Cutting device for label medium of handheld label printer

A cutting device and printer technology, applied in the field of printer components, can solve problems such as high friction of cutting devices, miscalculation of economic rationality, complex cutting mechanism, etc., achieve the effects of reducing unstable swing, wide application range, and reducing entry resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

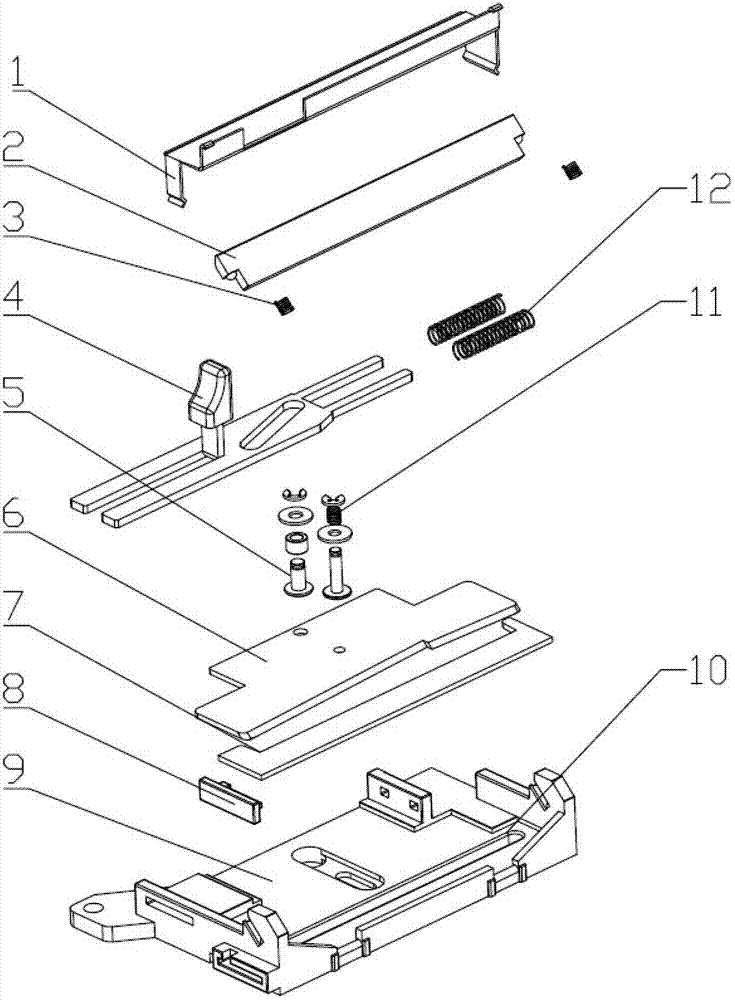

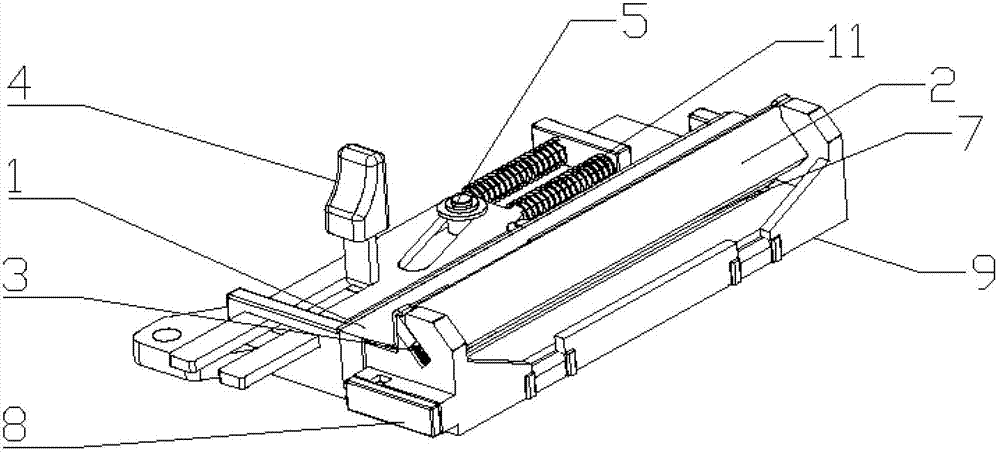

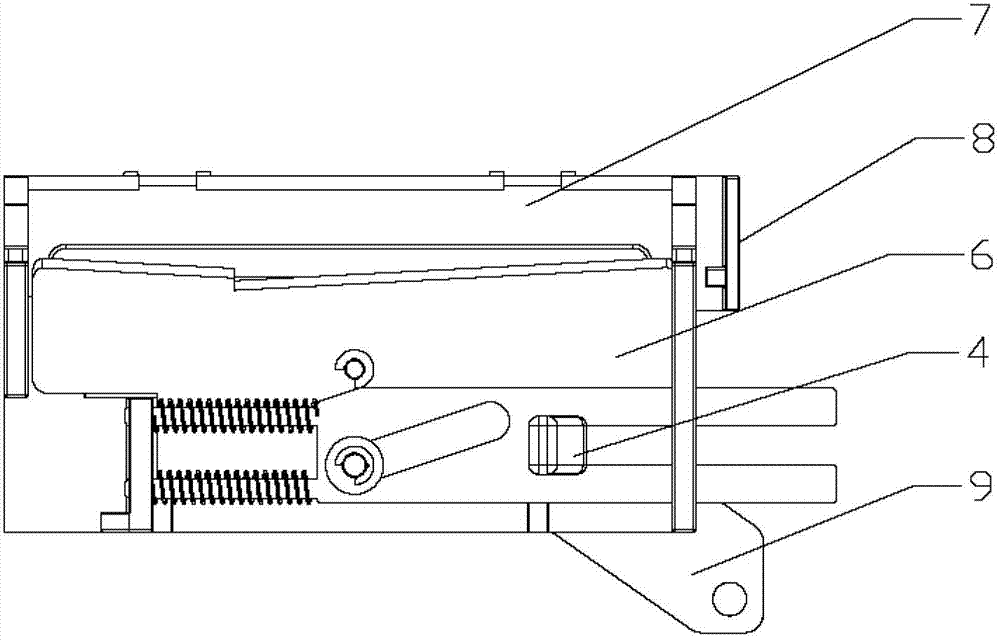

[0022] Such as Figure 1~4 shown. The label medium cutting device of the handheld label printer of the present invention includes a base 9, a cutting mechanism, and a paper pressing mechanism. The base 9 is provided with a guide groove and a transverse groove 10. The cutting mechanism includes a push rod 4 and a stepped movable blade 6. , the static blade 7, the step-shaped moving blade 6 is set opposite to the blade of the static blade 7; the step-shaped moving blade 6 is placed in the guide groove of the base 9; the step-shaped moving blade 6 is provided with a rivet 5, and the push rod 4 is provided with a chute, and the rivet 5 extends into the chute and is slidably connected with the push rod 4;

[0023] A return spring 12 is provided on the push rod 4 . The push rod 4 can be automatically returned from the cutting position to the non-cutting position.

[0024] The rivet 5 is provided with a pressing spring 11 for pressing the stepped movable blade 6 . The step-shaped...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com