Cutting device for prepreg

A cutting device and prepreg technology, applied in metal processing and other directions, can solve the problems of multi-resin powder, unable to meet the production requirements of the post-production section, residues, etc., and achieve the effect of eliminating the processing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

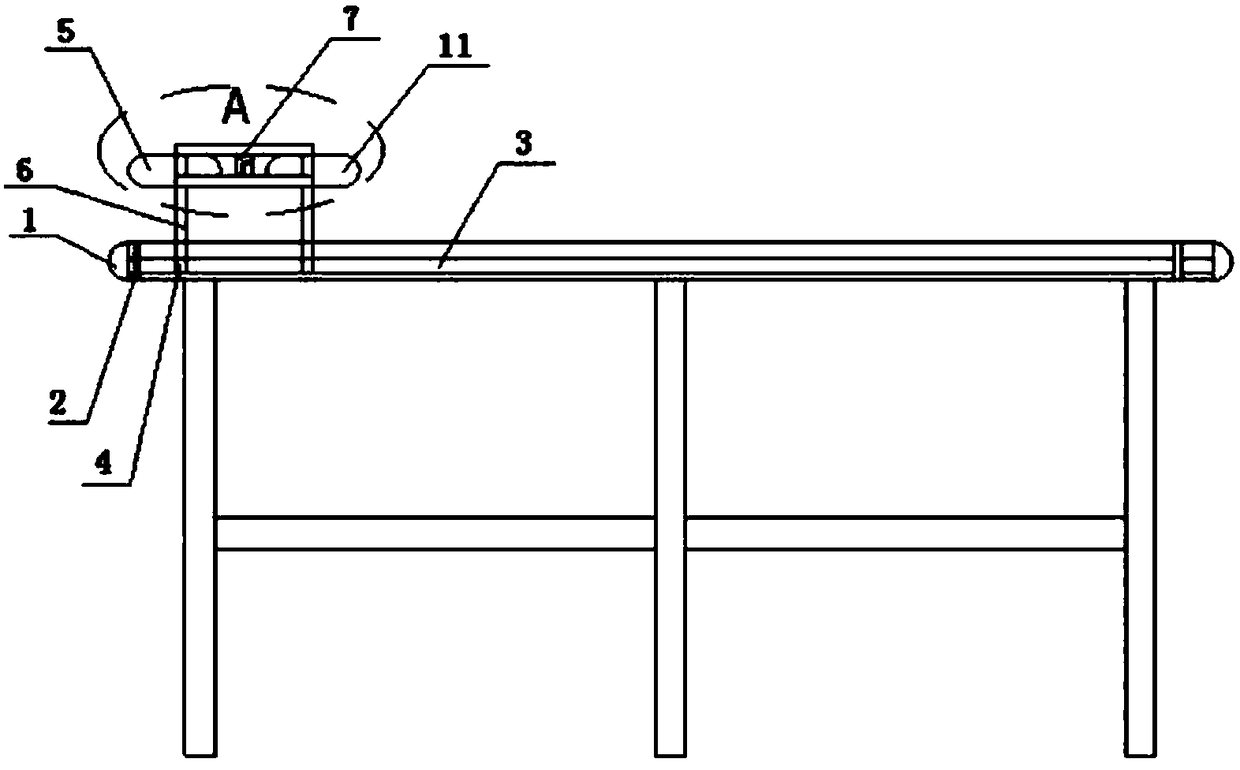

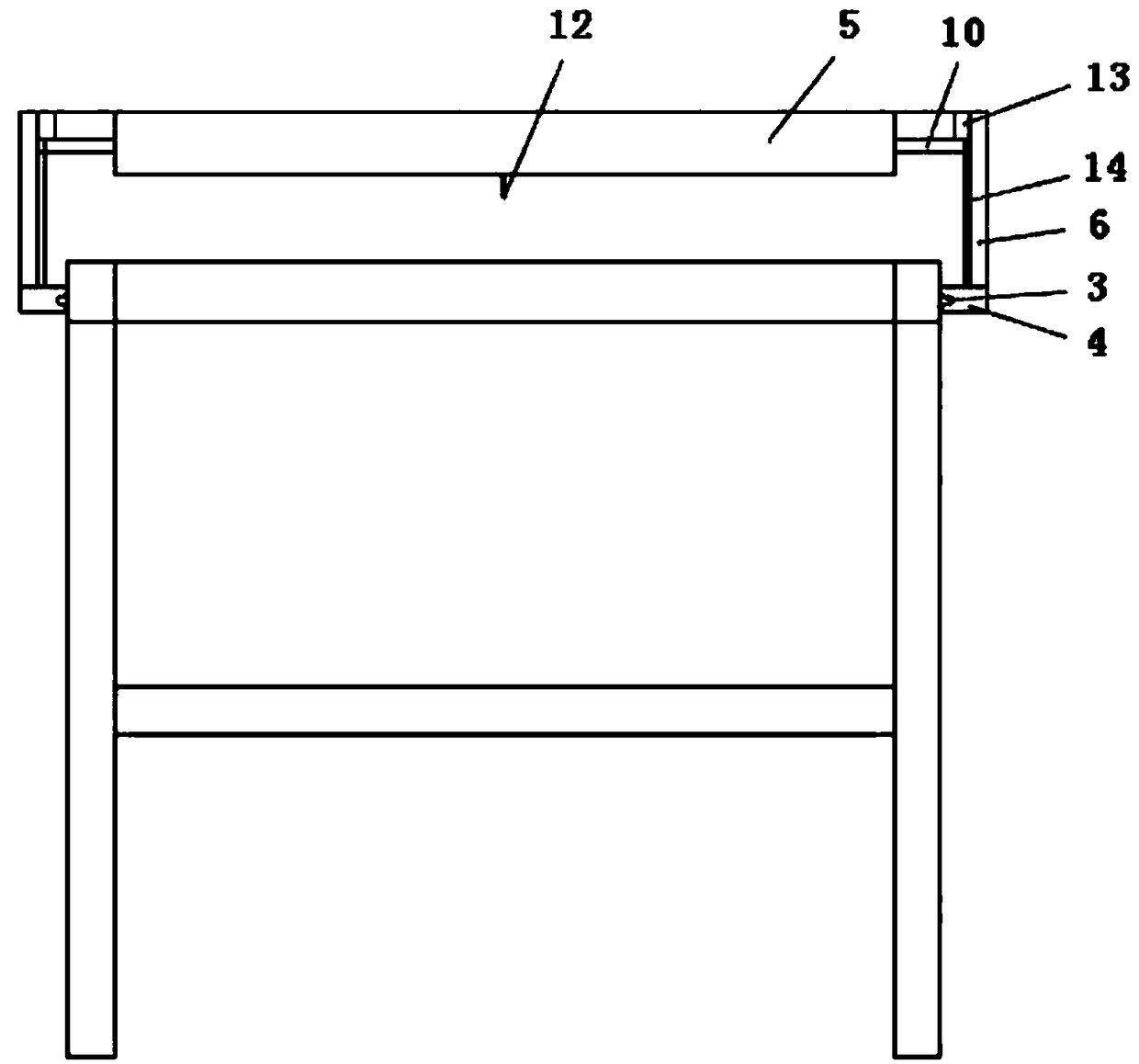

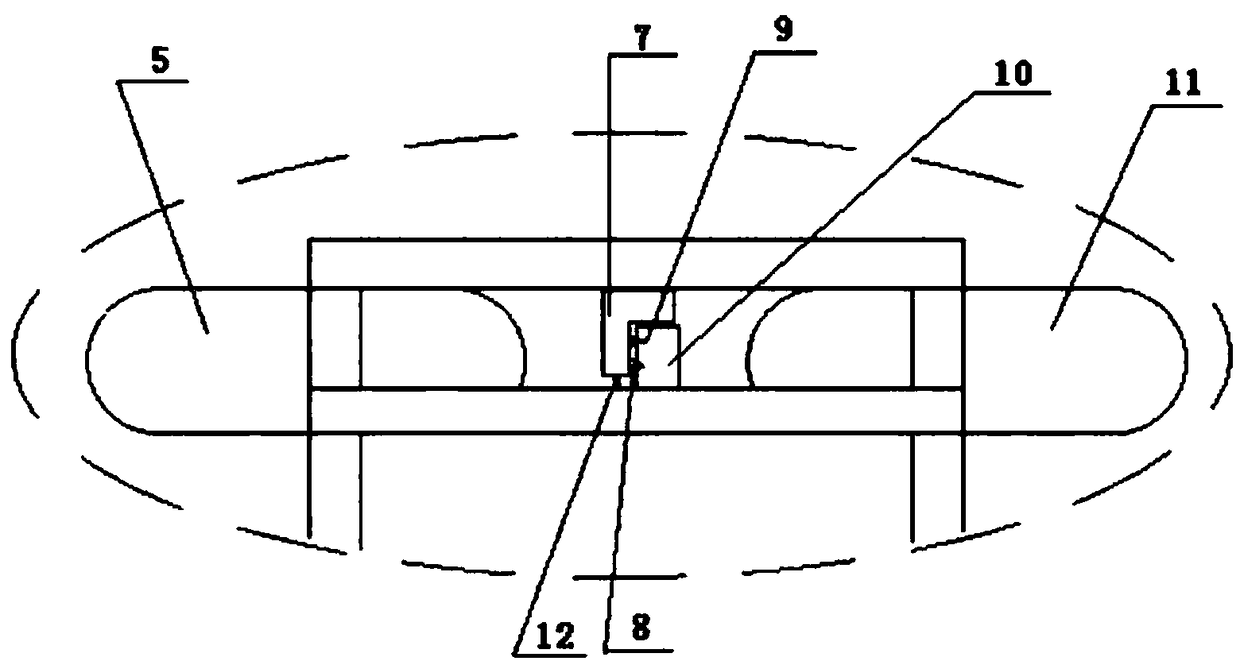

[0022] Such as Figure 1-3 As shown, the present invention is used for the cutting device of prepreg, comprises the first rolling vacuum suction platform 1, the second rolling vacuum suction platform 5, the third rolling vacuum suction platform 11, the mobile bracket 6, the tool seat 7 and the tool mounted on the The cutting tool on the seat 7; the mobile support 6 is slidably arranged on the first rolling vacuum adsorption platform 1; the mobile support 6 is provided with a horizontal fixed beam 10, and the tool holder 7 is slidably installed on the horizontal fixed beam 10; the second rolling vacuum adsorption Both the platform 5 and the third rolling vacuum adsorption platform 11 are installed on the mobile support 6 and are respectively installed on both sides of the tool holder 7 . The way in which the moving bracket is slidably arranged on the first rolling vacuum adsorption platform is: both sides of the first rolling vacuum adsorption platform 1 are provided with longi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com