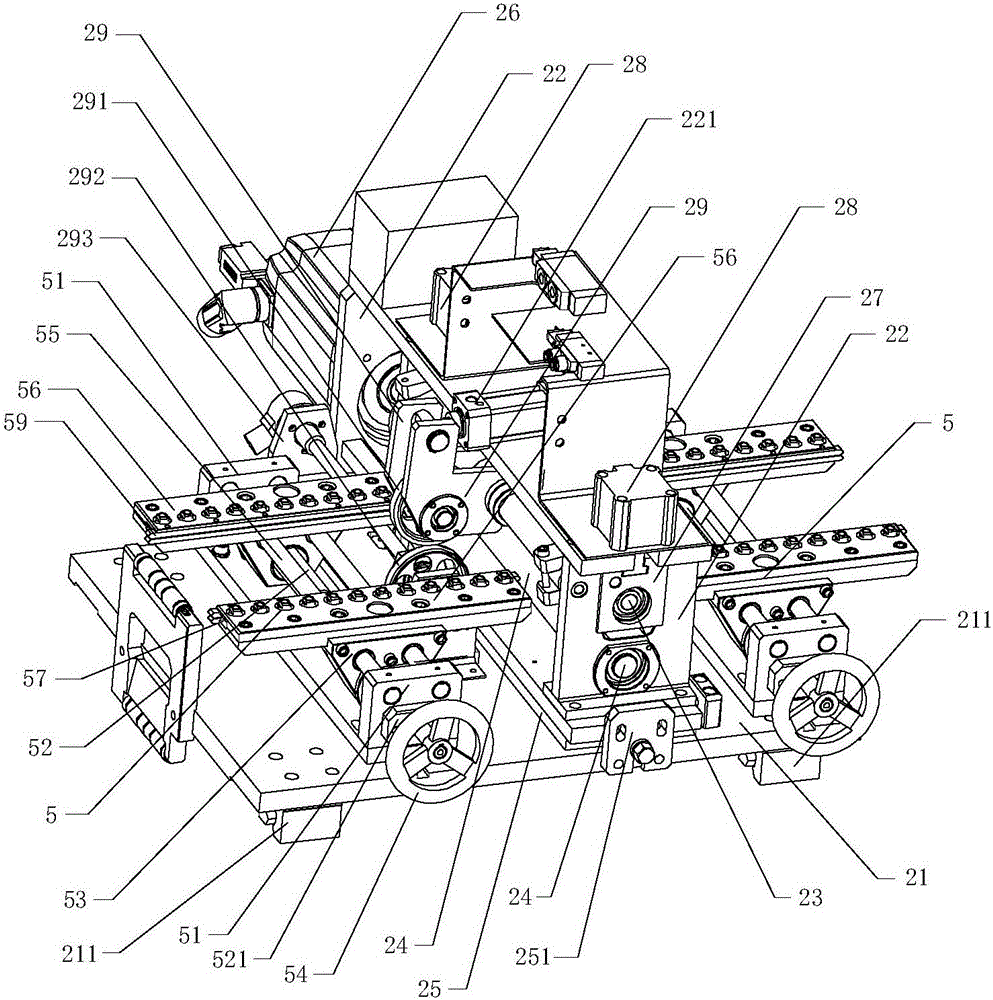

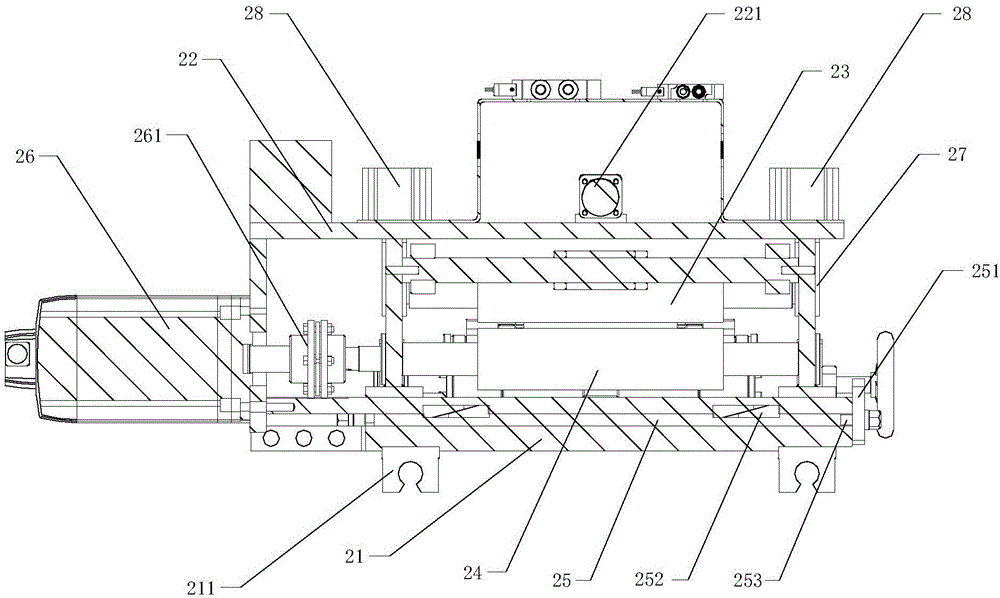

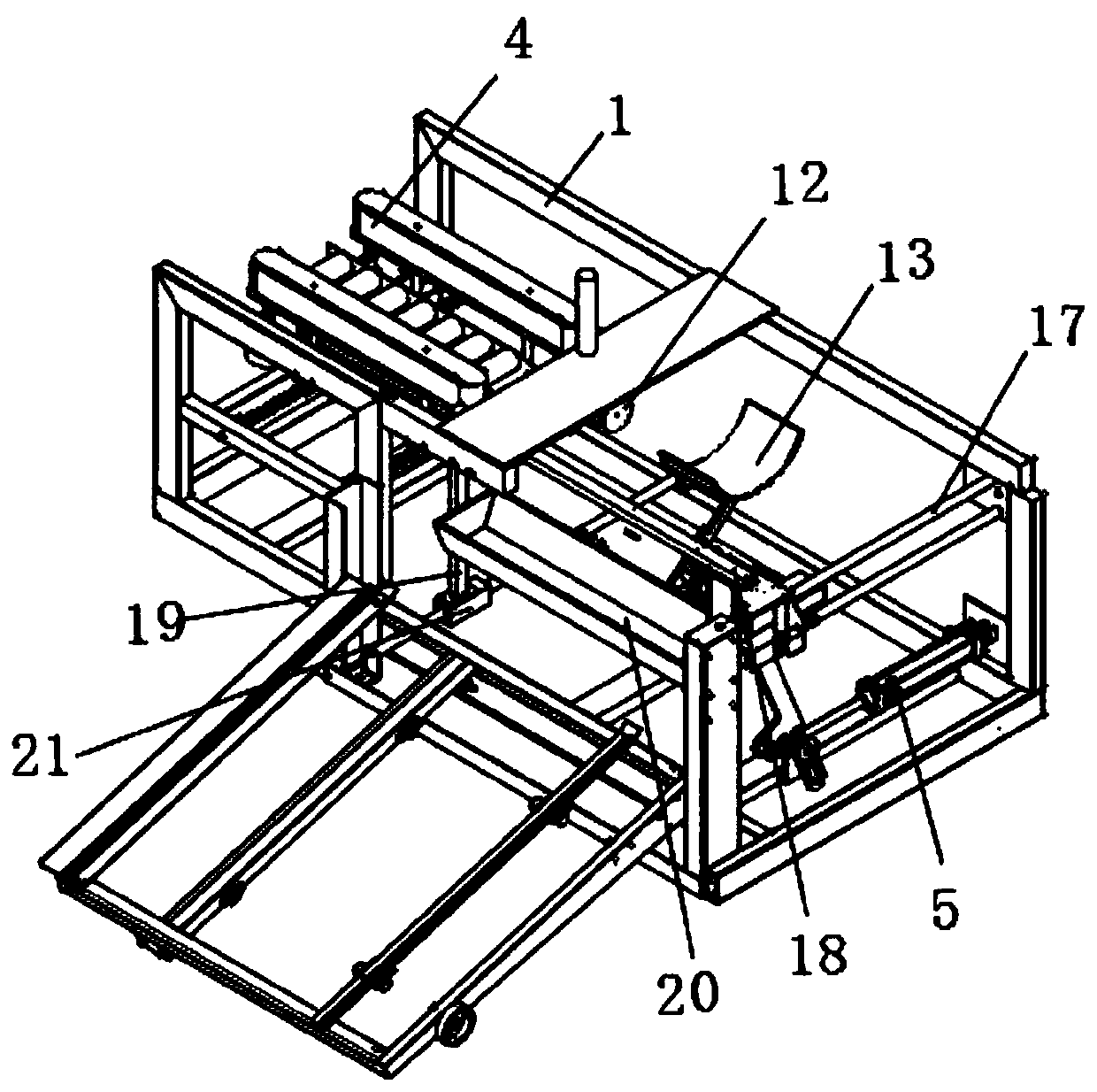

The invention discloses an automatic cutting machine. The automatic cutting machine comprises a bottom frame, a feeding mechanism and cutting units. A platform is arranged on the bottom frame. The two sides of the platform are provided with guide rails correspondingly. The feeding mechanism is located on the rear portion of the platform. A large bottom plate at the lower end of the feeding mechanism is in sliding connection with the guide rails. The feeding mechanism comprises a feeding bracket, an upper press roll and a lower press roll. The bottom of the feeding bracket is fixedly connected with the large bottom plate. The upper press roll and the lower press roll are vertically arranged on the feeding bracket. The lower press roll is driven by a first servo motor installed on one side of the feeding bracket. The front side and the rear side of the feeding mechanism are provided with material clamping mechanisms correspondingly. The three cutting units comprise the first cutting unit, the second cutting unit and the third cutting unit and are arranged on the guide rails from back to front in sequence. Through the cutting units of the cutting machine, impact force to a machine tool is decreased, equipment noise is lowered, the cutting precision is high, and the cutting machine is suitable for cutting sheets of various models; and the amount of cutting waste is small, the automation degree is high, and the production efficiency and safety are greatly improved.

Owner:青岛瑞宜利特变压器设备有限公司

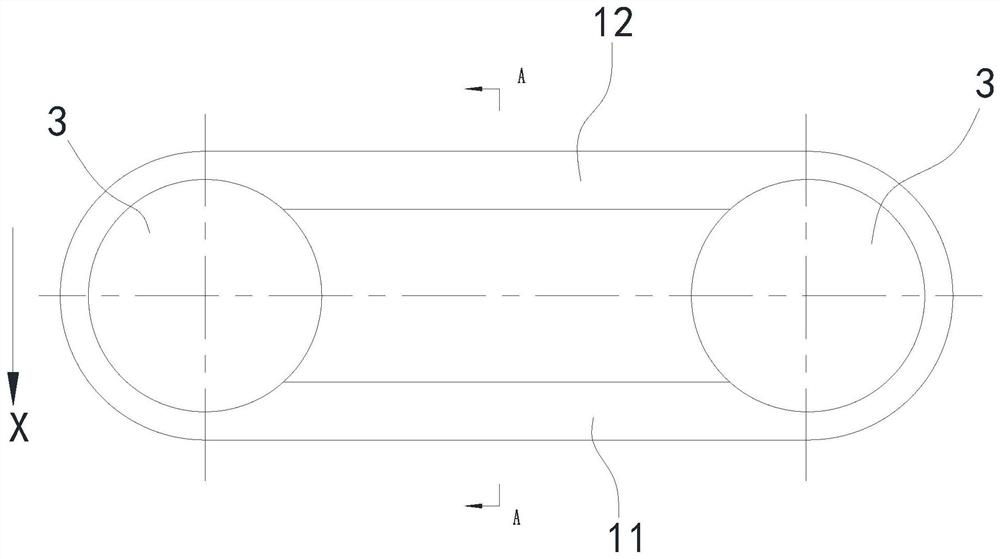

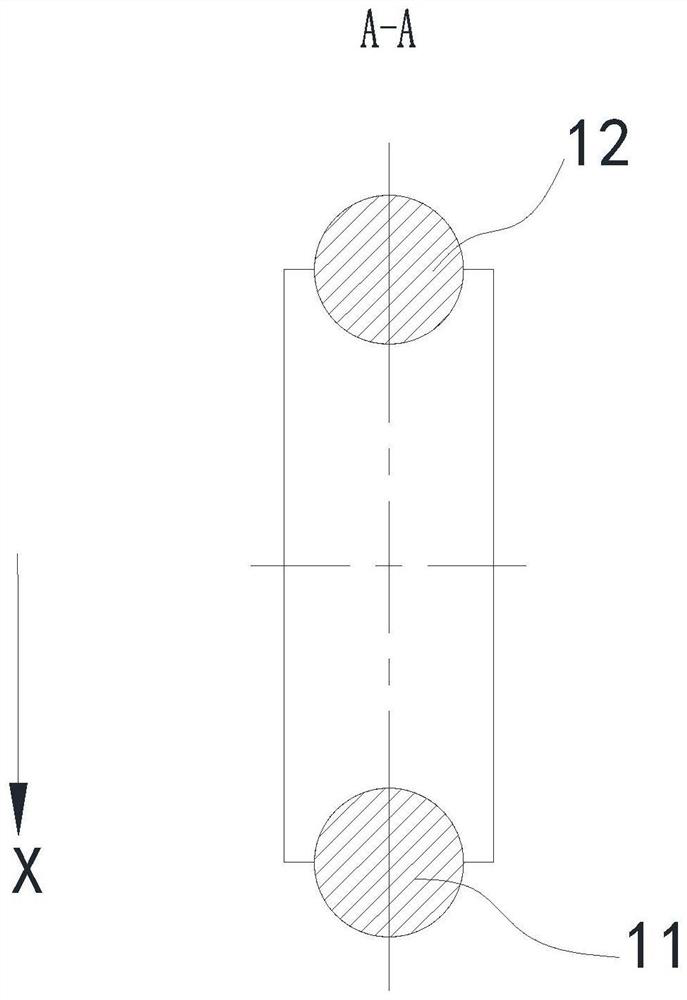

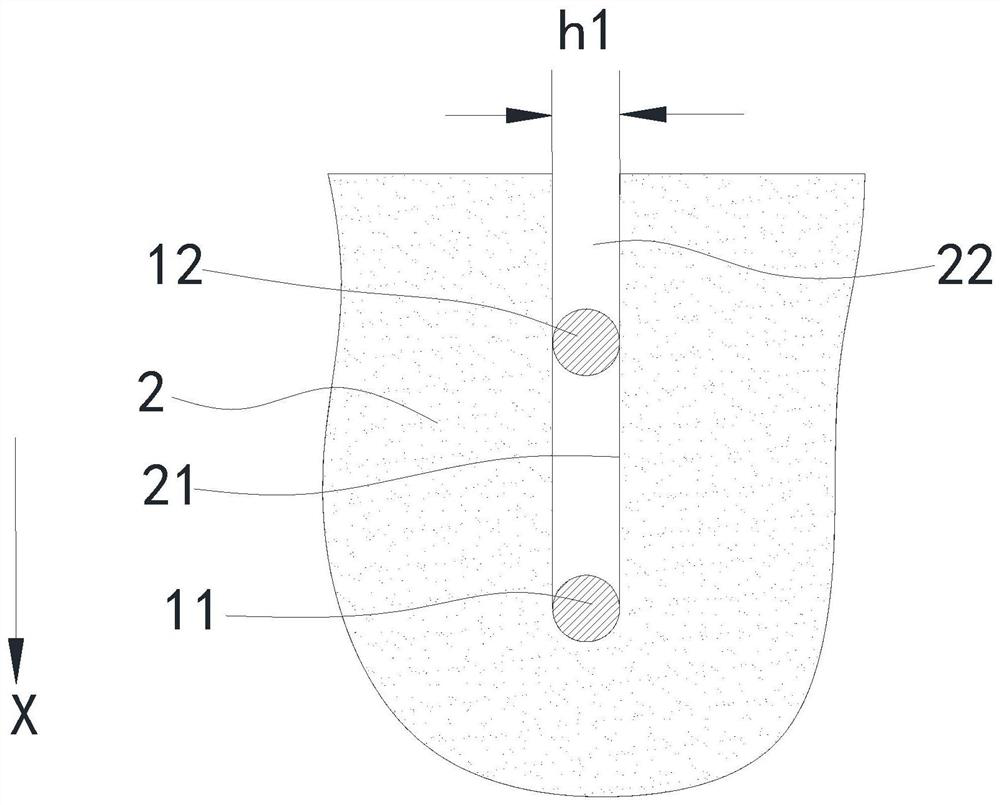

Cutting machine for cutting structural wall pipe

ActiveCN111037630ADrag minimizationAvoid consumptionMetal working apparatusElectric machineryKnife blades

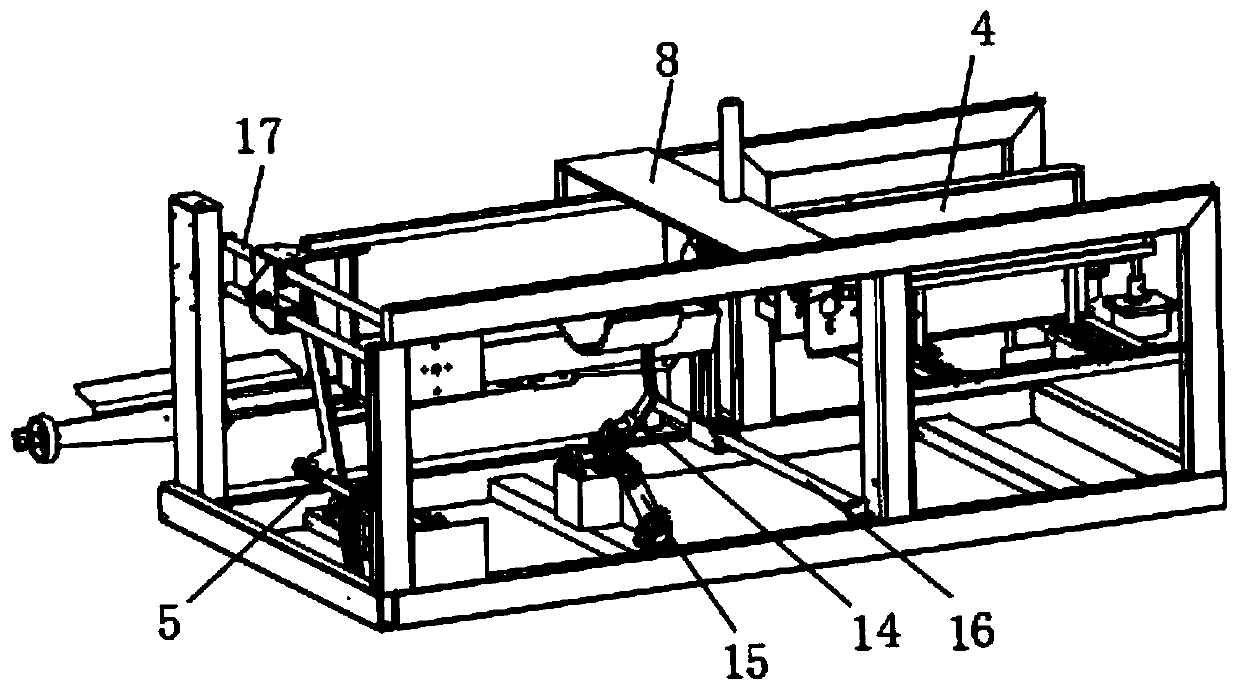

The invention discloses a cutting machine for cutting a structural wall pipe. The cutting machine comprises a mounting frame, wherein two supporting cross rods are fixed on the mounting frame, two belt conveying assemblies are arranged on the supporting cross rod, the belt conveying assemblies are in threaded connection with threaded rods through connecting longitudinal rods, a top supporting plate is fixed to the top of the mounting frame, a lifting air cylinder is fixed to the top supporting plate, a first motor mounting plate is fixed to an end of an output rod of the lifting air cylinder,a cutting motor is fixed to the first motor mounting plate, and a cutting blade is fixed to an output shaft end of the cutting motor. The cutting machine is convenient to adjust, structural wall pipescan be conveniently cut and fixed, and thereby the structural wall pipes are prevented from moving in the cutting process, the cutting effect is guaranteed, resistance of the structural wall pipe during moving is minimized, the service life of the cutting machine is guaranteed, the structural wall pipe can be automatically conveyed and collected, labor intensity is reduced, and production efficiency is improved.

Owner:ANHUI JIELANTE NEW MATERIAL CO LTD

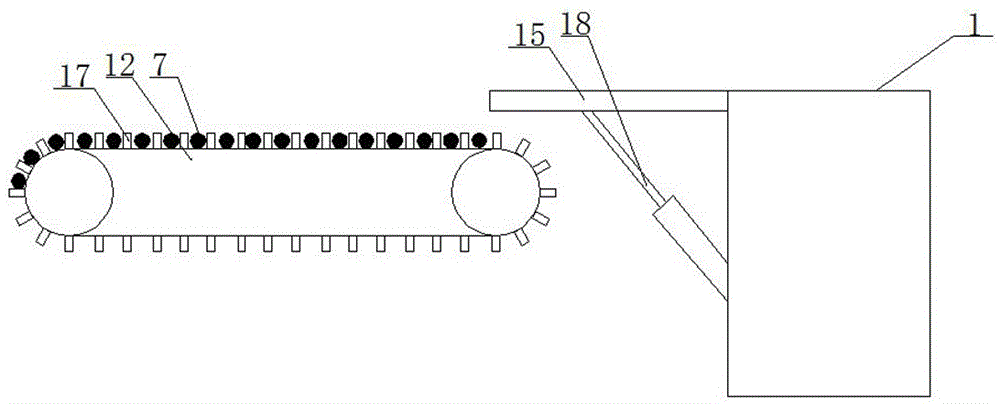

Automatic clamping pipe cutting machine

InactiveCN106216756AImprove work efficiencyReduce manual laborMeasurement/indication equipmentsTube shearing machinesEngineeringMechanical engineering

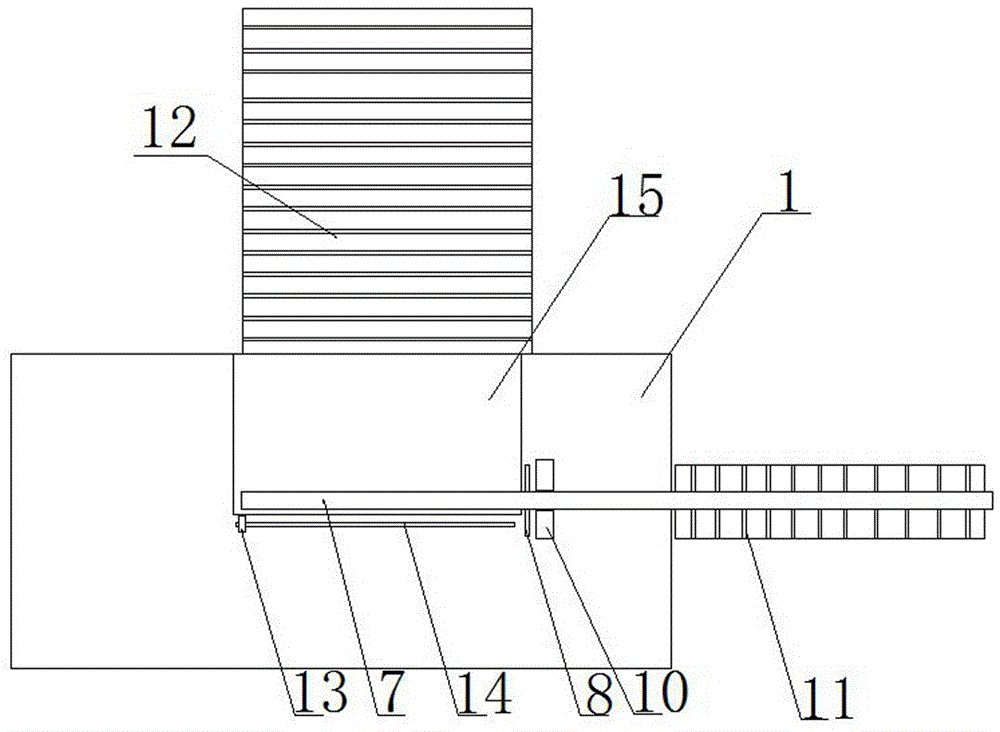

The invention discloses an automatic clamping pipe cutting machine. The automatic clamping pipe cutting machine comprises a machine body working surface. The machine body working surface is slidably provided with a pair of electromagnet clamping blocks and an infrared sensor. A cutting device is arranged on the machine body working surface. A scale ruler is arranged between a knife edge of the cutting device and the movement tail end of the infrared sensor. The machine body working surface is rotationally provided with a rotating plate flush with the machine body working surface. An air cylinder is arranged between the rotating plate and a machine body, and a discharging conveying belt is arranged on one side of the rotating plate. A plurality of protruding strips are uniformly arranged on the discharging conveying belt. A feeding conveying belt is arranged on one side of the machine body working surface. The machine body is internally provided with a controller. The controller is connected with the electromagnet clamping blocks and the infrared sensor. The automatic clamping pipe cutting machine can improve the working efficiency.

Owner:卢道东

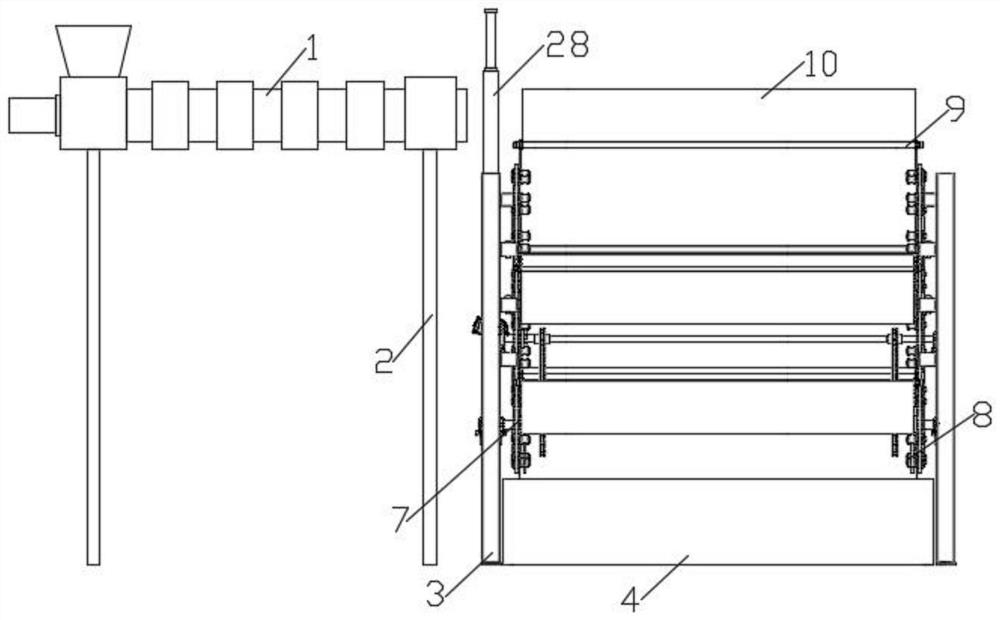

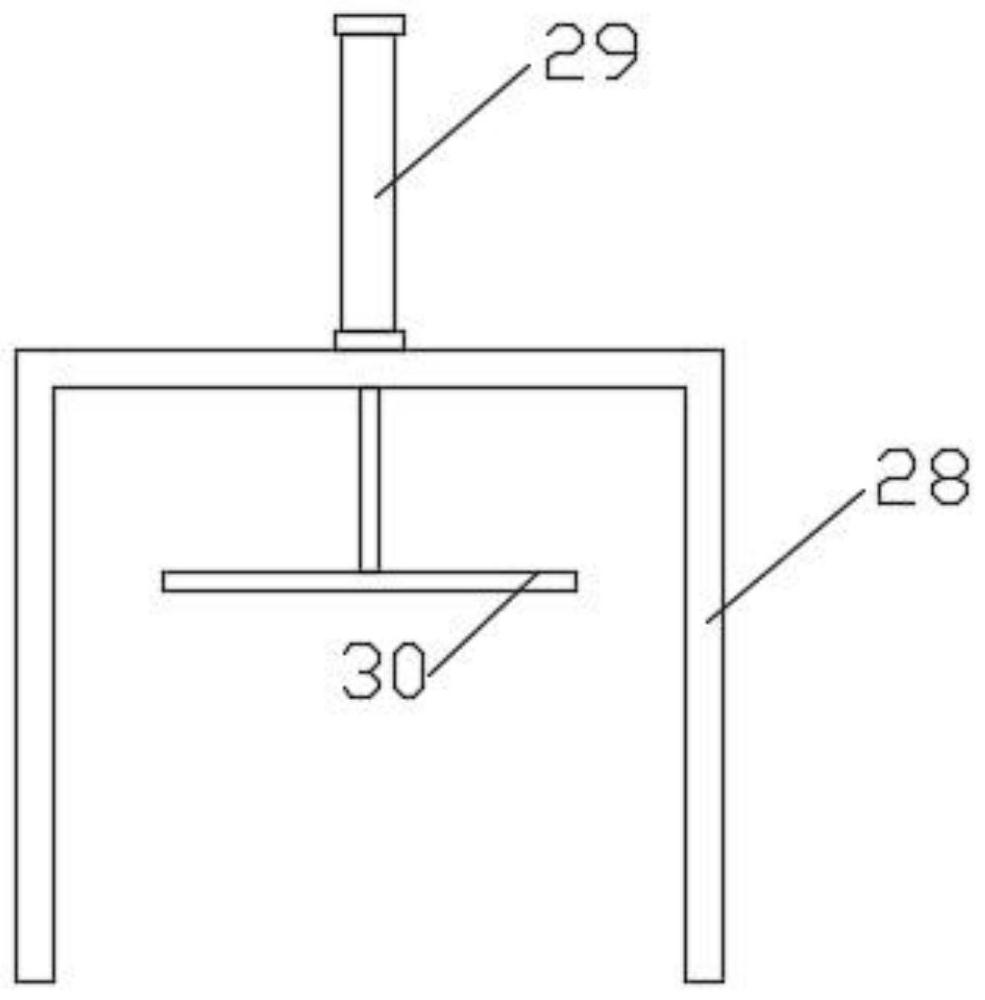

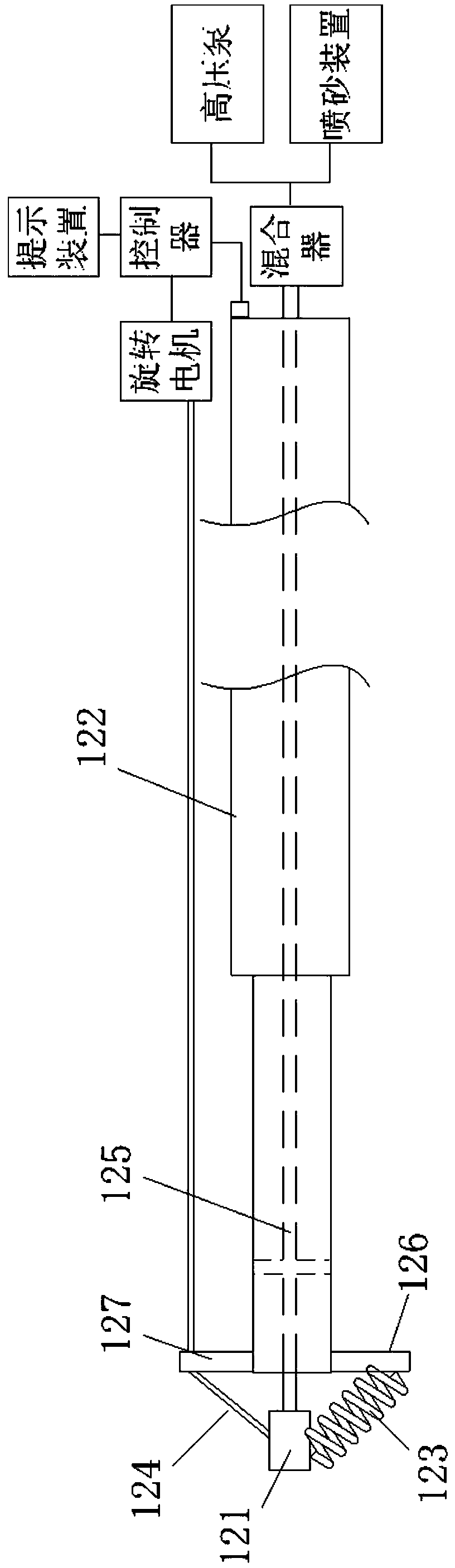

Heat-resistant insulating MPP cable tube and preparation method thereof

ActiveCN112625355AIncreased Vicat softening pointHigh modulusTubular articlesPolypropyleneElectric cables

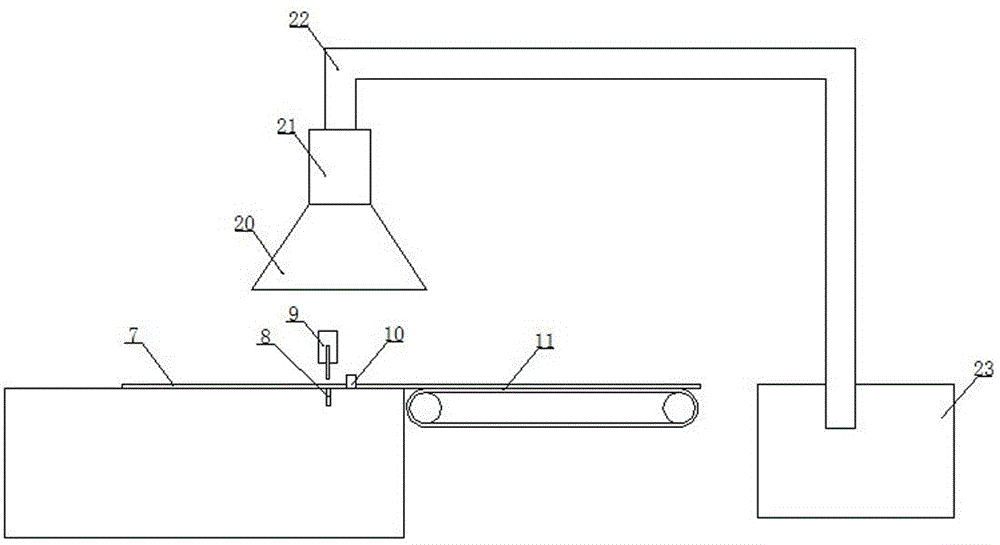

The invention discloses a heat-resistant insulating MPP cable tube and a preparation method thereof, the prepared heat-resistant insulating MPP cable tube has the characteristics of high Vicat softening point, high modulus and low-temperature brittleness by adding isotactic polypropylene, and the prepared heat-resistant insulating MPP cable tube has good wear resistance by adding ultra-high molecular weight polyethylene. According to measurement of GB / T 8802-2001, the Vicat softening point of the prepared heat-resistant insulating MPP cable tube is 154-163 DEG C. Meanwhile, the invention discloses extrusion cooling equipment which is provided with a plurality of circulating channels, so that circulating cooling of a plurality of cable tubes can be met at the same time, the cooling efficiency of the cable tubes is high, the extrusion cooling equipment can complete cooling of the bottom cable tube while cutting, conveying and cutting the top cable tube, and the production efficiency of the cable tube is greatly improved.

Owner:ANHUI JIELANTE NEW MATERIAL CO LTD

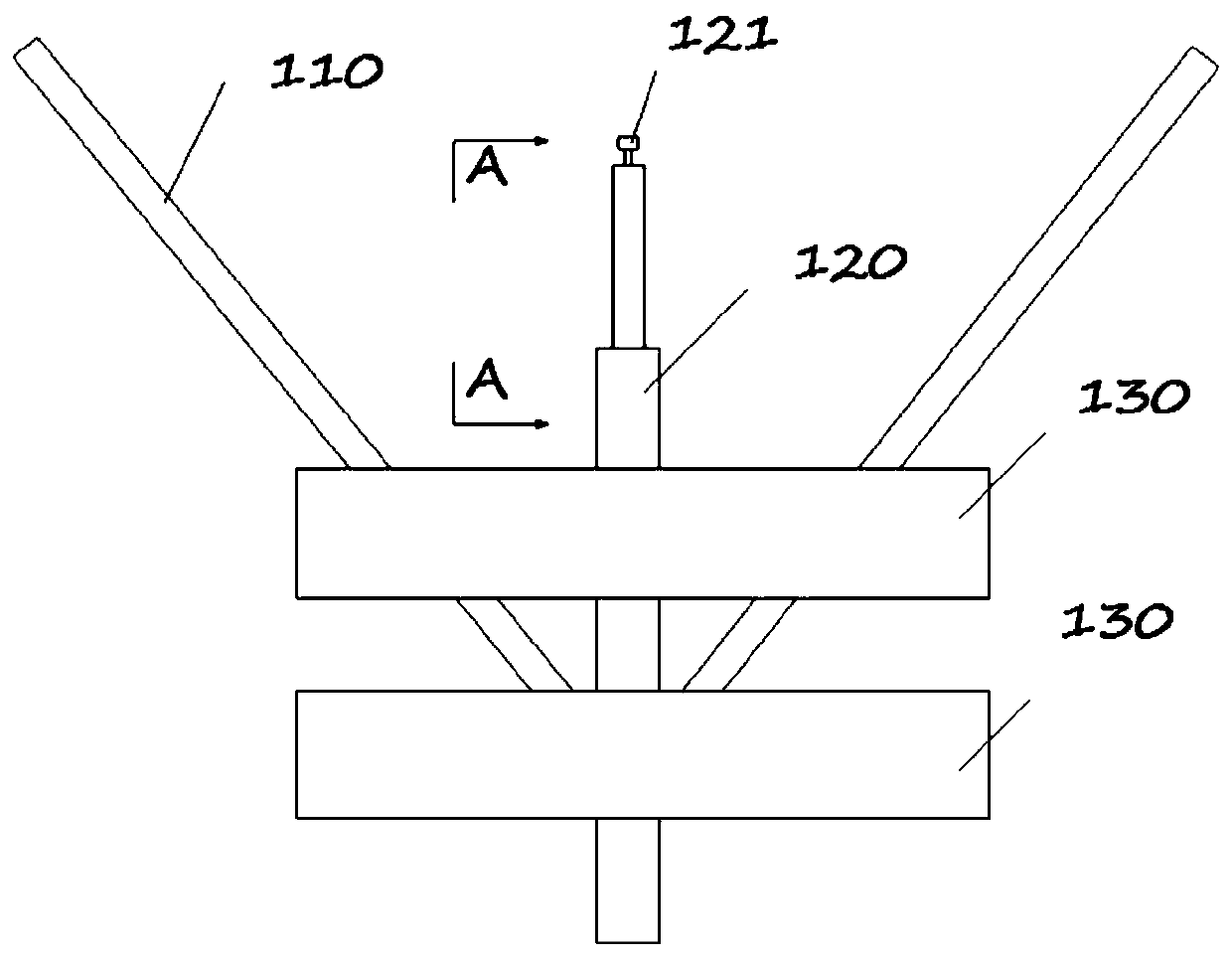

Aquatic plant fishing device

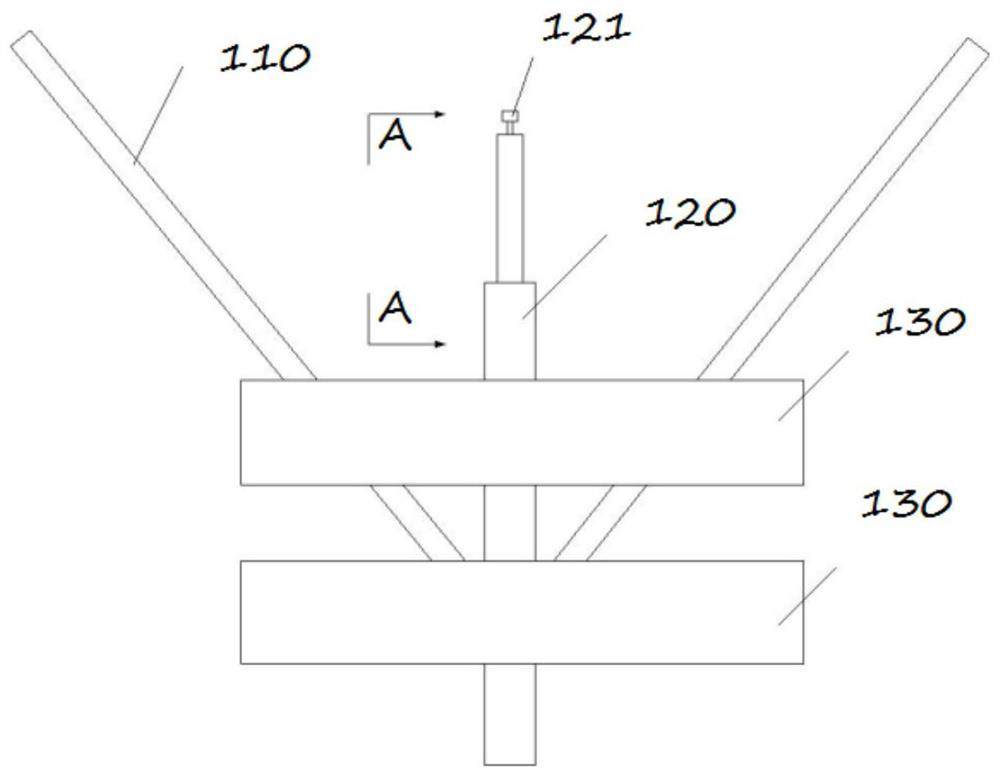

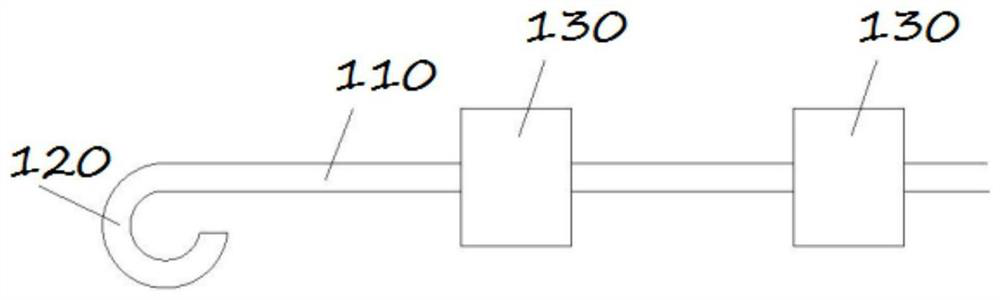

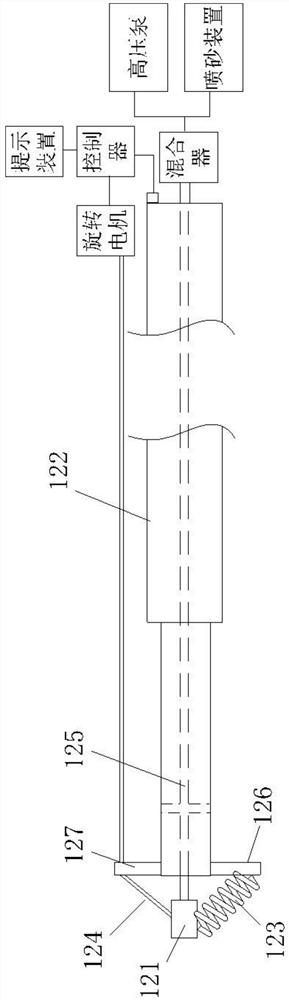

ActiveCN111496681AQuick and labor-saving salvageGuarantee the speed of salvageBlast gunsWater cleaningReciprocating motionEngineering

The invention relates to an aquatic plant fishing device. The device comprises supports located on the two sides and a nozzle cutting mechanism located between the two supports, wherein a corresponding hook-shaped structure is arranged at the front end of each support, the nozzle cutting mechanism is used for cutting entanglements based on a high-pressure water cutting principle and can stretch out and draw back in the front-back direction, a nozzle is arranged at the front end of the nozzle cutting mechanism, the nozzle can do up-down arc reciprocating motion within a preset angle range, andthe two supports are fixedly connected with the nozzle cutting mechanism. According to the device, the nozzle cutting mechanism is arranged between the two supports with the hook-shaped structures, the entanglements wound between the two supports can be cut, aquatic plants can be fished more quickly in a labor-saving manner, the nozzle cutting mechanism can stretch out and draw back in the front-back direction, the device can be rotated left and right to cut the entanglements independently wound around each support, the nozzle can do up-and-down arc reciprocating motion within the preset anglerange, the cutting speed can be prevented from being reduced, and energy waste is prevented from being increased.

Owner:CHONGQING JIAOTONG UNIVERSITY +1

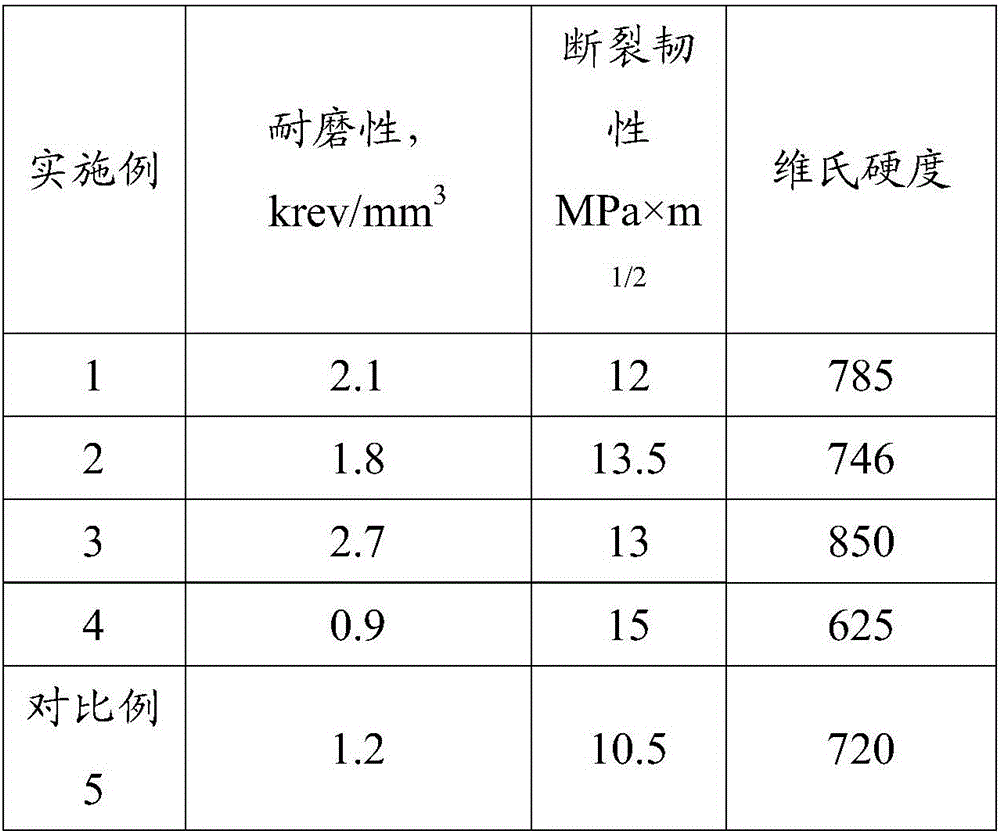

Composite metal ceramic and preparation method and application thereof

InactiveCN106270492AFreeze fastImprove wear resistanceAdditive manufacturing apparatusIncreasing energy efficiencySurface layerAlloy

The invention belongs to the technical field of 3D printing, and particularly relates to composite metal ceramic and a preparation method and application thereof. A composite metal ceramic particle is provided, and the composite metal ceramic particle sequentially comprises an abrasion-resistant phase, a transition phase and a toughening matrix phase from the center layer to the surface layer. The abrasion-resistant phase is TiC-Ni-Mo2C alloy. The invention further provides the preparation method of the composite metal ceramic. The invention further provides the application of the composite metal ceramic or a product obtained through the preparation method. According to the technical scheme, strength of the obtained product can meet the application requirements of tool cutting, mineral exploitation, shielding tools and petroleum drilling. Meanwhile, according to the composite metal ceramic, the abrasion resistance and fracture toughness of the metal ceramic can be improved at the same time. The technical defects that products of the complicated shapes cannot be prepared easily through conventional metal ceramic in the prior art, and the abrasion resistance and fracture toughness cannot be improved simultaneously are overcome.

Owner:GUANGDONG UNIV OF TECH

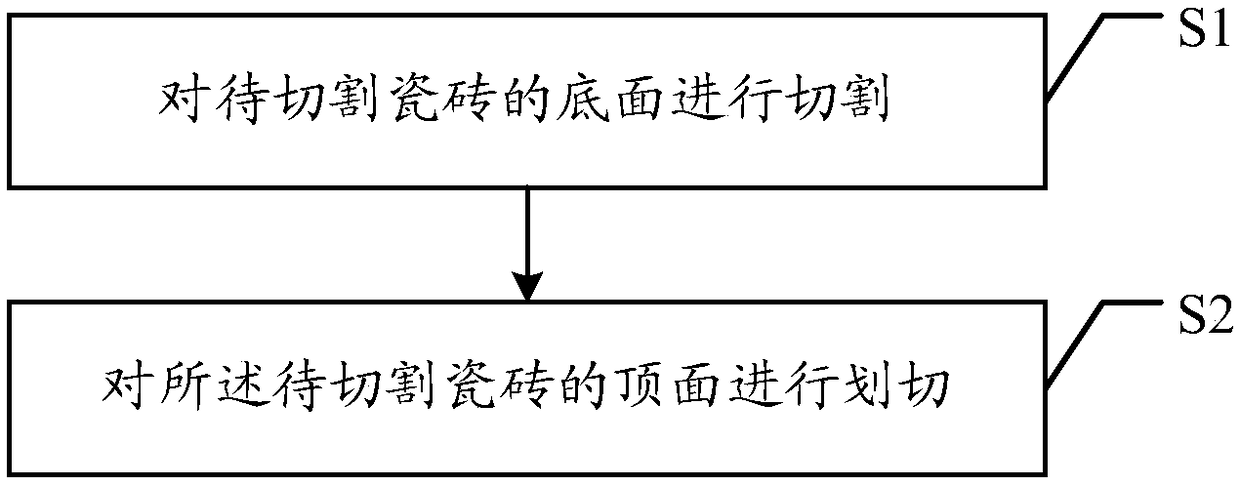

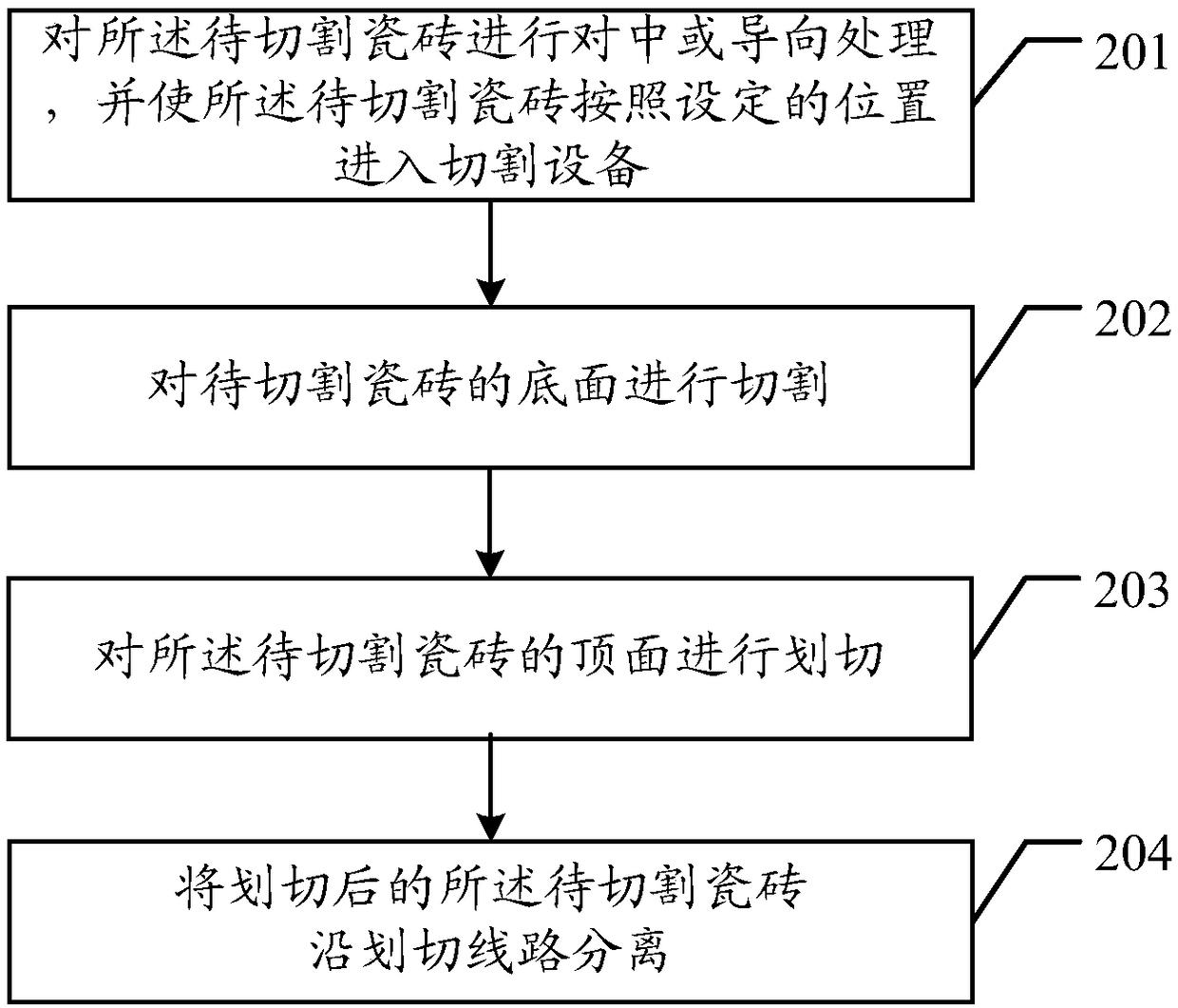

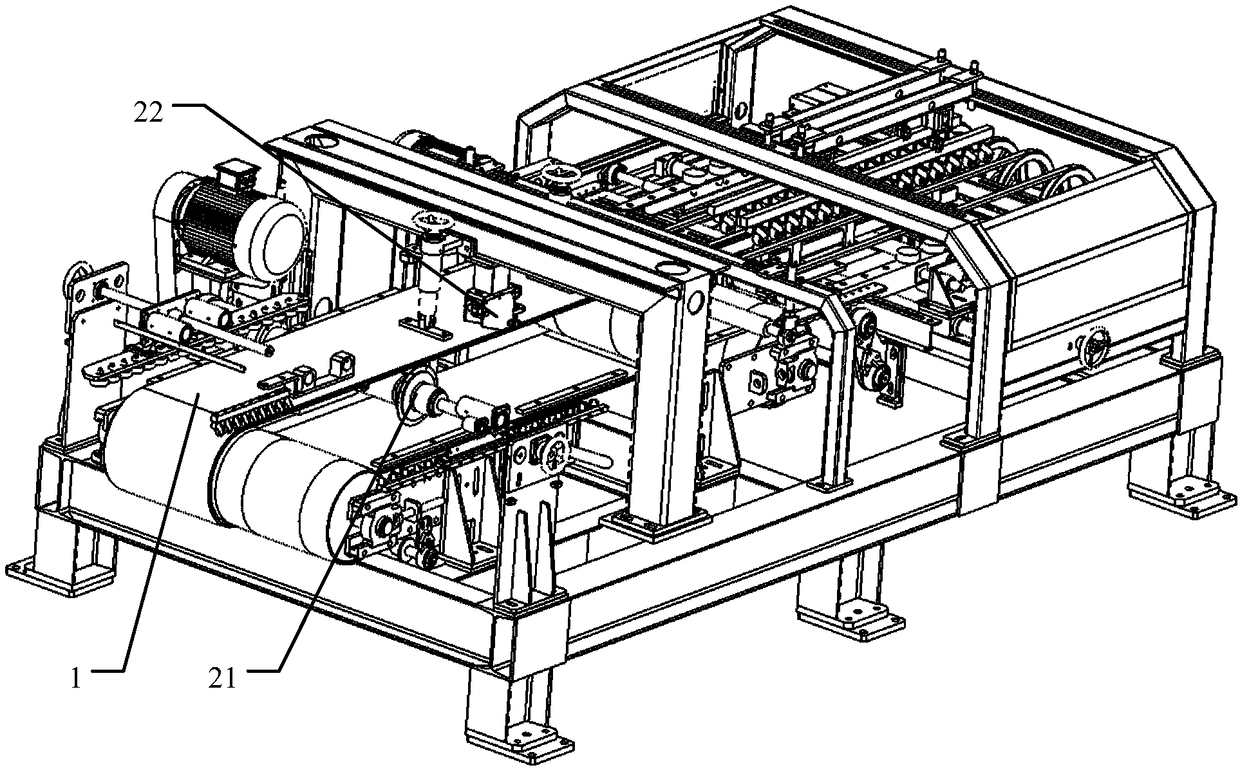

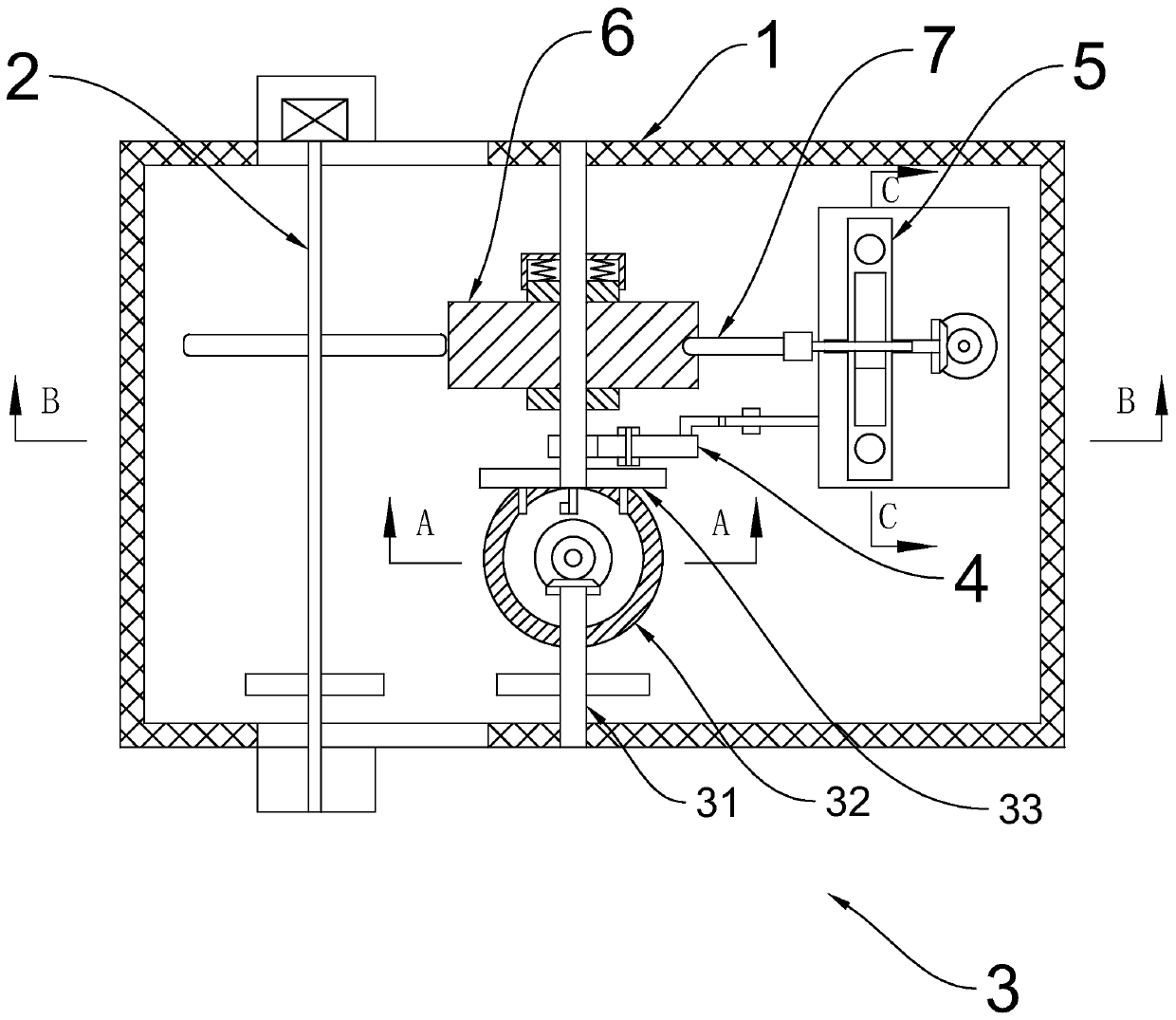

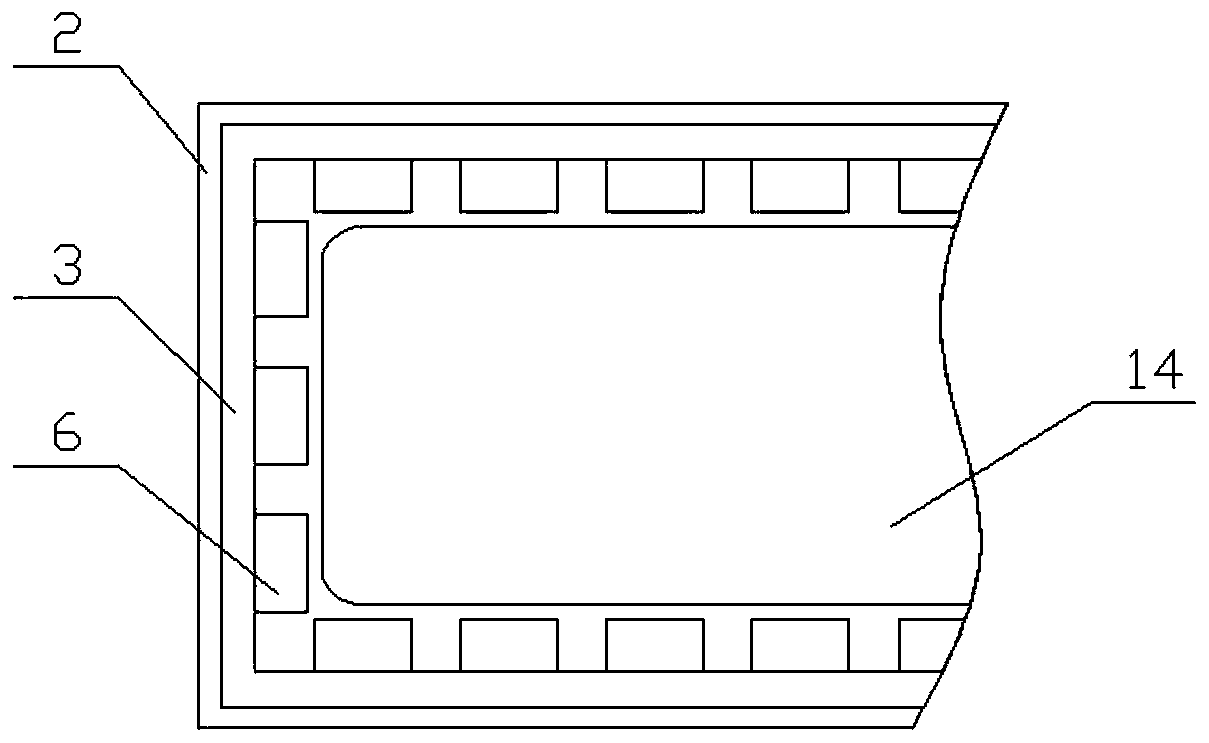

Ceramic tile cutting process and device

PendingCN109333831ASmall cutting allowanceReduce lossStone-like material working toolsMetallurgyScratch marks

The invention discloses a ceramic tile cutting process and device. By the adoption of a ceramic tile cutting method for cutting the bottom and scratching the face, one knife cuts the bottom face of ato-be-cut ceramic tile to a certain depth, another knife scratches marks on the top face of the to-be-cut ceramic tile, the back face of the to-be-cut ceramic tile is cut off along the cutting line through a breaking device, and the probability of breaking like edge breakage and bottom falling in the cutting process of the to-be-cut ceramic tile is effectively reduced. The ceramic tile cutting device comprises a ceramic tile cutting device body which comprises a conveying mechanism and a cutting mechanism; the cutting mechanism comprises a bottom cutting module and a face scratching module; the bottom cutting module is arranged below the conveying mechanism and used for cutting the bottom face of the to-be-cut ceramic tile; and the face scratching module is arranged above the conveying mechanism and used for scratching the top face of the to-be-cut ceramic tile.

Owner:佛山市爱陶机电设备有限公司

Integrated processing device of neodymium-iron-boron magnet

ActiveCN110509064AMeet cuttingSatisfy processabilityFeeding apparatusOther manufacturing equipments/toolsRotational axisSteering wheel

The invention discloses an integrated processing device of a neodymium-iron-boron magnet. The integrated processing device comprises a stand, a cutting assembly, a steering mechanism, a lifting mechanism, a traction mechanism and a grinding assembly, wherein the steering mechanism comprises a steering driving mechanism, a turning wheel and an abnormal-shaped steering wheel; the abnormal-shaped steering wheel and a processing piece are mounted on a seventh rotating shaft; the steering driving mechanism is in meshed transmission with a first gear which is arranged in the cutting assembly; the steering driving mechanism drives the abnormal-shaped steering wheel to be rotated through the turning wheel in a reversing manner; the cutting assembly and the grinding assembly are separately arrangedon the two sides of the processing piece; the cutting assembly is moved along sliding slots which are formed in the two sides of the stand in the horizontal direction; the grinding assembly is mounted on the lifting mechanism; the lifting mechanism is moved under an effect of the traction mechanism; and one end of the traction mechanism is connected with the lifting mechanism while the other endof the traction mechanism is connected with the seventh rotating shaft. The integrated processing device disclosed by the invention has the advantages of being high in integration degree, high in grinding efficiency and simple in operation; and moreover, cutting and grinding operations can be performed completely and sequentially, and meanwhile, double-sided grinding on the cut processing piece can be realized.

Owner:宁波可可磁业股份有限公司

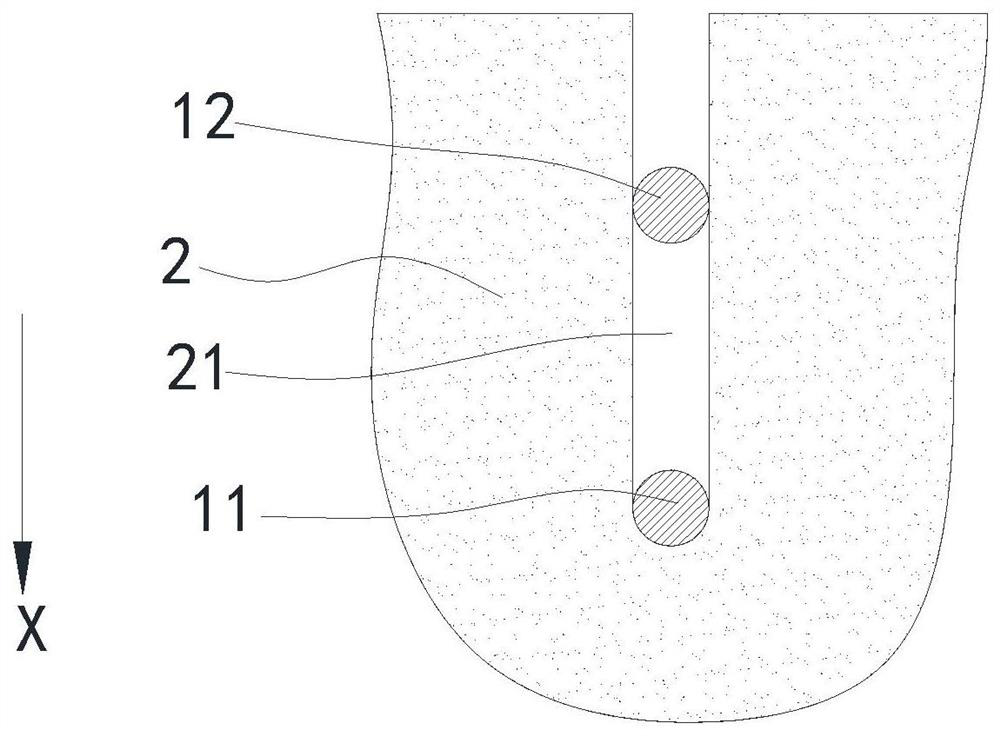

Brittle and hard material cutting method and device

PendingCN111823424AImprove cutting efficiencyFlexible and efficient cuttingGrinding drivesWorking accessoriesWire cuttingMaterials processing

The invention relates to the field of brittle and hard material machining, and discloses a brittle and hard material cutting method and device. The method comprises the steps that a brittle and hard material is fixed; two or more cutting wires parallel to each other are arranged on a cutting mechanism, and the cutting mechanism is adjusted, so that a plane where the cutting wires are located is parallel to a cutting feeding direction, or the cutting wires are spaced by a preset distance along a projection plane of the cutting feeding direction; and the brittle and hard material is cut, and during cutting, the two or more cutting wires are located in the same cutting groove in the brittle and hard material, or each of the cutting wires is located in a corresponding different cutting grooveof the brittle and hard material. According to the technical scheme, the brittle and hard material can be flexibly and efficiently cut, single-wire cutting can be carried out, and multi-wire simultaneous cutting can also be carried out, so that the cutting efficiency of the brittle and hard material is greatly improved.

Owner:福州天瑞线锯科技有限公司

Novel thermal insulation material sample cutting device

PendingCN113146728AMeet cuttingAvoid misalignmentMetal working apparatusThermal insulationWorking environment

The invention provides a novel thermal insulation material sample cutting device which comprises a portal frame. A machine base is slidably connected to the portal frame, a lifting device is fixedly installed on the machine base, the lifting end of the lifting device is fixedly connected with a main shaft, and the end, away from the lifting device, of the main shaft is movably connected with a cutter. A dust suction device is fixed to the side face, away from the portal frame, of the machine base, a workbench is arranged below the portal frame and slidably connected with the portal frame, a vacuum adsorption device is fixed to the lower portion of the workbench, the bottom end of the vacuum adsorption device is in pipeline connection with a vacuum pump, and a control box is arranged on one side of the workbench. The novel thermal insulation material sample cutting device is easy to operate, replaces a tedious working mode of manual cutting, is accurate in cutting size, improves the working efficiency while meeting the national standard requirements, and effectively improves the working environment and the physical and psychological health of related detection personnel.

Owner:LANGFANG CITY SUNSHINE CONSTR QUALITY INSPECTION CO LTD

Silica gel key self-cleaning edge cutting device

The invention discloses a silica gel key self-cleaning edge cutting device. The device comprises an installation frame, a supporting frame, a sliding head, an electric telescopic rod, an installationplate and a scrap cleaning unit. The installation frame is arranged in a long strip shape. A cross section of the installation frame is U-shaped. The supporting frame is fixedly connected to an uppersurface of a middle position of two side plates of the installation frame. The supporting frame is arranged in an inverted U shape. An installation groove is arranged in the middle of an upper rod ofthe supporting frame. The sliding head is fixedly connected into the installation groove of the supporting frame through a bolt, a lower surface of the sliding head is fixedly connected with a fixed end of the electric telescopic rod, and a telescopic end of the electric telescopic rod is fixedly connected with an upper surface of the installation plate. The structure is simple, part assembling isreasonable, a cleaning effect is good, splashing chippings can be cleaned in time, a fault is not easy to generate and stability is good.

Owner:INJECTION PRECISION RUBBER SUZHOU CO LTD

Plastic bag and suitcase trimming and positioning device

ActiveCN111376349AGood for circumferential cuttingImprove cutting efficiencyMetal working apparatusClassical mechanicsStructural engineering

The invention discloses a plastic bag and suitcase trimming and positioning device. The plastic bag and suitcase trimming and positioning device comprises a supporting periphery, wherein supporting legs are welded to the lower portion of the supporting periphery, the supporting legs are mounted on the ground through bolts, a sliding inlet is formed in the upper portion of the supporting periphery,transverse laser cutters are embedded in the supporting periphery, longitudinal laser cutters are embedded in the supporting periphery, and protective positioning plates are mounted in the supportingperiphery through bolts; and an adjusting sliding cavity is welded to the upper portion of a supporting bottom, the lower portion of the supporting bottom is installed on the ground through a bolt, fixing bases are installed at the bottom of the adjusting sliding cavity through bolts, adjusting push rods are installed on the upper portions of the fixing bases through bolts, and an adjusting sliding block is embedded in the adjusting sliding cavity. According to the plastic bag and suitcase trimming and positioning device, the transverse laser cutters, the longitudinal laser cutters, a bag andsuitcase supporting plate and positioners are arranged, so that the problems of low positioning precision, the complex feeding process and slow machining efficiency of an existing bag and suitcase trimming and positioning device are solved.

Owner:日照新睿招商发展有限公司

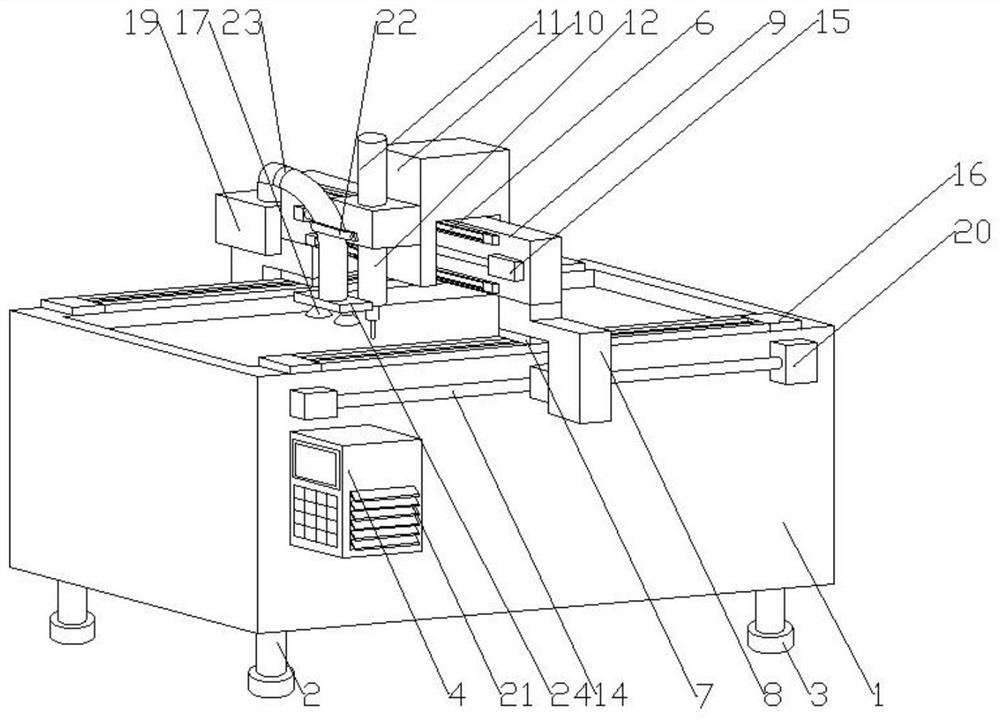

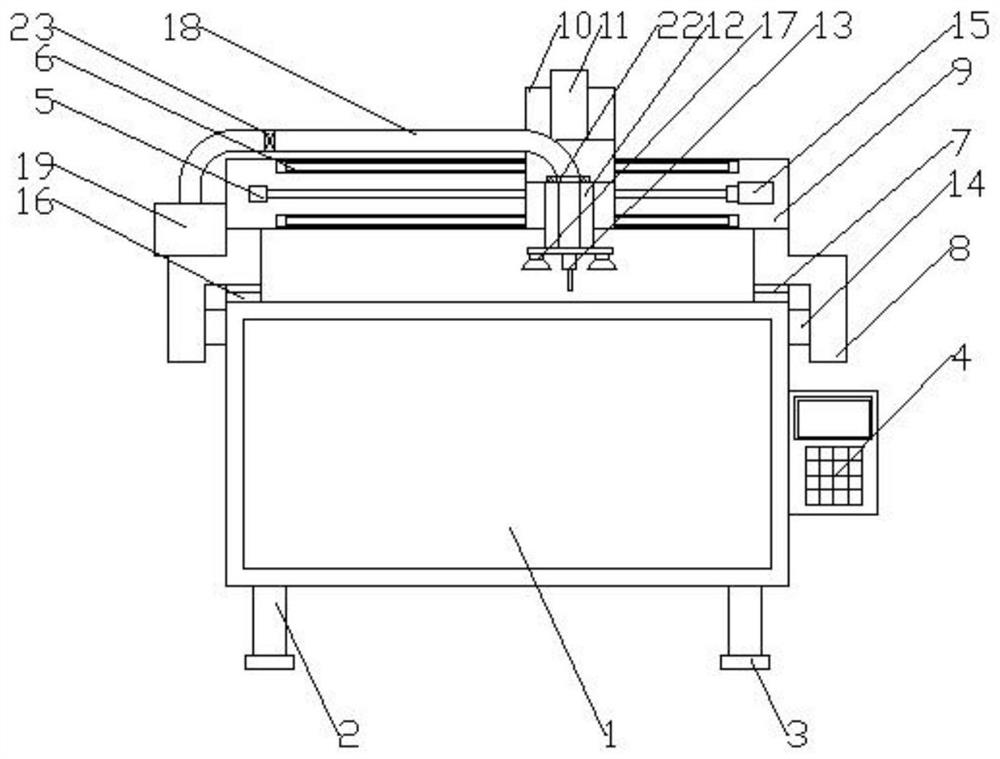

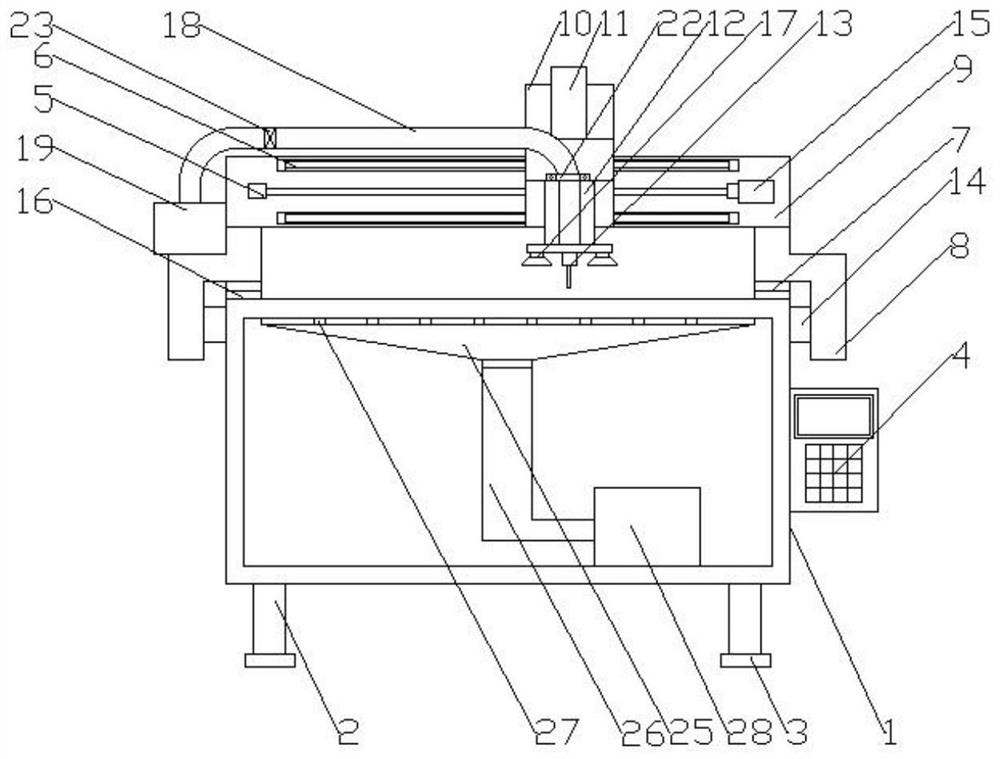

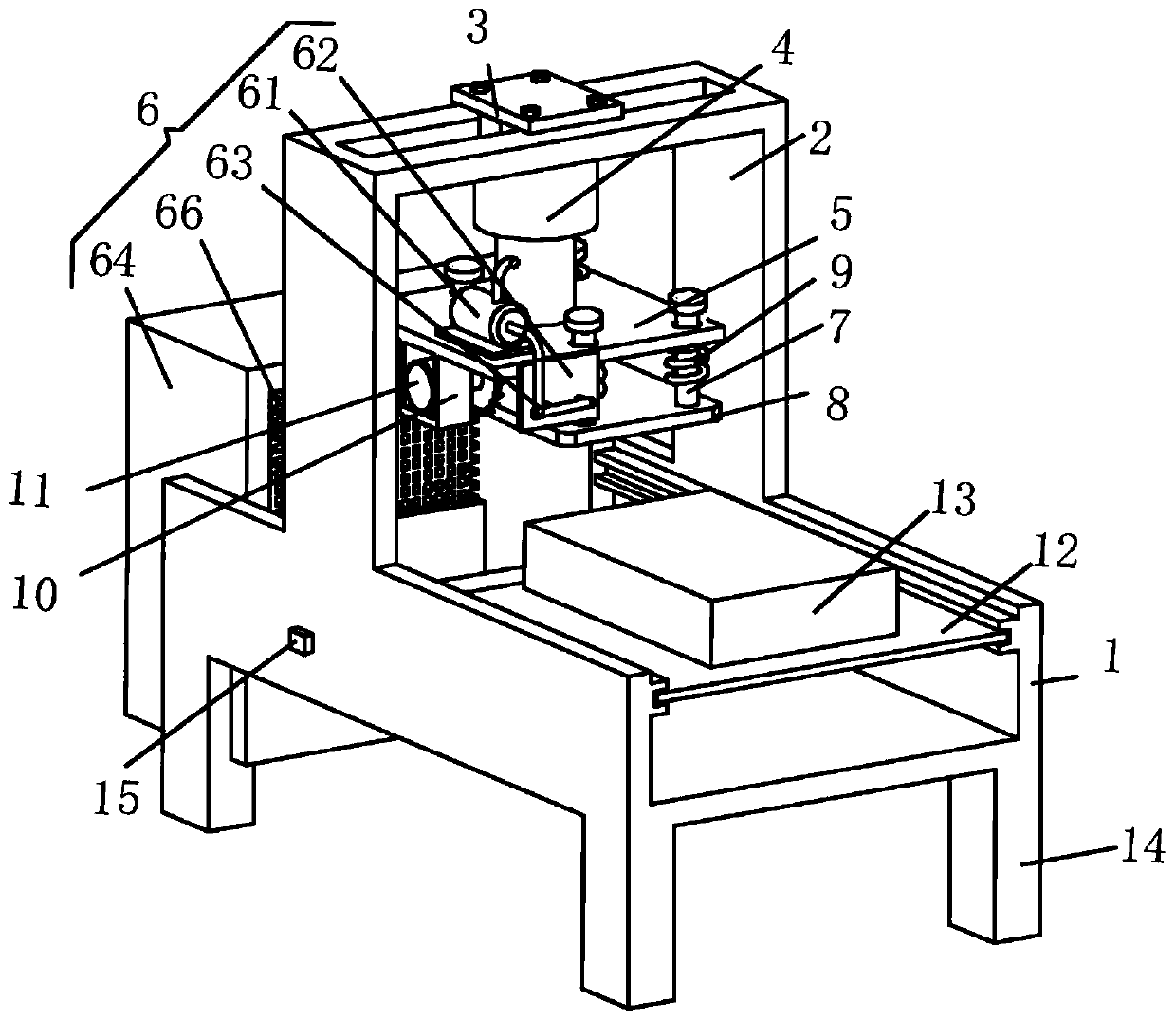

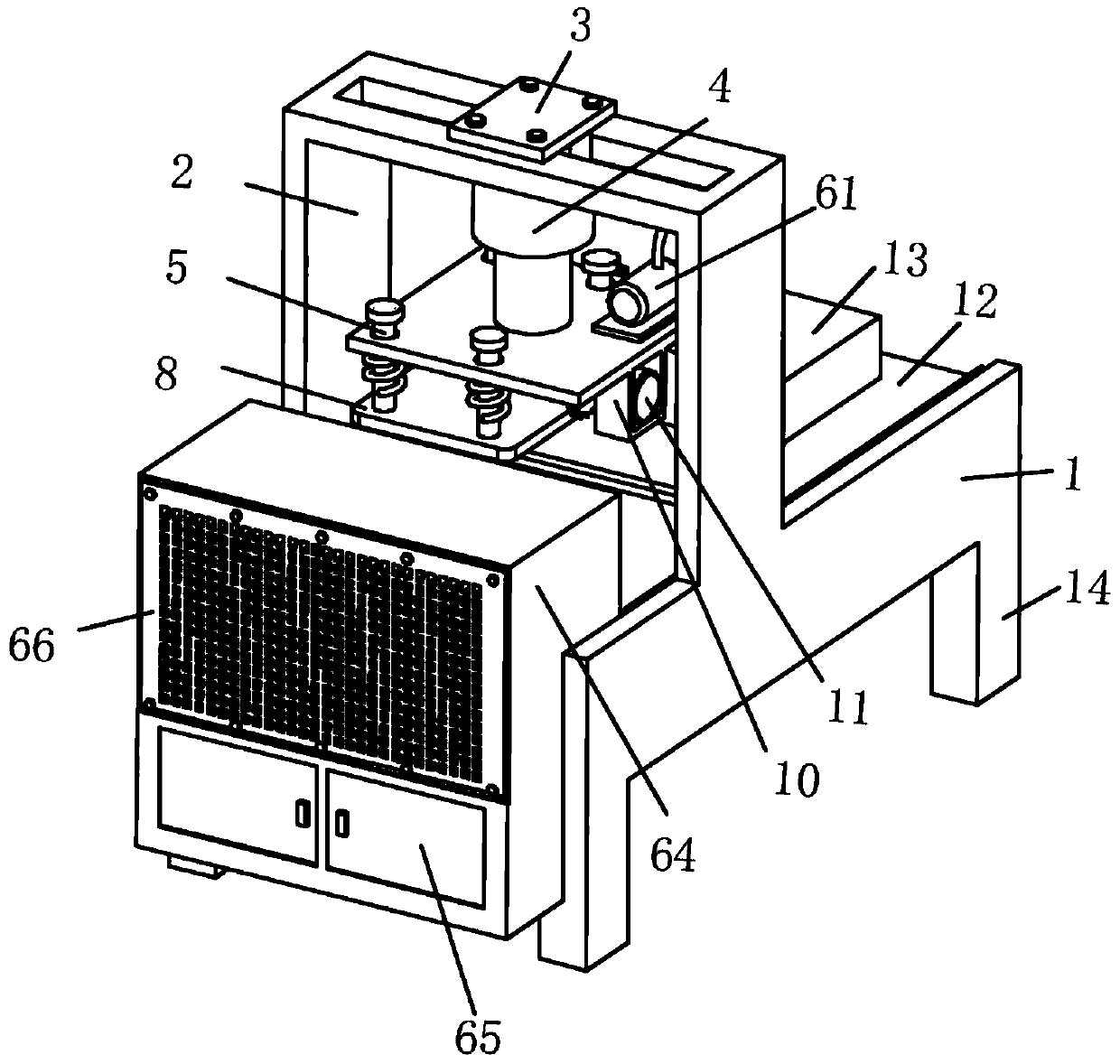

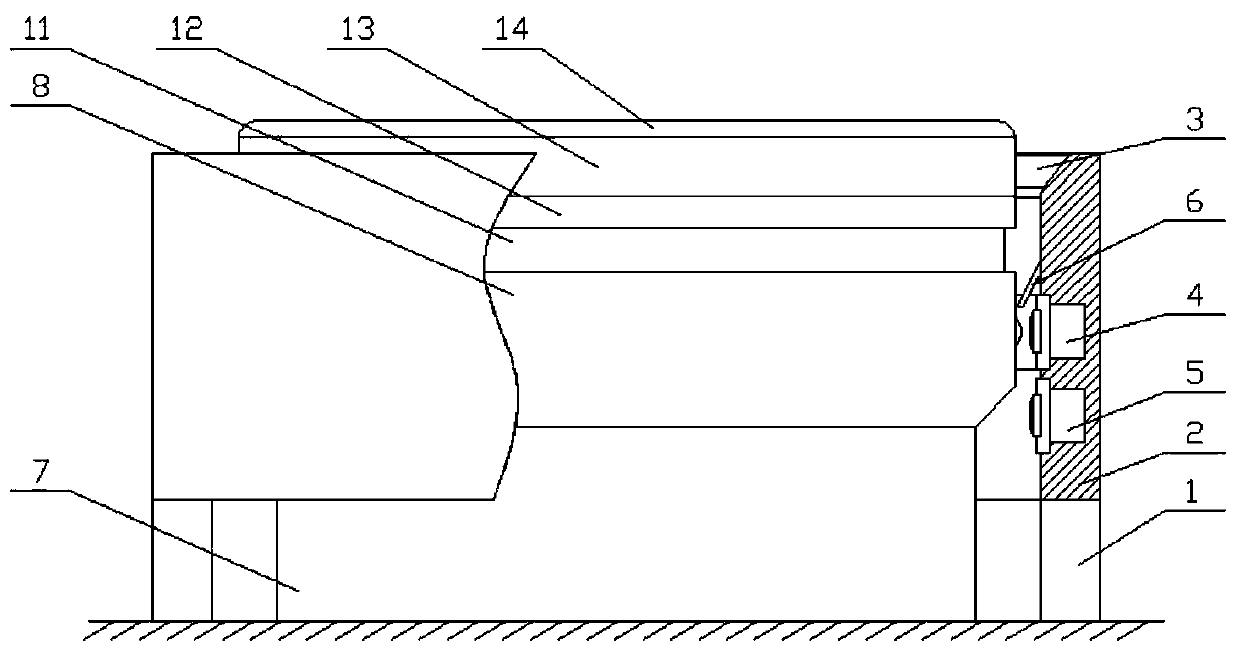

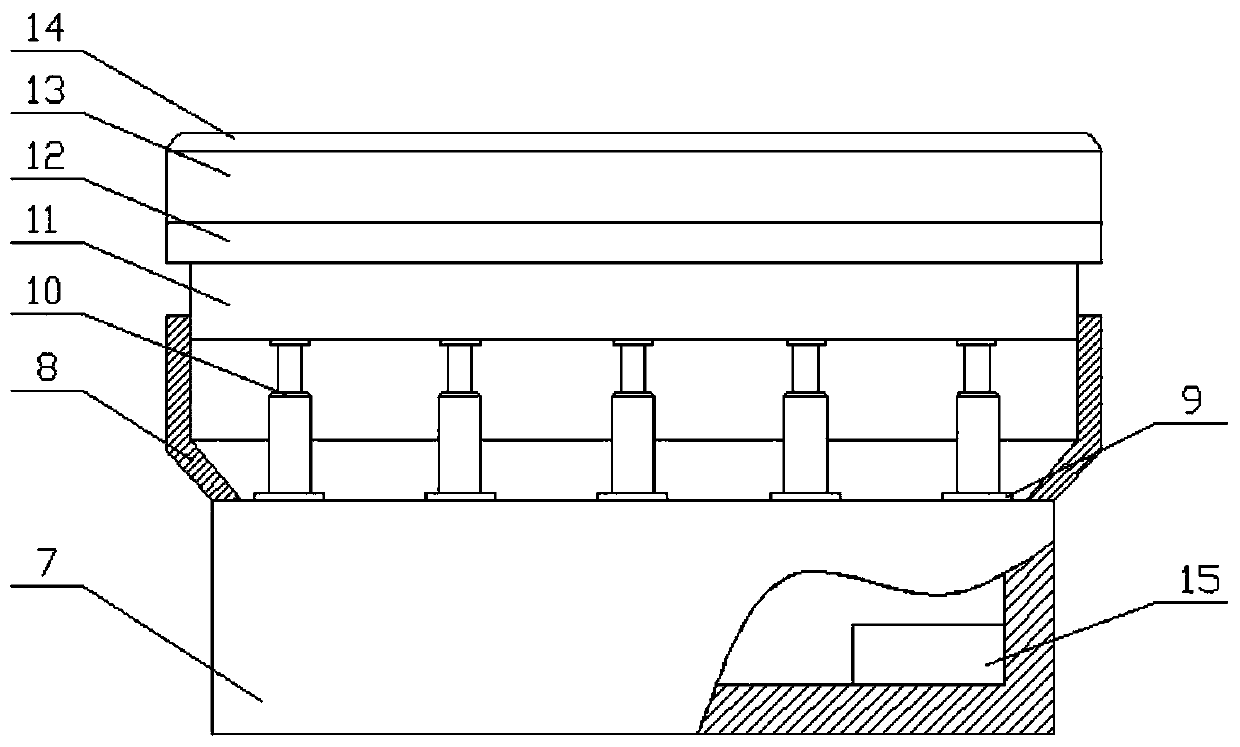

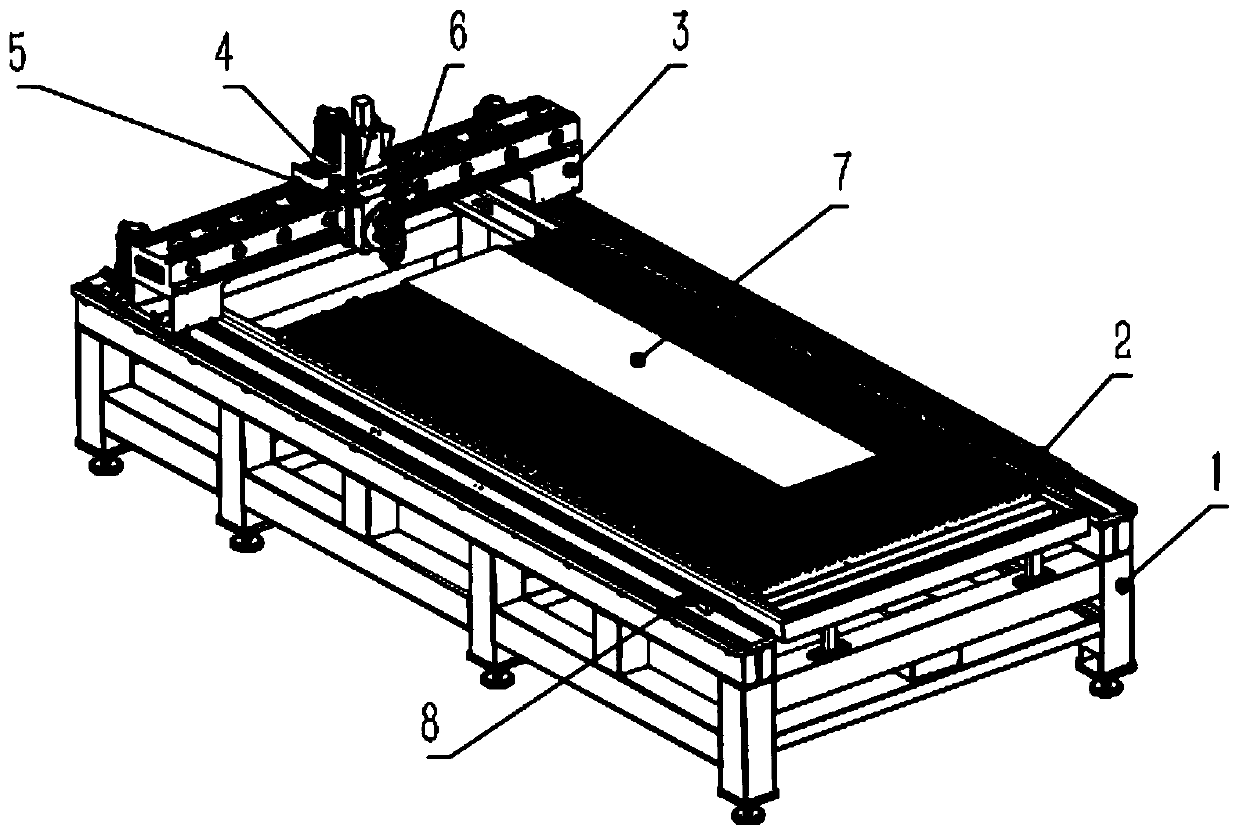

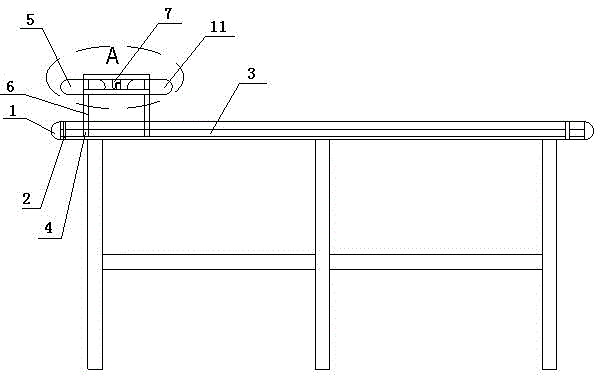

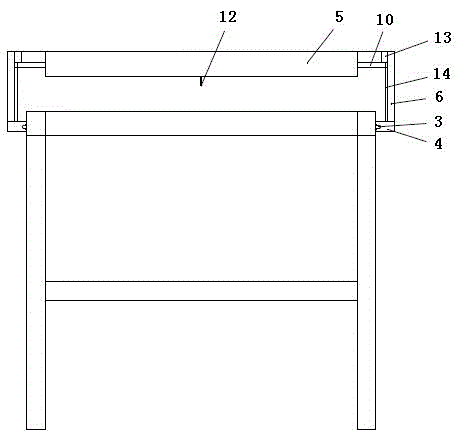

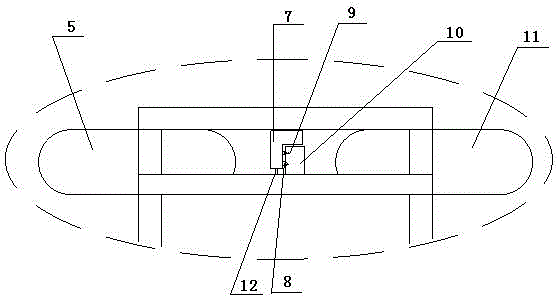

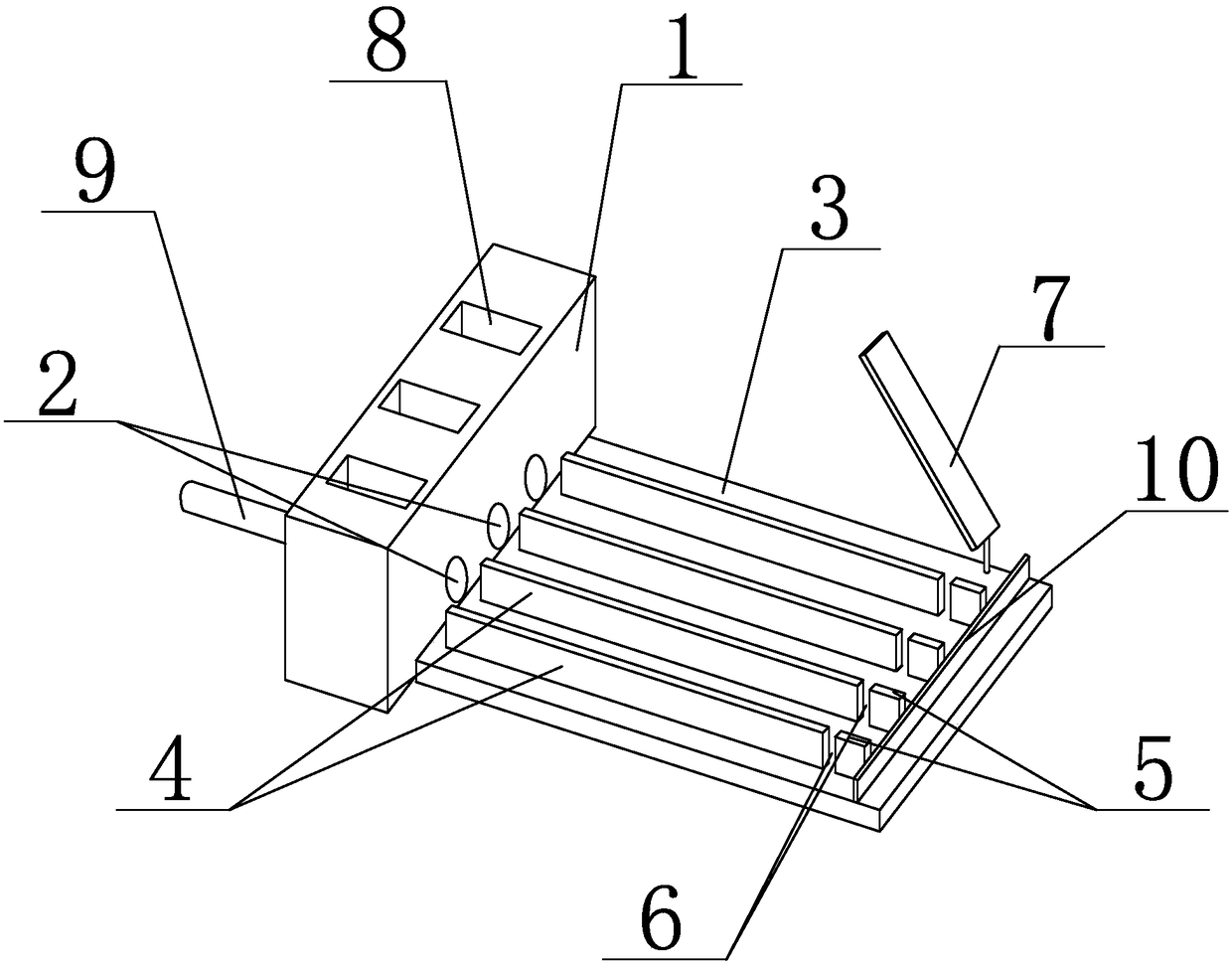

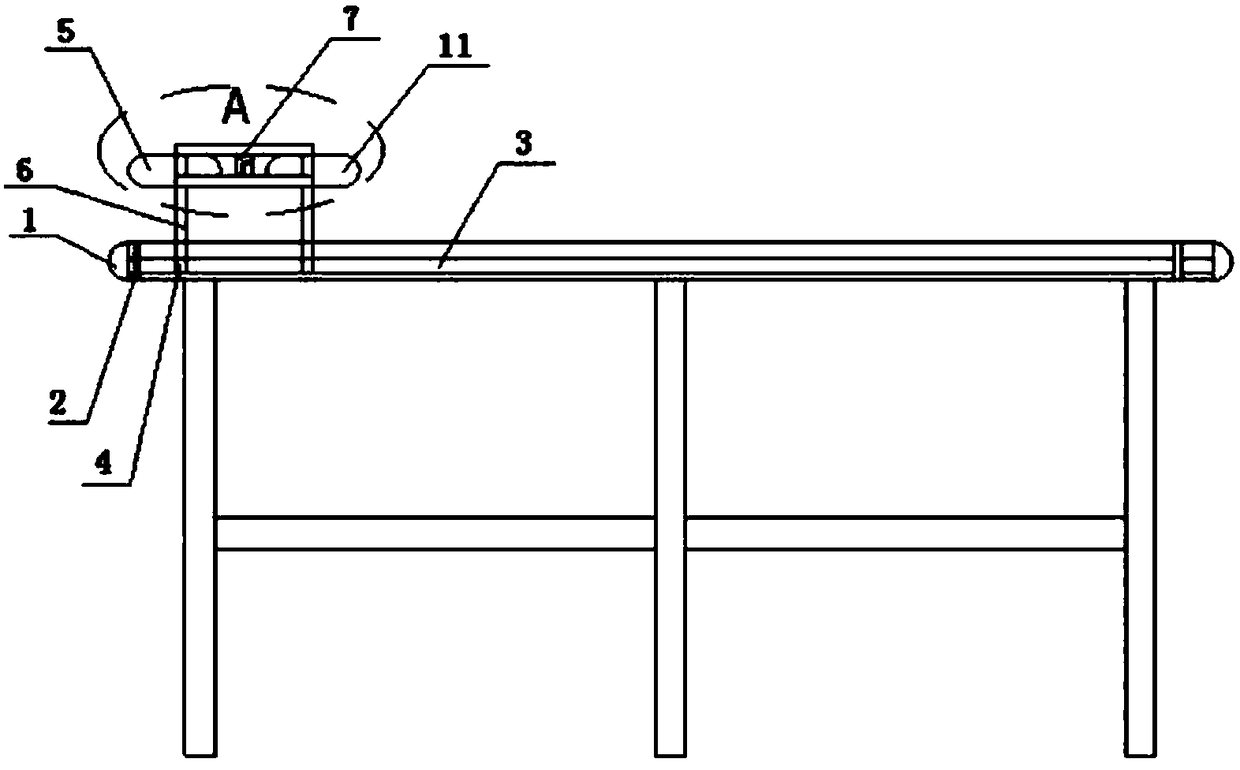

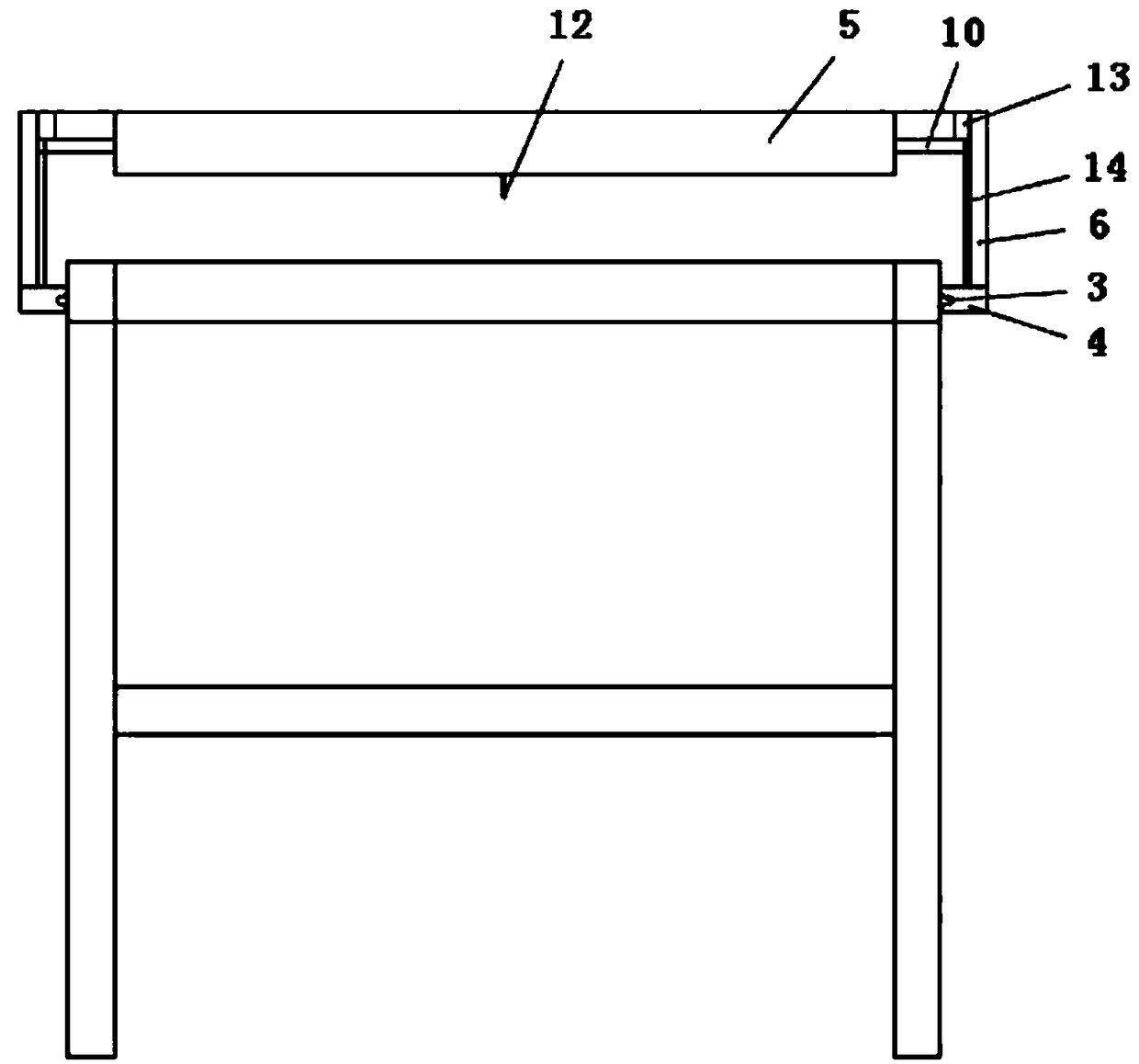

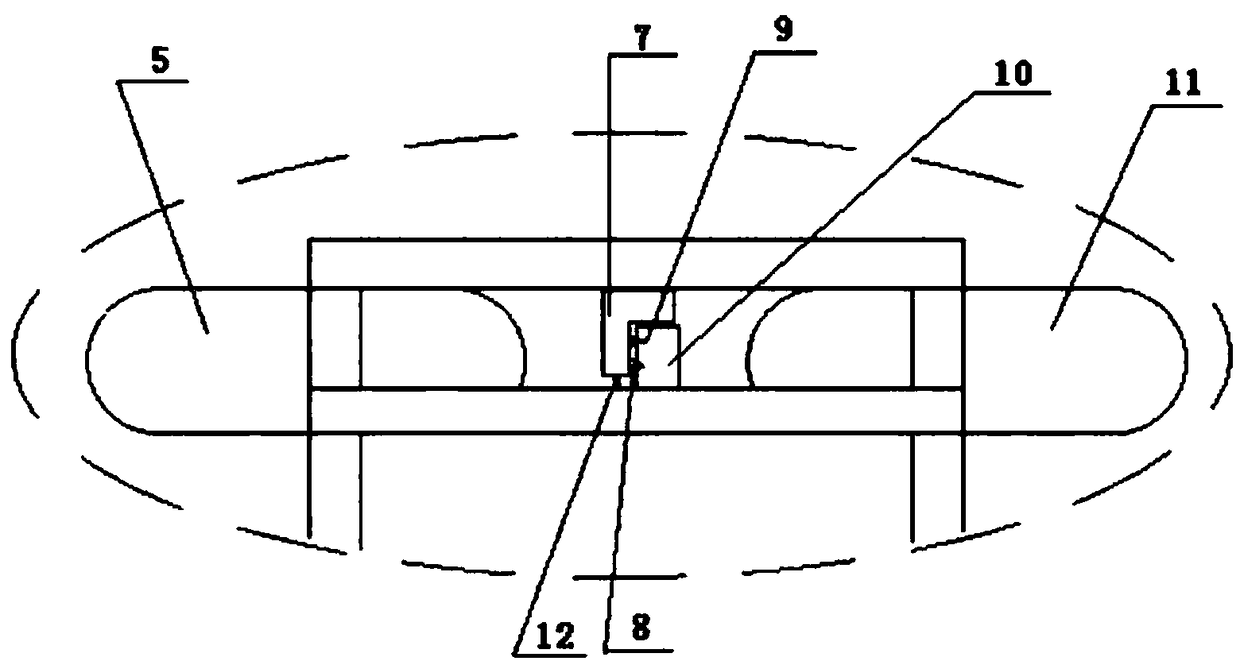

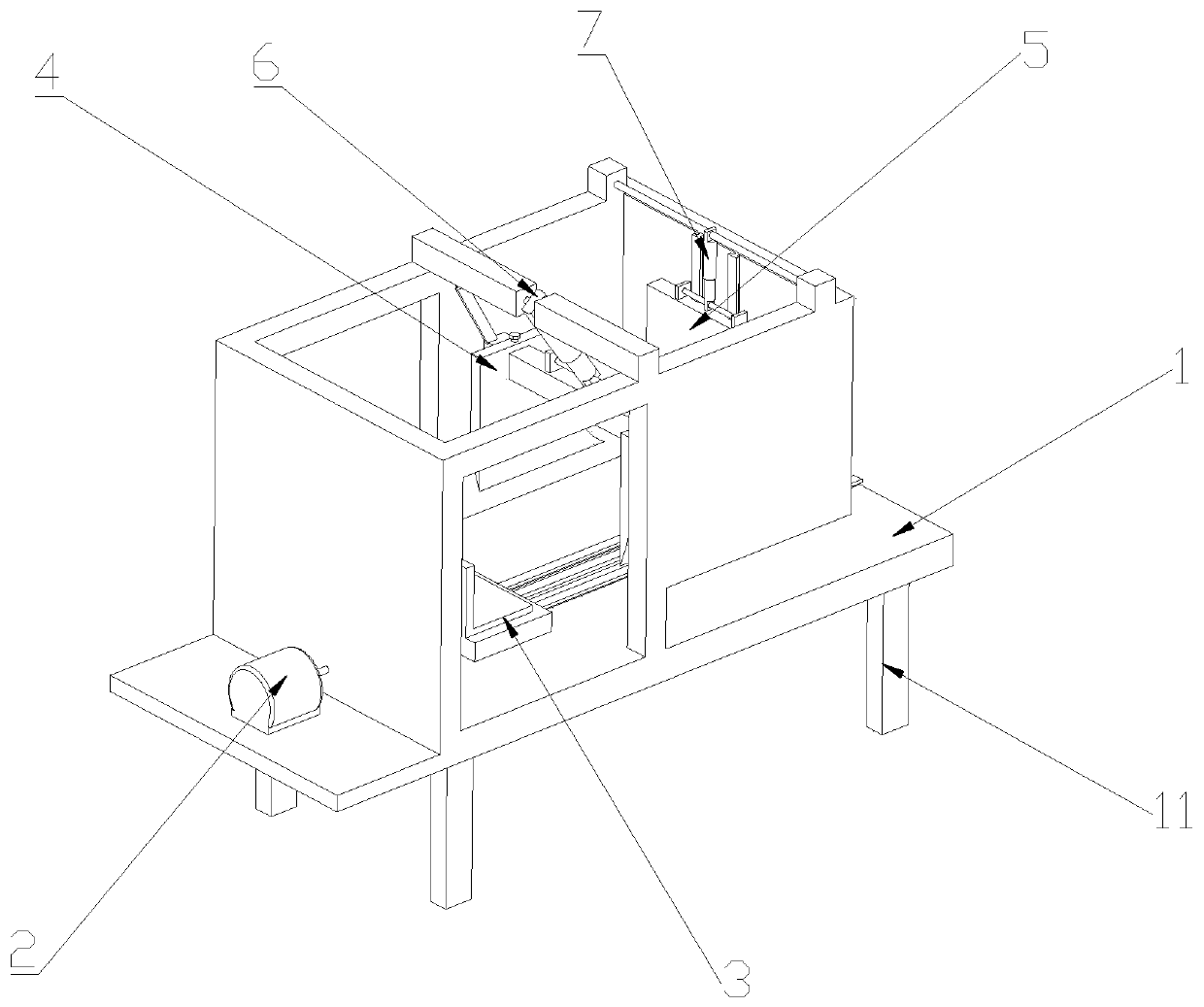

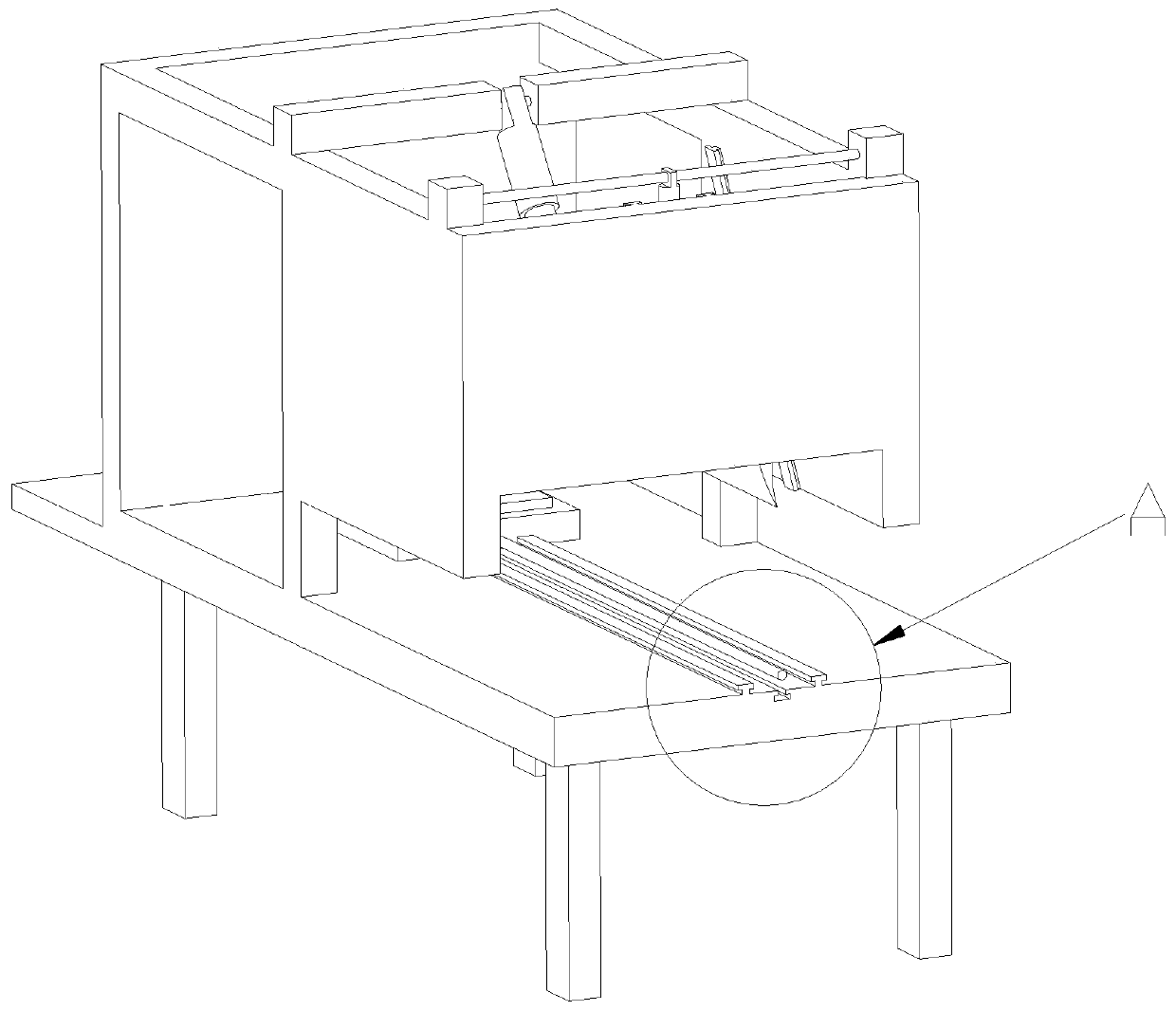

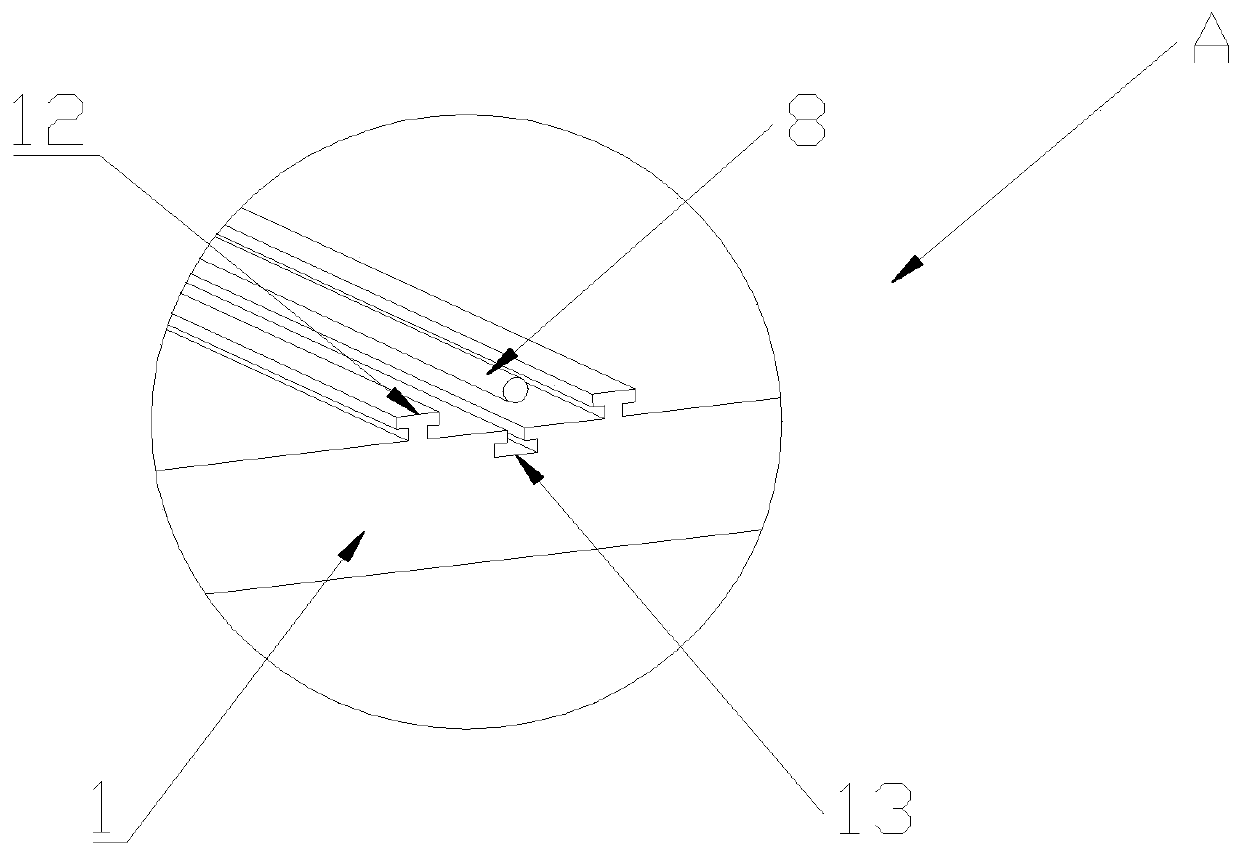

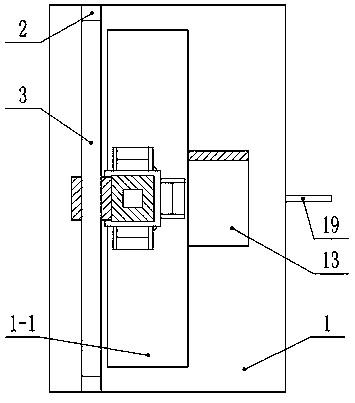

Worktable of cutting machine

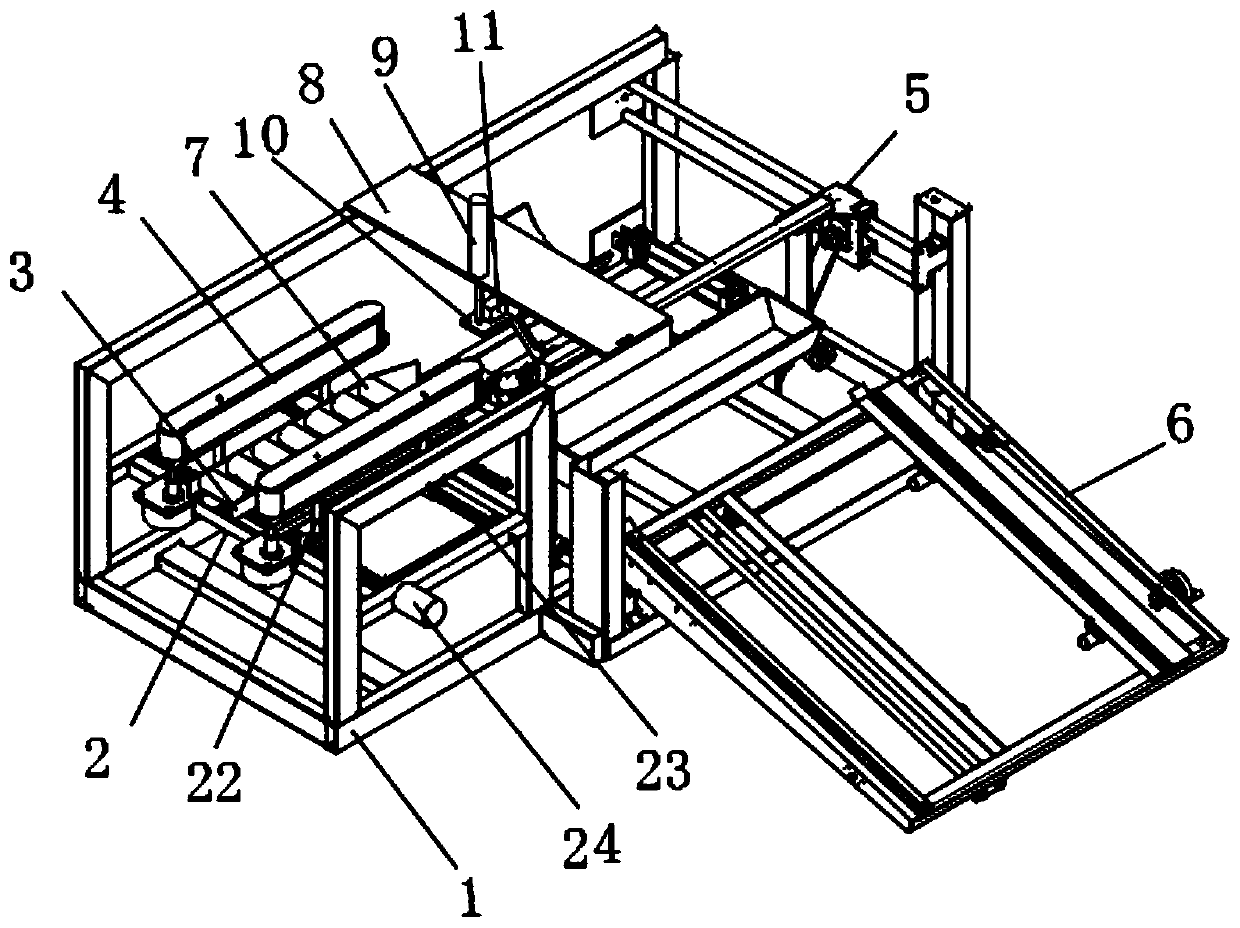

ActiveCN102632392ASmooth straight lineSmooth bending motionLarge fixed membersDrive shaftEngineering

A worktable of a cutting machine comprises a system bottom plate and a motor. A lead screw transmission shaft is horizontally arranged on the system bottom plate, a nut is fixedly sleeved on the outside of the lead screw transmission shaft and fixed to the lower portion of a lead screw and nut connecting plate, a moving substrate which is horizontally arranged, positioned above the lead screw transmission shaft and spaced from the lead screw transmission shaft is fixed to the top of the lead screw and nut connecting plate, a transmission plate and a moving platform are arranged above the moving substrate by a distance, the transmission plate is parallel to the moving substrate, the moving platform is horizontally supported on the upper side of the transmission plate and is spaced from the transmission plate, and a guide plate is further horizontally disposed between the transmission plate and the moving platform. The worktable not only can be used for cutting straight materials, but also can be used for cutting bent materials, the frequency of change among the straight materials and the bent materials is reduced, switching time is greatly saved, labor intensity is reduced, the safety of a product is improved, the service life of the product is prolonged, and the cutting precision of the product is guaranteed.

Owner:NINGBO XINTAI MACHINERY

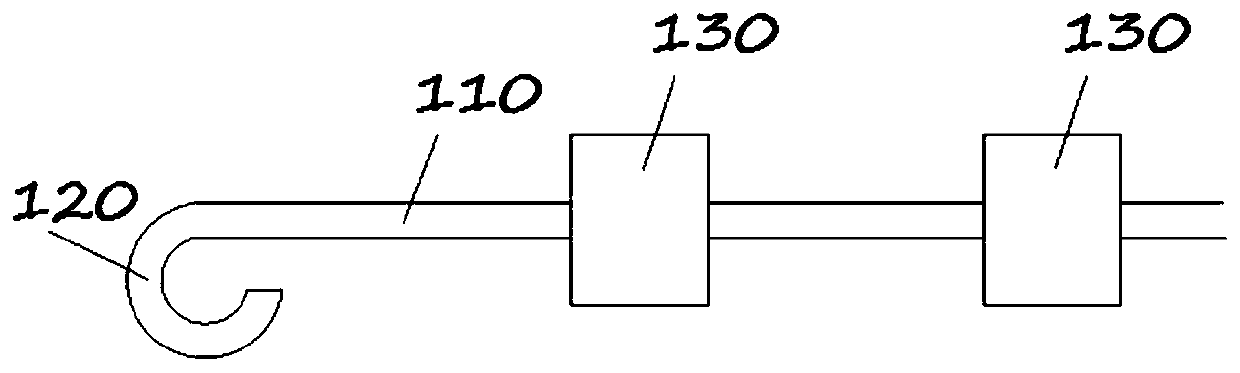

Cutting device for label medium of handheld label printer

InactiveCN102862719AEfficient cuttingMeet cuttingManual label dispensersTransverse groovePulp and paper industry

Owner:SOUTH CHINA UNIV OF TECH

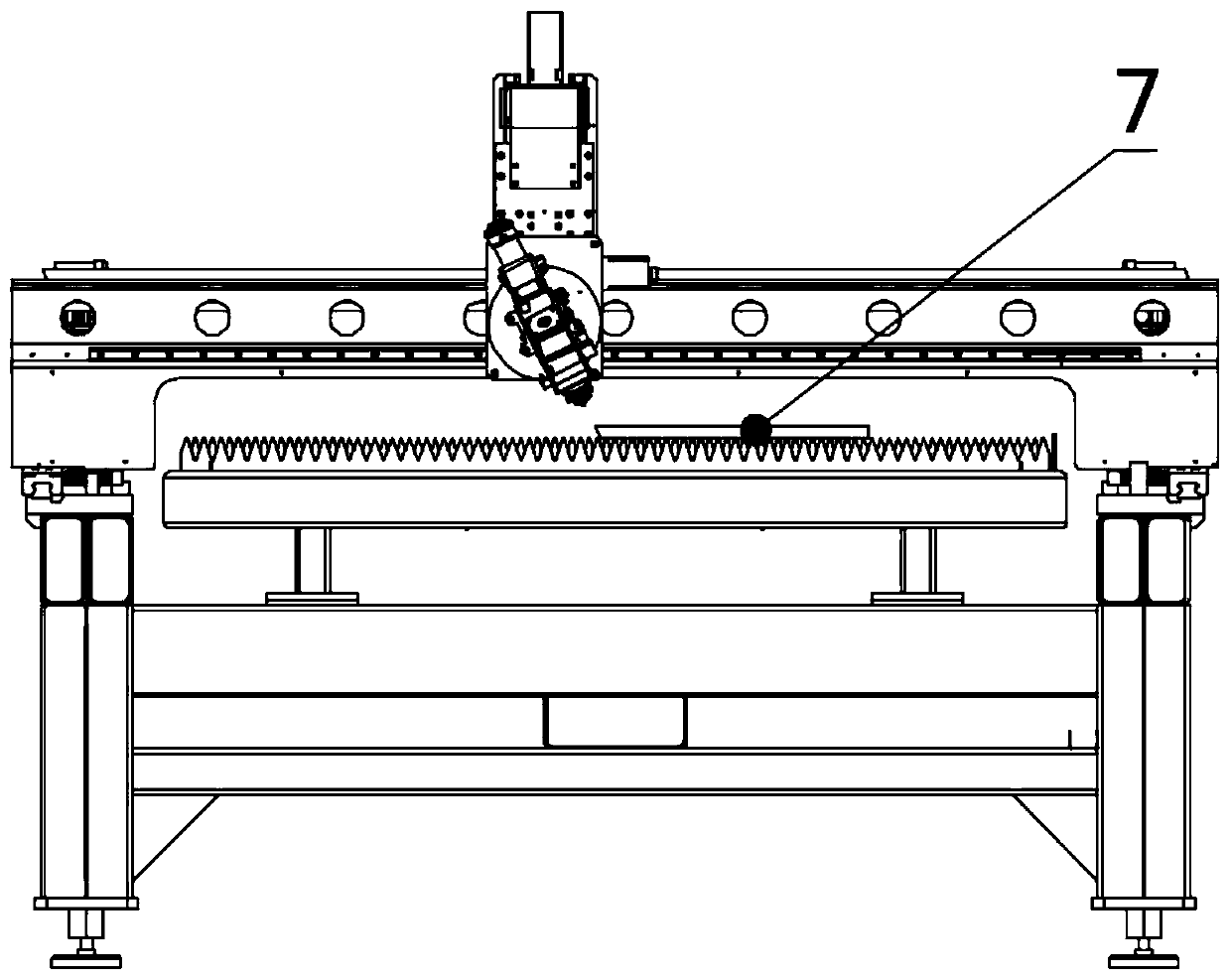

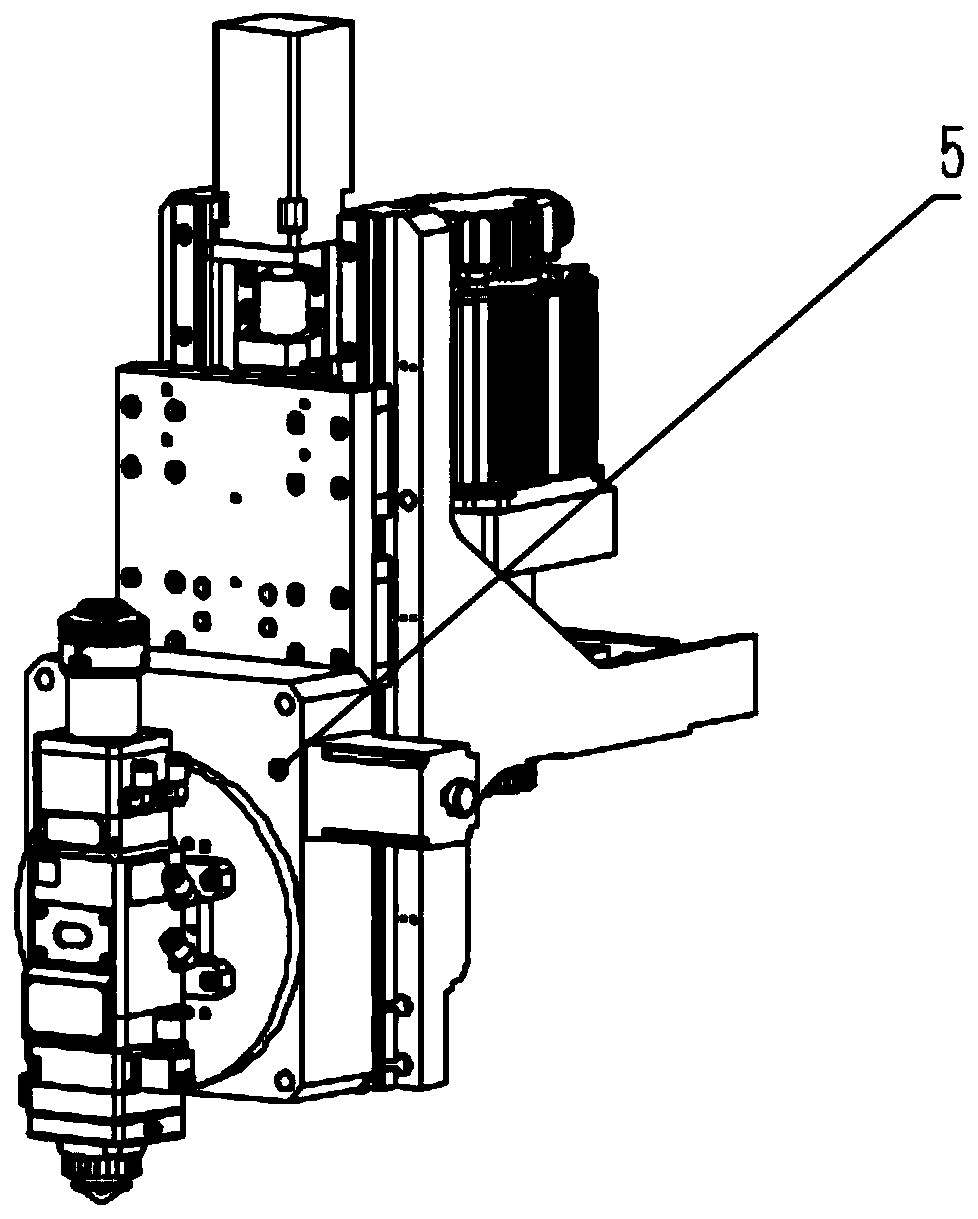

Laser cutting machine with rotatable laser head

InactiveCN111037116AMeet cuttingAchieve left and right swingLaser beam welding apparatusGear wheelEngineering

The invention relates to the technical field of plate processing accessory devices, in particular to a laser cutting machine with a rotatable laser head, and can meet the cutting requirement of a common plate and can also meet the cutting requirement of a workpiece with an angle on the cutting surface. The laser cutting machine comprises a machine body assembly, a linear sliding rail, a cross beamassembly, a machine head assembly, a laser head rotating device, a laser cutting device, a to-be-machined workpiece and a gear rack assembly. The linear sliding rail and the gear and rack assembly are both installed on the machine body assembly, the cross beam assembly is installed on the linear sliding rail in a sliding mode, the machine head assembly is installed on the cross beam assembly, thelaser head rotating device is installed on the machine head assembly, and the laser cutting device is installed on the laser head cutting device.

Owner:山东大图数控设备有限公司

Rapid hand-cranking egg cutting device

A rapid hand-cranking egg cutting device comprises a handle, a connecting rod, a transmission shaft, an upper cylindrical cam, a lower cylindrical cam, a tool rest, a guiding flat key, a fastening screw, a sawtooth-shaped cutter, an upper base, an upper egg base, a lower base, a lower egg base, guide columns, nuts, limiting blocks, a small spring and a big spring. The rapid hand-cranking egg cutting device is novel in structure, high in egg cutting efficiency and good in safety; different kinds of eggs can be cut by replacing different upper egg bases and lower egg bases and debugging other parameters, and the application range is wide; the sawtooth-shaped cutter is adopted, and thus edge cutting is more effortless; and the damage to the edge of an eggshell is minimized after an egg is cut, and the separation faces of the egg are flat and attractive.

Owner:HARBIN UNIV OF SCI & TECH

Cutting device for hollow fabric prepreg

ActiveCN105538373AMeet cuttingEliminate the processing steps of secondary cuttingMetal working apparatusEngineeringSurface layer

The invention relates to a cutting device for hollow fabric prepreg, which comprises a first rolling vacuum-adsorption platform, a second rolling vacuum-adsorption platform, a third rolling vacuum-adsorption platform, a movable bracket, a cutter holder and a cutter mounted on the cutter holder, wherein the movable bracket is arranged on the first rolling vacuum-adsorption platform in a sliding way; a transverse fixed beam is arranged on the movable bracket, and the cutter holder is mounted on the transverse fixed beam in a sliding way; and the second rolling vacuum-adsorption platform and the third rolling vacuum-adsorption platform are both mounted on the movable bracket and are mounted on two sides of the cutter holder respectively. The cutting device is dedicated to the hollow fabric prepreg, can satisfy aligned cutting of an upper surface layer and a lower surface layer at a time, and omits the processing procedure of secondary cutting required in the prior art.

Owner:NANJING FIBERGLASS RES & DESIGN INST CO LTD

Slicing machine capable of improving medicinal material uniformity

InactiveCN108501074AIncrease productivityQuality improvementMetal working apparatusSlice thicknessEngineering

The invention discloses a slicing machine capable of improving the medicinal material uniformity. The slicing machine capable of improving the medicinal material uniformity comprises a material conveying platform. Multiple material conveying holes penetrating through the two side faces of the material conveying platform are formed in the side wall of the material conveying platform. One end of thematerial conveying holes is provided with a horizontally arranged slicing work plate. Multiple partition plates are perpendicularly arranged on the slicing work plate. The end, far away from the material conveying platform, of each partition plate is provided with a dimension clamping plate. A cutting opening is formed between each dimension clamping plate and the corresponding partition plate. Acutter is arranged over the cutting openings. The top face of the material conveying platform is provided with multiple material inlets. Each material inlet communicates with the material conveying holes. The end, far away from the slicing work plate, of the material conveying holes is provided with a parallel push rod. The end, far away from the partition plates, of the dimension clamping plateis perpendicularly provided with a limiting plate. The slicing machine capable of improving the medicinal material uniformity can automatically slice the traditional Chinese medicinal materials, improves the production efficiency, achieves uniform slicing, guarantees that the thicknesses of all the slices are identical and improves the product quality; and meanwhile, since the slicing thickness can be adjusted according to needs, the slicing machine capable of improving the medicinal material uniformity can meet the requirements for machining of slices of different thicknesses.

Owner:四川西蜀九锦现代中药有限公司

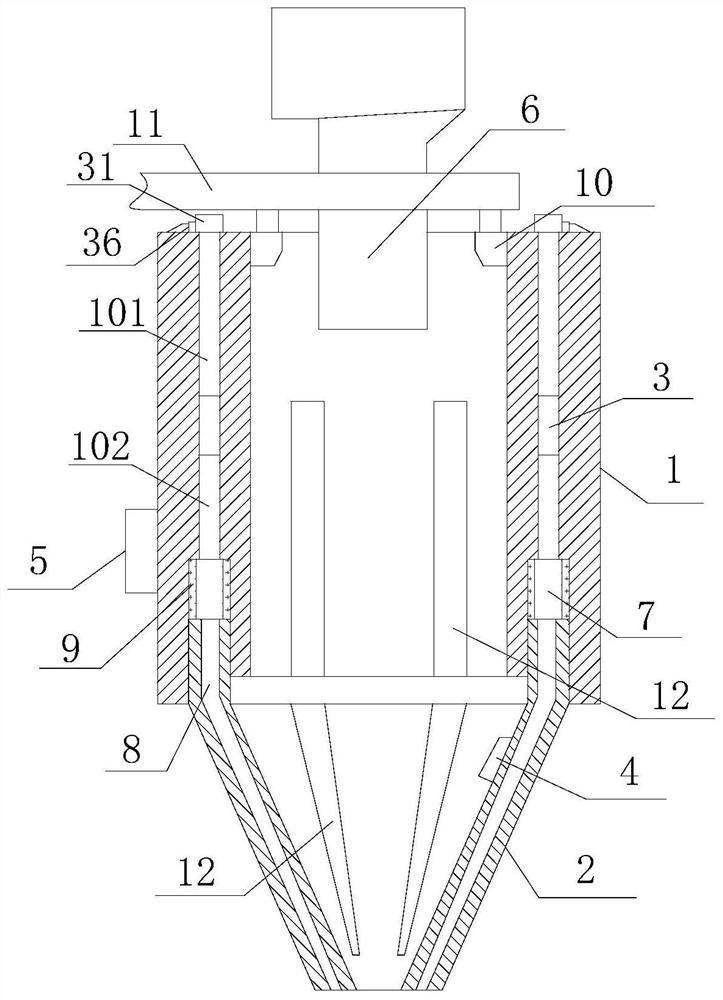

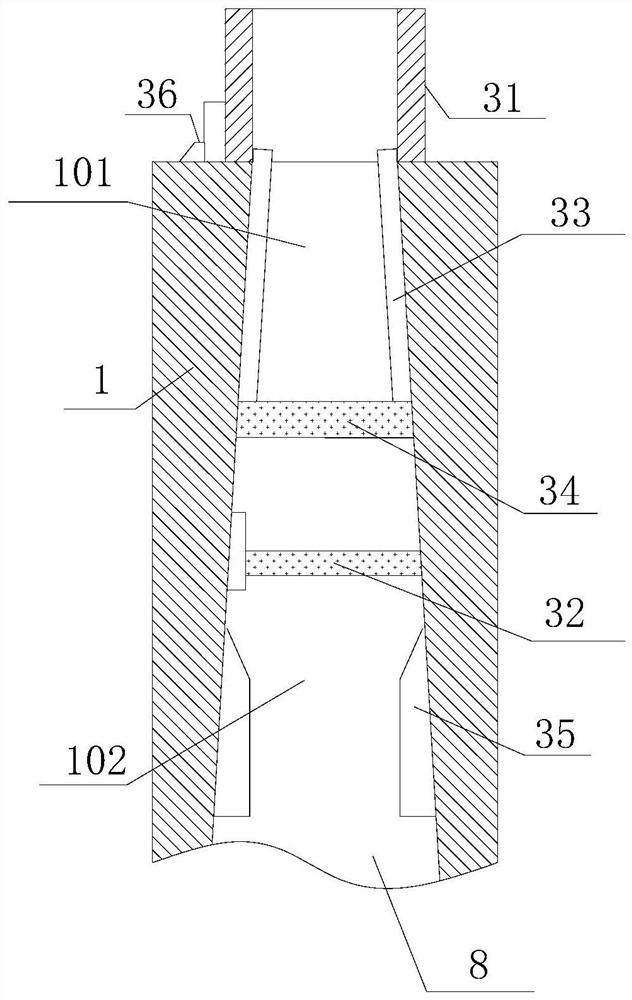

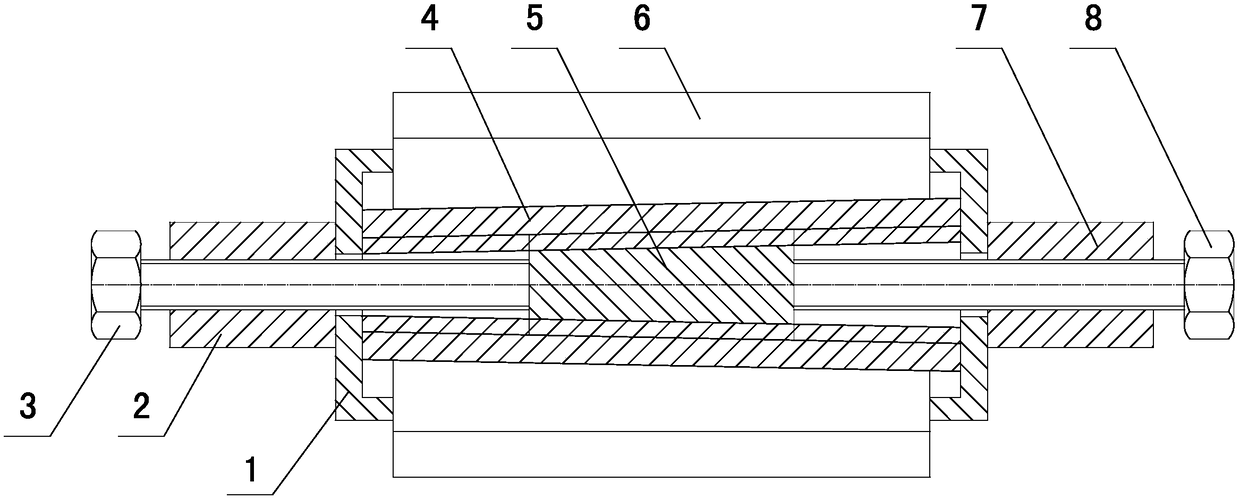

A ring nozzle for laser and its application method

ActiveCN112122807BEasy to monitorHigh precisionLaser beam welding apparatusLaser processingOptical axis

The invention provides an annular nozzle for a laser, which includes a positioning adjustment sleeve, a molding sleeve, an adjustment mechanism and a control circuit. There are at least three diversion grooves evenly distributed around the optical axis of the laser head, and an adjustment mechanism coaxially distributed with the diversion groove is provided in the diversion groove of the positioning adjustment sleeve. The adjustment mechanism includes a guide tube, a load spring, an elastic film sheet, piston plate, demister and pressure sensor. Its use method includes two steps of equipment assembly and laser operation. On the one hand, the present invention can effectively meet the needs of synchronous matching operation with various structural types of lasers, and can effectively meet the needs of various laser welding, cutting and pyrolysis operations; on the other hand, it greatly improves the monitoring and control of laser processing operations. Manipulation and control precision, and effectively improve the degree of automation of operation.

Owner:安徽中科春谷激光产业技术研究院有限公司

Cutting roller for cutting leftover materials of resin tiles

ActiveCN109015427AMeet cuttingEasy to adjust the radial sizeBonded abrasive wheelsEngineeringMechanical engineering

The invention relates to a cutting roller for cutting leftover materials of resin tiles. The cutting roller for cutting the leftover materials of the resin tiles comprises a cutting roller shaft, wherein a first connecting shaft is horizontally arranged at the left end of the cutting roller shaft; a second connecting shaft is horizontally arranged at the right end of the cutting roller shaft; a cone-shaped body is horizontally arranged in the cutting roller shaft; a plurality of cone-shaped bearing bushes are arranged on the excircle of the cone-shaped body; a tension spring is arranged between each two adjacent cone-shaped bearing bushes; the cone-shaped bearing bushes sleeve on the cone-shaped body through the tension springs; a cutting knife is fixed onto each corresponding cone-shapedbearing bush; a cutting head of each cutting knife penetrates through the cutting roller shaft; a first adjusting screw is horizontally arranged on the first connecting shaft in a penetrating way; theend head of the first adjusting screw is pressed against the left side end surface of the cone-shaped body; a second adjusting screw is horizontally arranged on the second connecting shaft in a penetrating way; the end head of the second adjusting screw is pressed against the right side end surface of the cone-shaped body. The cutting roller for cutting the leftover materials of the resin tiles provided by the invention can meet the requirement on cutting the resin tiles with different thicknesses.

Owner:XUANCHENG GUIXIN NEW MATERIAL CO LTD

Weed salvage device

ActiveCN111496681BQuick and labor-saving salvageGuarantee the speed of salvageBlast gunsWater cleaningFisheryStructural engineering

The invention relates to a fishing device for aquatic plants, which comprises brackets on both sides and a nozzle cutting mechanism between the two brackets, each bracket is provided with a hook-shaped structure at the front end, and the nozzle cutting mechanism is used to The winding is cut, and it can be retracted along the front and back, and the front end is provided with a nozzle. The nozzle can move up and down in a circular arc within a preset angle range, and the two brackets are fixedly connected with the nozzle cutting mechanism. In the embodiment of the present invention, a nozzle cutting mechanism is provided between the two brackets with a hook structure, which can cut the entanglement between the two brackets, so that the salvage of aquatic plants is faster and labor-saving; by making the nozzle cutting mechanism can be Retractable back and forth, the device can be turned left and right to cut the wrappings individually wound on each support; by making the nozzle move back and forth in a circular arc up and down within the preset angle range, it can avoid reducing the cutting rate and increasing energy waste .

Owner:CHONGQING JIAOTONG UNIVERSITY +1

Cutting device for prepreg

The invention discloses a cutting device for prepreg, and relates to a first rolling vacuum adsorption platform, a second rolling vacuum adsorption platform, a third rolling vacuum adsorption platform, a movable support, a tool rest and a cutting tool mounted on the tool rest. The movable support is arranged on the first rolling vacuum adsorption platform in a sliding manner. A transverse fixed cross beam is arranged on the movable support, and the tool rest is mounted on the transverse fixed cross beam in a sliding manner. The second rolling vacuum adsorption platform and the third rolling vacuum adsorption platform are both mounted on the movable support and mounted on the two sides of the tool rest correspondingly. According to the cutting device, the upper surface and the lower surfaceof the hollow fabric prepreg are adsorbed and fixed by the first rolling vacuum adsorption platform, the second rolling vacuum adsorption platform and the third rolling vacuum adsorption platform correspondingly through the vacuum negative pressure effect, the tool rest moves back and forth on a transverse moving guide rail through a transverse moving guide rail sliding block, and the transversefixed cross beam vertically moves along a vertical moving guide rail through a vertical moving sliding block.

Owner:四川佳信绝缘材料有限公司

A cutting device for printed matter

The invention discloses a cutting device for printed matter. The cutting device comprises an operation platform, wherein the operation platform is provided with symmetrically distributed first T-shaped sliding blocks and a first T-shaped sliding groove, and the operating platform is provided with a sliding member. A first cutting member is disposed between second support plates, and the first cutting member includes a cutting shaft and first cutters. A third support plate is provided with a second cutter. A first hydraulic cylinder is disposed between a first rotating shaft and a third rotating shaft, and a second hydraulic cylinder is disposed between a second rotating shaft and a fourth rotating shaft. The cutting device cuts the printed matter successively through the first cutter and the second cutter to ensure the neatness during cutting, and the cutting device can meet the cutting requirements of the printed matter of different specifications by adjusting the feeding of the sliding member and the position of the first cutters on the cutting shaft.

Owner:JIESHOU CITY CHANGXING PRINTING PACKAGING CO LTD

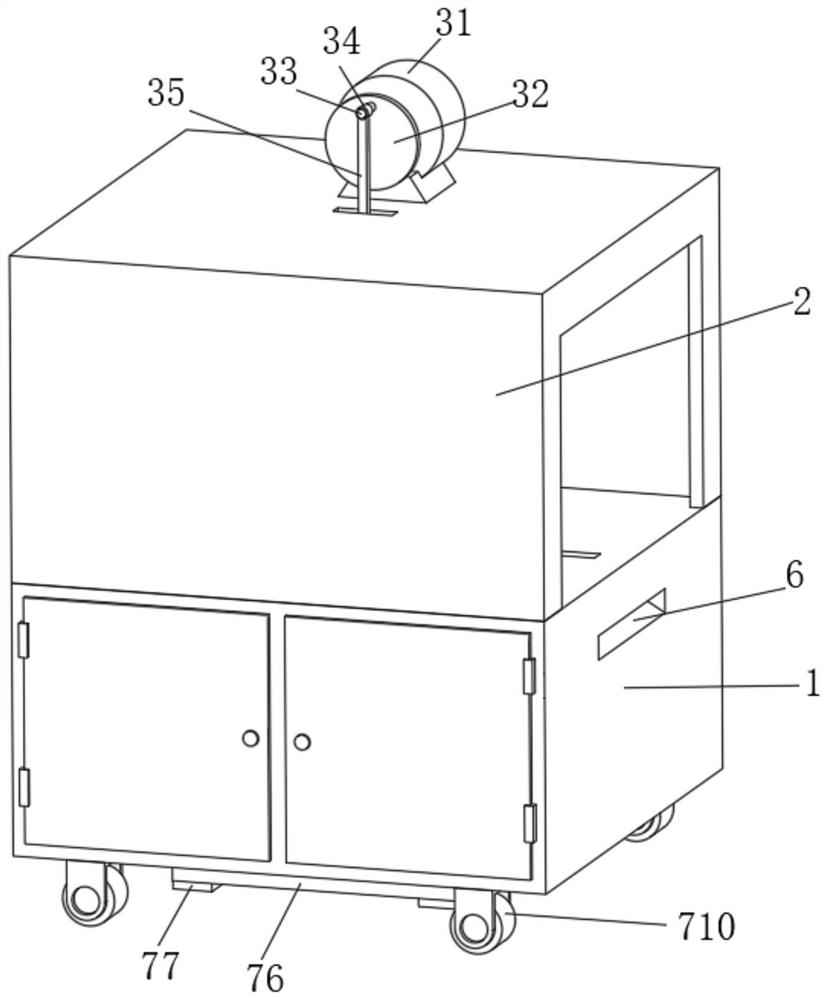

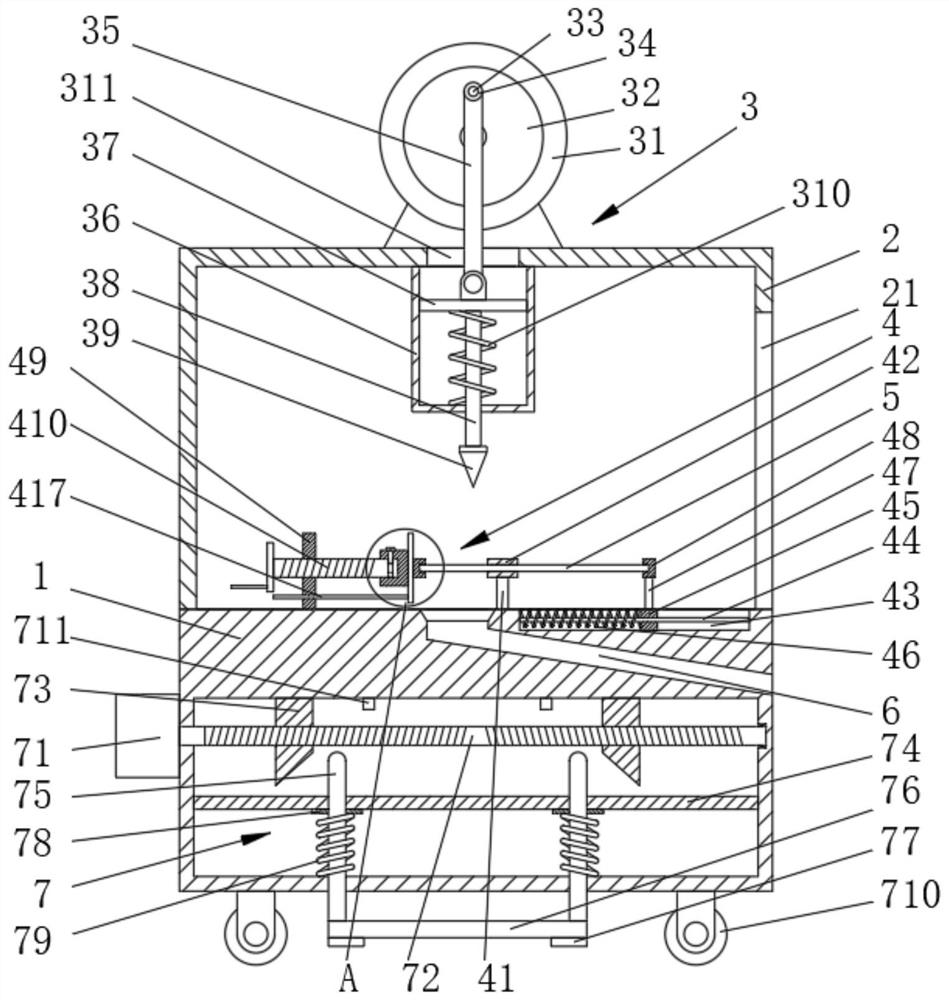

Automatic section cutting device for glasses arm support machining

PendingCN114274206AImprove applicabilityMobilityMetal working apparatusHand cart accessoriesPhysicsEngineering

The automatic section cutting device comprises a machine body, a machine shell, a cutting mechanism, a positioning mechanism, a blank, a discharging channel and a moving mechanism, the upper end of the machine body is fixedly connected with the machine shell, an operation window is formed in the machine shell, the cutting mechanism is arranged at the top of the machine shell, the machine body is provided with the positioning mechanism, and the positioning mechanism is arranged on the machine body. A discharging channel is formed in the machine body, a moving mechanism is arranged on the machine body, and four evenly-distributed rolling wheels are arranged at the bottom of the machine body. The invention relates to an automatic section cutting device for glasses arm support machining. The automatic section cutting device has the characteristics of being good in applicability and having mobility.

Owner:佛山市埃科机器人科技有限公司

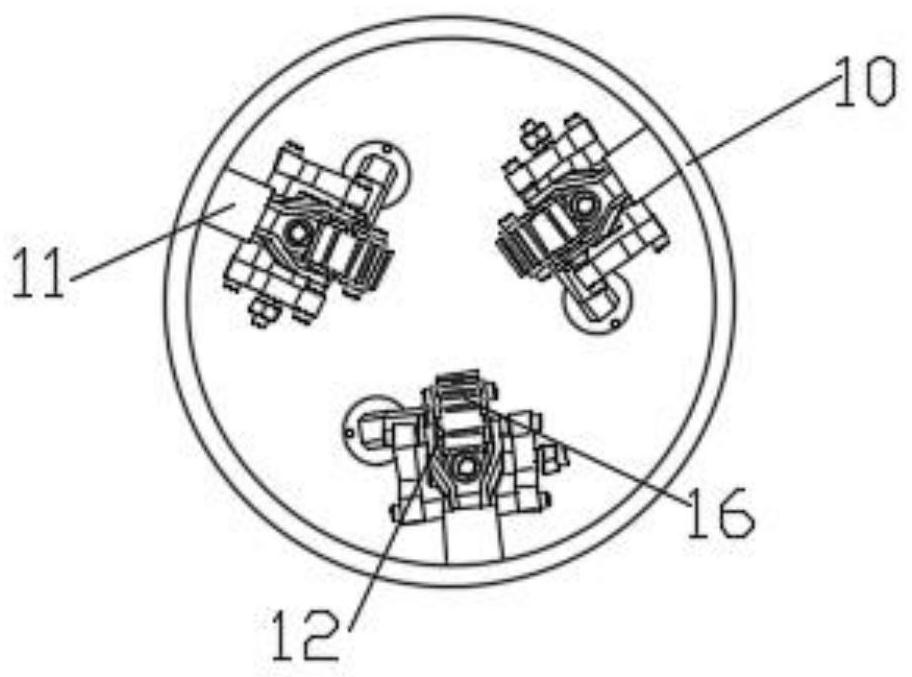

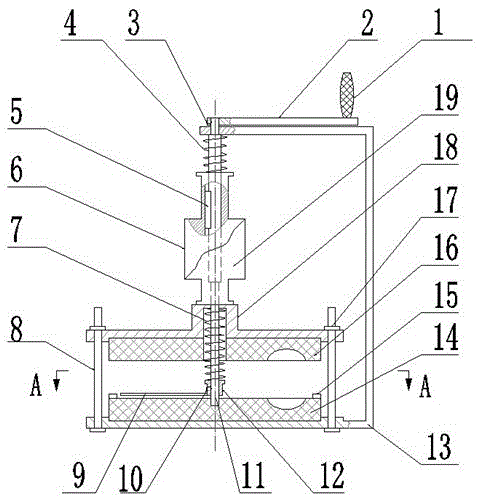

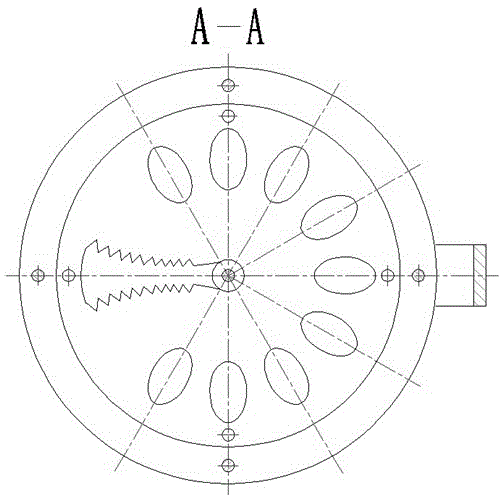

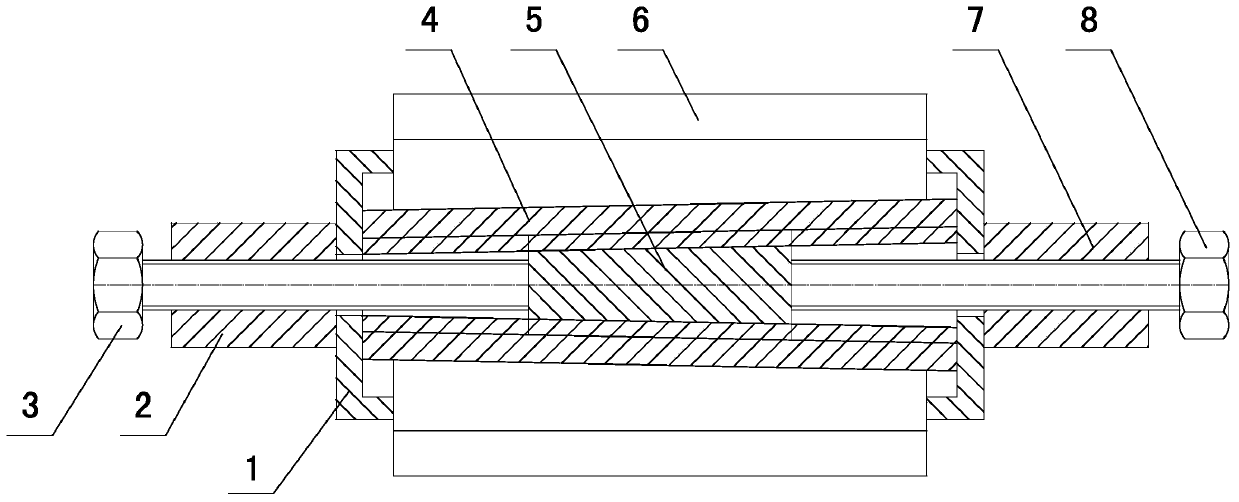

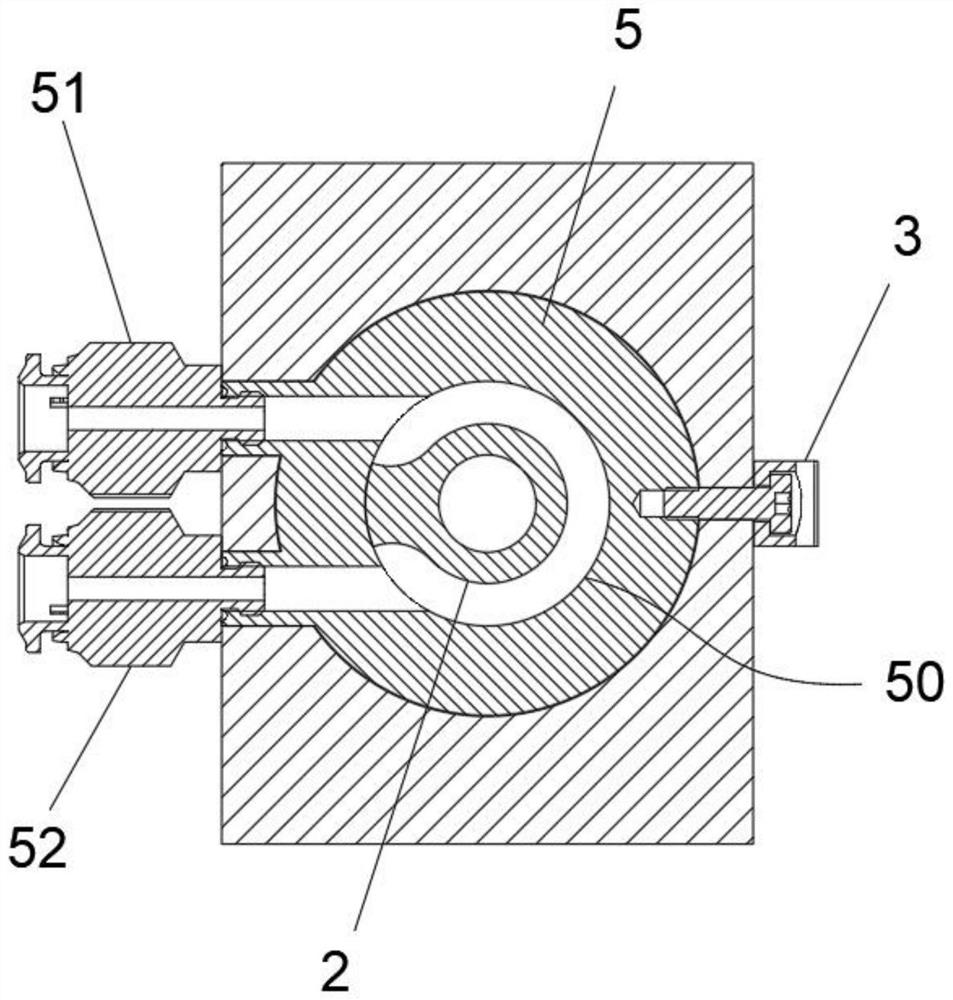

Circuit board V-cutting equipment based on adjusting assemblies and using method thereof

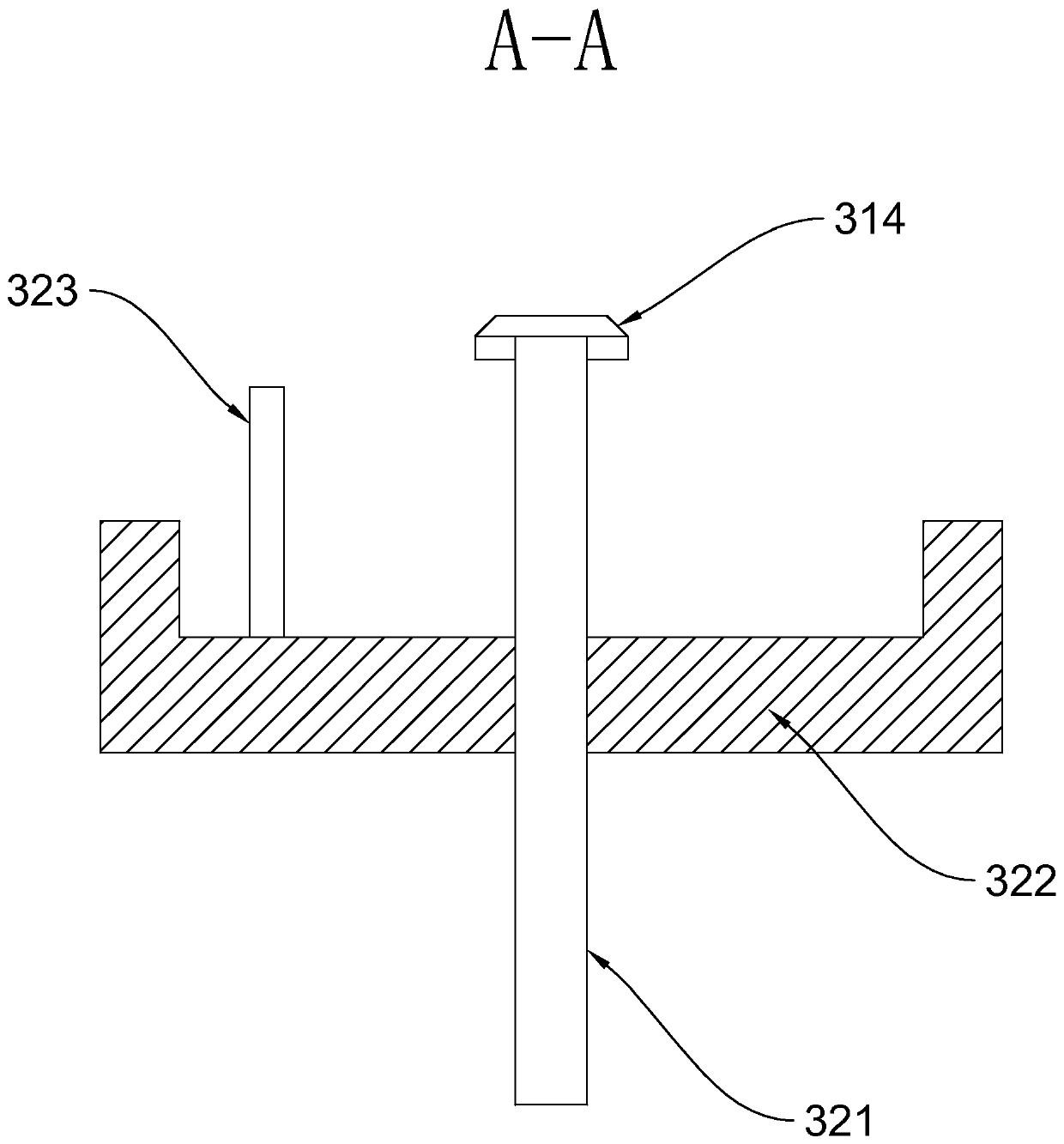

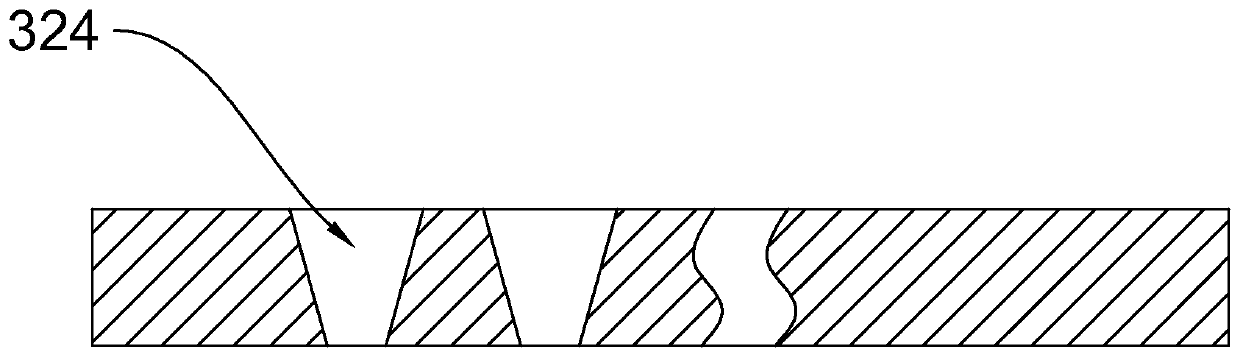

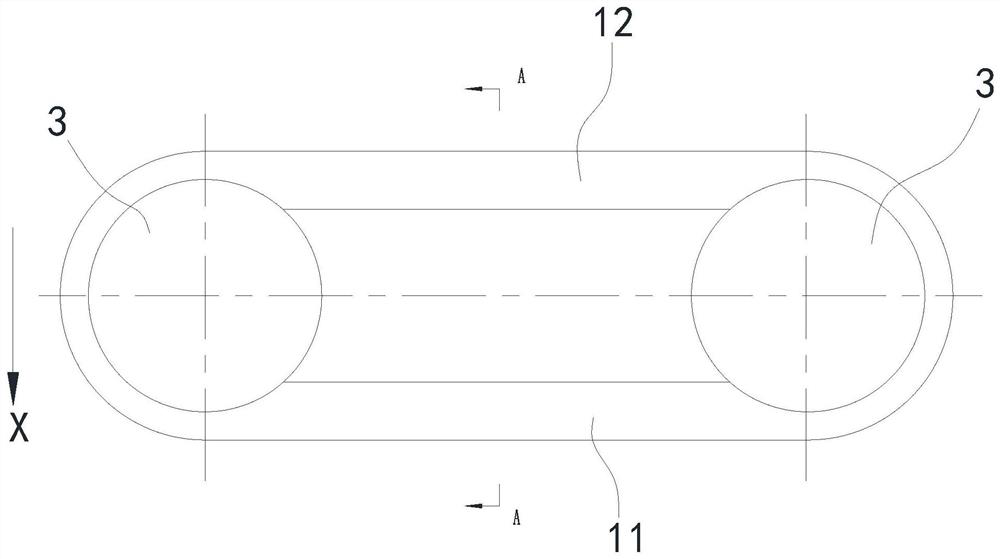

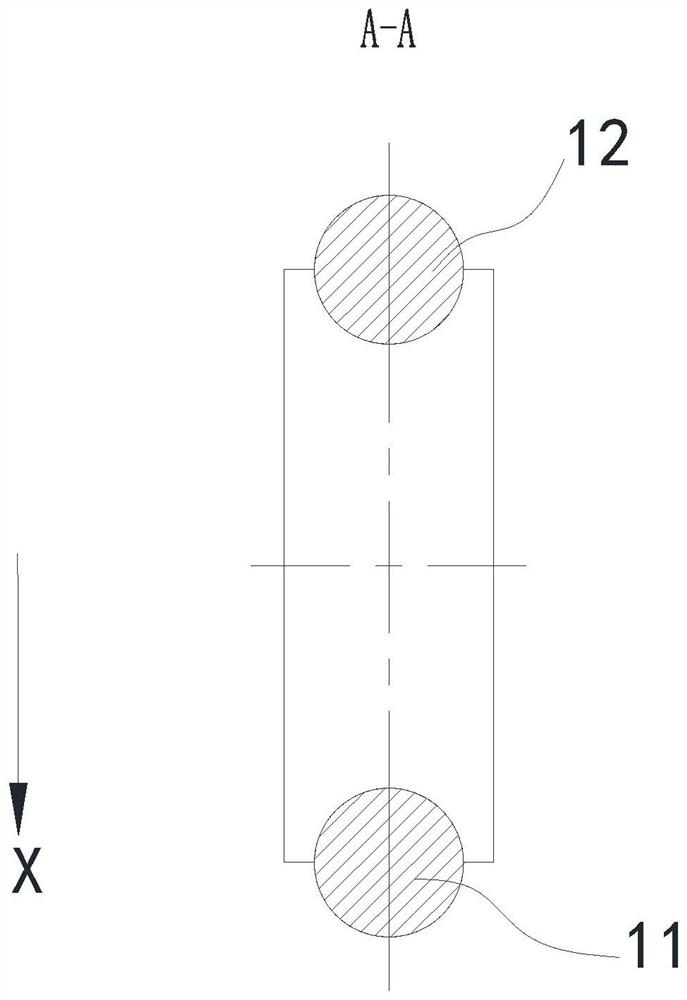

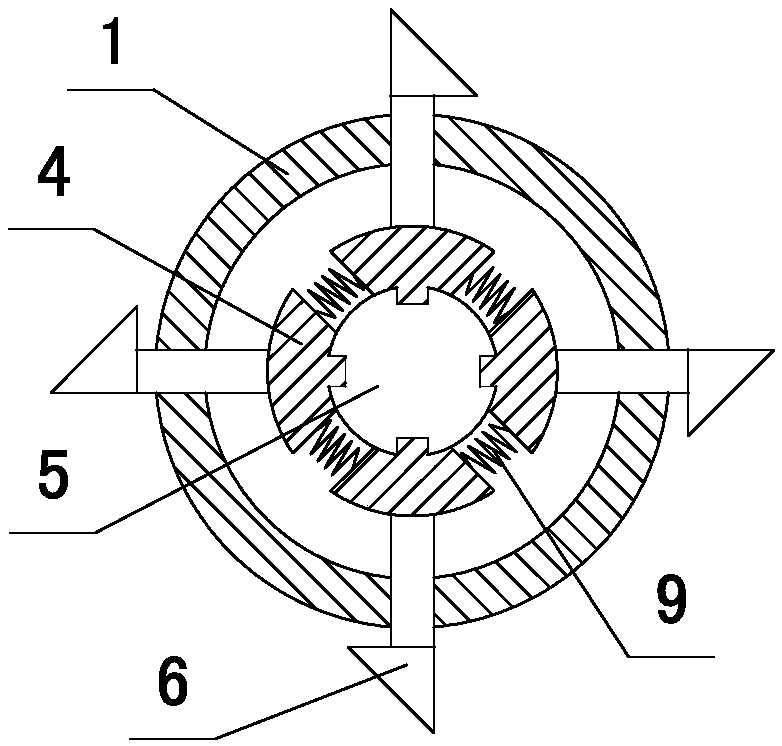

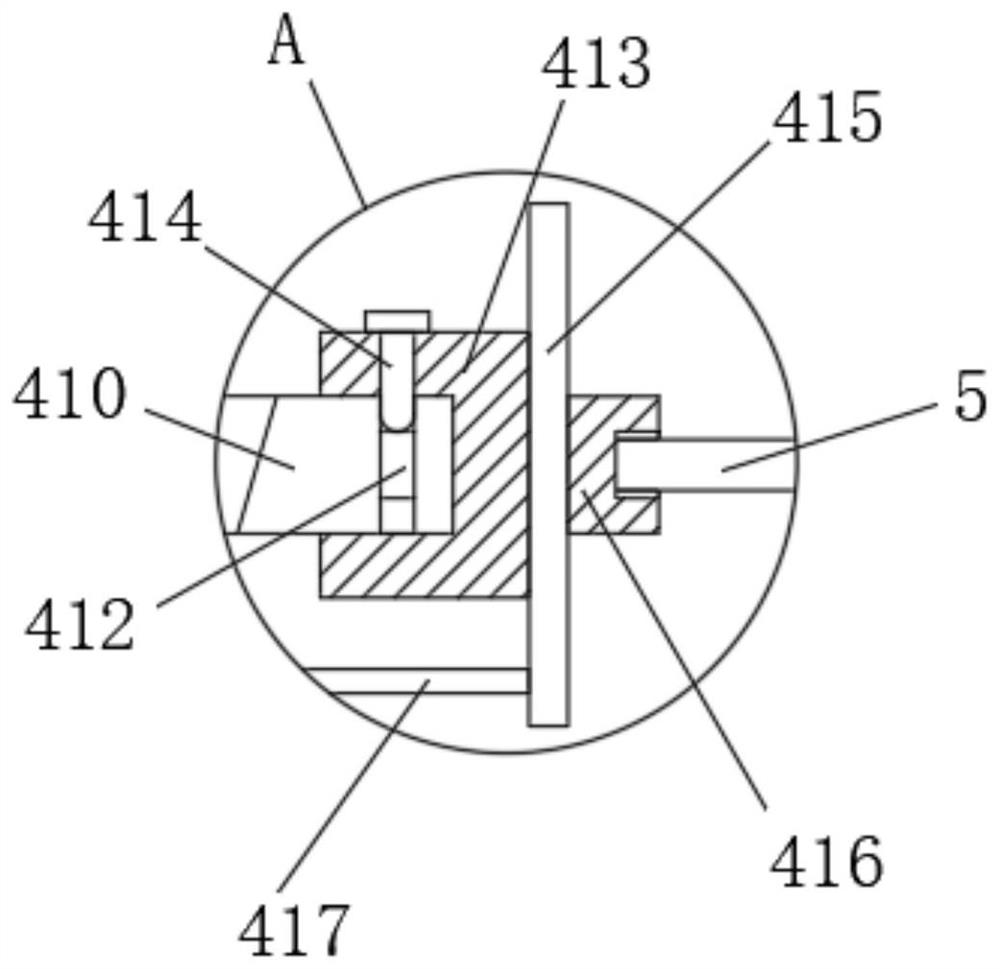

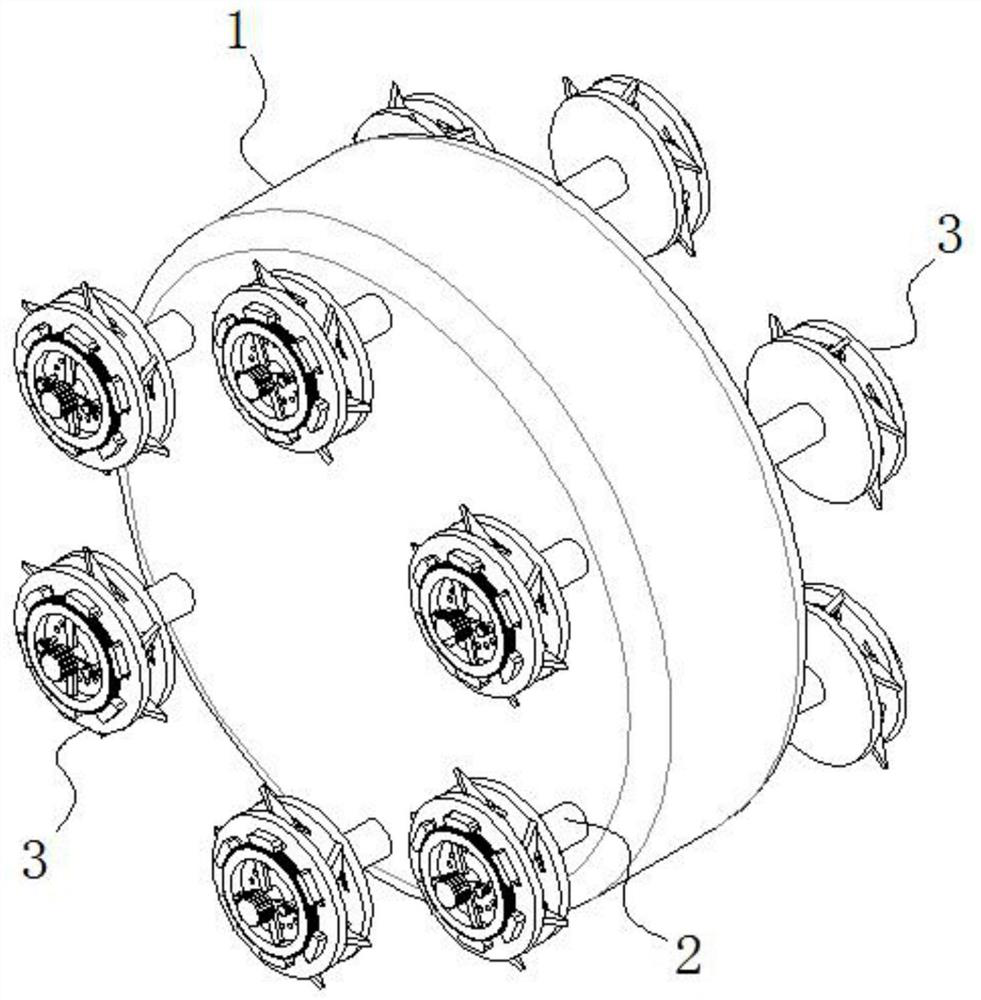

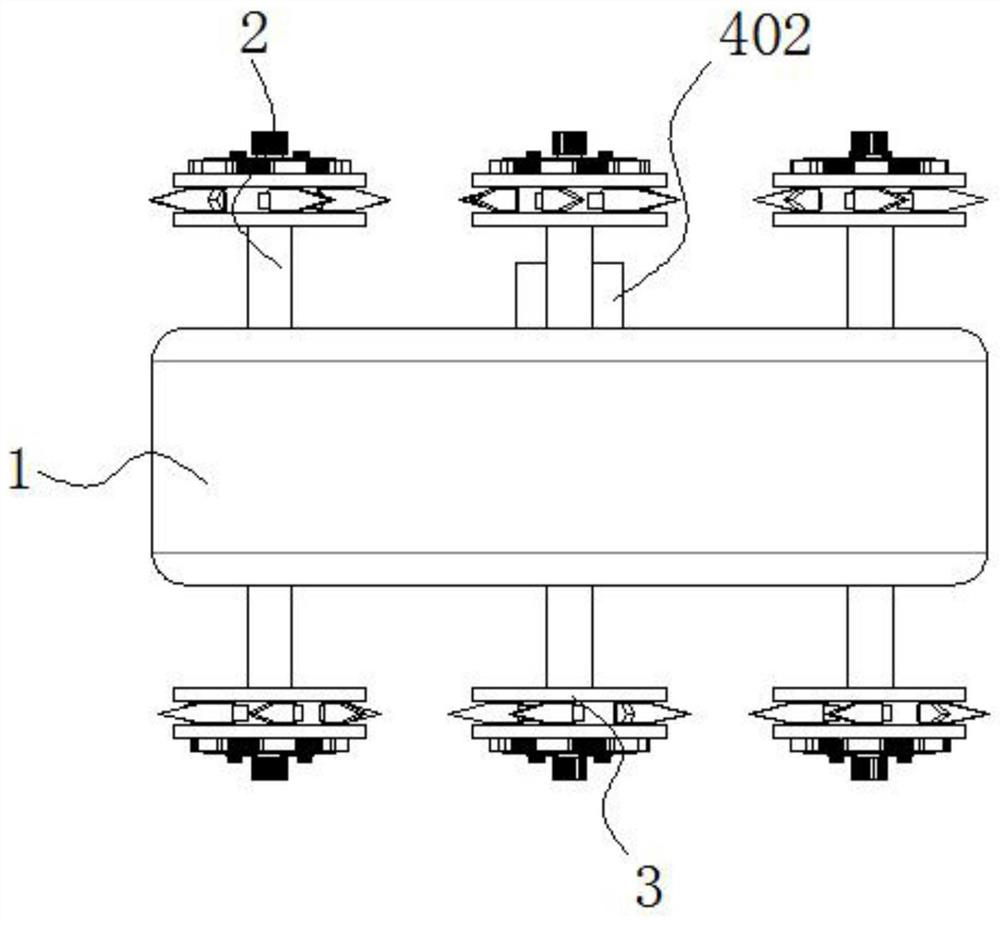

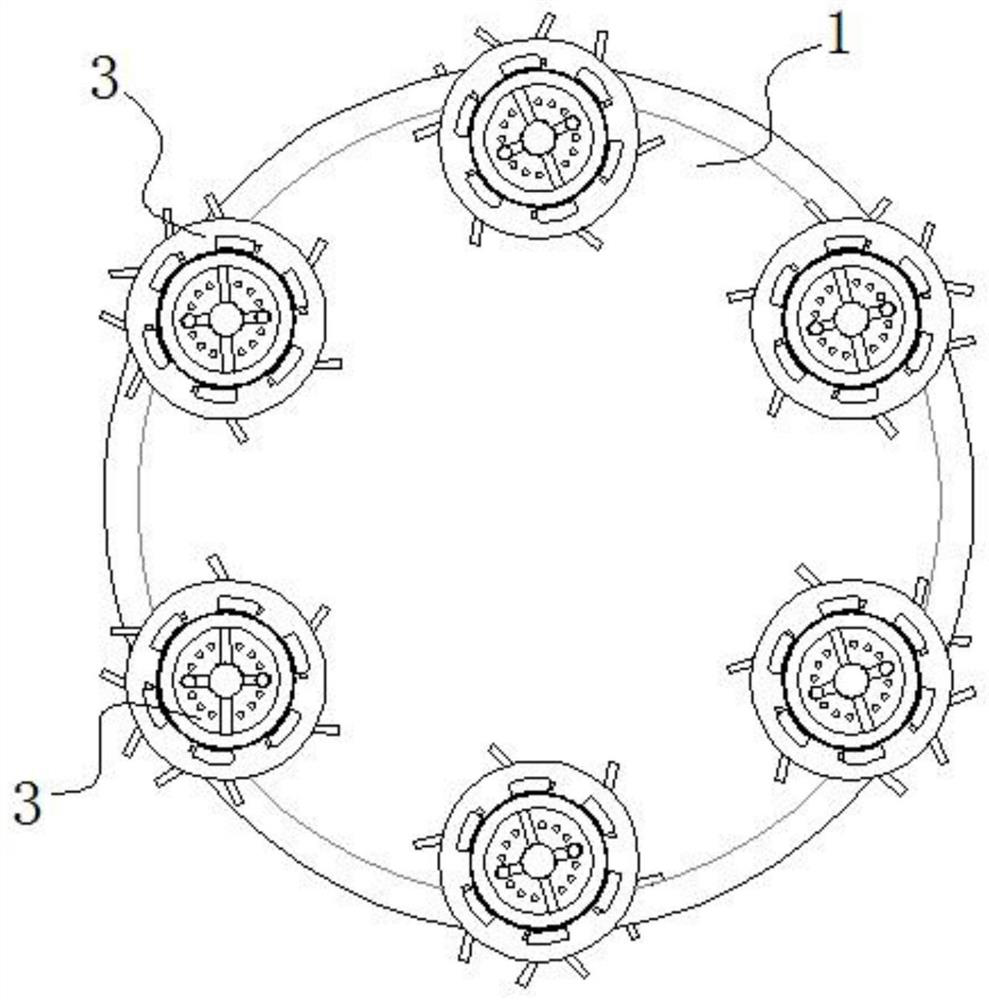

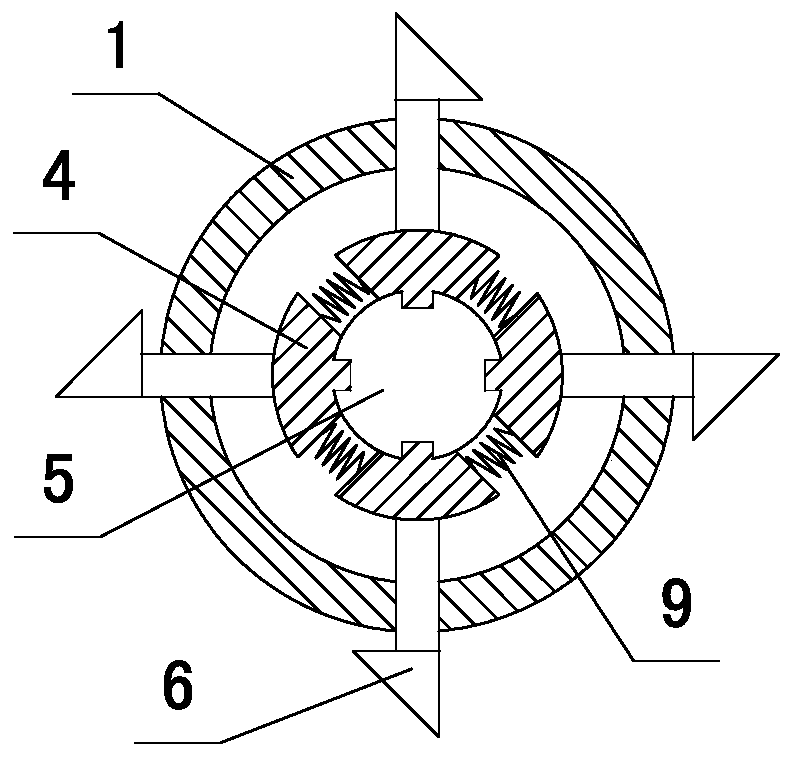

InactiveCN113664895AAdjust radial distanceRealize synchronous rotationPrinted circuit manufactureMetal working apparatusStructural engineeringElectrical and Electronics engineering

The invention discloses circuit board V-cutting equipment based on adjusting assemblies and a using method thereof, and relates to the technical field of machinery. The circuit board V-cutting equipment comprises a rotating assembly, distance adjusting assemblies, V-cutting mechanisms and a rotation driving assembly; the distance adjusting assemblies are located in the rotating assembly, and the two ends of each distance adjusting assembly penetrate through the rotating assembly; the two ends of each distance adjusting assembly are fixedly connected with the corresponding V-cutting mechanisms coaxially; the distance adjusting assemblies are uniformly arranged in the circumferential direction of the rotating assembly and are in threaded fit with the rotating assembly; and the rotation driving assembly is located in the rotating assembly and engaged with the distance adjusting assemblies. By rotating a rotary positioning assembly, synchronous rotation of the multiple adjusting assemblies arranged in the annular direction is achieved under the cooperative effect between the rotary positioning assembly and the adjusting assemblies, and the adjusting assemblies are used for driving V-cutting assemblies to rotate, so that the radial distance between tool noses of V-cutting tools and the circumferential side face of an I-shaped mounting disc is flexibly adjusted, and cutting of V-shaped grooves with different sizes in a circuit board is met.

Owner:合肥巨步机械科技有限公司

Brittle and hard material double-wire cutting method and device

PendingCN111823420AImprove cutting effectImprove cutting efficiencyFine working devicesWire cuttingMaterials processing

The invention relates to the field of brittle and hard material machining, and discloses a brittle and hard material double-wire cutting method and device. The method comprises the steps of fixing a brittle and hard material; setting positions of a first cutting wire and a second cutting wire so as to enable the first cutting wire to be located in front of the second cutting wire in a cutting feeding direction; and controlling the first cutting wire and the second cutting wire or the brittle and hard material to move in the cutting feeding direction to cut the brittle and hard material. According to the technical scheme, the first cutting wire and the second cutting wire are involved, the first cutting wire is located in front of the second cutting wire in the cutting feeding direction, the brittle and hard material is cut through the first cutting wire and the second cutting wire, and the second cutting wire can conduct secondary cutting or grinding on a cutting end face formed by cutting of the first cutting wire, so that the cutting effect and the cutting efficiency of the brittle and hard material can be greatly improved.

Owner:福州天瑞线锯科技有限公司

Cutting rollers for cutting resin tile offcuts

ActiveCN109015427BMeet cuttingEasy to adjust the radial sizeBonded abrasive wheelsMechanical engineeringEngineering

The invention relates to a cutting roller for cutting leftover materials of resin tiles. The cutting roller for cutting the leftover materials of the resin tiles comprises a cutting roller shaft, wherein a first connecting shaft is horizontally arranged at the left end of the cutting roller shaft; a second connecting shaft is horizontally arranged at the right end of the cutting roller shaft; a cone-shaped body is horizontally arranged in the cutting roller shaft; a plurality of cone-shaped bearing bushes are arranged on the excircle of the cone-shaped body; a tension spring is arranged between each two adjacent cone-shaped bearing bushes; the cone-shaped bearing bushes sleeve on the cone-shaped body through the tension springs; a cutting knife is fixed onto each corresponding cone-shapedbearing bush; a cutting head of each cutting knife penetrates through the cutting roller shaft; a first adjusting screw is horizontally arranged on the first connecting shaft in a penetrating way; theend head of the first adjusting screw is pressed against the left side end surface of the cone-shaped body; a second adjusting screw is horizontally arranged on the second connecting shaft in a penetrating way; the end head of the second adjusting screw is pressed against the right side end surface of the cone-shaped body. The cutting roller for cutting the leftover materials of the resin tiles provided by the invention can meet the requirement on cutting the resin tiles with different thicknesses.

Owner:XUANCHENG GUIXIN NEW MATERIAL CO LTD

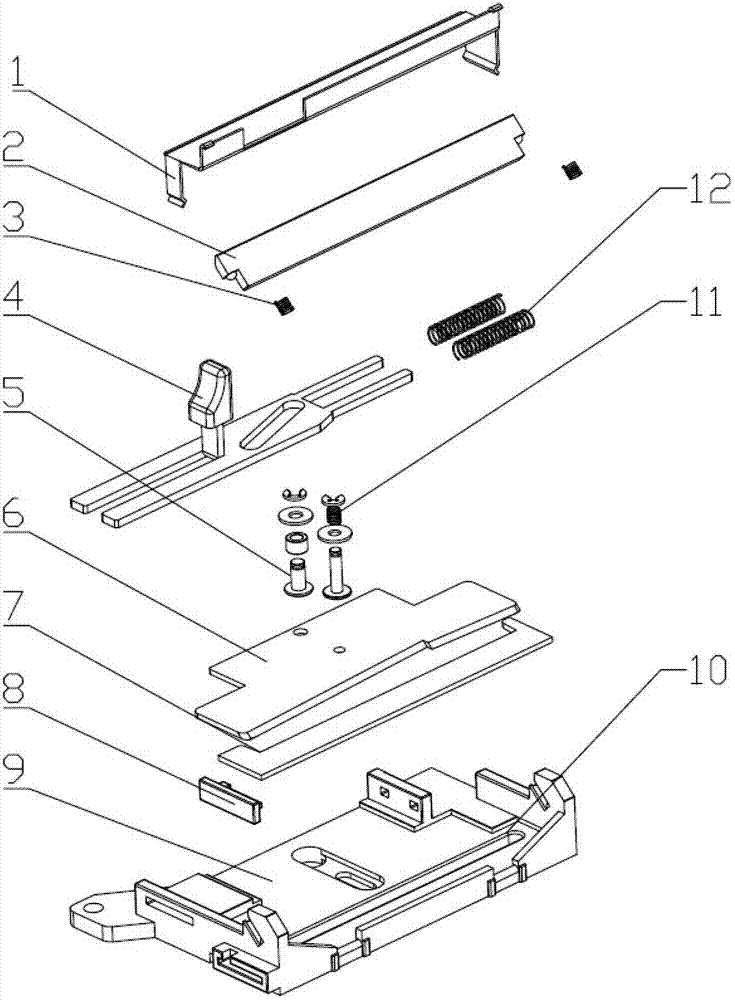

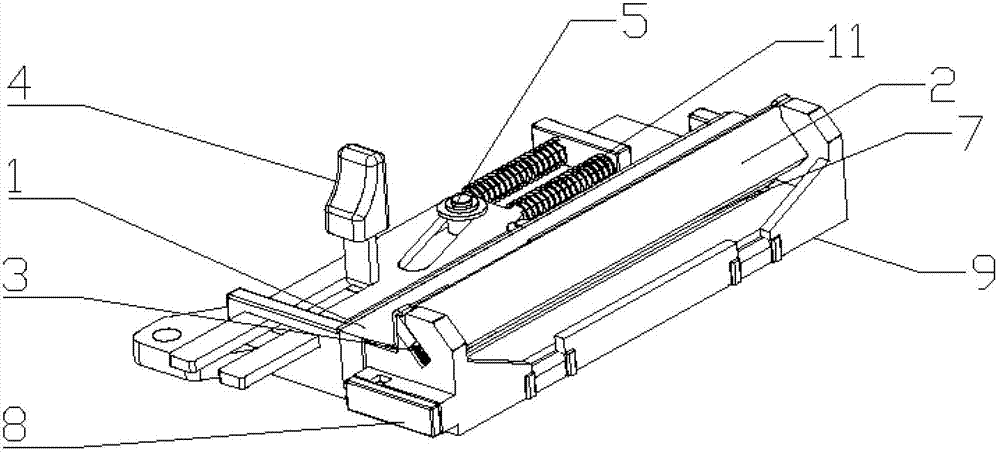

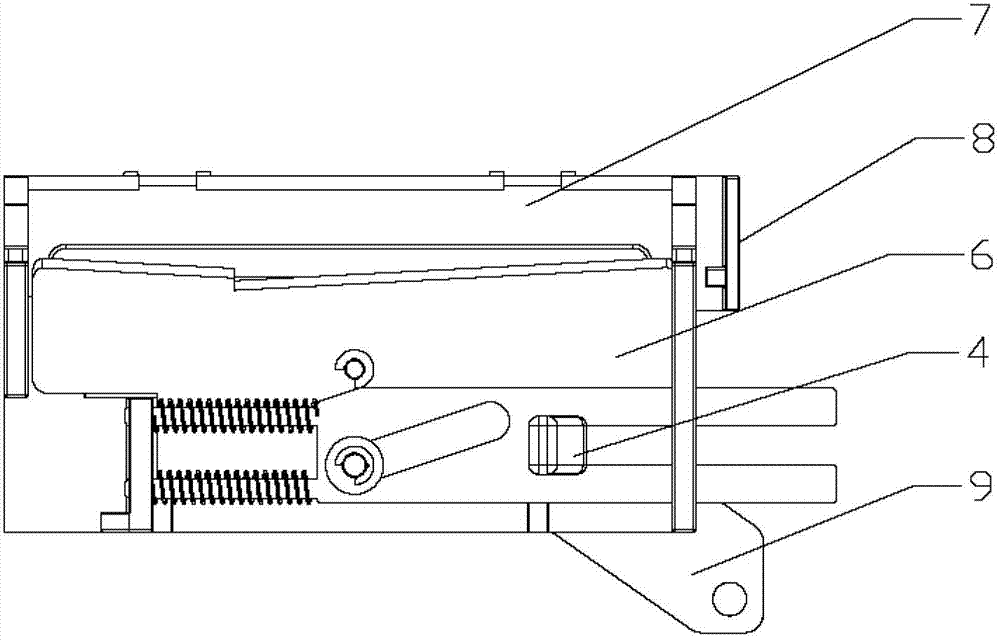

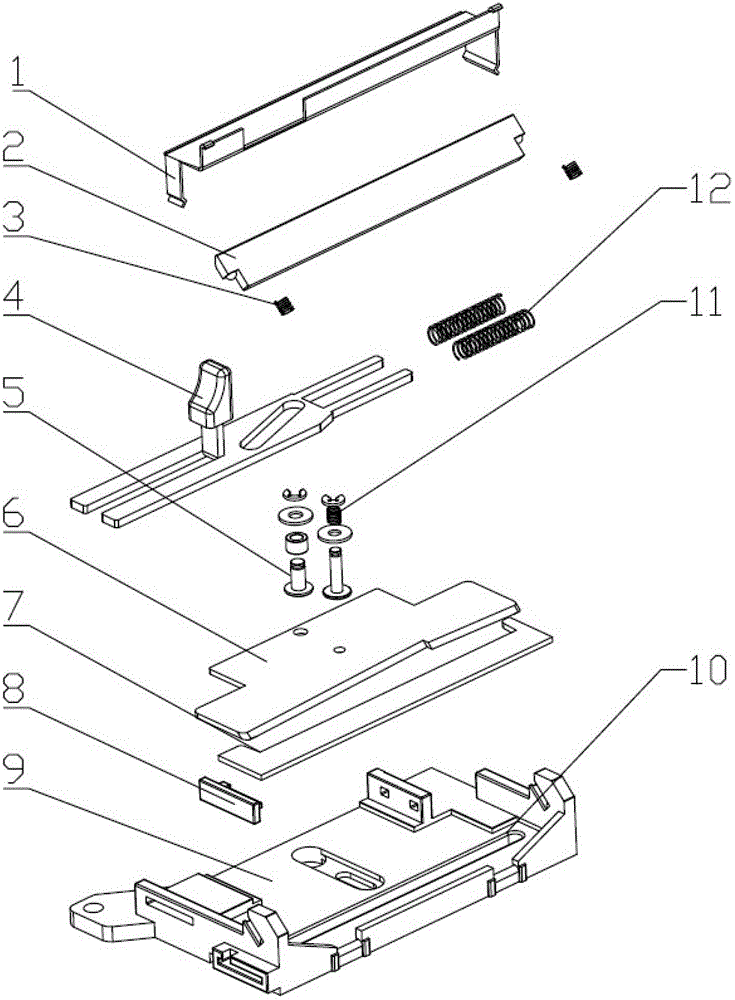

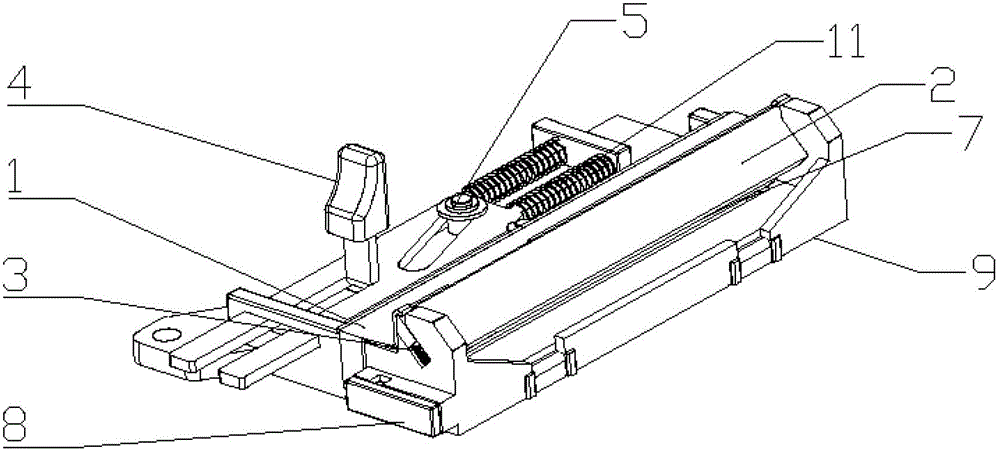

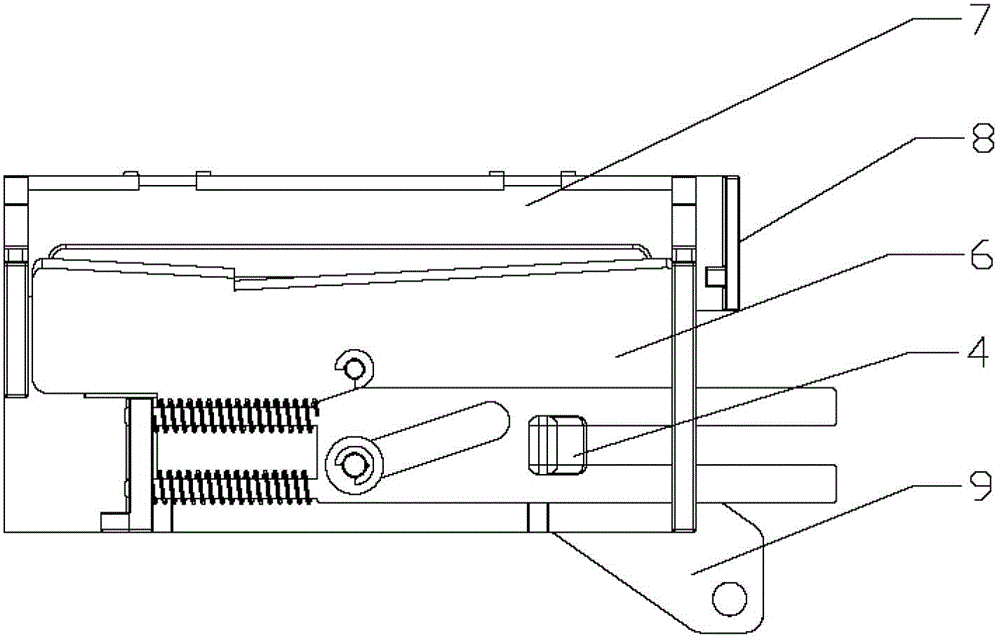

Cutting device for label medium of handheld label printer

InactiveCN102862719BEfficient cuttingMeet cuttingManual label dispensersTransverse groovePulp and paper industry

The invention discloses a cutting device for a label medium of a handheld label printer. The cutting device comprises a base, a cutting mechanism and a paper pressing mechanism, wherein the base is provided with a guide groove and a transverse groove, the cutting mechanism comprises a push rod, a stepped movable blade and a static blade, and a blade of the stepped movable blade is opposite to a blade of the static blade; the stepped movable blade is arranged in the guide groove of the base; the stepped movable blade is provided with a rivet, the push rod is provided with a chute, and the rivet is extended into the chute and is connected with the push rod in a sliding manner; the push rod is connected with the base in a sliding manner, and the static blade is fixed above the transverse groove. When a cutting edge adopting the stepped movable blade is moved from a non-cutting position to a cutting position and is in contact with the label medium, the cut label medium is compressed by the both ends of the stepped movable blade firstly, so that looseness of the label medium is effectively avoided, and the stepped movable blade integrally penetrates through the label medium, so that effective cutting is realized.

Owner:SOUTH CHINA UNIV OF TECH

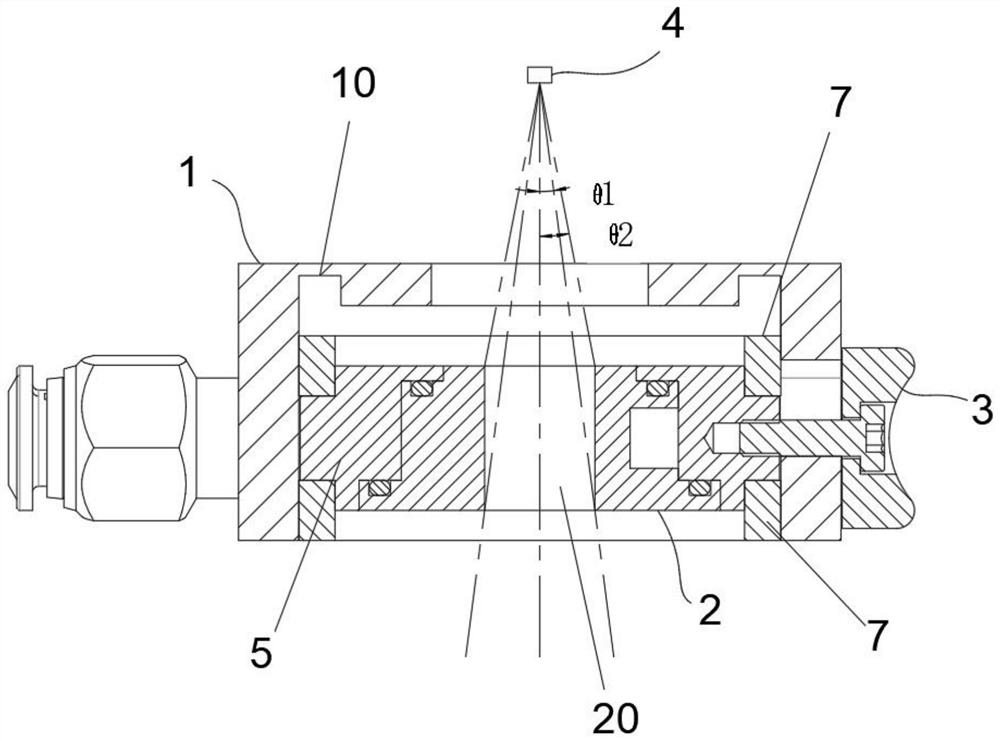

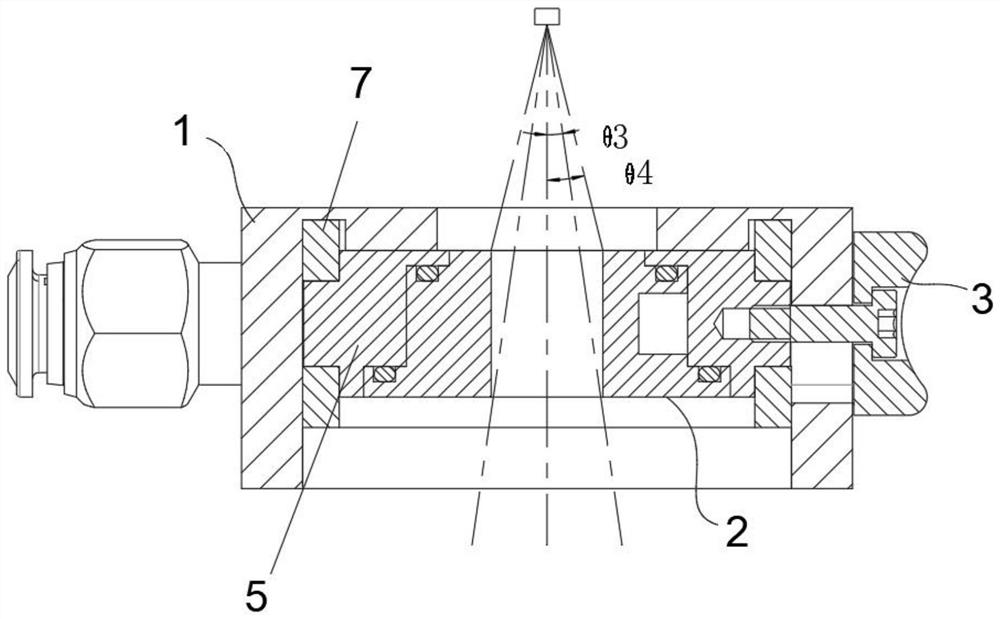

Stray light absorption device

PendingCN113458626AMeet cuttingFulfil requirementsLaser beam welding apparatusEngineeringLaser cutting

The invention belongs to the technical field of laser cutting devices, and discloses a stray light absorption device. The device comprises a fixed seat with an inner cavity, a stray light absorption unit and a pushing unit, wherein the top end of the inner cavity is provided with a light inlet hole; the stray light absorption unit is provided with an absorption cavity; the pushing unit drives the stray light absorption unit to move between a first position and a second position, and when the stray light absorption unit is located at the first position, a minimum absorption angle in a high stray light absorption rate state is formed between the first end of the absorption cavity and a light source; a maximum absorption angle in a high stray light absorption rate state is formed between the second end of the absorption cavity and the light source; and when the stray light absorption unit is at the second position, a minimum absorption angle in a low stray light absorption rate state is formed between the first end of the absorption cavity and the light source, and a maximum absorption angle in the low stray light absorption rate state is formed between the second end of the absorption cavity and the light source. Two requirements of carbon steel cutting and stainless steel cutting can be met on the same laser cutting head.

Owner:上海波刺自动化科技有限公司

Timber cutting device

InactiveCN109278121AMeet cuttingMeet actual use needsProfiling/shaping machinesArchitectural engineeringEngineering

The invention discloses a timber cutting device including a pedestal. Two supports are symmetrically fixed to the upper end of the pedestal. A transversal rod is fixed between the two supports and issleeved with a first sleeve in a sliding connection manner. A first bolt for fastening the transversal rod is arranged on the first sleeve. A second sleeve is fixed to a side end of the first sleeve.A vertical rod is sleeved with the second sleeve in a sliding connection manner. A second bolt for fastening the vertical rod is arranged on the second sleeve. A baffle piece is fixed to the upper endof the vertical rod. A spring sleeving the vertical rod is arranged between the baffle piece and the second sleeve. A cutting machine is fixed to the lower end of the vertical rod. A square groove isformed in the pedestal under the cutting machine. Handles are fixed to the front side, back side and side ends of the cutting machine. A U-shaped board is arranged beside the square groove. A first bolt bar passes through the upper wall of the U-shaped board in a threaded connection manner. A top plate is attached to the lower end of the upper wall of the U-shaped board. The lower end of the first bolt bar in inserted in the top plate and is fixedly provided with a round sheet. The device is convenient to use and can satisfy practical application demands.

Owner:江苏树仁木业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com